3

Calibration of the Motion Encoder System

Calibration of the Motion Encoder System is not necessary nor is it possible. The

printed bars on the track determine the scale, and the cart encoder counts the passage

of the bars. Available units are meters and feet, selectable in the software.

In contrast, it is possible and desirable to zero the encoder. Unlike an ultrasonic

motion detector, there is no way for the system to have an unchanging reference

position; it can only count bars from the point at which the cart is placed on the

track. As a result, you may want to move the cart to the receiver end of the track and

zero the reading in the software.

The positive direction can be reversed so that readings increase as the cart moves

toward the receiver. A reversed coordinate system is helpful when using two Motion

Encoder Systems to monitor the motion of two encoder carts, so that the positive

direction is the same in both cases.

Because the encoder strip must be continuous, the Motion Encoder System cannot be

used with a Track-to-Track Coupler.

Power

The Motion Encoder Cart requires two AAA batteries. Either NiMH rechargeable

batteries or alkaline disposable batteries can be used. Turn on the cart by pressing the

clear power button on the cart endcap. It will glow blue when power is on. Press

again to turn off. The cart will turn itself off after 20 minutes of inactivity. Any

motion on the track will cause the timer to reset. The receiver is powered by the

data-collection interface.

Battery life depends on use and the range setting. Low battery level may cause

erratic detection of the cart motion, including incorrect velocity signs. Replace the

batteries if this is seen.

Range Setting of the Motion Encoder Cart

The IR transmitter on the cart has two power levels available. The default 1 m

setting conserves battery power. If the cart is used on a 2.2 m track, set the cart to the

higher 2 m power level. If the high-power setting is not used on a 2.2 m track, the

receiver will not reliably sense the position of the cart at the far end of the track. The

switch is located inside the battery compartment.

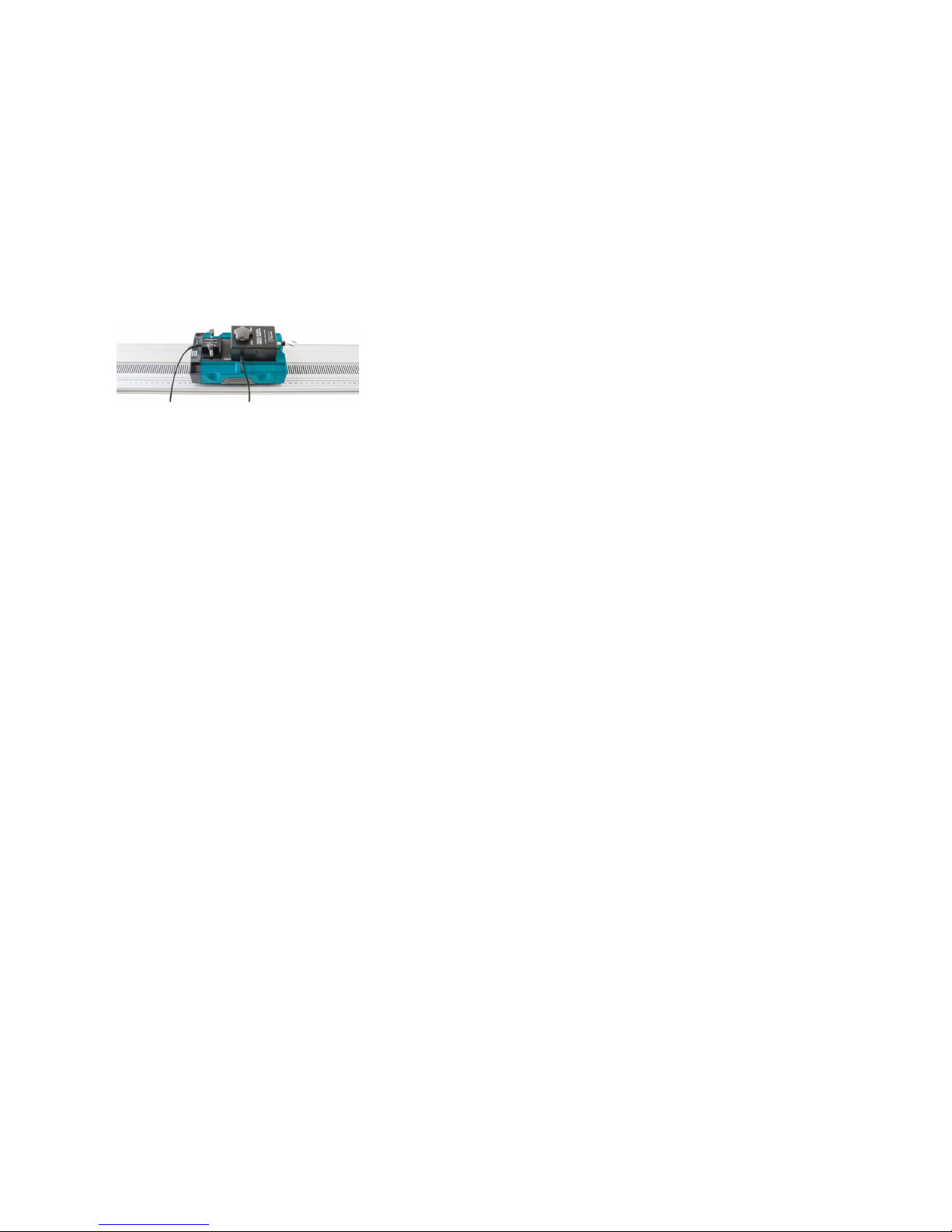

Use of Two Vernier Motion Encoder Systems on the Same Track

Some experiments require measuring the motion of two carts. This can be done by

purchasing the Motion Encoder Cart and Receiver (order code DTS-MEC) to add a

second encoder cart, receiver, and strip to your Vernier Motion Encoder System. A

Motion Encoder Receiver is placed at either end of the track, and two Motion

Encoder Carts are used on the track, each with its transmitter facing the unobstructed

receiver. A second encoder strip must be applied to the track, resulting in one on

either side of the center slot.

Consider reversing the direction of one receiver so that the same direction is positive

for each system. Put the carts together, and zero both systems. This will put the carts

4

on the same coordinate system; if they move together in contact, their position

readings will be the same.

Use of Multiple Vernier Motion Encoder Systems

in the Same Room

Because of the narrow IR beam used for signaling between the cart and receiver,

interference should be rare. However, if one apparatus is apparently interfering with

another, the problem can be resolved by repositioning one of the tracks.

All Motion Encoder Carts are interchangeable; that is, there is no matching of cart to

receiver.

Data-Collection Notes for the Motion Encoder System

The optical motion encoder can only make relative position measurements, so the

zero point is initially determined by the location on the track that the cart is first

placed when the power is on. If you want zero to be near the receiver, initially

place the cart next to the receiver. This behavior is very different from the

ultrasonic Motion Detector, which by default uses a fixed origin near the detector.

The motion encoder is nearly immune to interference, but it cannot work if the IR

beam between the cart and receiver is blocked. Keep your hand away from this

region.

Since the zero position (origin) of the encoder depends on where the cart is placed

initially, it is often useful to zero the encoder in the software. Place the cart in the

position that you want to declare as zero. On LabQuest, tap the Meter Screen to

access the zero command. In Logger Pro, use the toolbar button.

It can also be useful to reverse the direction of the coordinate system, so that

values increase as the cart moves toward the receiver. Do this from the Meter

Screen on LabQuest, or by using the Sensor menu in the Set Up Sensors dialog

box for your interface in Logger Pro.

High data-collection rates are not useful for the motion encoder. Rates above

30 Hz will produce noisy velocity and acceleration graphs because of few counts

during each time period.

Just like the ultrasonic Motion Detector, it can be useful to adjust the number of

points used to calculate derivatives for velocity and acceleration graphs. Higher

values create quieter graphs, while lower values result in more temporal detail.

Adjust this value in LabQuest preferences or in Settings For… from the File menu

in Logger Pro.

Photogate Bracket

Photogate Brackets are attached to the side of the track.

With the nut loosely on the T-handled bolt, slide the nut

into the side channel of the track. Attach the photogate

using the supplied wing bolt in the long slot. Adjust the

gate height so the beam intercepts the desired portion of

the target.