This instruction manual deals with Överum conventional ploughs type CT

_______________________________________________________________

Contents Page

1Description of function 2

1.1 Identification of plough 3

2General safety precautions with safety signs 4

3Technical description 5

3.1 Checking the tractor prior to ploughing 5

3.2 Preparation of plough 6

3.3 Mounting the plough onto the tractor 6

3.4 Checking the plough 7

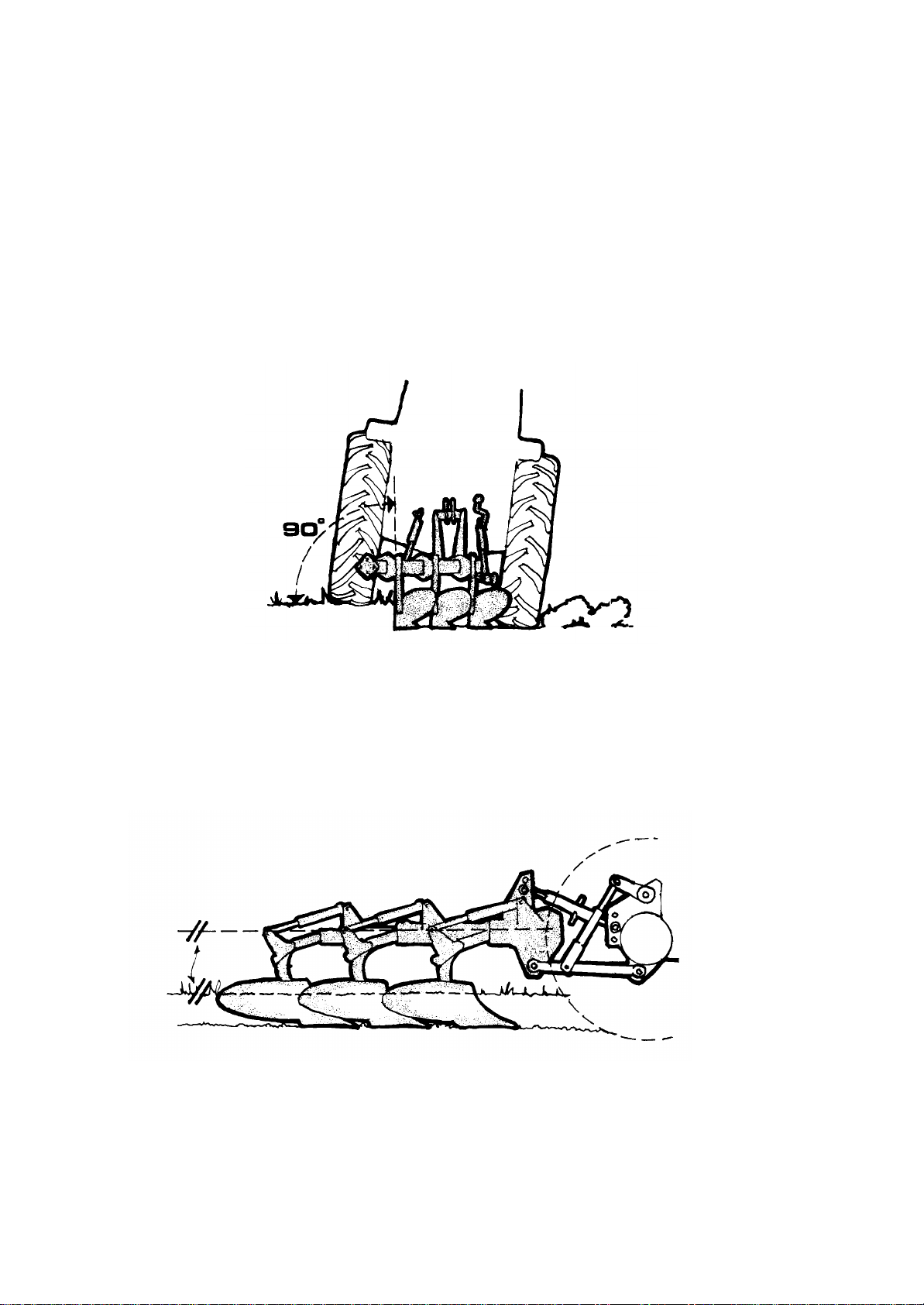

4Basic settings8

4.1 Basic settings mounted ploughs 8-9

4.2 Adjustment of skimming device 10-11

5Stone trip system 12

5.1 Shear bolt protection (F) 12

5.2 Hydraulic type (H) 12

5.3 Adjustment of operating pressure 13

5.4 Checking the accumulator 13

6Adjustment of working width 14

6.1 Adjustment of working width 14-15

7Care, maintenance and replacement of wearing parts 16

7.1 Greasing of the beam hinge points 16

7.2 Winter storage 16

7.3 Replacement of wearing parts 17

7.4 Mouldboards, Tightening torques 18

7.5 Lubrication chart 19

8Extra equipment 20

9Useful advice 21

Read these instructions carefully. If you follow the instructions given, YOU can expect good results

along with a good economic return from YOUR choice of plough.

If carefully operated, adjusted and maintained, the plough will meet all reasonable demands made on it

and will give YOU reliable service in years to come. Should YOU need further instructions, which

are not included in this manual, or require the help of experienced service personnel, we advise YOU

to contact one of our local representatives, which also will have spare parts in stock.

It has always been the ambition of Överums Bruk to constantly improve its products. Consequently,

in the interest of product improvement, no specification is final or binding and we reserve the right to

alter the design of new machine series and equipment without previous notice.

Överums Bruk AB

SE-590 96 Överum

Telephone: Int+46 493 361 00