2

GENERAL NOTES AND WARNINGS ABOUT ASSEMBLY

Due to the high degree of complexity of the Venge ViAS, proper assembly requires a high degree

of mechanical expertise, skill, training and specialty tools. Therefore, it is essential that the

assembly, maintenance and troubleshooting be performed by an Authorized Specialized Retailer.

In order to successfully build the Venge ViAS bicycle, it is very important to

follow the order of operations as outlined in this guide. Modifying the order of

assembly will result in a much longer and more frustrating build process, with

less than optimal results.

WARNING! Many components on the Venge ViAS, including, but not limited to,

the handlebars, the stem, and the brakes, are proprietary to the Venge ViAS.

Only use originally supplied components and hardware at all times. Use of

other components or hardware will compromise the integrity and strength of

the assembly. Venge ViAS specific components should only be used on the

Venge ViAS and should not be used on bicycles other than the Venge ViAS.

Failure to follow this warning could result in serious injury or death.

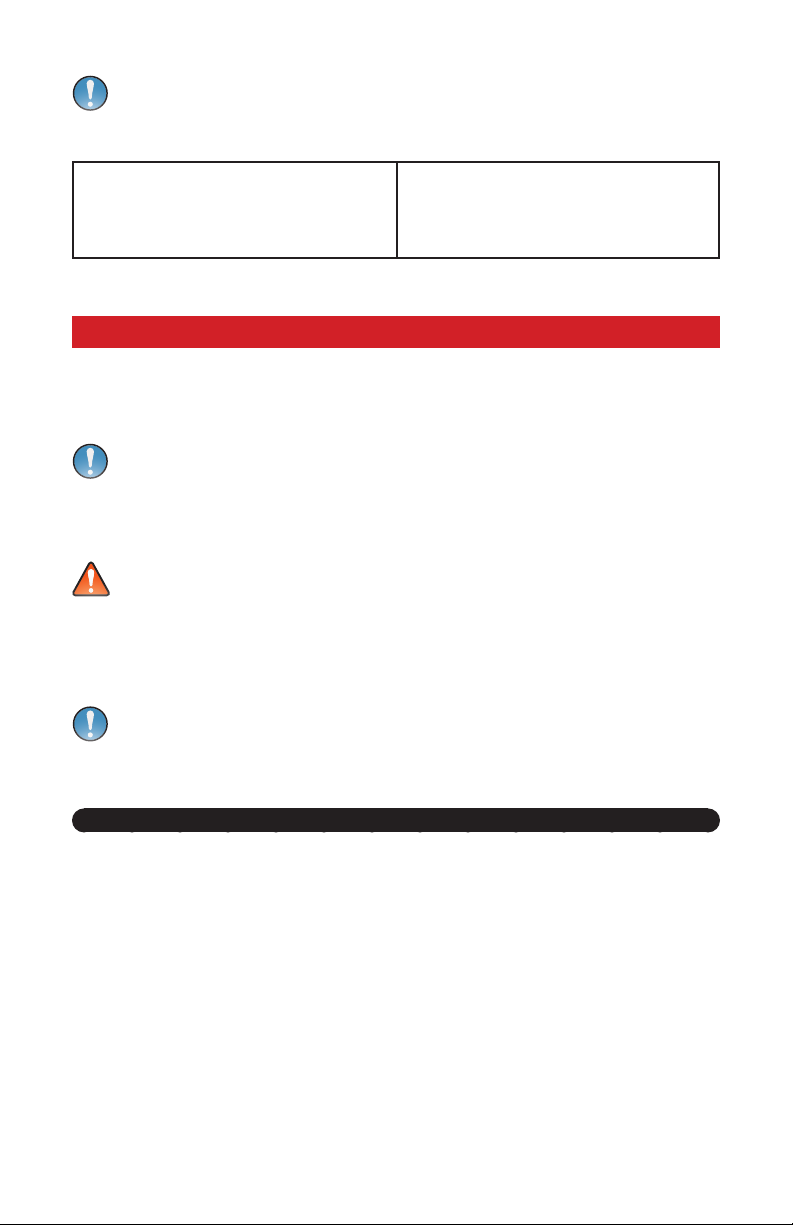

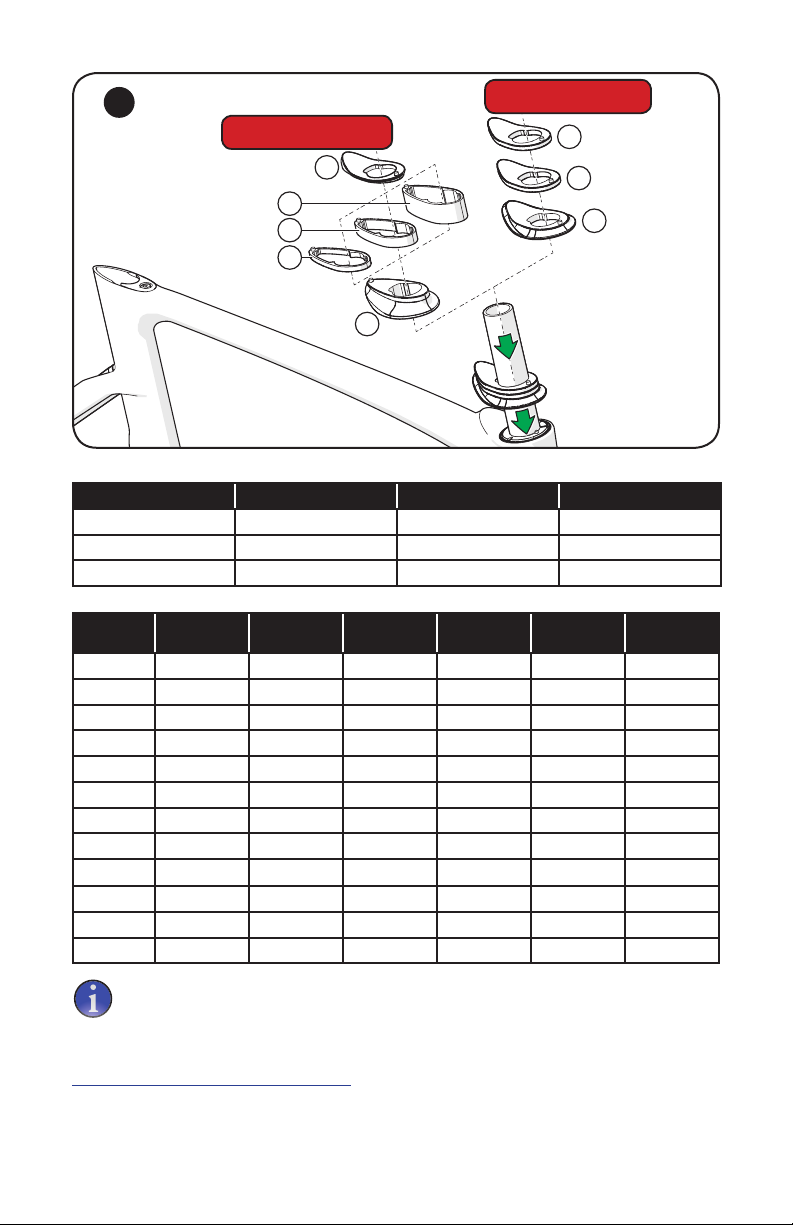

BOLT SIZE / TOOLS / TORQUE SPECS

WARNING! Correct tightening force on fasteners (nuts, bolts, screws) on your

bicycle is important. If too little force is applied, the fastener may not hold

securely. If too much force is applied, the fastener can strip threads, stretch,

deform or break. Either way, incorrect tightening force can result in component

failure, which can cause you to lose control and fall.

Where indicated, ensure that each bolt is torqued to specification. After your

first ride, and consistently thereafter, recheck the tightness of each bolt to

ensure secure attachment of the components. The following is a summary of

torque specifications in this guide:

LOCATION Bolt Spec Torque (in-lbf) Torque (Nm)

Stem @ Steerer Tube 4mm 45 5.1

Stem @ Handlebar 5mm 100 11.3

Stem cable guides (bolted to each other) 2mm

Stem cable guides (bolted to stem) 3mm 45 5.1

Garmin mount bracket @ stem 2.5mm 25 2.8

Garmin mount @ bracket 2.5mm 25 2.8

Front brake mounting bolts 4mm 55 6.2

Front brake cable pinch bolt T10 Torx

Rear brake mounting bolts 5mm 70 7.9

Rear brake cable pinch bolt 4mm 45 5.1

Brake pads 5mm 55 6.2

Fork expander plug 4mm 45 5.1

Bottom bracket door (Di2 only) 2.5mm 10 1.1

Bottom bracket door (Carbon - mechanical or electronic) 2.5mm 15 1.7

Saddle rail clamp bolt 5mm 120 13.5

Seat collar bolt 5mm 55 6.2

Derailleur hanger 3mm 20 2.3

Brake pad / spring tension adjusters 2mm

Front brake cable release lever 2.5mm

Stem top cap 3mm