Vertiv Liebert PEX3 DX Series User manual

Other Vertiv Air Conditioner manuals

Vertiv

Vertiv Liebert CRV4 Series User manual

Vertiv

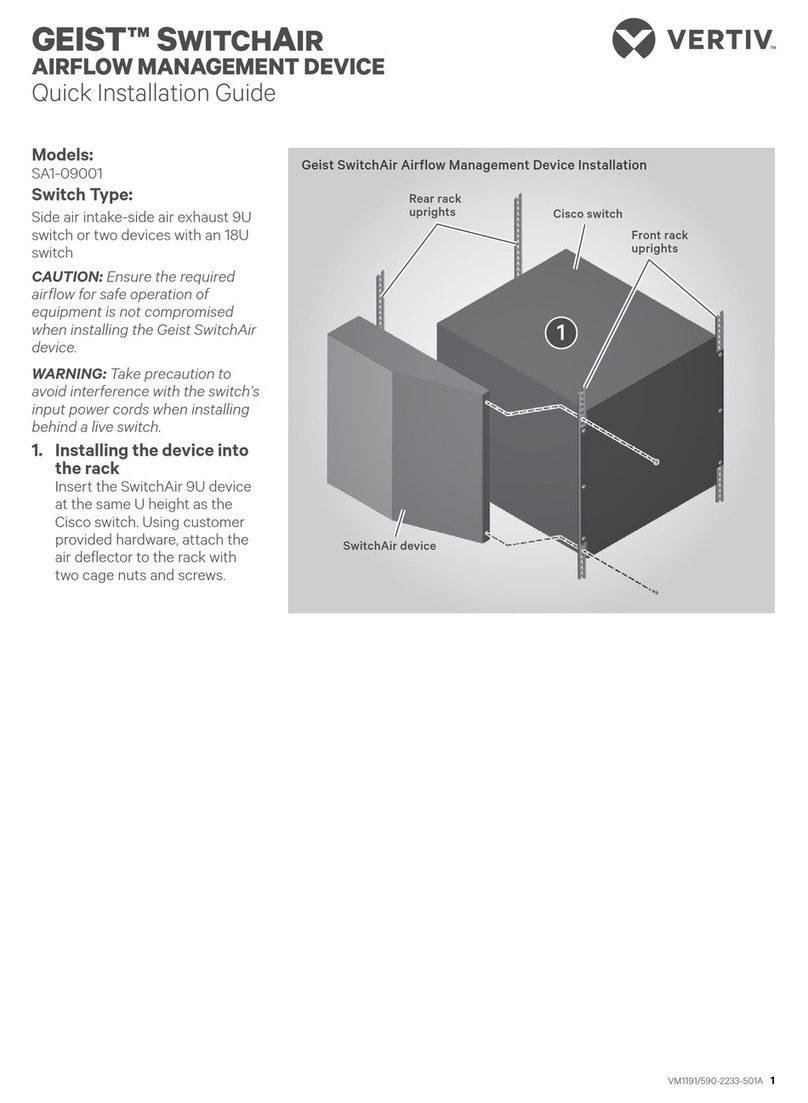

Vertiv GEIST SwitchAir SA1-01001NB User manual

Vertiv

Vertiv Liebert XDH User manual

Vertiv

Vertiv GEIST SwitchAir SA1-01002 User manual

Vertiv

Vertiv Liebert XDH User manual

Vertiv

Vertiv Liebert PEX+ Series User manual

Vertiv

Vertiv GEIST SA1-09001 User manual

Vertiv

Vertiv P1025UA13C User manual

Vertiv

Vertiv Liebert XDO User manual

Vertiv

Vertiv Liebert AHU Series User manual

Vertiv

Vertiv Liebert DM Series User manual

Vertiv

Vertiv Liebert XDC User manual

Vertiv

Vertiv Liebert CR012 User manual

Vertiv

Vertiv Liebert LPC Series User manual

Vertiv

Vertiv Liebert CRV Plus User manual

Vertiv

Vertiv Liebert CRV4 Series User manual

Vertiv

Vertiv Liebert CRV CRD10 Series User manual

Vertiv

Vertiv GEIST SwitchAir SA1-02003 User manual

Vertiv

Vertiv Liebert DM Series User manual

Vertiv

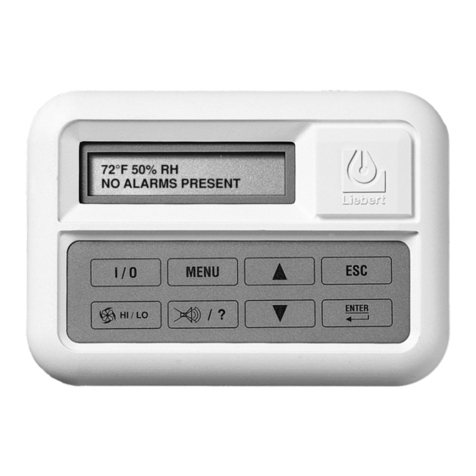

Vertiv Liebert Mini-Mate2 Instruction manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions

McQuay

McQuay MCK020A Technical manual

Webasto

Webasto Frigo Top 25 DS Instructions for use

Frigidaire

Frigidaire FAZ12ES2A installation instructions

Mitsubishi Electric

Mitsubishi Electric MSC-GE20VB operating instructions

Mitsubishi Electric

Mitsubishi Electric PLA-M100EA installation manual

Daikin

Daikin Split Sensira R32 Service manual