-

--

-

4

VERLINDE reserves the right to alter or amend the above information without notice. 02/2010

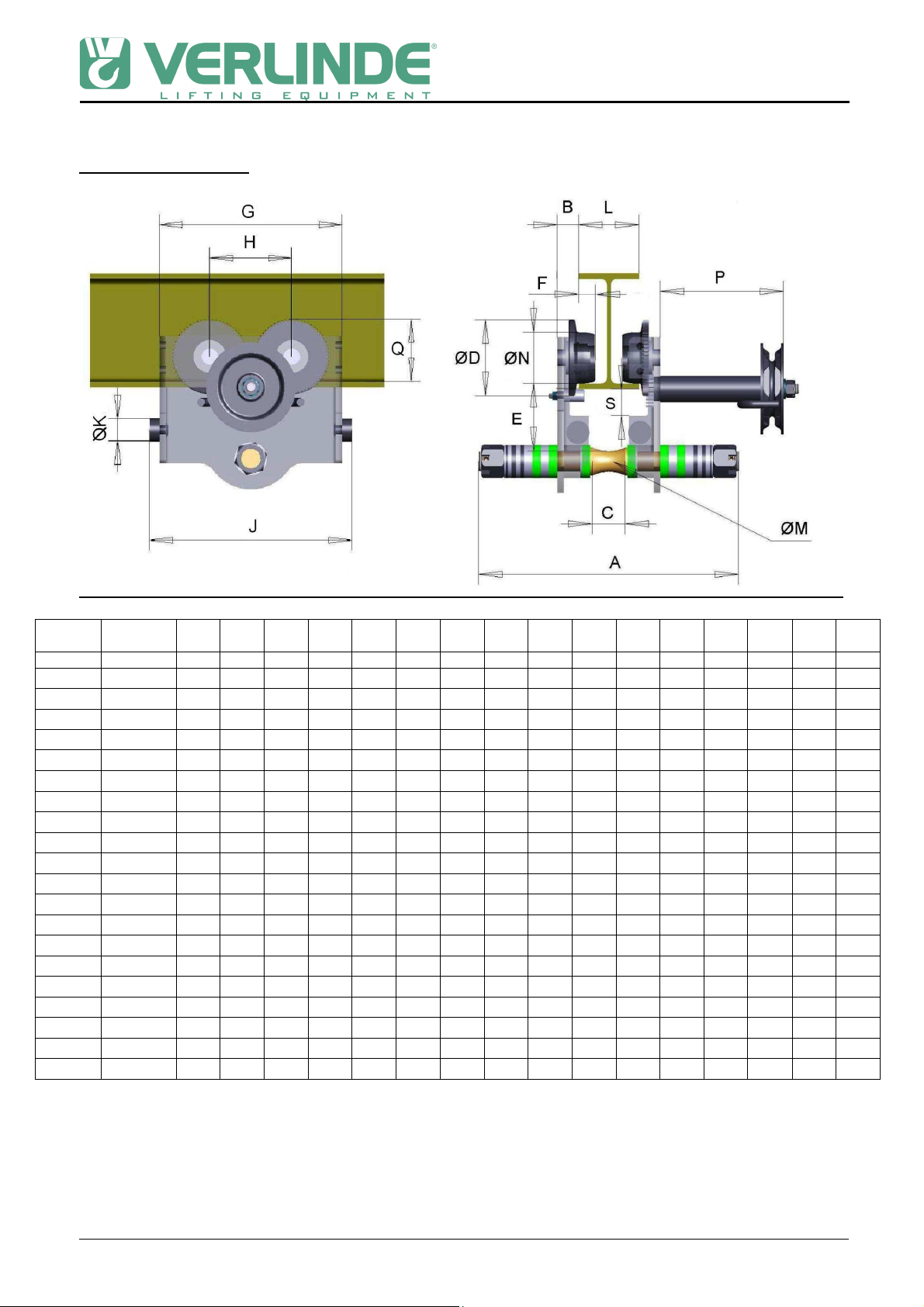

•Travelling hand wheel,

•Coupling part or traversing parts,

•Travelling wheels,

1.2

1.21.2

1.2

What not to do

What not to doWhat not to do

What not to do

Do not set down the machine without having an adapted support, to avoid damaging the

sensitive sides.

Do not let the machine drop.

Never modify the machine unless the constructor has studied and authorized the

modification.

Never modify the values and adjustments of the safety components, outside the limits

provided for in the manual, or without the approval of the constructor.

Never try to repair or intervene on the machine (welding...) without the authorization of the

constructor or a trained maintenance agent.

Do not let an unqualified person use the machine.

Never lift more than the maximum working load indicated on the machine. Shocks or

accidental collision of the load with objects can cause excess loads.

Never remove the hook safety catches.

Never use the machine to extract, loosen, or pull sideways.

Never use the machine to transport people.

Do not touch the moving components.

Do not operate the machine if your physical condition does not allow it.

Never use the machine when in bad repair (wear, deformation...).

Never use suspect spare parts or parts whose origin is not known.

Never swing the load intentionally.

Do not subject the machine to brutal shocks.

Do not use the mechanical stops as a repetitive means of stopping.

Never distract the operator while the machine is being operated.

Never leave a suspended load hanging, if it is not necessary

Do not use the machine for a purpose or in an area for which it is not intended.

Do not expose the machine to an aggressive atmosphere (temperature, acidity..).

Do not use the safety components as operation components.

Do not use the controls needlessly (avoid inching - stop-start operation of the buttons). This

can cause overheating and even damage to the machine.

Never pull the load slantwise. Make sure that the machine is vertical to the load before lifting

it.

Never transport a load with people nearby. Do not pass the machine, with or without a load,

above a person.

1.3

1.31.3

1.3

What to do

What to doWhat to do

What to do

Handle the machine by its structure, or by the devices provided for this purpose, or in its

original packing.

Store the machine in its normal operating position (without load) away from aggressive

atmospheres (dust, humidity...).

Make sure that the machine is always clean and protected from corrosion (lubrication...).

The machine should be installed by a technician with the necessary competence.

Make sure that the machine attaching structure is rigid.

Make sure that the safety rules are followed (harness, clearance of work areas, posting up of

instructions to be followed in the area...).

Use the trolley between –10°C and + 50°C.