3

Collecting Data with the 3-Axis Accelerometer

This sensor can be used with the following interfaces to collect data:

•Vernier LabQuest®as a standalone device or with a computer

•Vernier LabQuest®Mini with a computer

•Vernier LabPro®with a computer, TI graphing calculator, or Palm®handheld

•Vernier SensorDAQTM

•CBL 2TM

Here is the general procedure to follow when using the 3-Axis Accelerometer:

1. Connect the 3-Axis Accelerometer to the interface.

2. Start the data-collection software1.

3. The software will identify the 3-Axis Accelerometer and load a default data-

collection setup. You are now ready to collect data.

Data-Collection Software

This sensor can be used with an interface and the following data-collection software.

•Logger Pro 3 This computer program is used with LabQuest, LabQuest Mini,

LabPro, or Go!Link.

•Logger Pro 2 This computer program is used with ULI or Serial Box Interface.

•Logger Lite This computer program is used with LabQuest, LabQuest Mini,

LabPro, or Go!Link.

•LabQuest App This program is used when LabQuest is used as a stand-alone

device.

•EasyData App This calculator application for the TI-83 Plus and TI-84 Plus can

be used with CBL 2, LabPro, and Vernier EasyLink. We recommend version

2.0 or newer, which can be downloaded from the Vernier web site,

www.vernier.com/easy/easydata.html, and then transferred to the calculator.

See the Vernier web site, www.vernier.com/calc/software/index.html for more

information on the App and Program Transfer Guidebook.

•DataMate program Use DataMate with LabPro or CBL 2 and TI-73, TI-83,

TI-84, TI-86, TI-89, and Voyage 200 calculators. See the LabPro and CBL 2

Guidebooks for instructions on transferring DataMate to the calculator.

•Data Pro This program is used with LabPro and a Palm handheld.

•LabVIEW National Instruments LabVIEW™ software is a graphical

programming language sold by National Instruments. It is used with

SensorDAQ and can be used with a number of other Vernier interfaces. See

www.vernier.com/labview for more information.

NOTE: This product is to be used for educational purposes only. It is not

appropriate for industrial, medical, research, or commercial applications.

1If you are using Logger Pro 2 with either a ULI or SBI, the sensor will not auto-ID. Open an

experiment file for the 3-Axis Accelerometer in the Probes & Sensors folder.

4

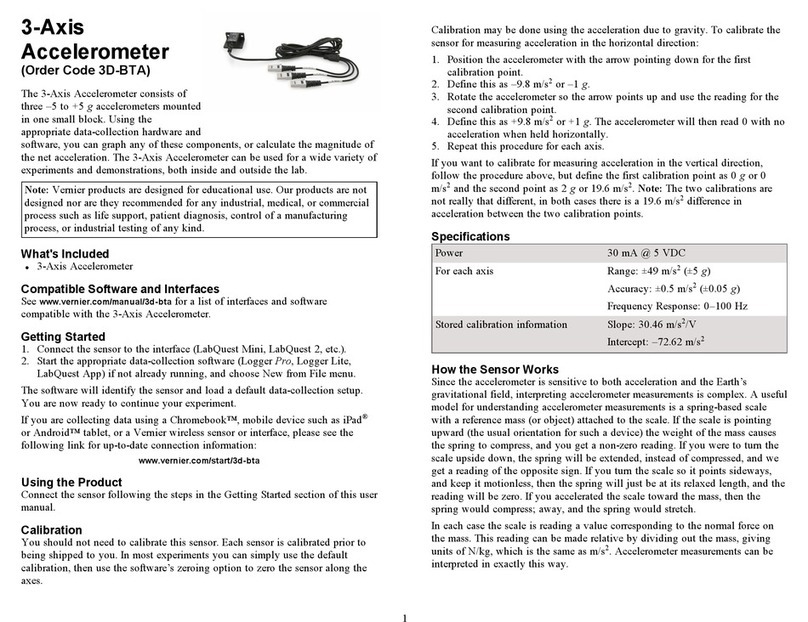

Specifications

Power: 30mA@5VDC

For each axis:

Range: ±49

m/s2(±5 g)

Accuracy: ±0.5

m/s2(±0.05 g)

Frequency Response: 0–100 Hz

Resolution

13-bit (with SensorDAQ) 0.018

m/s2

12-bit (with LabPro LabQuest,

LabQuest Mini, Go!Link, ULI, or SBI) 0.037 m/s2

10-bit (with CBL 2) 0.15 m/s2

Stored calibration information:

Slope 30.46 m/s2/V

Intercept –72.62 m/s2

How the Accelerometer Works

The 3-Axis Accelerometer contains three acceleration-sensing integrated circuits

(IC’s), along with the associated electronics. It is functionally equivalent to three of

our Low-g Accelerometers (LGA-BTA) mounted in a small block at orthogonal

angles. Each of the accelerometers measures acceleration along one line and

produces a signal on one of the three outputs. These three axes and three outputs are

labeled X, Y, and Z. The IC sensors are similar to those originally designed to

control the release of air bags in an automobile. This IC is micro-machined with very

thin “fingers” carved in silicon. These fingers flex when accelerated. They are

arranged and connected like the plates of a capacitor. As the fingers flex, the

capacitance changes, and a circuit included in the IC monitors the capacitance,

converting it into a voltage. An op-amp circuit amplifies and filters the signal from

the IC. The net result is that the voltage varies in a linear way with acceleration.

Each of the outputs is labeled with X, Y, or Z. This corresponds with the directions

shown on the label on the sensor. Accelerations are normally measured in either

meters per second per second (m/s2) or g’s. One gis the acceleration due to gravity

at the Earth’s surface, or 9.8 m/s2. This accelerometer will measure accelerations in

the range of –5 g(–49 m/s2) to +5 g(+49 m/s2) in each direction.

This is a range of accelerations which a human body could experience without

damage. Many collisions will produce much larger accelerations. In fact, dropping

the Accelerometer on a hard surface from even a few centimeters can produce

accelerations of a hundred g’s. The 3-Axis Accelerometer will not be damaged by

accelerations up to 1000 g’s.

When properly calibrated, when the arrow representing an axis points upward, that

channel reads +9.8 m/s2. When an axis arrow points down, that channel should read

–9.8 m/s2. When an axis arrow is held horizontally, that channel will read zero. In

most cases, data collection software can be used to create a New Column to calculate

the square root of the sum of the squares of the accelerations. It will be equal to

9.8 m/s2when the 3-Axis Accelerometer has no acceleration, and zero when it is in

free fall. The orientation of the 3-Axis Accelerometer does not matter. To understand

how this works, try holding the 3-Axis Accelerometer in your hand and very slowly