8| BL530 PH/RX DOSAGE SYSTEM

Injection Line (also see drawing on the previous page)

1. Unscrew the fixing nut of the connector located on the bottom right side of

the pump head and marked in the figure with an outgoing arrow.

2. Cut the white, semi-rigid polyethylene tube to the correct length.

3. Insert the fixing nut and the tube-wrench on the tube.

4. Mount the tube on the conic tube-holder of the suction connector,

pushing it firmly until it reaches the stop collar.

5. Fix the tube by screwing the fixing nut onto the head connector of the pump head.

6. Place the injection tube avoiding as much as possible the curves and ensuring

that the pulses do not make the tube rub against rigid bodies.

7. At the injection point on the pipeline, mount a ½” GAS

connection, internally threaded (not supplied).

8. Wrap Teflon tape to the thread and tighten the injection valve to the fitting.

9. Unscrew the pipe-wrench nut of the injection valve fitting.

10. Cut the white, semi-rigid, PE tube to the correct length.

11. Insert the pipe-wrench on the PE tube.

12. Mount the tube on the conic hose of the injection valve,

pushing it until it reaches the stop collar.

13. Screw the pipe-wrench nu tonto the valve fitting.

Note: The injection valve also works as non-return valve: do not dismantle.

ELECTRICAL CONNECTIONS

The BL530 unit is supplied already wired internally and complete with

power cable (without plug). This is the only electrical connection to be

performed by the customer. Standard power supply: 230 V, 50 Hz.

Carefully follow all the rules of electrical safety. Before starting the unit, check

that all electrical and plumbing connections have been properly executed.

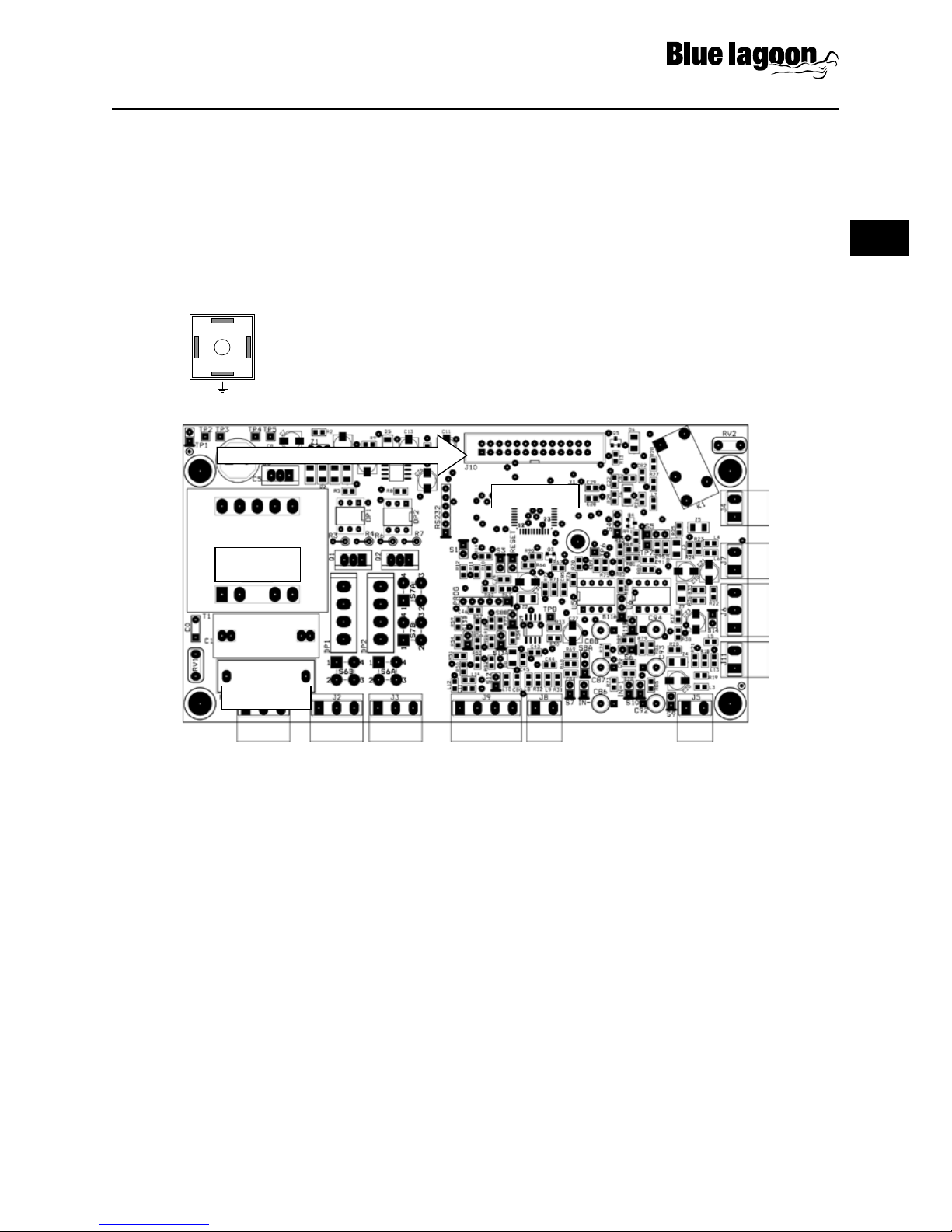

The measure inputs from pH and redox electrodes are available on BNC connectors.

Note: the pH and redox inputs should never be left open; if an

input is not used, you need to short- circuit it.

Level Control

The system is supplied already configured for disabling the dosage in case of low level in the tank.

The level control is made through a specific float sensor (optional, see “Accessories and spare

parts”), to be connected to pins 3 and 4 of the LEV connector (see Figure) When

the product level in the tank falls below the level sensor, the unit stops dosing

and the fault is shown on the display. The alarm condition is generated with a

delay of a few seconds compared to the detection of low level, to avoid errors

due to extreme situation (such as fluctuations in water). Two inputs for level

sensor are available, one for each pump / tank.

BL530 PH/RX DOSAGE SYSTEM

3