Inhaltsverzeichnis

3

Inha ltsverzeichnis

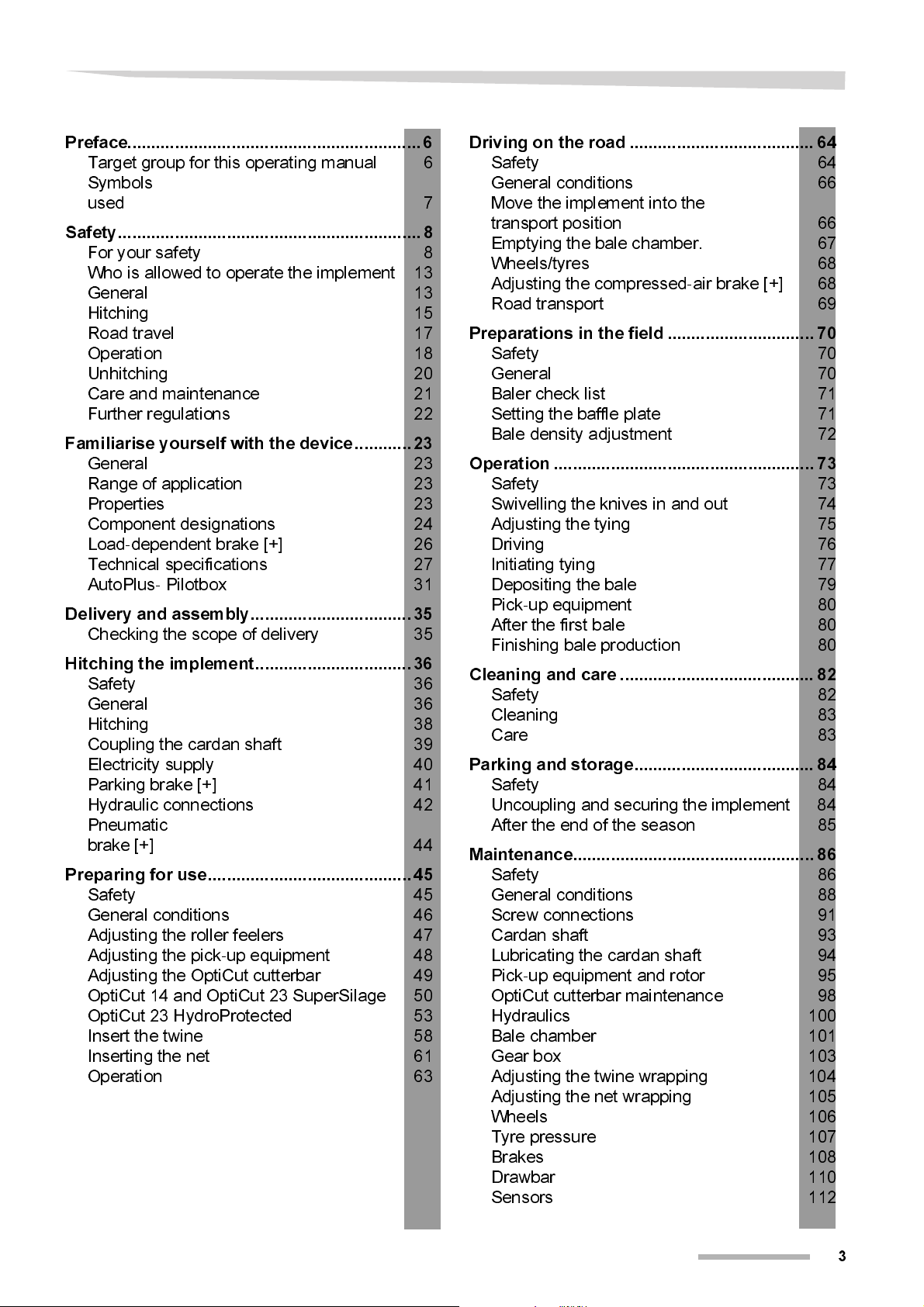

Preface..............................................................6

Target group for this operating manual 6

Symbols

used 7

Safety................................................................8

For your safety 8

Who is allowed to operate the implement 13

General 13

Hitching 15

Road travel 17

Operation 18

Unhitching 20

Care and maintenance 21

Further regulations 22

Familiarise yourself with the device............23

General 23

Range of application 23

Properties 23

Component designations 24

Load-dependent brake [+] 26

Technical specifications 27

AutoPlus- Pilotbox 31

Delivery and assembly..................................35

Checking the scope of delivery 35

Hitching the implement.................................36

Safety 36

General 36

Hitching 38

Coupling the cardan shaft 39

Electricity supply 40

Parking brake [+] 41

Hydraulic connections 42

Pneumatic

brake [+] 44

Preparing for use...........................................45

Safety 45

General conditions 46

Adjusting the roller feelers 47

Adjusting the pick-up equipment 48

Adjusting the OptiCut cutterbar 49

OptiCut 14 and OptiCut 23 SuperSilage 50

OptiCut 23 HydroProtected 53

Insert the twine 58

Inserting the net 61

Operation 63

Driving on the road ....................................... 64

Safety 64

General conditions 66

Move the implement into the

transport position 66

Emptying the bale chamber. 67

Wheels/tyres 68

Adjusting the compressed-air brake [+] 68

Road transport 69

Preparations in the field ...............................70

Safety 70

General 70

Baler check list 71

Setting the baffle plate 71

Bale density adjustment 72

Operation ....................................................... 73

Safety 73

Swivelling the knives in and out 74

Adjusting the tying 75

Driving 76

Initiating tying 77

Depositing the bale 79

Pick-up equipment 80

After the first bale 80

Finishing bale production 80

Cleaning and care ......................................... 82

Safety 82

Cleaning 83

Care 83

Parking and storage...................................... 84

Safety 84

Uncoupling and securing the implement 84

After the end of the season 85

Maintenance................................................... 86

Safety 86

General conditions 88

Screw connections 91

Cardan shaft 93

Lubricating the cardan shaft 94

Pick-up equipment and rotor 95

OptiCut cutterbar maintenance 98

Hydraulics 100

Bale chamber 101

Gear box 103

Adjusting the twine wrapping 104

Adjusting the net wrapping 105

Wheels 106

Tyre pressure 107

Brakes 108

Drawbar 110

Sensors 112