Last update: 2021/08/26 14:26 ffc:100 https://vescent.com/manuals/doku.php?id=ffc:100&rev=1605577217

https://vescent.com/manuals/ Printed on 2022/04/17 02:01

Fig. 9: Select PZT Gain

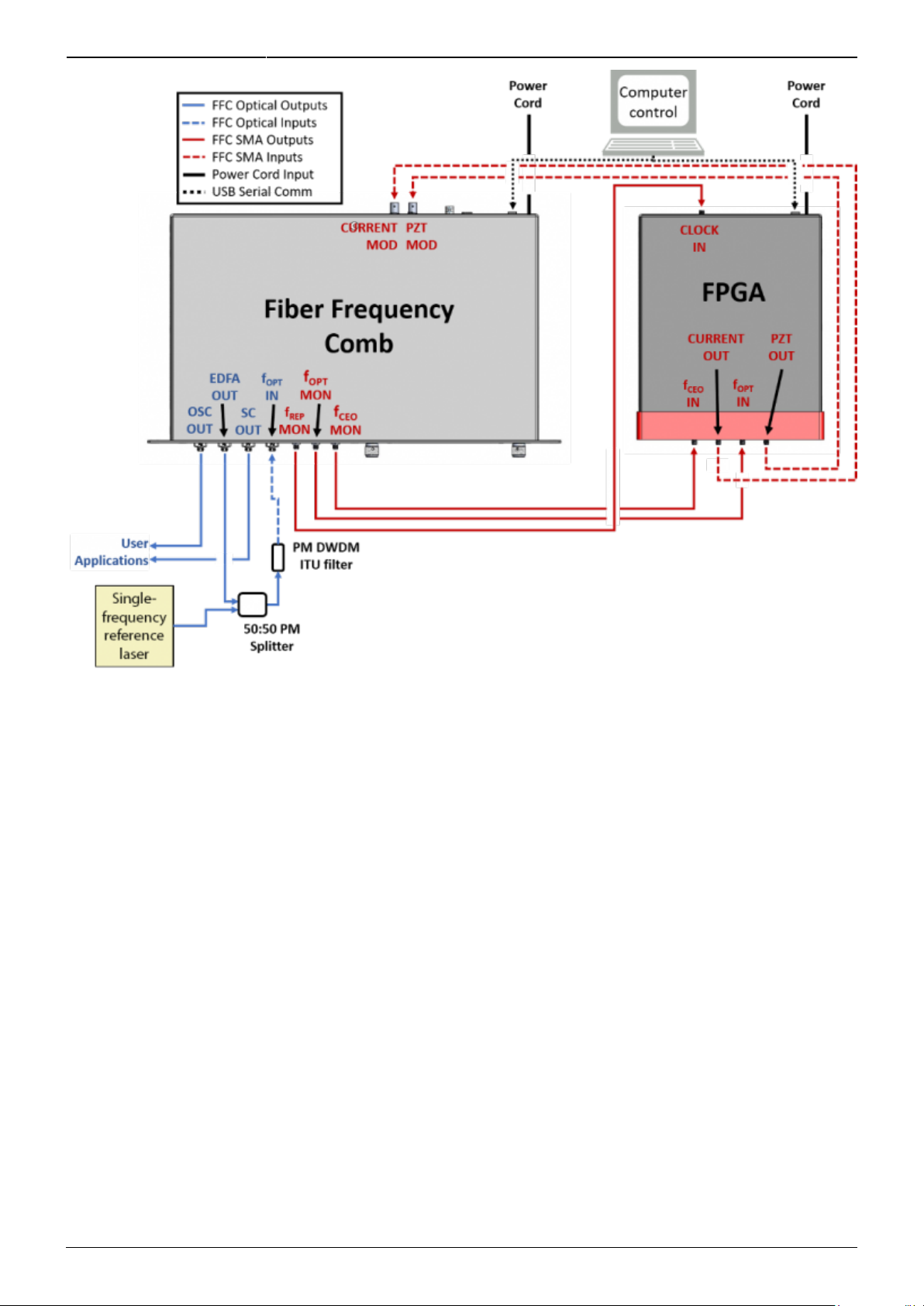

FPGA Control

Open a WinPython command window and navigate to the folder “GUI and Firmware”.1.

Execute the GUI code by typing “python XEM_GUI3_VPv4.py” (tabbing to autocomplete is useful2.

here. figure 10).

A start-up menu should appear (figure 11). Make sure “superlaserland_v12.bit” is selected and3.

select an appropriate clock option. Press OK.

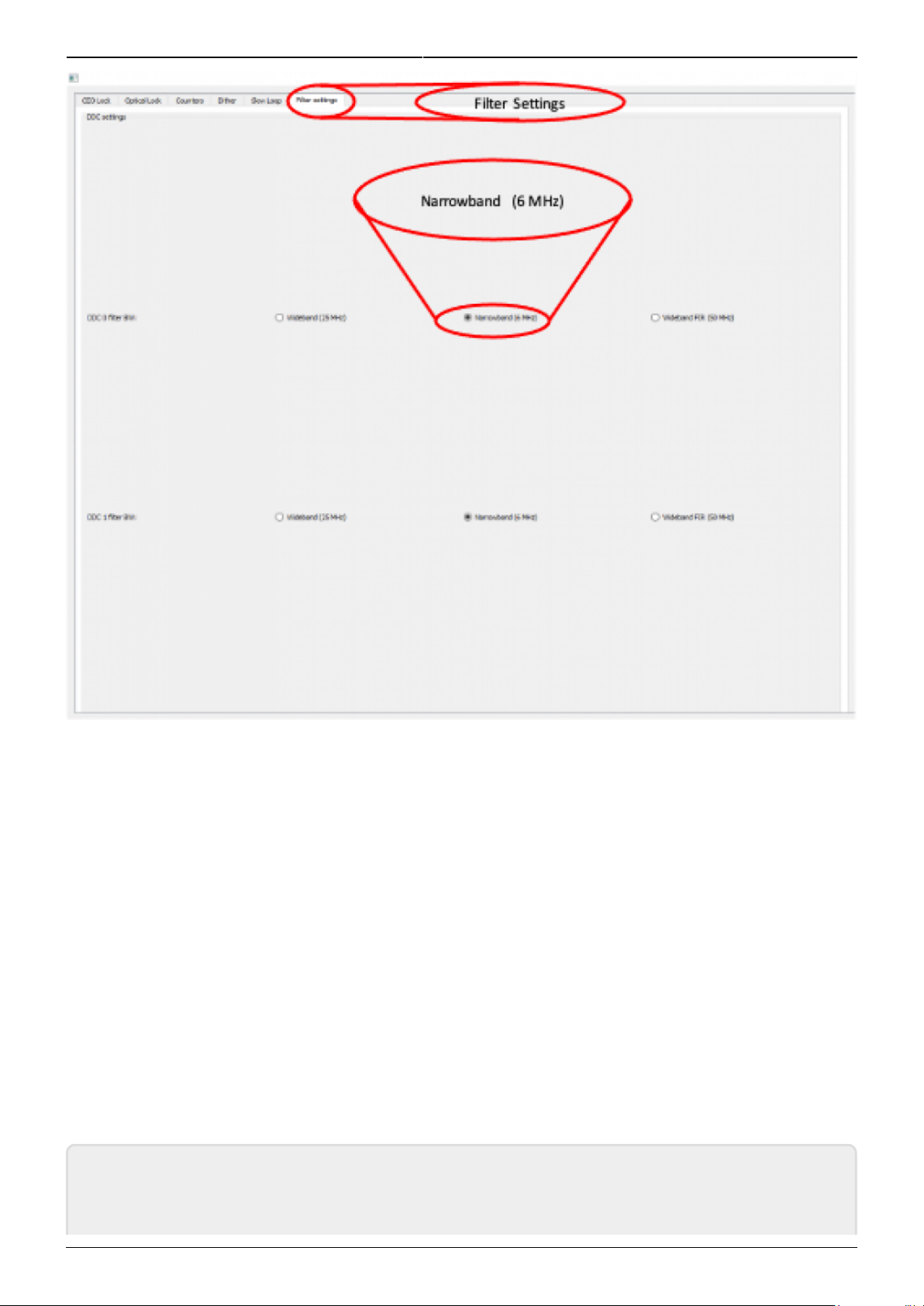

Navigate to the “Filter Settings” tab and select “Narrowband (6MHz)” for both DDC0 and DDC14.

(figure 12).

Navigate to the “CEO Lock” tab and adjust the “Offset DAC 0” slider (or oscillator current on the5.

laser’s front panel) until the Baseband IQ diagram is circular.

Press the “Lock” button. If it doesn’t lock, change the VCO sign to the opposite polarity and try6.

again. If trouble persists, try lowering the Kp value.

Navigate to the “Optical Lock” window and adjust the “Offset DAC 1” slider (or your reference7.

laser current) until you see a circular Baseband IQ diagram.

Press the “Lock” button. If it doesn’t lock, change the VCO sign to the opposite polarity and try8.

again. If trouble persists, try lowering the Kp value.

Adjust PID settings accordingly to lower the integrated phase noise of each parameter. The9.

default settings provided in the software are a good place to start but tweaking the values can

often improve performance.