1.Parts List

Part No Part Name Explanation Quantity Picture

Part No Part Name Explanation Quantity Picture

L1 Laser kit Optional 1 Set ——

L2 Laser wire 3P 1 ——

3Inner hexagon screw M5*16 8 L3Protective glass Optional 1

4Trapezoidal nut M5-20 8

5Inner hexagon screw M4*10 4 Part No Part Name Explanation Quantity Picture

6Trapezoidal nut M4-20 4 D1Guard plate —— 2

7 Rubber mat —— 4D2Inner hexagon screwM5*108

8Milling cutter ——2Set C3Ship nut M5-10 8

Part No Part Name Explanation Quantity Picture

10 Inner Hexagon Wrench 2/2.5/3/4/5mm 1Set

11 Nut Wrench 14/17mm 1Set

12 Soft brush —— 1 G2 X-limit switch Already assembled 1

13 Line pressing plate 290/150mm 1 —— G3 Y-limit switch Already assembled 2

14 Protective wire net pocket 300mm(optional) 1 —— G4 Z-limit switch Already assembled 2

15 Winding pipe 500mm(optional) 1 —— G5 Y-limited block Already assembled 1

16 Cable ties —— 6 —— G6 X-limited block Already assembled 1

17 Instruction manual —— 1 —— G7 Inner hexagon screw M6*14,Already assembled 2

18 U Disk —— 1 G8 Inner hexagon screw M3*6,Already assembled 4

G9 Self-tapping screw M2.6*8,Already assembled 2

Part No Part Name Explanation Quantity Picture G10 Self-tapping screw M2.6*6,Already assembled 4

9-1 Pressing plate 50*20*3 4 G11 Shim Already assembled 2

9-2 Screw M6*40 4 G12 Z1/Z2-Limit wire 2.0-2.54,Length 600mm 2 ——

9-3 Screw M6*45 4 G13 X/Y2-Limit wire 2.54-3P,Length 600mm 2 ——

9-4 Butterfly nut M6 4 G14 Y1-Limit wire 2.54-3P,Length 300mm 1 ——

9-5 Washer M6*2mm 4

Part No Part Name Explanation Quantity Picture

C2 Inner hexagon screw M5*12 4

C3 Ship nut M5-10 4

C4 Stepper motor wire 4P,Length 480mm (X/Z) 2

C5 Stepper motor wire 4P,Length 150mm (Y1) 1

C6 Spindle motor wire 2P,Length 480mm 1

C7 USB cable —— 1 ——

C8 Power supply 24V,5A 1

`Part No Part Name Explanation Quantity Picture

2/12 3018 Prover Ver:V1.2

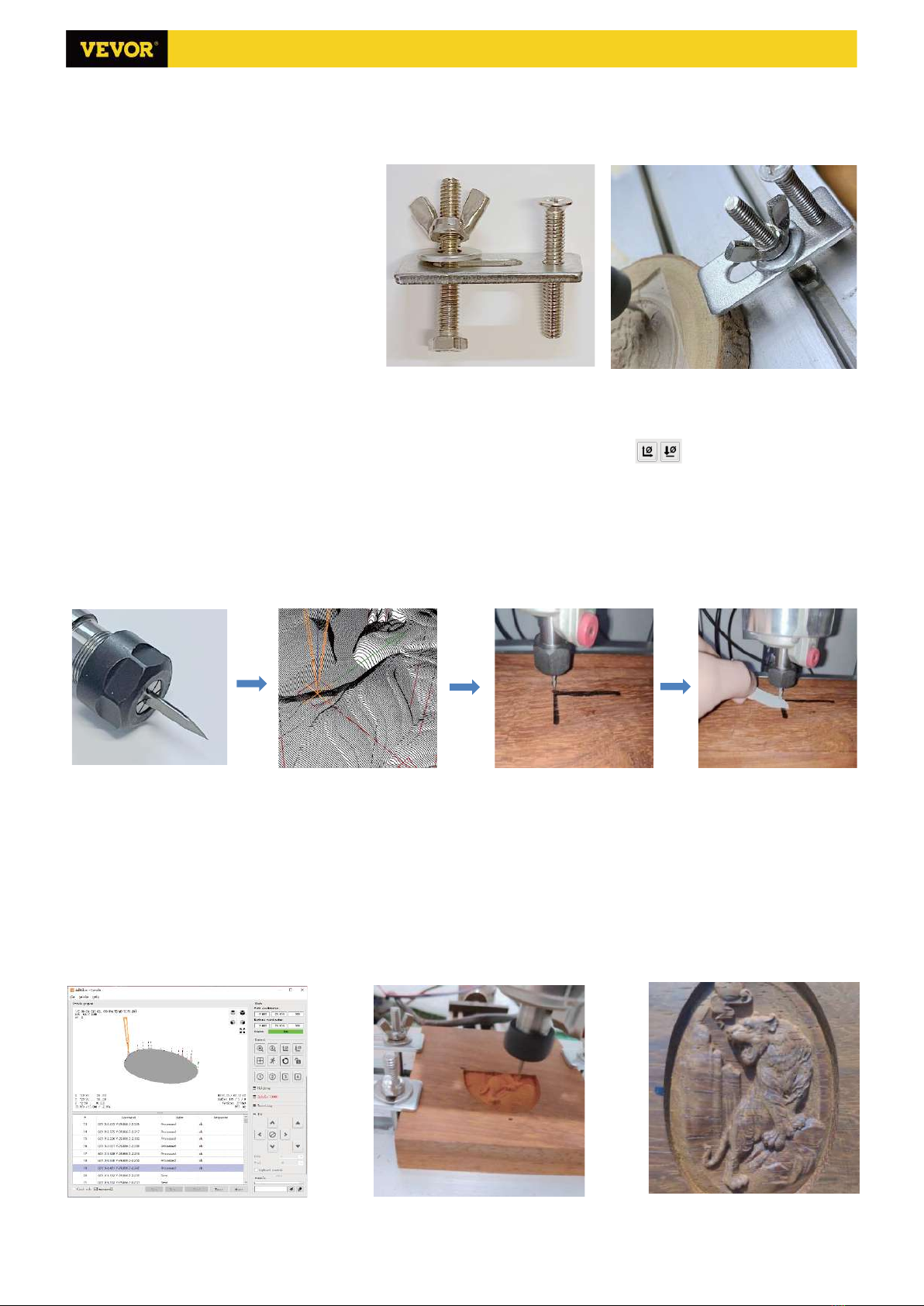

Laser package ( optional )

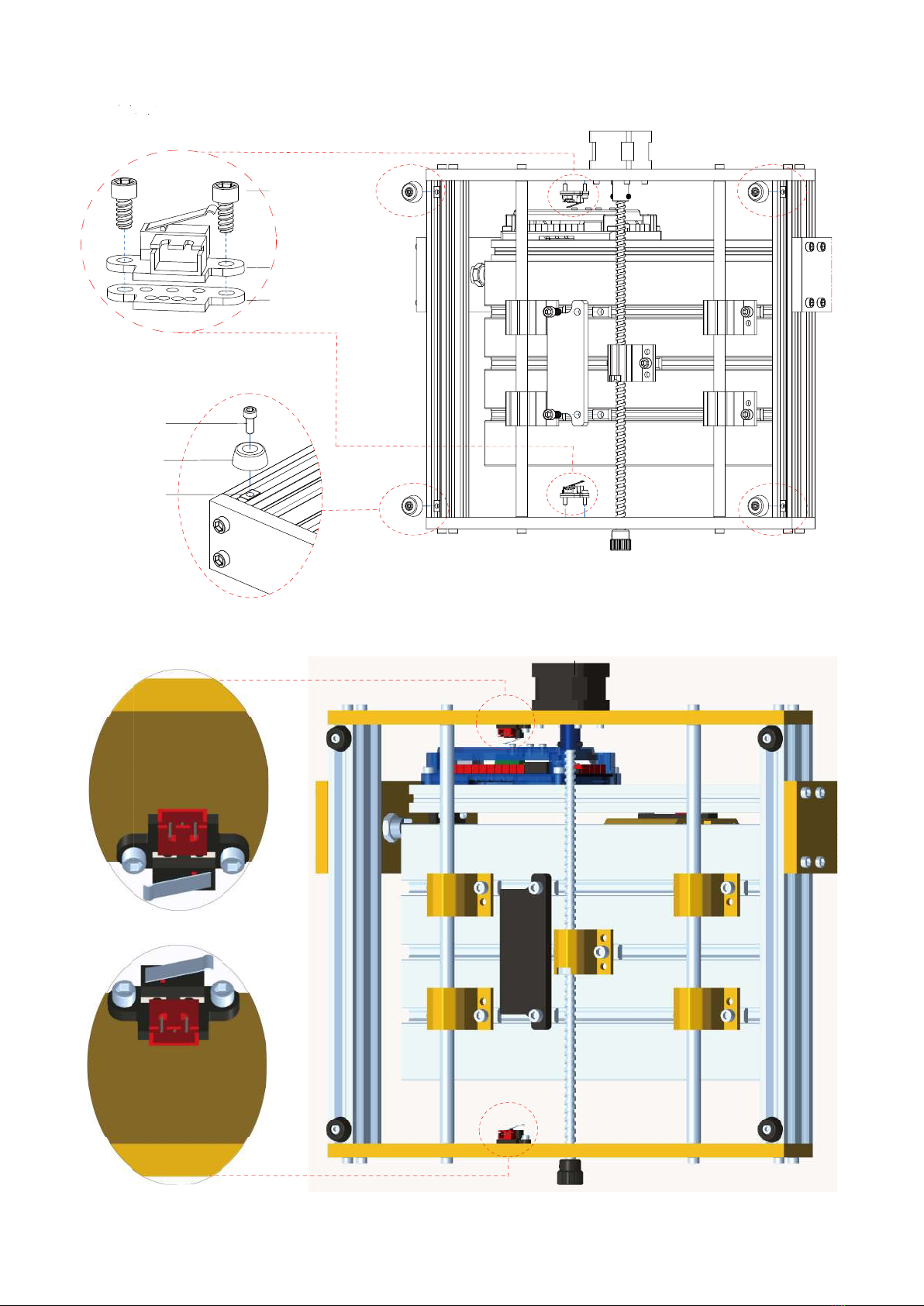

1 Component for X-axis —— 1Set

3018 Prover Parts List Optional package

Laser Guard plate Emergency stop and limit switch Offline controller

Guard plate package

2 Component for Y-axis —— 1Set

Emergency stop and limit switch package

9Fixture ——4Set

Emergency stop

switch —— 1Set

Fixture(9) assembly

G1

1.8 inches with SD card 1SetC9 Offline controller

and data cable

Control board package

VIGOTECControl board

Offline controller

C1 1Set

9-3

9-4 9-2

9-1

9-5