3

that may have occurred during the shipping .Remove the protective coverings

(plastic bags, etc.) and insure that they are stored out of the reach of children. The

equipment must never be lifted by the tank or plastic components when being

moved, and improper handling may damage near the machine .Always lift the

machine by the bottom of the machine near the legs and hold the machine on both

sides when lifting and carrying.

Prior to operating the machine, check that the power supply is adequately

grounded, as required by law ,and corresponds to the power specifications printed

on the label equipment located on the inside panel of the machine or as printed in

this manual. Plug the machine either directly into an outlet or into a single

approved extension cord of not more than 10 feet long. Do not use multiple power

adapters or extension cords, as they may damage the machine and void the

warranty.

If you are in any way unsure about the power supply or the power

requirements of the machine, have the machine and the power supply

inspected by a qualified technician prior to using the machine.

The manufacturer and all distributors are not responsible damage to the machine,

property, or the operators resulting from

improperly connecting or installing the

machine. Also before operating the

equipment, clean the machine as directed in

the Cleaning # Maintenance section.

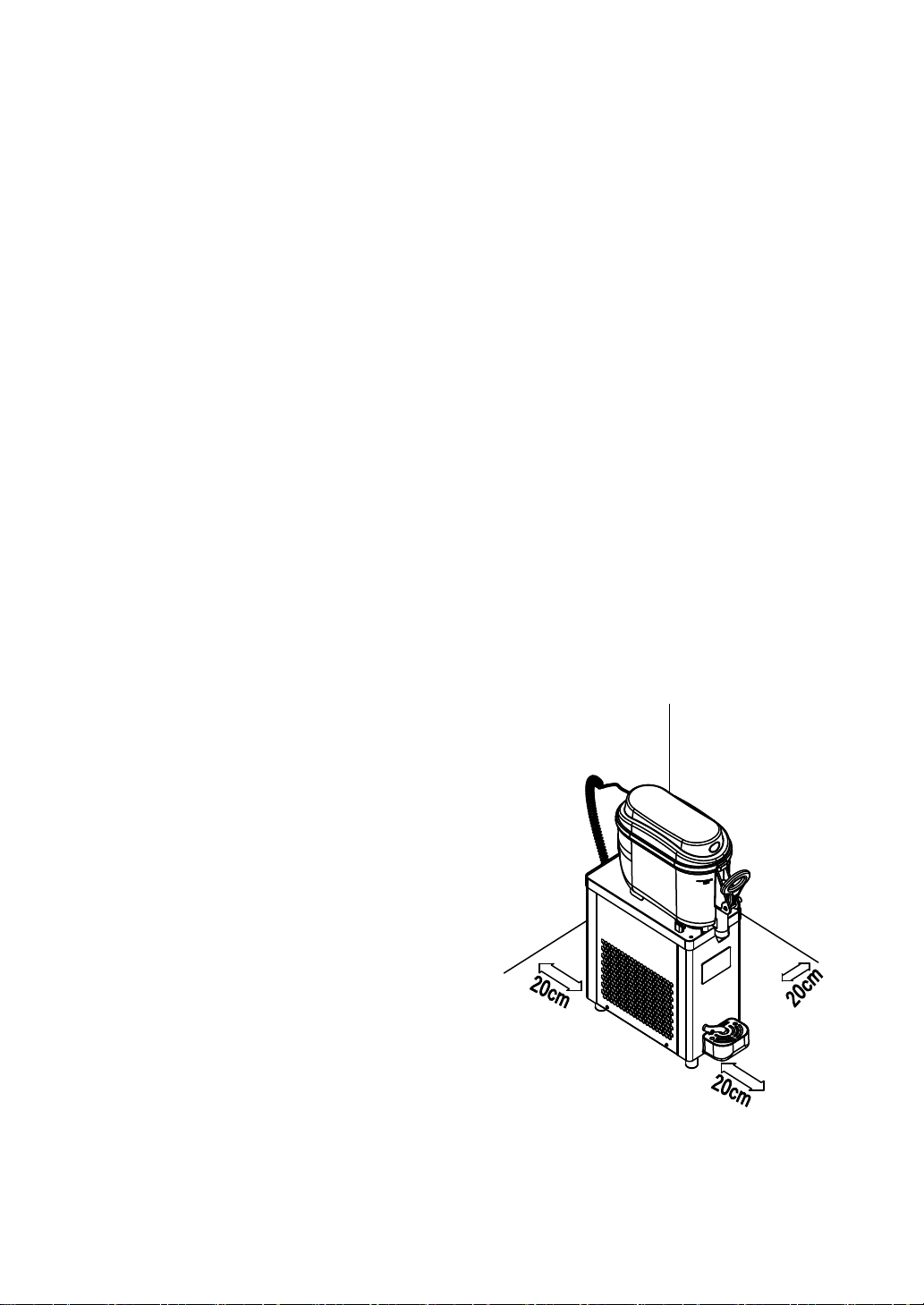

$Install the equipment away from heat

sources and leave sufficient space around

the machine to ensure adequate cooling by

air circulation. There should be at least

20cm inches of open air on each side of the

machine

Operating instruction

Before filling the tank, carefully clean and rinse all surfaces that will be exposed

20cm

20cm 20cm

V