11 LIMITED WARRANTY

Vertex Water Products (“ anufacturer”) sell its products through independent retailer dealers (“Dealer”) who re-sell

to the end-user customer. In this limited warranty, “Vertex” refers to Vertex Water Products and not to the Dealer.

WHO IS COVERED BY THIS WARRANTY

This limited warranty covers only the first purchaser of the Vertex PureWaterCooler™ from a Dealer for use by that

purchaser, and is not transferrable. “Consumer Use” means personal residential household use by a consumer or

consumers. “Commercial Use” means all other uses, including (but not limited to) use for commercial, income pro-

ducing purposes and/or when purchased by a business and/or when purchased for use in an office, business, or indus-

trial setting. “Purchaser” means the end-user customer, and not a Vertex re-seller Dealer.

PERIOD OF COVERAGE OF THIS WARRANTY

anufacturer warrants the complete water cooler (“the unit”) against defects in material and workmanship, subject to

the exclusions described below, for a period of ONE YEAR, beginning on the later of either (a) the date of purchase

or (b) the date of manufacture as identified by the Vertex unit’s serial number. anufacturer additionally warrants

the compressor for a period of THREE YEARS from the above date. The purchaser must provide the original sales

receipt as proof of the date of purchase. If the purchaser is unable to produce the original sales receipt, the Warranty

Period commencement date will be determined by anufacturer, in its sole and absolute discretion, based upon the

unit’s serial number. This warranty does not apply if the original serial number affixed by anufacturer is removed,

defaced, altered, obscured, tampered with, or obliterated. If anufacturer provides a replacement part or parts, or

repairs a part or parts, under this limited warranty, then the replacement part(s) or repaired part(s) will be covered

under this limited warranty for the time remaining under the original Warranty Period applicable to the part(s) re-

paired or replaced.

The duration of ALL OTHER WARRANTIES, INCLUDING ANY AND ALL IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO MERCHANTABILITY AND FITNESS FOR A PARTICULAR PUR-

POSE, ARE RESTRICTED TO THE TWO-YEAR LIMITED WARRANTY PERIOD. Some states do not

allow limitations on how long an implied warranty lasts, so the above limitation may not apply to purchaser.

WHAT IS COVERED BY THIS WARRANTY

This limited warranty covers defects in materials or workmanship, subject to the exclusions below and for the time

period stated above. anufacturer promises to repair or to replace, at anufacturer’s sole and absolute discretion,

any part of this water cooler that proves to be inoperative due to a defect in material or workmanship under normal

use.

WHAT IS NOT COVERED BY THIS WARRANTY

This limited warranty does not extend to and expressly excludes:

• conditions, losses, malfunctions, or damages not resulting from defects in material or workmanship;

• conditions, malfunctions, losses, or damages or the inability to operate the Vertex unit resulting from

conditions beyond anufacturer’s control, including but not limited to failure of the unit or any of its

parts due to damage caused by: improper installation; accident; fire; flood; windstorm; acts of God;

rodent and/or insect infestation; vandalism; modification; alteration; combination with any other device

or machine; abuse and/or misuse of the unit; negligence by purchaser or third parties; any part of the

water system that has become fouled due to liming, dirt, unsatisfactory/unsanitary water conditions,

corrosion, or faulty plumbing; failure to install, maintain, assemble, mount or place the Vertex unit in

accordance with anufacturer’s instructions and/or local, state, or national plumbing and electrical

codes; wear and tear expected to occur in the normal course of use, including but not limited to cosmetic

rust, scratches, dents or comparable and reasonably expected losses or damages; exposure to extreme

variations in ambient environmental conditions (including but not limited to changes in heat, humidity,

moisture, or exposure to sunlight).

• labor for installation or deinstallation of the unit or any of its parts; shipping of the unit or any of its parts

to anufacturer for repair/replacement.

In addition to the above exclusions, this limited warranty does not apply if any of the following conditions

of operation are not met: System Pressure 35 - 100 psi, Temperature 40 - 100 degrees F, PH range 4 - 10, ax TDS

1500 PP ax., Turbidity <1.0NTU, Hardness <20gpg, R version: <3.5 gpg, F version, Iron

<0.1 mg/l, anganese <0.1 mg/l, Hydrogen Sulfid e <0.00 mg/l.

17

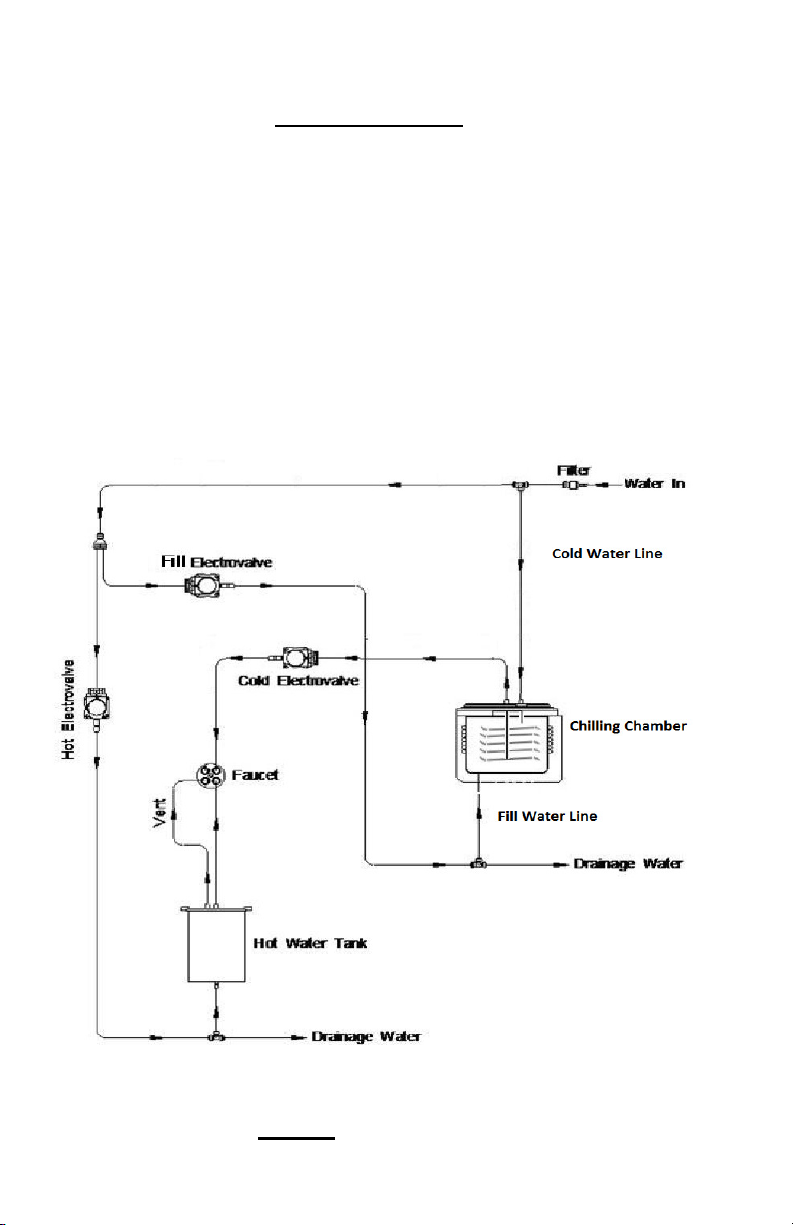

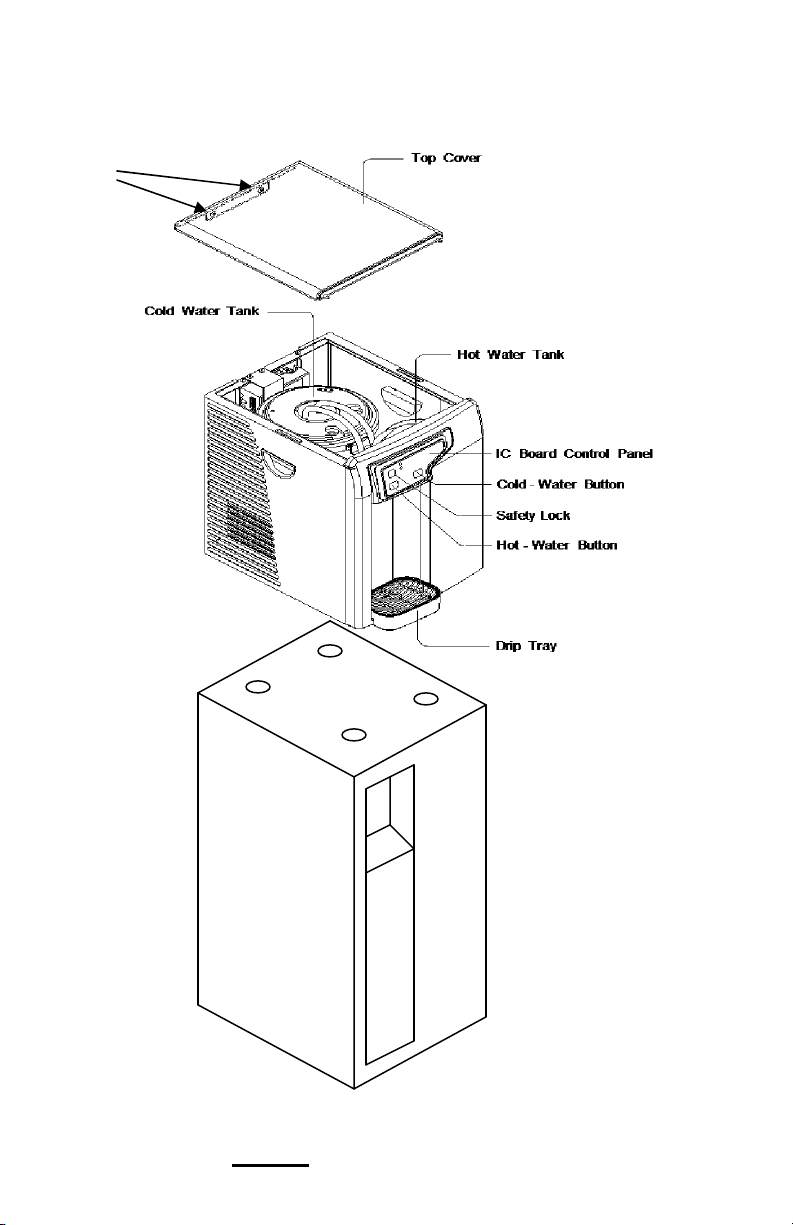

.1 Assembly

The countertop portion of the PWC-9500 assembly drawing is shown in

Figure 1. The cooler has one chilling chamber and one hot tank. This chilling

chamber holds one gallon of water and is automatically filled at start-up. This

water is cooled in the chilling chamber with refrigerant coils. The cold water

drinking line is comprised of a sealed stainless steel coil submerged inside this

chamber. There is a separate hot water tank with an internal heater coil which is

fed by water pressure directly from the line in. The hot water tank is directly be-

side the cold water tank. The compressor and expansion valve are inside the

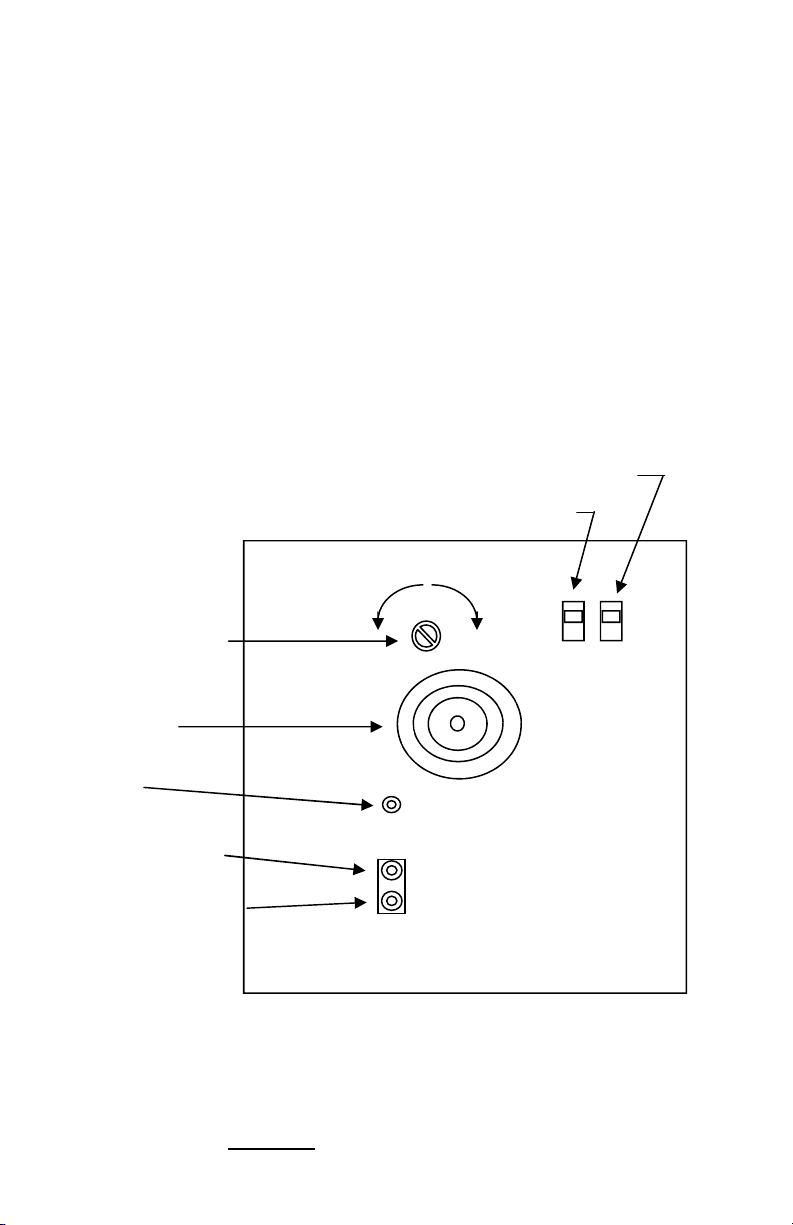

cabinet. The controls for dispensing water are on the front panel.

.0 Description

2

Figure 1 Flow Schematic