03/10/03 Rev. 3/22/2018 FE, MANUAL

Copyright 2018 Vestil Manufacturing Corp. 5 of 8

Use recommendations:

Vestil strives to identify foreseeable hazards associated with the use of its products. However, material

handling is dangerous and no manual can address every conceivable risk. The most effective means for

avoiding injury is for the user to exercise sound judgment whenever using these extensions.

Improper or careless operation might result in serious personal injuries.

ONLY use fork extensions as a means for supporting palletized loads or skids.

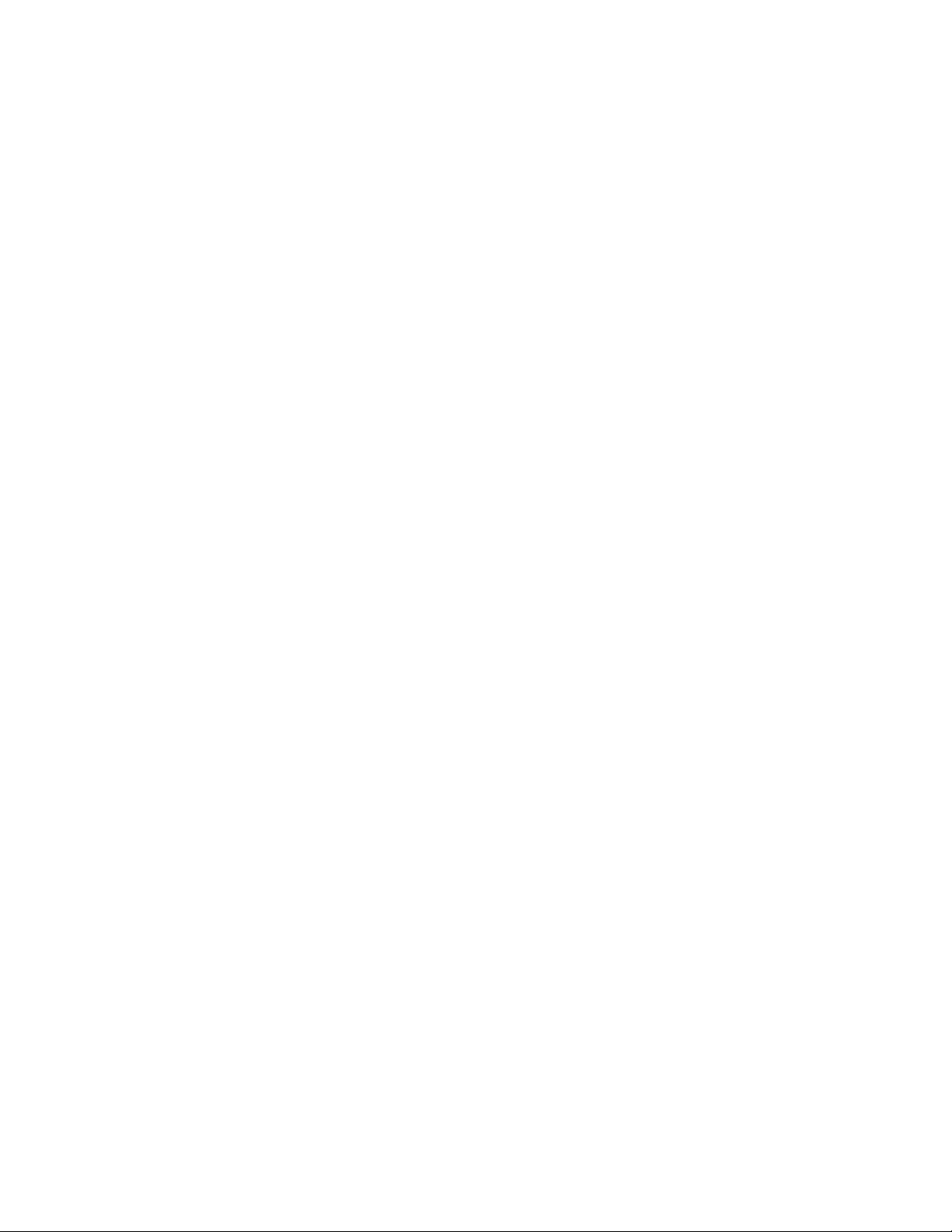

Inspect both extensions before each use according to the inspection instructions (below on same

page). DO NOT use a damaged fork extension. Examples of structural damage include: a) broken tine

lock, retaining loop, or welds connecting the loop/lock to the main body of the extension (fork pocket); b)

cracked, warped, bent or excessively corroded fork pockets; and c) cracks, warps, bends or excessive

corrosion of the cast toe piece welded to the end of each fork pocket.

DO NOT sit on or ride on the extensions.

DO NOT use a fork extension UNLESS each label shown in “Labeling Diagram” on p. 7 is affixed to

the extension and is undamaged and readable.

DO NOT attempt to lift loads that exceed the capacity of your extensions. DO NOT exceed the load

rating of the fork truck. (See “4. Contact the manufacturer…” on p. 6-7).

DO NOT attempt to lift a load using only the toe of a fork extension. Permanent damage to the fork

extension, damage to property, or serious personal injury could result.

DO NOT modify either fork extension in any way. Unauthorized modifications might make the

extension unsafe to use and could result in operator and/or bystander injury. Any modification not

expressly approved beforehand by Vestil in writing automatically voids the warranty.

Inspections:

Before putting an extension into regular service, make a written record of its appearance. Pay

particular attention to tine locks and tine lock hardware. This record establishes normal condition.

During future inspections, compare observations to the record to determine if an extension is in normal

condition. DO NOT use the extension unless it is in normal condition.

Before each use:

Look for damage to either the fork extension or the tine lock/loop. Verify that the locking

mechanism functions normally.

Examine the cast tapered end of the extension. Make sure that it is not cracked or deformed,

and that the weld between the tapered end and the fork pocket portion is intact.

At least once per month:

Inspect each extension for warps, bends, and cracks.

Closely inspect the tine lock/loop for damage.

Verify that all welds are intact.

Confirm that each label is located as shown in the “Labeling Diagram” on p. 7 and is

undamaged and readable.

Using the fork extensions:

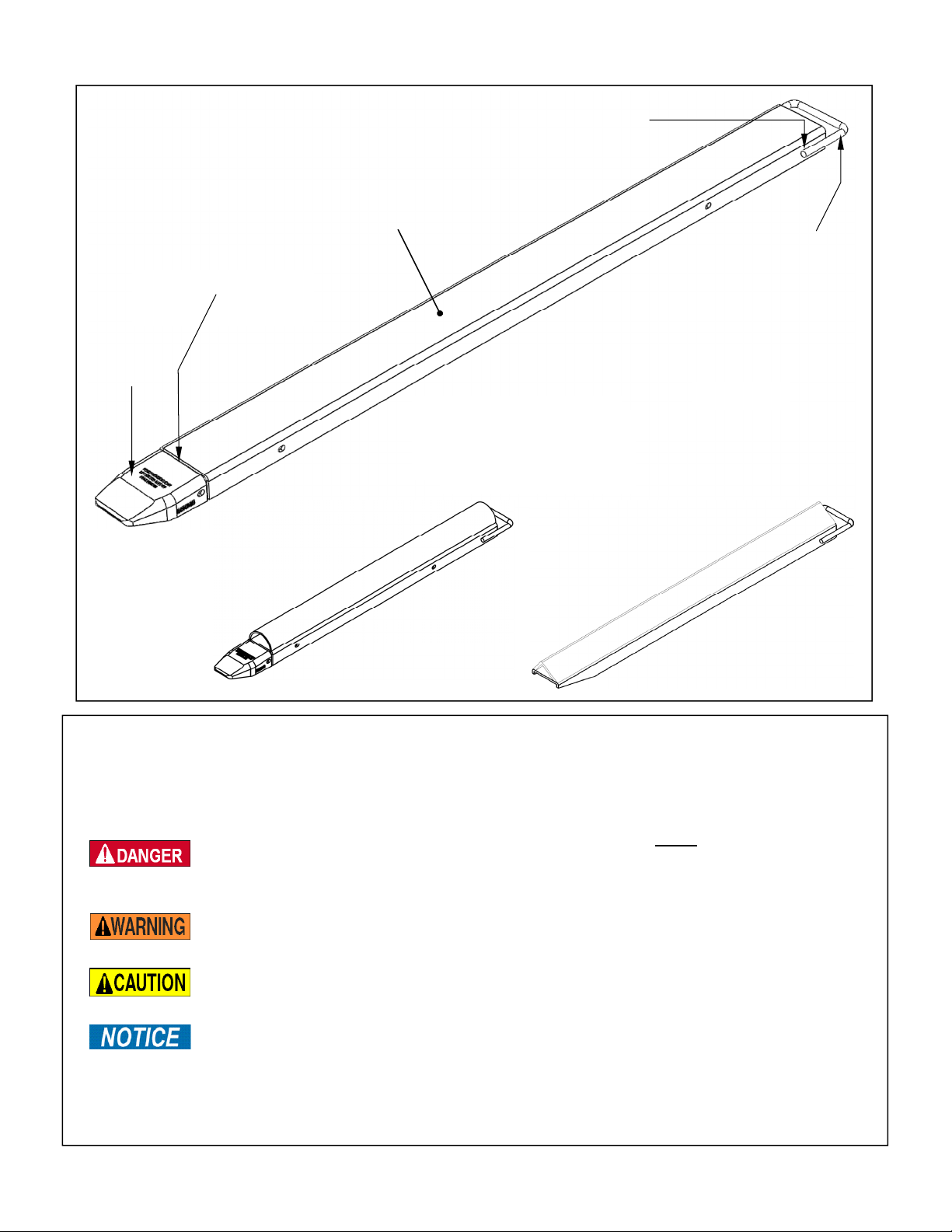

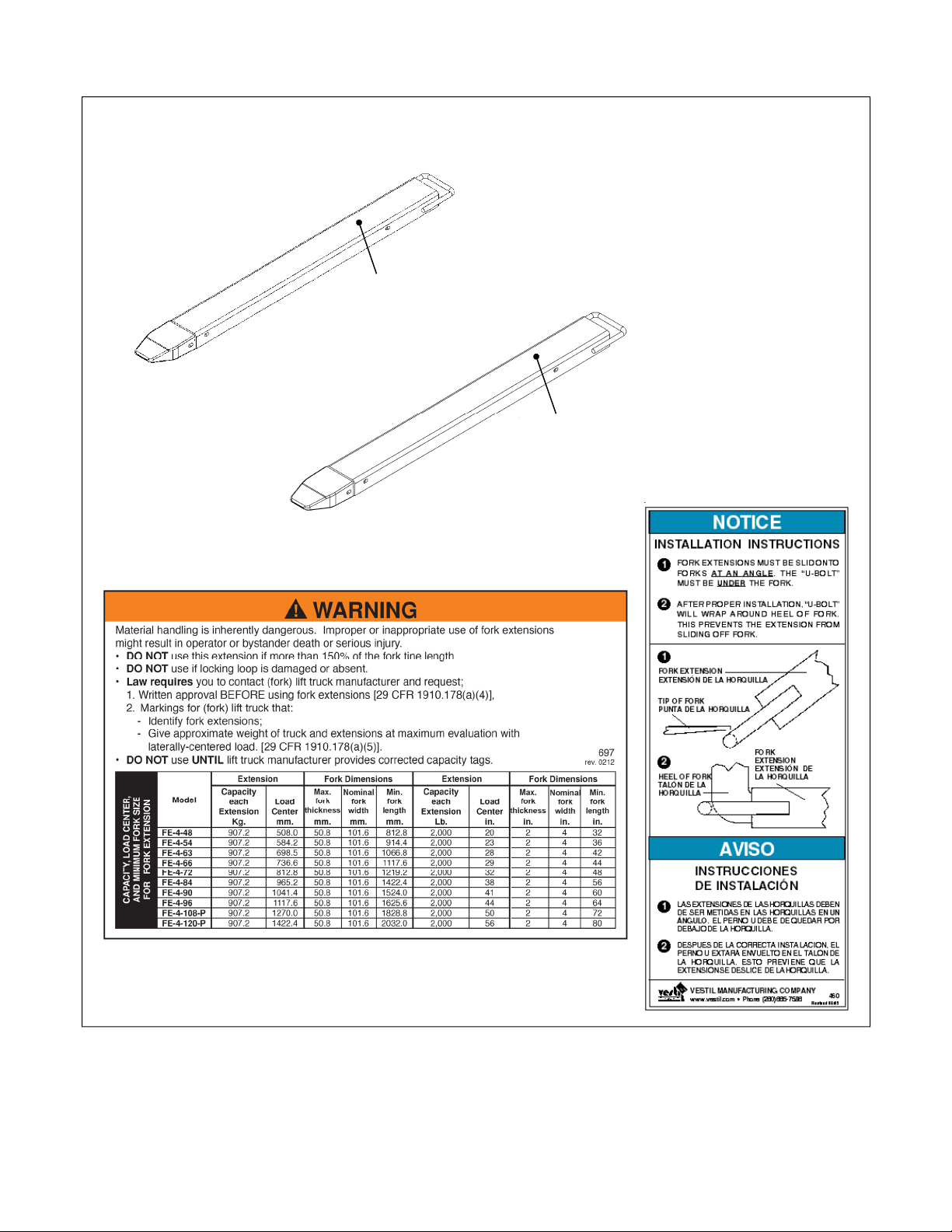

1. Compare the length of the forks to the length of the fork extensions; each extension must not be more

than 150% of the length of the tine.

2. Review labeling applied to your fork extensions. The warning label displays important information

about your extensions as well as minimum and maximum fork dimensions.

3. To prevent the fork extension from moving from side-to-side during use, select a model that matches

the tine width (see “Nominal fork width in inches (cm)” from the table on p. 3; also see ANSI/ITSDF

B56.1-2005, paragraph 7.39.5, p. 51, “Fork extensions shall be designed to avoid unintentional

disengagement from the forks. Lateral clearance shall not exceed 12mm between fork and

extension.”)

4. Contact the manufacturer of your fork lift to verify that your fork extensions can safely be used with

the fork lift. The manufacturer must also provide updated labels/tags for the fork lift because, of

course, regulations impose these obligations: