Last update: 2021/10/06 23:13 ffc:100 https://www.vescent.com/manuals/doku.php?id=ffc:100

https://www.vescent.com/manuals/ Printed on 2021/10/08 00:37

Instructions on how to download & install control software

Final Test Documentation

Other items depending on specific configuration

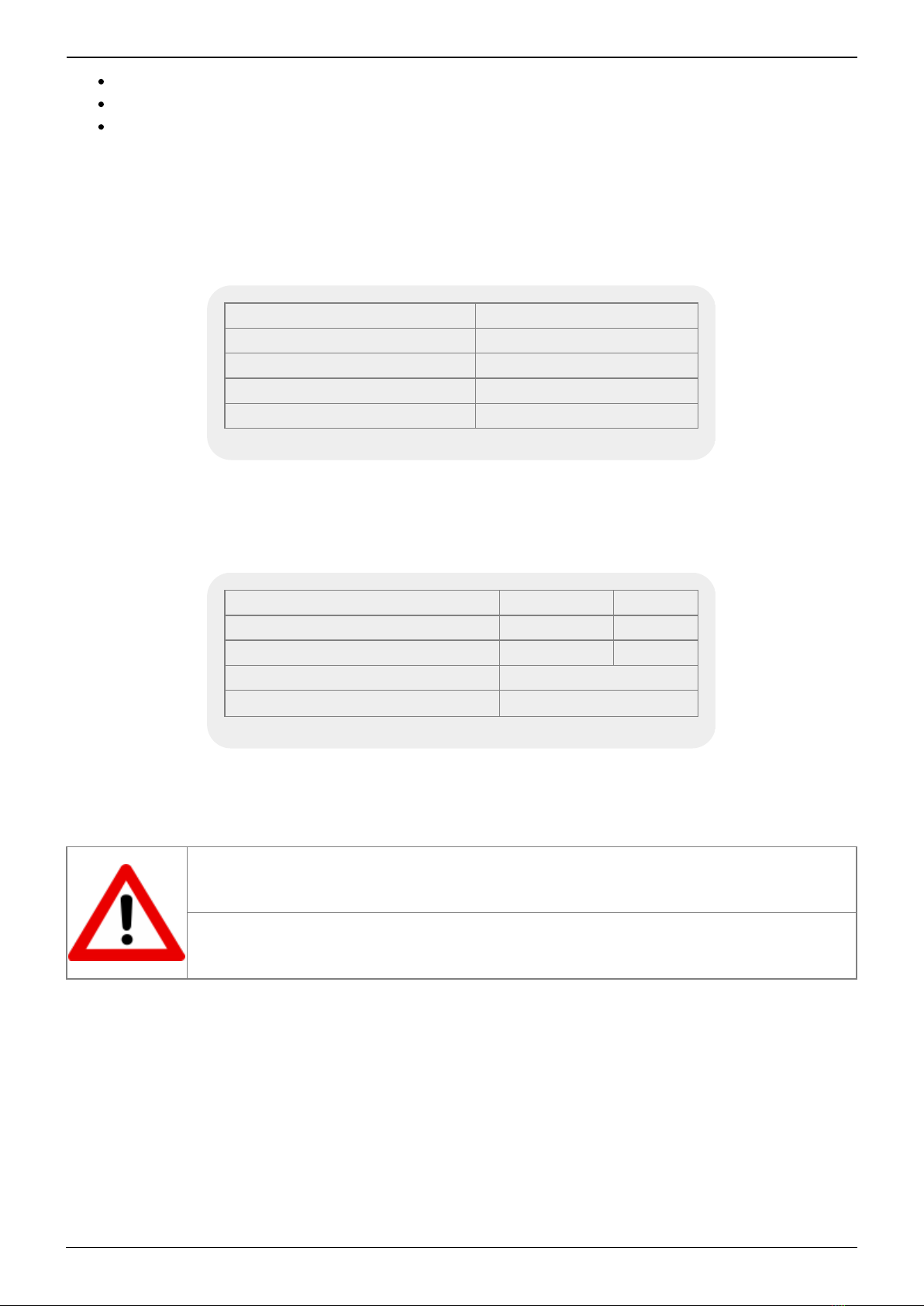

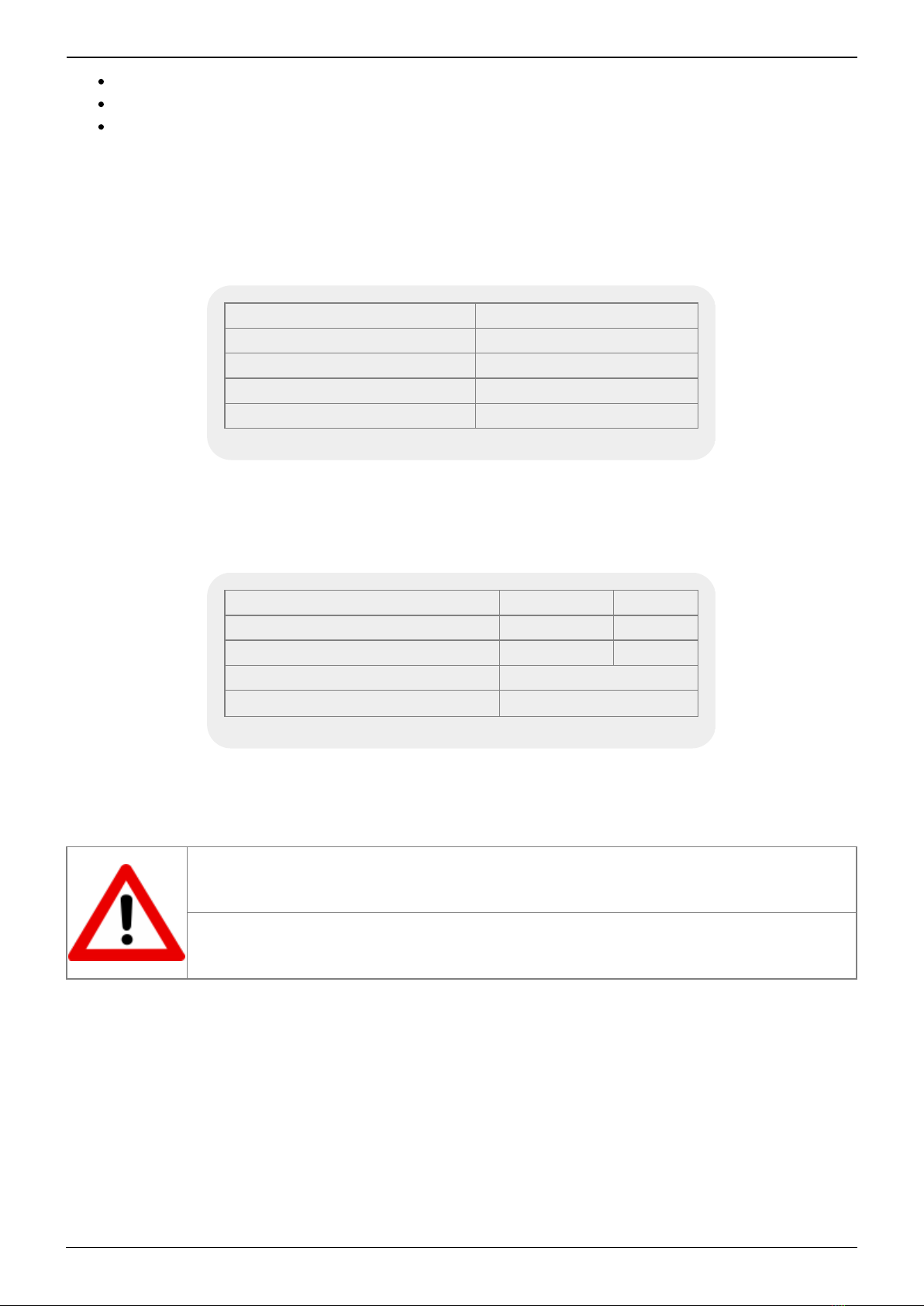

Absolute Maximum Ratings and Power Input

Note: All modules designed to be operated in a laboratory environment.

Parameter Rating

Environmental Temperature >15°C and <30°C

Environmental Humidity <60%

Environmental Dew Points <15°C

Maximum AC Line Input Current 2 A

Tab. 1: Absolute Maximum Ratings

The FFC-100 employs a proprietary design hybrid power supply that is both low noise and capable of

accepting a range of AC input line voltages. It will accept input line voltages within the ranges shown

in table 2.

Parameter Value Units

Input Line Voltage 100-240 VAC

Frequency 50-60 Hz

Phase 1 phase

User-serviceable fuse1) T 2.0 A L 250V

Tab. 2: Input Voltage Specifications

Proper Usage

If this instrument is used in a manner not specified by the manufacturer in this

manual or other relevant literature, protection provided by the instrument may be

impaired.

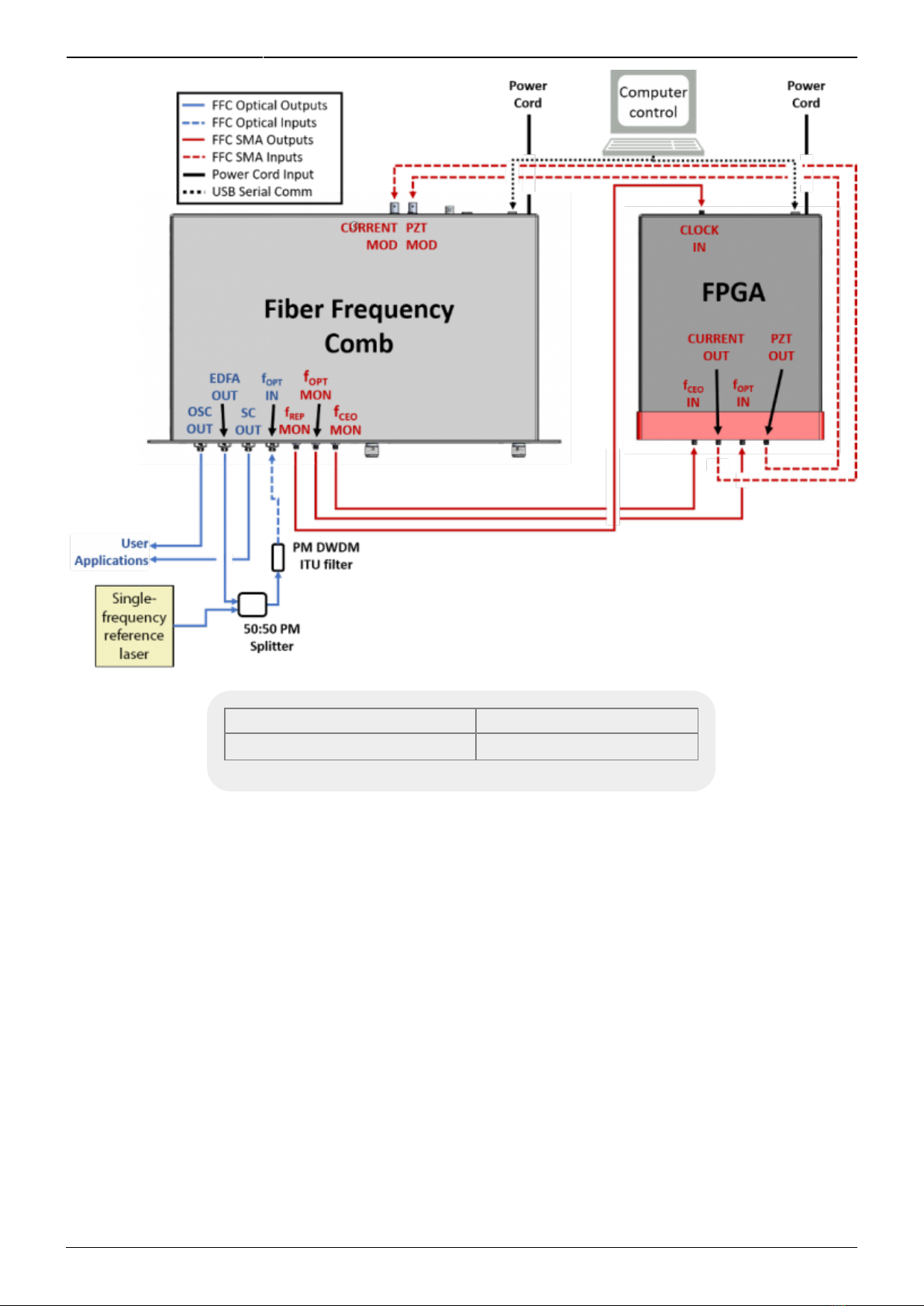

Successful implementation of the FFC-100 depends critically on the design of the

whole system: FFC-100, phase locking electronics, and any references to which the

FFC is locked or vice versa.

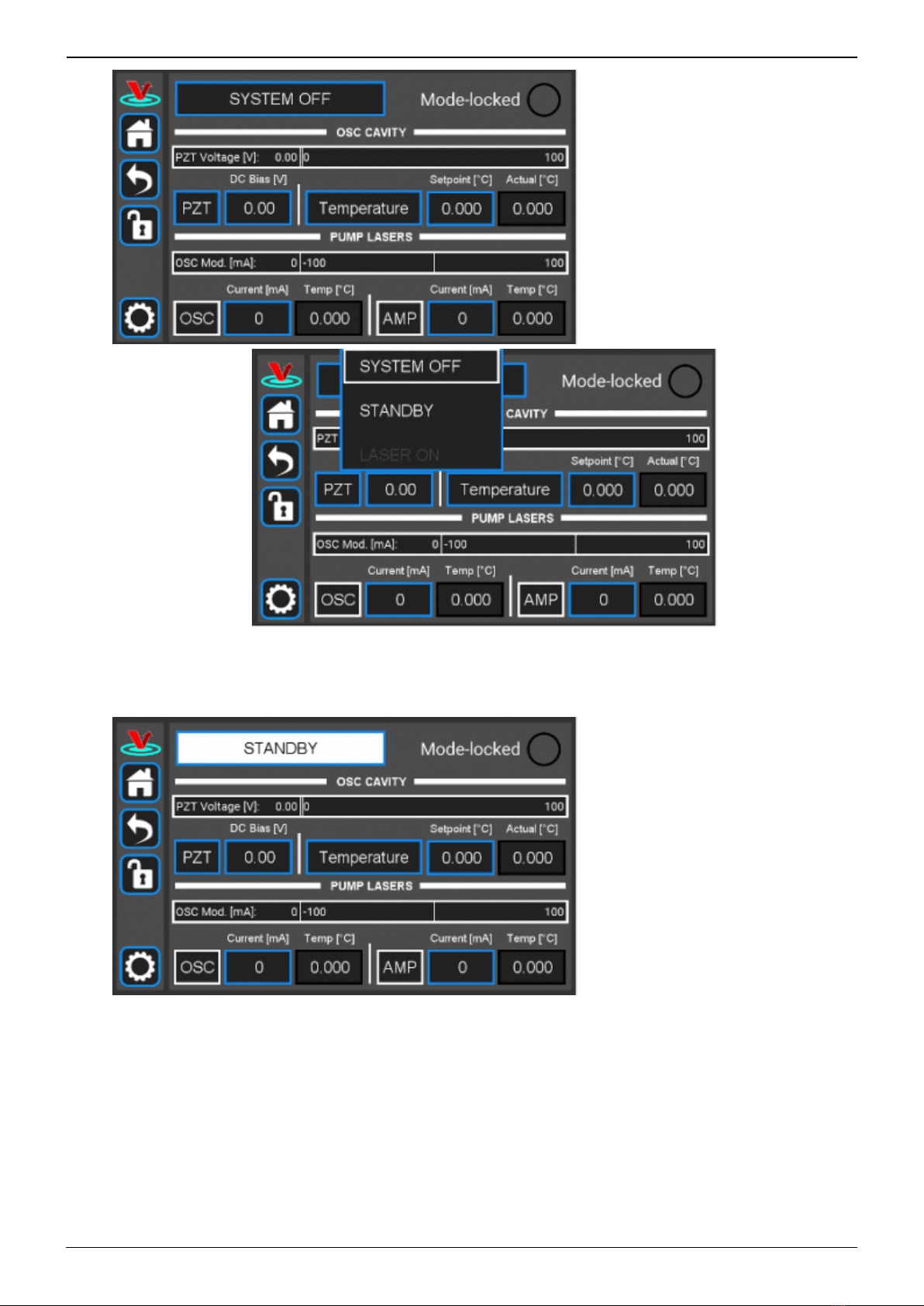

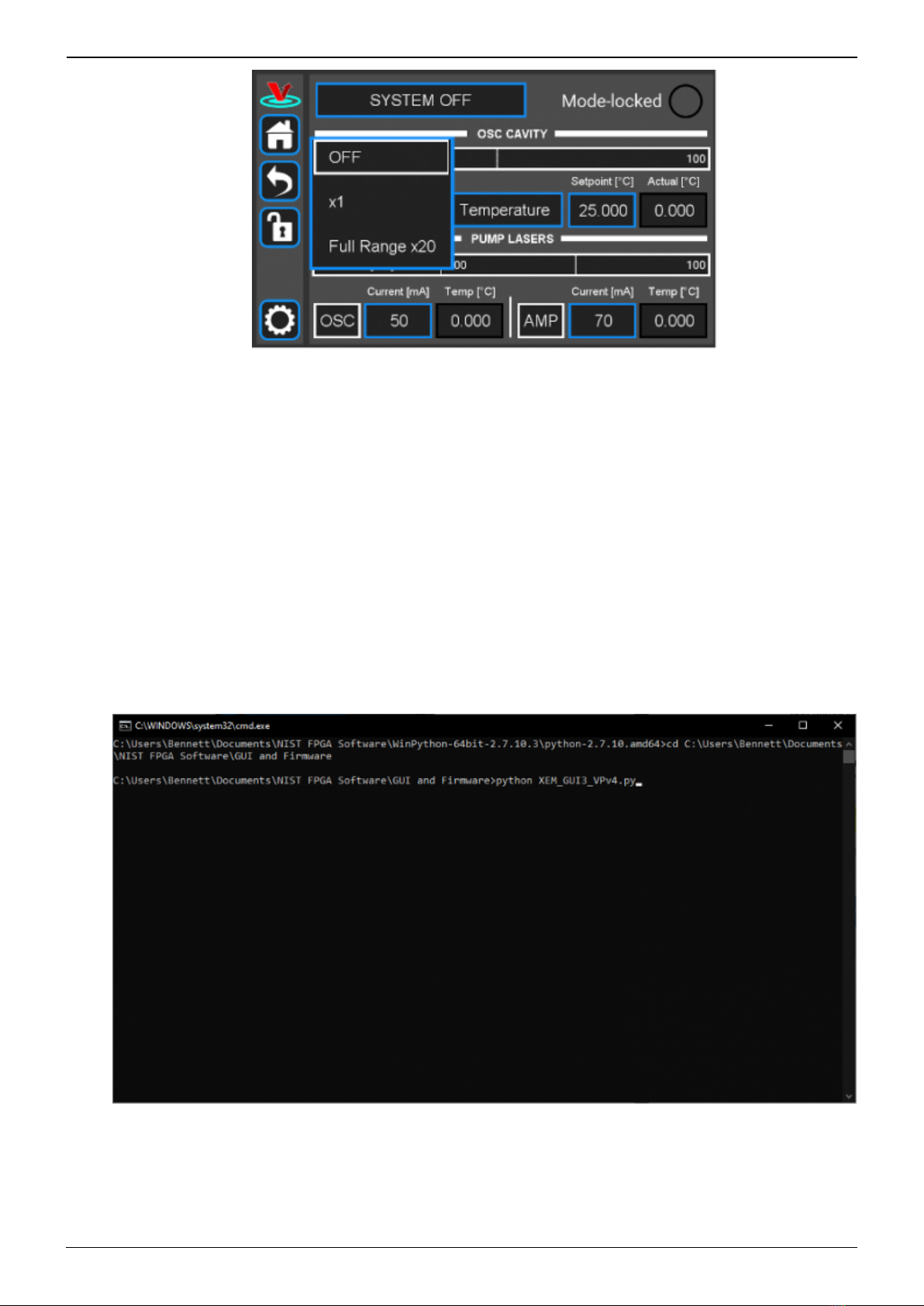

Initial Set-up

Download and install software according to instructions found here.1.

Ensure all cables and fibers are connected according to the connection diagram figure 2.2)

2.

Turn on the power to the Fiber Frequency Comb (FFC) and the FPGA, as well as the reference3.

laser.