WARNING: Failure to read and follow these installation instructions and safety precautions could result in personal injury, equipment damage,

shortened service life or unsatisfactory equipment performance. All information in this document is vital to the proper installation and operation

of the equipment. It is important that all personnel who will be coming in contact with this product thoroughly read and understand this manual.

INSTRUCTION

MANUAL

©2020 VIBCO, Inc. IM_H_B-H_05020

B&H SERIES

HYDRAULIC

5VIBRATOR PLACEMENT 6MOUNTING HARDWARE

7STITCH WELD MOUNTING

1START 2MOUNTING CHECKLIST

qDetermine vibrator placement on equipment (box 5).

qDetermine length of channel iron and style of mounting plate (box 4).

qSTITCH weld mounting plate to channel iron (box 7).

qSTITCH weld channel iron & mounting plate combo to bin (box 7).

qAttach vibrator to mounting plate. Check mounting plate for warping

and shim if necessary. DO NOT OVER TIGHTEN THE BOLTS (box 8).

qInstall safety chain or cable (box 9).

qConnect Hydraulics for vibrator using the ASME and

SAE Standards (box 10).

qFILL OUT WARRANTY CARD & MAIL TO VIBCO!!!!

ADDITIONAL DETAILS AVAILABLE ONLINE AT www.vibco.com

3TECHNICAL DATA

DO NOT

EXCEED

MAXIMUM

FLOW

RATE

FOR ANY

MODEL

4PLATE & CHANNEL SELECTION

Bin Wall

Thickness

Factor

B

1/8"

(10 ga.)

or less

6

1/8" - 1/4" 5

1/4" - 3/8" 4

3/8" - 1/2" 3

1/2" & up 2

Factor

A + B

Use

Channel Iron

Length

11 N/A

10 6 - 8 FT.

(80 - 90%)

95 - 7 FT.

(70 -80%)

84 - 6 FT.

(60 - 70%)

73 - 5 FT.

(50 - 60%)

62 - 4 FT.

(50 - 60%)

51 - 2 FT.

(50 - 60%)

4 N/A

NOTE:

1. Longer channel iron will not affect vibrator performance, but

total channel length should not exceed length of bin wall.

2. Percentages shown indicate % of bin wall height your channel iron

should be for shorter bins.

3. To match your vibrator on chart above, model number sufxes

generally correspond to pounds of force generated. See chart (box 3).

MOUNTING PLATES, CHANNEL IRON & ACCESSORIES AVAILABLE FROM VIBCO OR LOCAL DEALER

For coarse materials: mount

vibrator 1/3 of the distance

from the discharge opening to

the top of the sloped portion of

the bin.

For ne materials: mount

vibrator 1/4 of the distance

from the discharge to the top of

the sloped portion of the bin.

FOR ALTERNATE MOUNTS: refer to full detail instruction manual online

at www.vibco.com or call 800-633-0032

A MOUNTING PLATE MUST BE USED

to ensure proper stability for the vibrator.

Always start & stop welds 1 in. from ends to

prevent heat

concentration.

Then weld 2 to

3 inches, skip

1 to 2 inches

and repeat

until the plate

is securely

mounted.

NO! YES!

MOUNTING PLATE MUST BE MOUNTED

PARALLEL TO CHANNEL IRON, NOT

PERPENDICULAR. OTHERWISE, IT WILL CAUSE

FLEXING & DAMAGE THE UNIT OR EQUIPMENT

IT IS MOUNTED TO.

STITCH

WELDS

SHOULD

BE 3” - 6”

LONG

LEAVING

3” (7.5cm)

BETWEEN

EACH

WELD

STITCH WELDS SHOULD

START & STOP 1” (2.5cm)

FROM BOTH ENDS OF

CHANNEL TO PREVENT

CRACKING

DO NOT MOUNT

VIBRATOR DIRECTLY TO

SURFACE OF THE BIN !!!

Always use mounting plate &

channel iron

Be sure you have selected the

proper length of channel using the

tables above (SECTION 4).

Improper mounting can

result in failure of

unit or damage

to equipment.

8BOLTING PROCEDURE

Angle Iron Channel Iron

DAMAGE TO THE BIN OR THE

VIBRATOR WILL OCCUR IF NOT

MOUNTED SECURELY!

For other bolt grades,

please consult VIBCO.

GRADE 5

BOLT SIZE

MAX

TORQUE

ft-lbs

1/4" 9

5/16" 18

3/8" 32

1/2" 78

5/8" 160

3/4" 260

1" 580

1-1/4" 1105

Check mounting bolts every 200 hours.

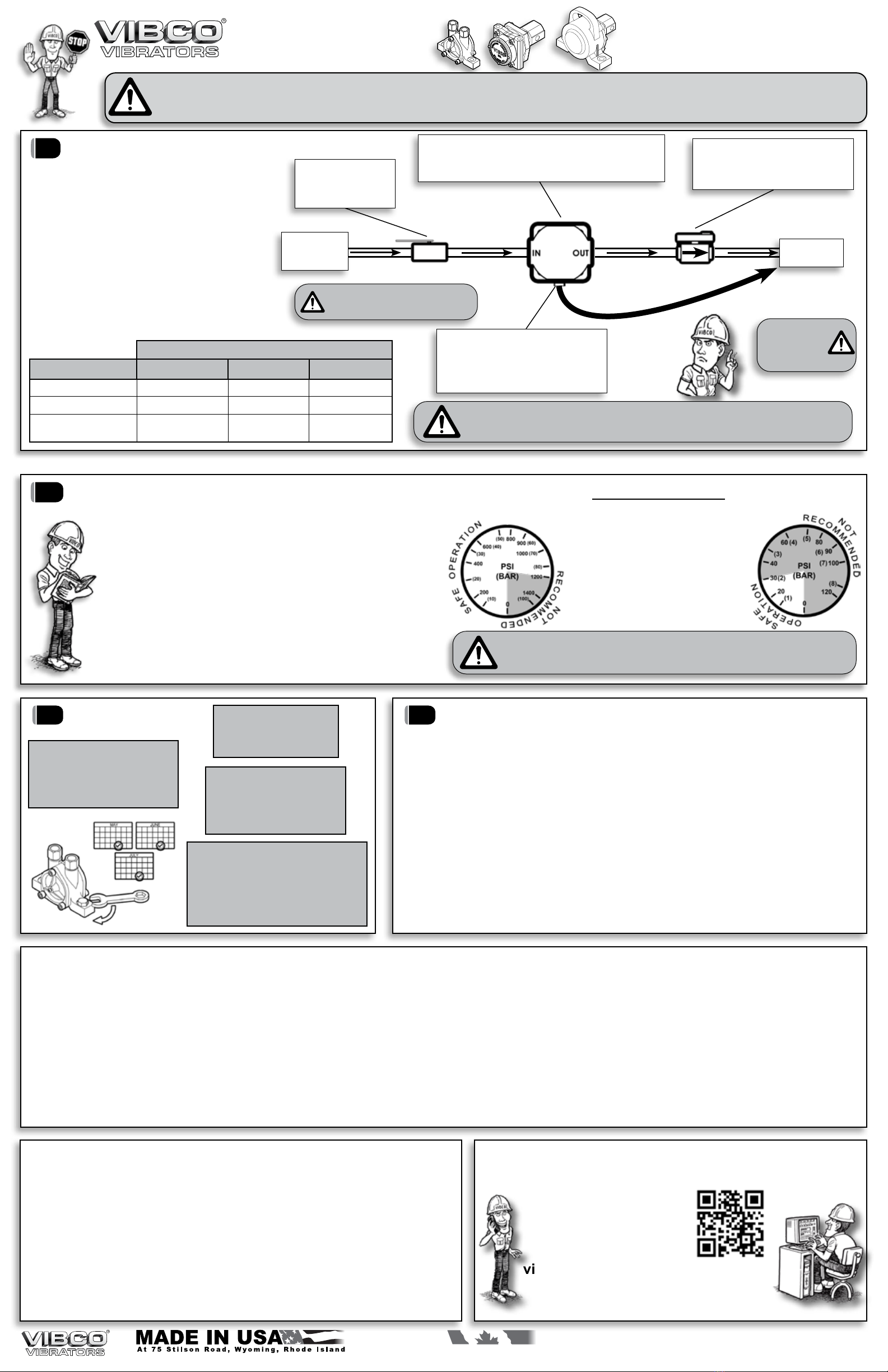

10 HYDRAULIC CONNECTION B-SERIES

1. Coat all ttings with sealing compound

and secure hydraulic hoses to inlet

& outlet sides of motor as marked by

directional arrows.

2. Hook up ball valve on inlet side and

check valve on outlet side to reservoir.

3. Check & tighten all ttings &

connections before test running

vibrator.

4. Hydraulic system MUST have a

ltration system & oil is industrial

petroleum-based oil, SAE 10 to 30,

with wear oxidation and foaming

inhibitors, and a viscosity of 200 SSU.

DO NOT OVER

TIGHTEN

HYDRAULIC

HOSE FITTINGS

MAXIMUM

OIL TEMP.

150°F (65°C)

THREAD SIZE

MODEL

NUMBER INLET OUTLET

B-190 3/8” - NPT 3/8” - NPT

B-250 1/2” - NPT 1/2” - NPT

B-320 1/2” - NPT 1/2” - NPT

FROM

HYDRAULIC

PUMP

FLOW

CONTROL VALVE

MUST be located on

inlet side of motor

TO

RESERVOIR

ATTENTION: WHEN HOOKING UP MULTIPLE UNITS YOU MUST

SUPPLY INDEPENDENT HYDRAULIC LINES. UNITS WILL NOT RUN TO

FULL SPECIFICATIONS & MAY FAIL WHEN INSTALLED IN SEQUENCE.

CHECK VALVE

MUST be located 16” - 24” (400mm-600mm)

away from motor on outlet line side

RETURN LINE

Return line must be connected back to the oil

reservoir and NOT to any line under pressure

STANDARD STUDDED

2 BOLT

4 BOLT

THANK YOU FOR CHOOSING

A VIBCO VIBRATOR!

DON’T FORGET

TO MAIL IN YOUR

WARRANTY CARD!

Hydraulic

Models

Weight

600 PSI (41.4 Bar) 800 PSI (55.2 Bar) 1000 PSI (69 Bar)

Vibration

/min.

Gallon

/min.

Centrifugal

Force

Vibration

/min.

Gallon

/min.

Centrifugal

Force

Vibration

/min.

Gallon

/min.

Centrifugal

Force

lbs. kg. VPM GPM lbs. Newtons

VPM GPM

lbs. Newtons

VPM GPM

lbs. Newtons

B-190

1.0 0.45 4,600 4.5 190 890 6,100 4.8 330 80 7,400 6.5 286 1,272

B-250

2.0 0.91 4,200 4.5 280 1,245 5,000 4.5 400 1,765 5,800 6.5 535 2,375

B-320

3.5 1.60 3,700 5.0 300 1,340 4,500 6.0 445 1,980 5,300 7.0 615 2,745

Hyd.Models Weight Avg. Vibration/min. Gallon/min. Centrifugal Force Sound*

lbs. kg. PSI

VPM GPM

lbs. Newtons

dB

HF-800

37 17.0 600 5,000 3.2 1,300 5,785 72

HF-1200

38 17.4 800 4,500 2.9 1,900 8,450 74

HF-1500

39 17.7 900 4,000 2.6 2,000 8,900 76

HF-HC-3500

51 23.0 1,200 3,500 2.4 3,500 15,570 80

HL-3000

39 17.7 1,000 5,000 3.2 3,400 15,125 76

HLF-700

14 6.5 900 9,000 2.8 700 3,115 72

HLF-1300

20 9.0 1,000 9,000 2.8 1,300 5,785 72

HLF-1750

30 14.0 1,000 5,000 2.6 2,300 10,230 72

HLF-3500

35 16.0 1,200 4,000 2.5 3,500 15,570 72

HLF-5000

41 18.6 1,500 4,000 2.5 4,500 20,020 72

* Decibel from A-scale at 1 meter & avg. PSI (or max. listed value)

Dataobtainedonlaboratorytestblock•Datasubjecttodesignchanges

Frequency&forcewilldecreaseonlessrigidmount•Maxpressure3,000PSI

Vibrator

Force

in lbs

Mounting

Plate

Thickness

Channel Iron Size Factor

A

101 - 500 1/4" - 3/8" 3" x 4.1 lbs.

3" x 5 lbs. 2

501- 1200 1/2" 4" x 5.4 lbs.

4" x 7.5 lbs. 3

1201-3000 5/8" 6" x 8.2 lbs. / 6" x 10.5 lbs. 4

3001-5000 3/4" - 1" 6" x 8.2 lbs. / 6" x 10.5 lbs.

8" x 8.5 lbs. / 8" x 11.5 lbs. 5

9R

ESTRAINT

ALWAYS

INSTALL

SAFETY

CABLE or

CHAIN

Mount one end to the

vibrator and the other to

the hopper or bin

above the vibrator

NEVER ATTACH TO

THE MOUNTING

PLATE!