INDEX

Hazard Identification . . . . . . . . . . . . . . . . . . . . 4

Operator Safety Instructions. . . . . . . . . . . . . . . 4

Introduction...........................6

Receiving the Tool......................6

VE460 Large Container Contents . . . . . . . . . 6

VE460 Small Container Contents . . . . . . . . .6

Tool Nomenclature......................7

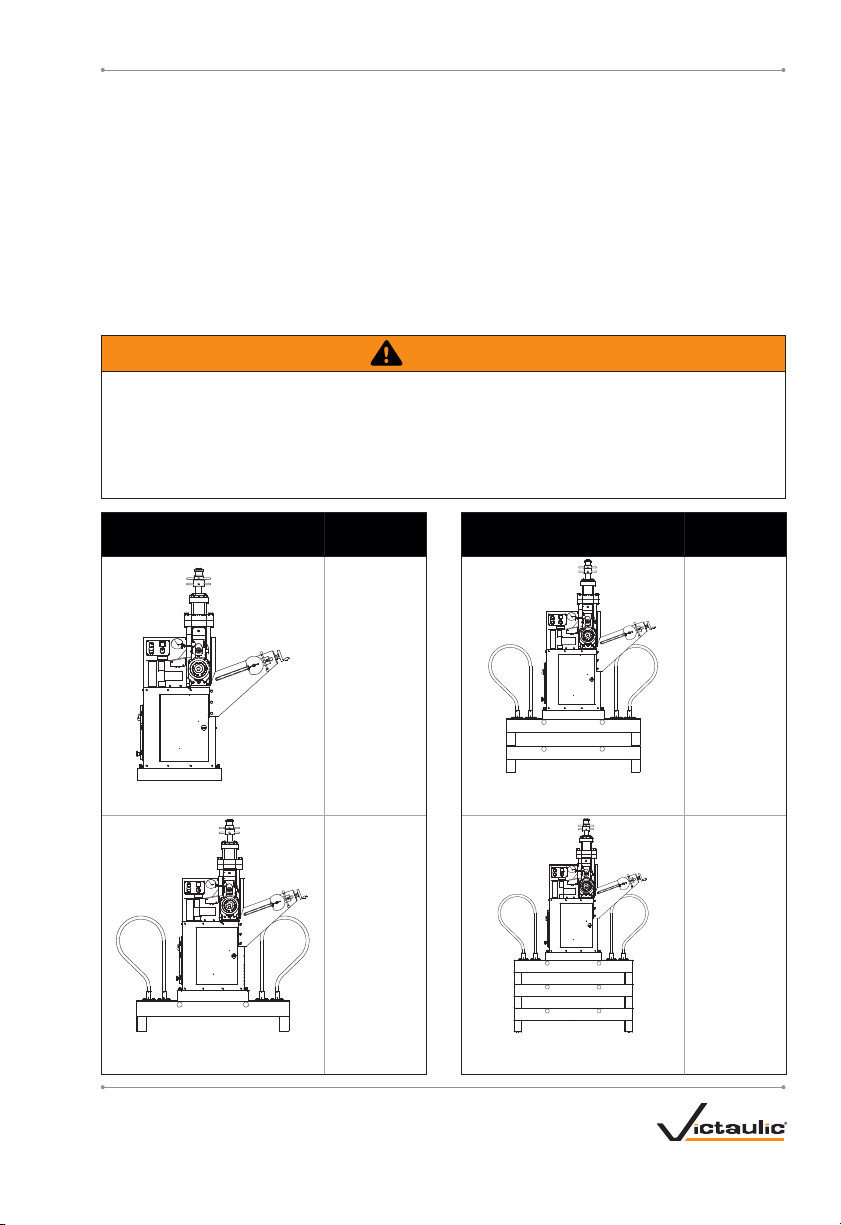

Tool Setup for Grooving 24-inch/610.0-mm

and Smaller Pipe Sizes . . . . . . . . . . . . . . . . 8

Important Information for Tool Setup . . . . . . . 10

Tool Setup for Grooving 26-inch/660.0-mm

and Larger Pipe Sizes . . . . . . . . . . . . . . . . 11

Power Requirements . . . . . . . . . . . . . . . . . . . 17

Power Hookup and Verification of Pipe

Rotation Direction . . . . . . . . . . . . . . . . . . . 17

Preparing Pipe for Grooving . . . . . . . . . . . . . .20

Pipe Length Requirements. . . . . . . . . . . . . . . 21

Checking and Adjusting the Tool Prior to

Grooving ..........................23

Grooving Rolls ......................23

Adjusting the Roll Guards. . . . . . . . . . . . . . 23

Pipe Stabilizer Adjustment . . . . . . . . . . . . . 26

Ram Speed Adjustment . . . . . . . . . . . . . . .28

Dwell Control Adjustment. . . . . . . . . . . . . . 29

Time Range Adjustment. . . . . . . . . . . . . . .29

Pipe Size Adjustment. . . . . . . . . . . . . . . . . 30

Groove Diameter Stop Adjustments . . . . . . 30

Grooving Short Pipe Lengths . . . . . . . . . . . . .33

Grooving Long Pipe Lengths . . . . . . . . . . . . .35

Roll Changing ........................39

Lower Roll Removal . . . . . . . . . . . . . . . . . . 41

Upper Roll Removal. . . . . . . . . . . . . . . . . . 41

Upper Roll Installation . . . . . . . . . . . . . . . . 42

Lower Roll Installation . . . . . . . . . . . . . . . .43

Maintenance .........................46

Lubrication ........................46

Checking and Filling Gear Reducer Oil. . . . 47

Checking and Filling Hydraulic Oil . . . . . . . 47

Replacing Hydraulic Oil and Filter . . . . . . .48

Air Bleeding........................51

Recommended Lubricants. . . . . . . . . . . . . . . 53

Bearing and Slide Grease. . . . . . . . . . . . . .53

Gear Oil...........................53

Hydraulic Oil .......................53

Parts Ordering Information. . . . . . . . . . . . . . . 53

Troubleshooting.......................54

Tool Rating and Roll Selection . . . . . . . . . . . .56

Original Groove System and “ES” Rolls for

Steel and Schedule 40 Stainless Steel Pipe -

Color Coded Black. . . . . . . . . . . . . . . . . . . 56

Original Groove System Rolls for Aluminum

and PVC Plastic Pipe - Color Coded Yellow

Zinc..............................58

Original Groove System Rolls for Schedule 5S

and 10S Stainless Steel Pipe - Color Coded

Silver.............................59

RW Rolls for Grooving Standard-Weight Steel

Pipe to AGS Specifications - Color Coded

Black with Yellow Band . . . . . . . . . . . . . . . 60

RWX Rolls for Grooving Schedule 5S and 10S

Stainless Steel Pipe to AGS Specifications -

Color Coded Silver with Black Band. . . . . .60

Explanation of Critical Roll Groove

Dimensions ........................62

Roll Groove Specifications -

Original Groove System for Steel and

Stainless Steel Pipe . . . . . . . . . . . . . . . . . .63

Roll Groove Specifications -

Original Groove System for Steel Pipe and

All Materials Grooved with “ES” Rolls. . . . .65

Roll Groove Specifications - Advanced Groove

System (AGS) Roll Groove . . . . . . . . . . . . . 66

Advanced Groove System (AGS) Roll Grooving

Specifications for Carbon Steel Pipe . . . . .67

Advanced Groove System (AGS) Roll Grooving

Specifications for Stainless Steel Pipe . . . . 69

TM-VE460_3

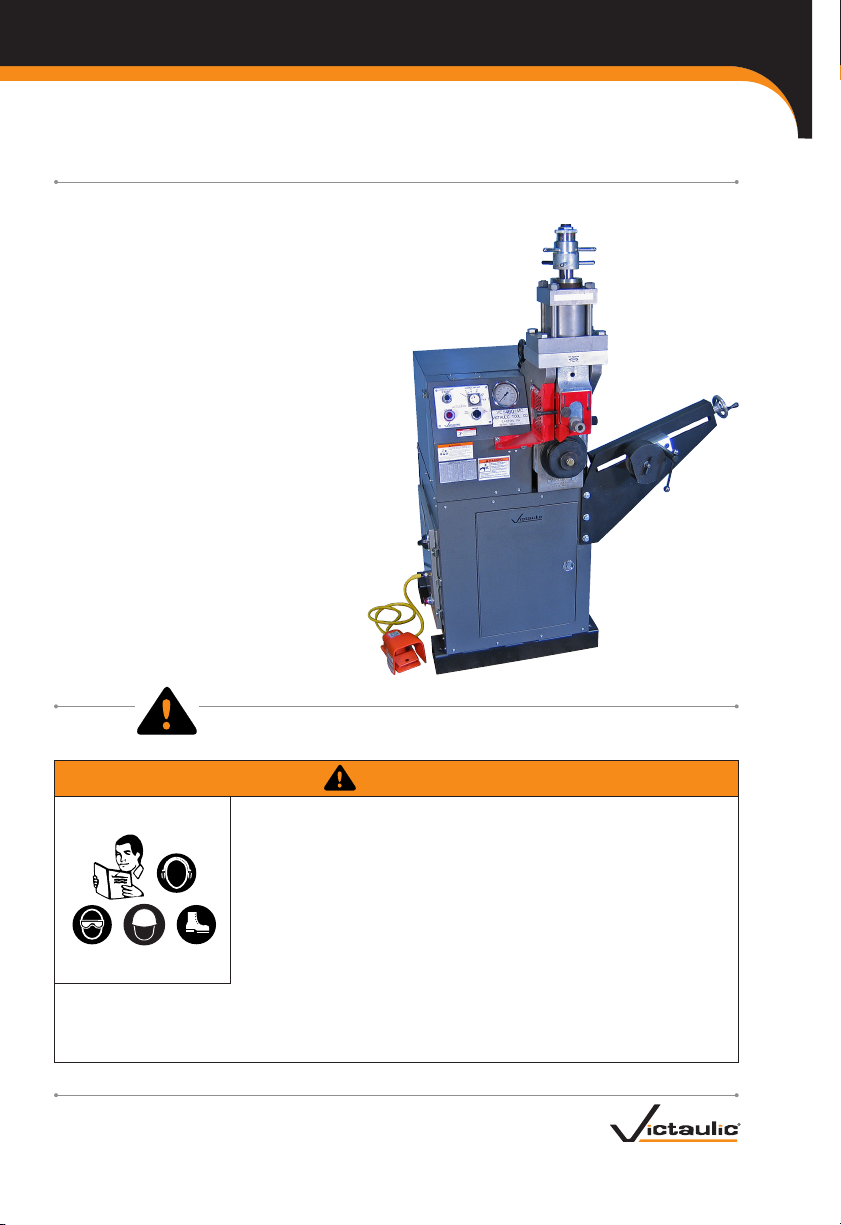

TM-VE460OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY.

REV_A