1

Revised 08-14

A company dedicated to providing

ergonomic

material handling

products

since

1955

.

VESTIL MANUFACTURING CORPORATION

2999 North Wayne St., Angola, IN 46703

Phone (260) 665-7586 • Fax (260) 665-1339

JIB CRANES MODELS

WTJ-20, WTJ-E , & VAN-J

OWNER’S

MANUAL

Vehicle-Mounted Jib Cranes

Exploded Parts Drawings & BOMs............... 6-8

Maintenance / Safety & Troubleshooting ........ 9

Safety Label Identification ..............................10

Warranty ........................................................ 11

Contents

Installation Instructions ...................................... 2

Loading Instructions .......................................... 3

Operation Instructions ................................... 4-5

WARNING!

Material handling is dangerous. Any person who uses

or maintains this product must be familiar with the

hazards associated with it.

Failure to read and understand this owner’s

manual before using or servicing the lifting jib

constitutes a misuse of the product.

•

•DO NOT leave suspended loads unattended.

Always unload the crane before leaving it.

•DO NOT use the jib to lift, support, or move people.

•Always watch the jib and the load carefully when the

jib is in use.

•Unload the jib, lower the boom and secure it to the

mast before moving the vehicle.

•DO NOT move the vehicle with a load suspended

from the jib.

•Keep clear of the boom while it is loaded or rotated.

Never allow personnel to climb under or onto any

part of a suspended load.

•Keep hands, fingers, loose clothing, etc., clear of the

winch and cable.

• Do not use the jib if any damage or unusual noise

is observed.

•AC-powered winches must only be plugged into a

115V, GFCI-protected, grounded supply circuit.

•

Apply all relevant DOT, state, and federal

regulations concerning the installation and use of

vehicle-mounted cranes.

•

Confirm that all labels are in place (see "Label

placement diagram" on p. 10A-10C) and legible.

•DO NOT modify this jib crane in any way.

Unauthorized modifications automatically void

the limited warranty and might make the crane

unsafe to use.

REPLACEMENT PARTS

We use quality parts and materials to manu-

facture this equipment. Only install manufacturer-

approved replacment parts and accessories. VESTIL

is not responsible for problems resulting from the

use of unapproved replacement parts.

To order replacemetn parts or to ask questions

regarding the use or operation of the product,

contact VESTIL via the phone number that appears

above. Be prepared to provide the serial number,

which is displayed on the machine data label (see

label 287 on p. 10A-10C).

RECEIVING INSTRUCTIONS

Although each unit is tested and inspected prior to

shipment, it is possible that the unit was damaged

during transit. Inspect the crane closely when it

arrives. If you see evidence of damage or rough

handling to either the packaging or the product when

it is delivered, immediately make a note of it on the

Bill of Lading!

To be able to make a timely claim for freight

damage with the carrier, It is important that you

remove the packaging upon delivery. Examine the

product carefully, especially if the packaging is

damaged.

Confirm that the product matches your order.

E

N

G

L

I

S

H

E

S

P

A

N

O

L

F

R

A

N

Ç

A

I

S

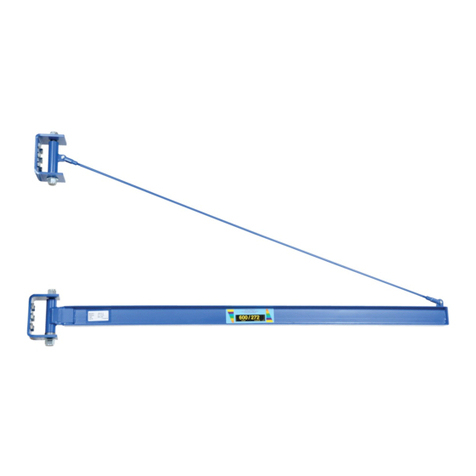

WTJ-DC

VAN-J

WTJ-AC