5

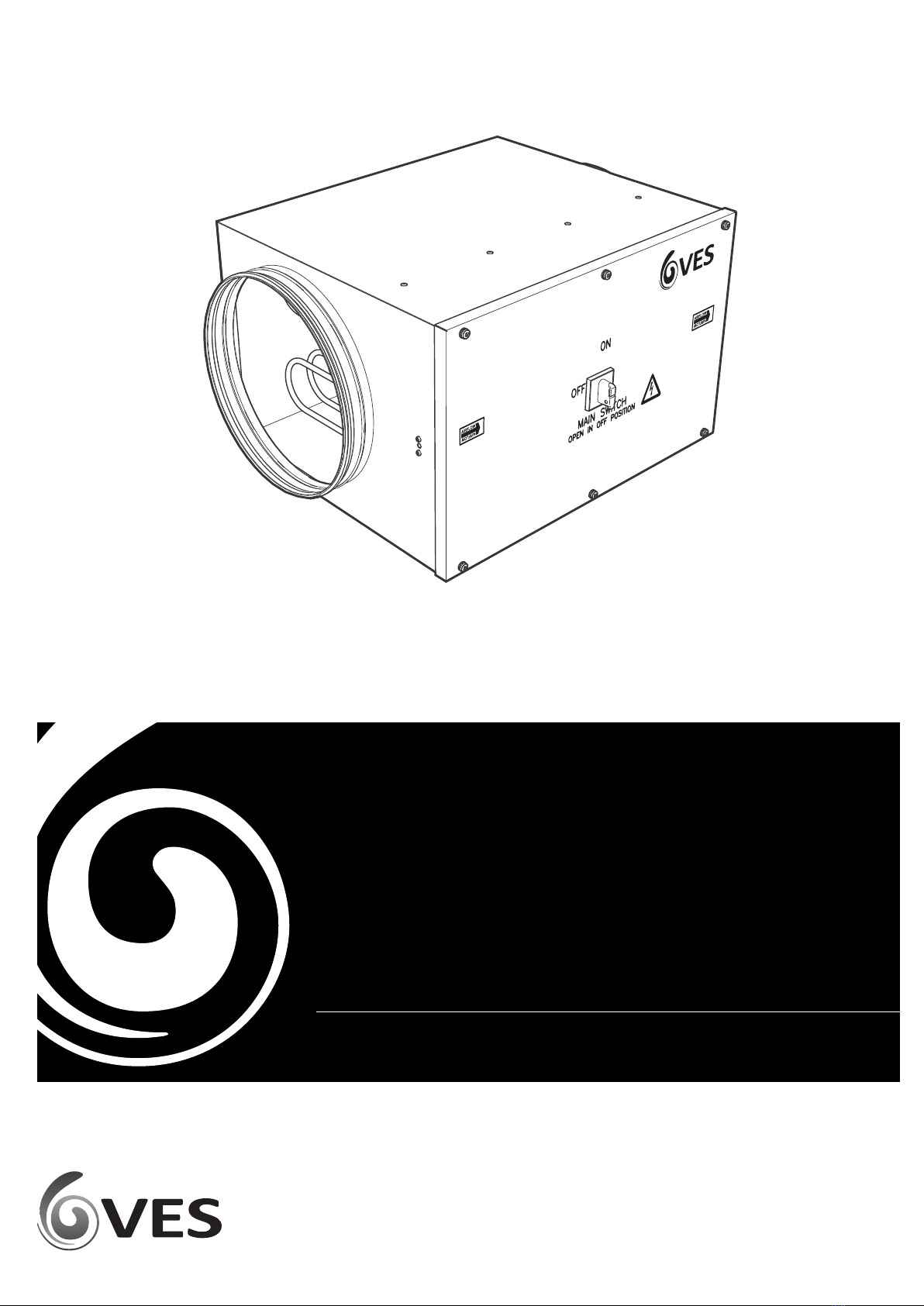

heatline Duct mounted Heaters

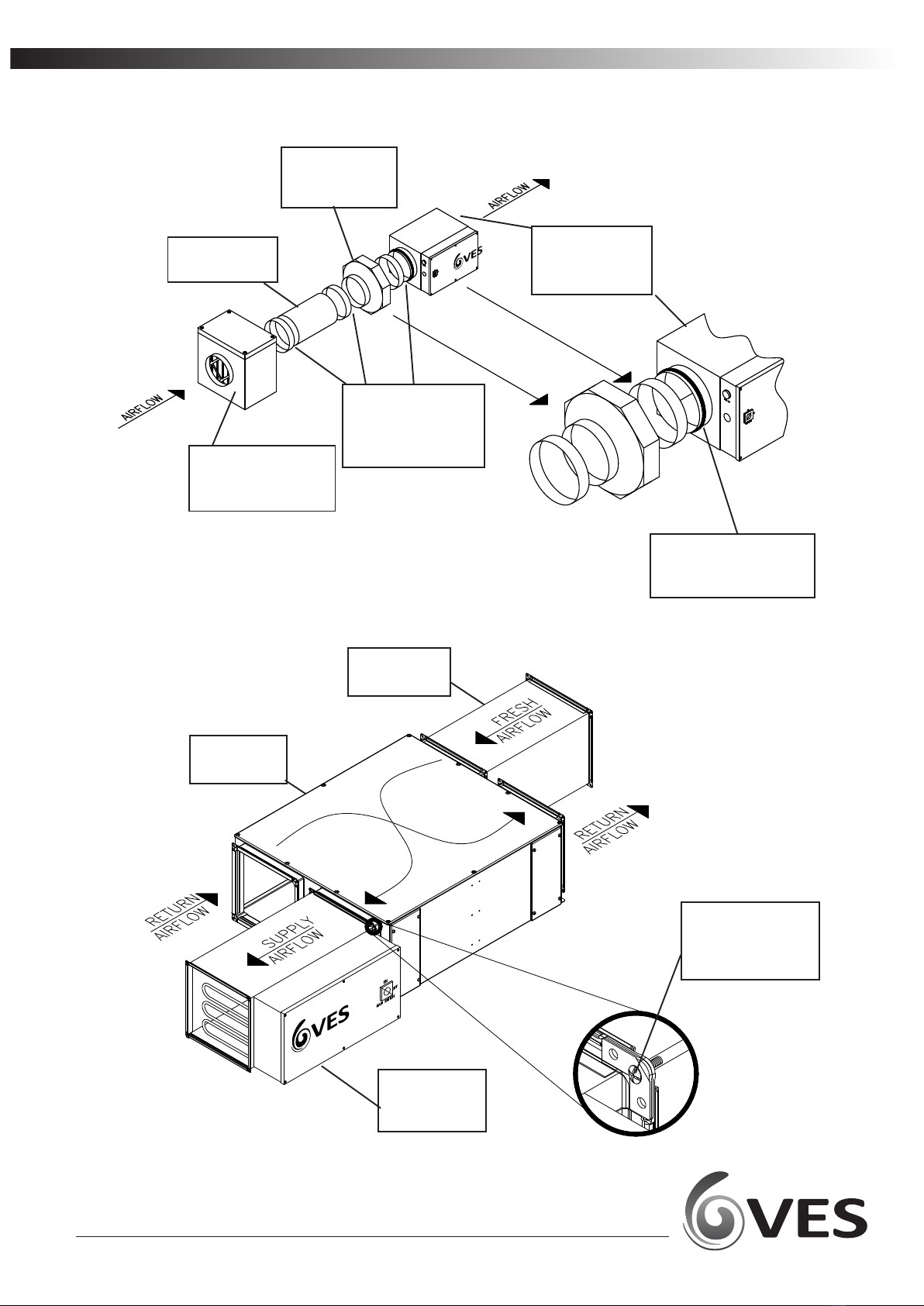

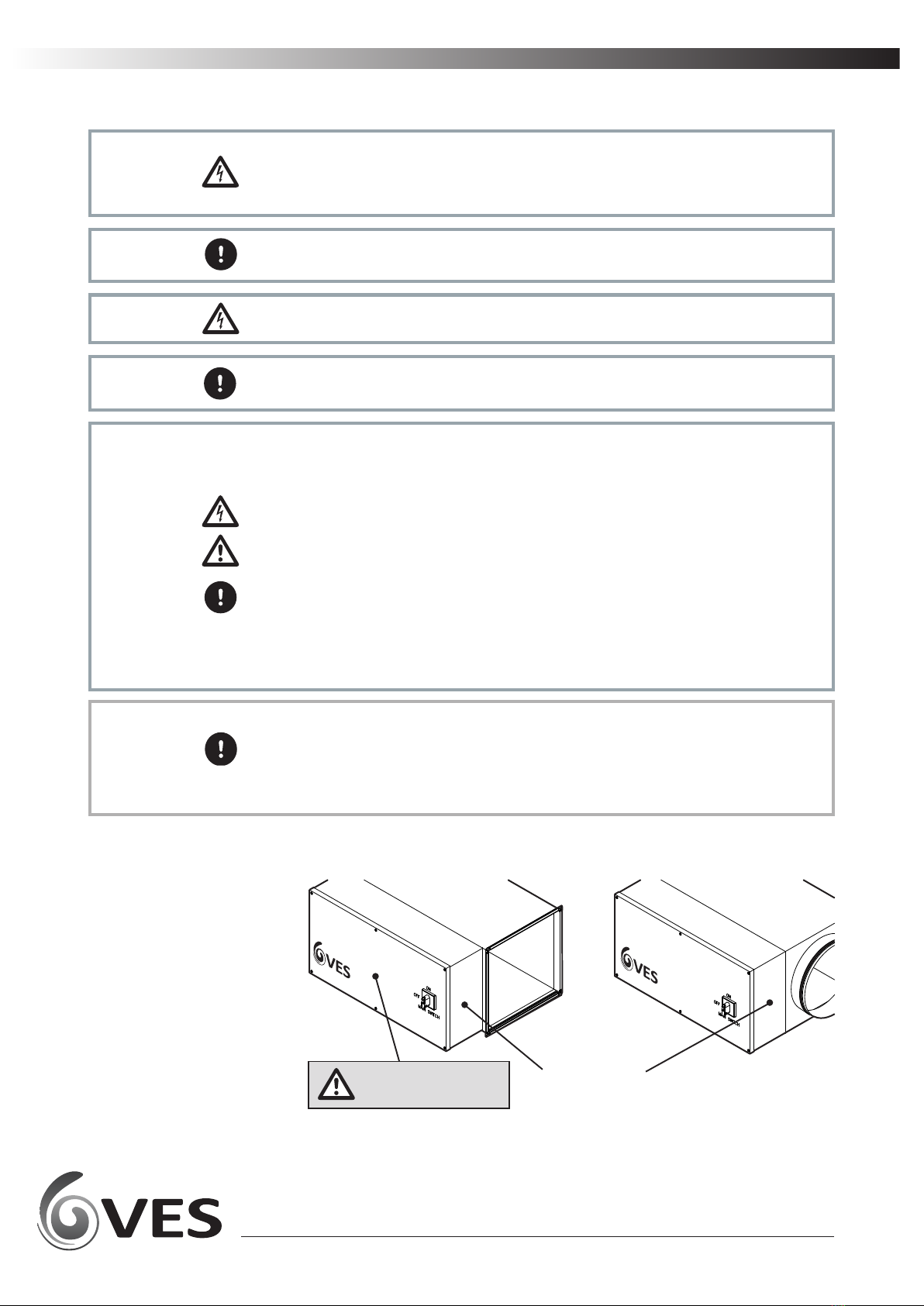

When moving the unit, handle with care and in such a manner

as to avoid damaging the external finish as this may reduce

the ability to reduce corrosion. Units are to be rigged and

lied using spreaders, taking into account the weight of the

unit, and liing gear should be arranged so as not to bear on

the casework see right.

Cauon Lids, housing and coil connecons must NOT be used as liing points.

Cauon

Where units have been supplied, without feet fied, take all necessary measures &

precauons to ensure the unit is fully supported and does not rely on adjoining ductwork

for full weight bearing.

Only experienced fitters should undertake this w ork. Take necessary safety precauons

when working in elevated posions.

5.1 Orientaon

Installaon 5

Correct

Not suitable

Not suitable

AIRFLOW

AIRFLOW

AIRFLOW Eagle Close,

Chandlers Ford Ind. Estate,

Chandlers Ford, Eastleigh,

Hampshire, SO53 4NF

Tel: (08702) 404340

Fax: (08702) 404550

Web: www.ves.co.uk

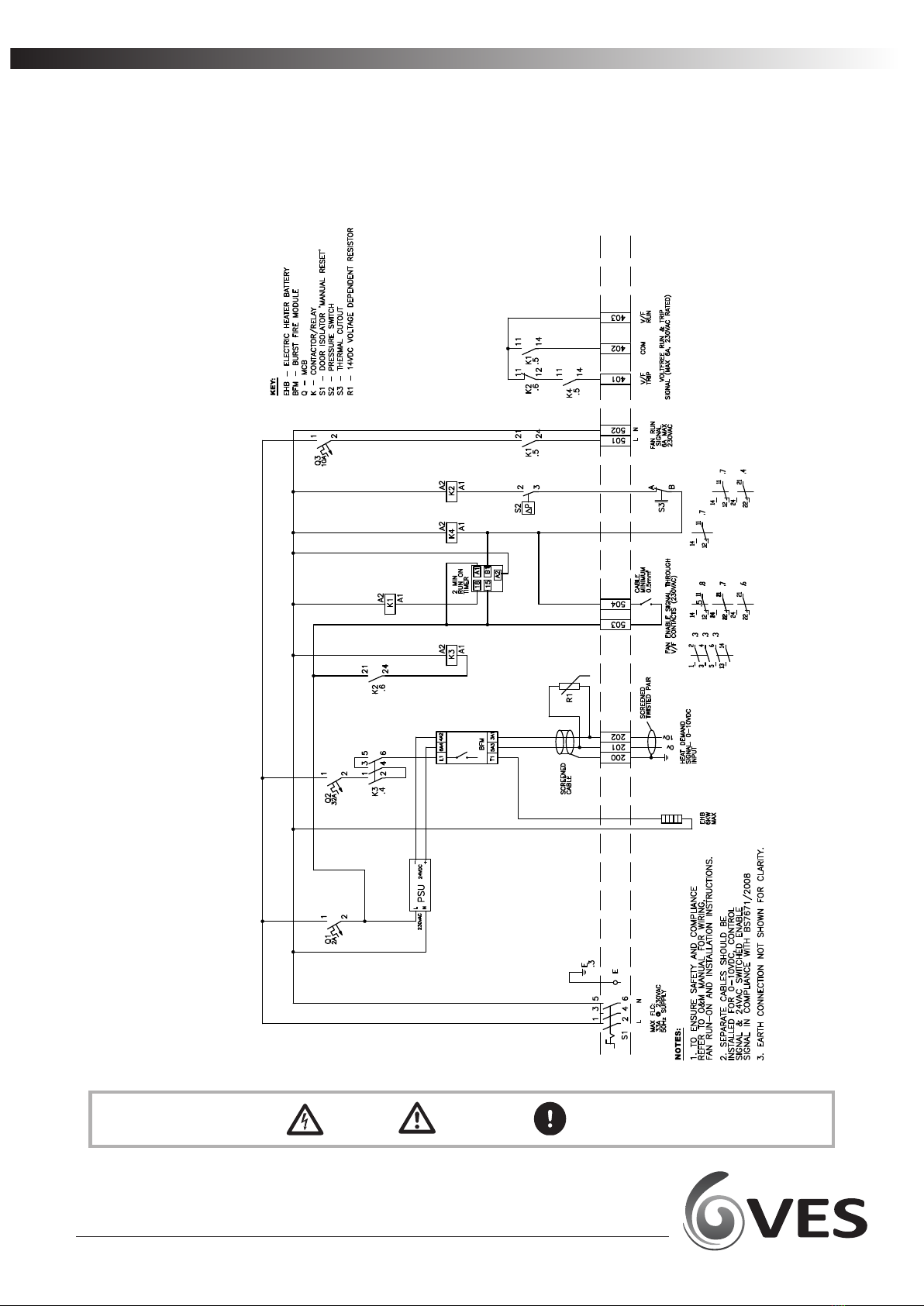

MODEL

SUPPLY

MAX. PERMISSIBLE LOAD

VES REF.

PLANTREF.

HLC200/3KW/1X1/CP

230V 1PH 50Hz 400V 3PH 50Hz

N/AA @ 230V 26.0A @ 400V

S/O. SERIALNo. PRA4143767

INSPECTED 18/10/10 ED

Eagle Close,

Chandlers Ford Ind. Estate,

Chandlers Ford, Eastleigh,

Hampshire, SO53 4NF

Tel: (08702) 404340

Fax: (08702) 404550

Web: www.ves.co.uk

MODEL

SUPPLY

MAX. PERMISSIBLE LOAD

VES REF.

PLANTREF.

HLC200/3KW/1X1/CP

230V 1PH 50Hz 400V 3PH 50Hz

N/AA @ 230V 26.0A @ 400V

S/O. SERIALNo. PRA4143767

INSPECTED 18/10/10 ED

Eagle Close,

Chandlers Ford Ind. Estate,

Chandlers Ford, Eastleigh,

Hampshire, SO53 4NF

Tel: (08702) 404340

Fax: (08702) 404550

Web: www.ves.co.uk

MODEL

SUPPLY

MAX. PERMISSIBLE LOAD

VES REF.

PLANTREF.

HLC200/3KW/1X1/CP

230V 1PH 50Hz 400V 3PH 50Hz

N/AA @ 230V 26.0A @ 400V

S/O. SERIALNo. PRA4143767

INSPECTED 18/10/10 ED

VESANDOVER LTD

Eagle Close,Chandlers Ford Ind. Est.,

Eastleigh,Hampshire, SO53 4NF

Tel: 08448-15-60-60

ELECTRIC HEATER

VESANDOVER LTD

Eagle Close,Chandlers Ford Ind. Est.,

Eastleigh,Hampshire, SO53 4NF

Tel: 08448-15-60-60

ELECTRIC HEATER

VESANDOVER LTD

Eagle Close,Chandlers Ford Ind. Est.,

Eastleigh,Hampshire, SO53 4NF

Tel: 08448-15-60-60

ELECTRIC HEATER

WARNING: DISCONNECT THE MAINS SUPPLY

BEFORE REMOVING THIS COVER

WARNING: DISCONNECT THE MAINS SUPPLY

BEFORE REMOVING THIS COVER

WARNING: DISCONNECT THE MAINS SUPPLY

BEFORE REMOVING THIS COVER

KW

KW

KW

X

X

X

PHASE

STEPS

PHASE

STEPS

PHASE

STEPS

SUPPLY

VOLTS

SUPPLY

VOLTS

SUPPLY

VOLTS

MIN.AIR

VOLUME

MIN.AIR

VOLUME

MIN.AIR

VOLUME

m³/SEC

m³/SEC

m³/SEC

REF.

REF.

REF.

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

Connued