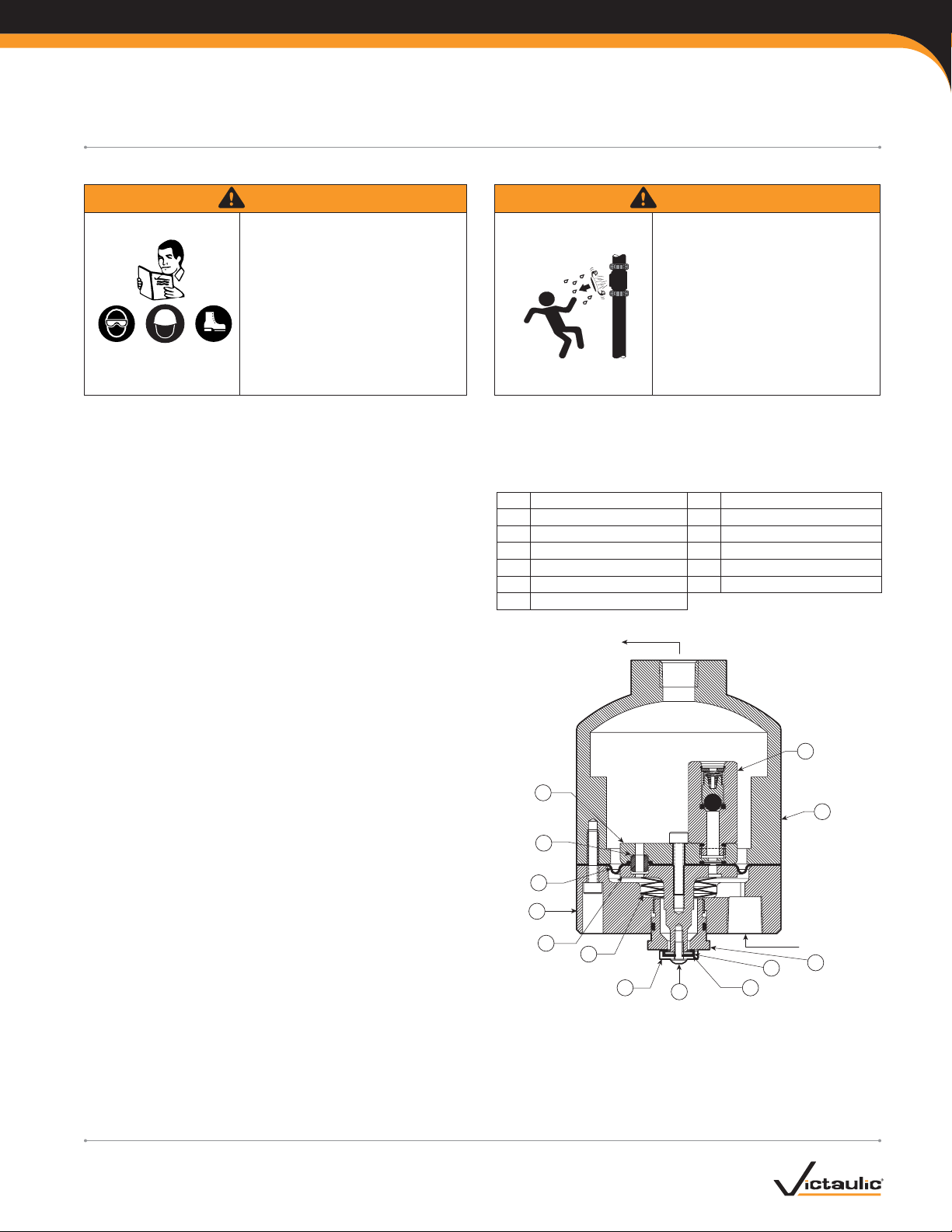

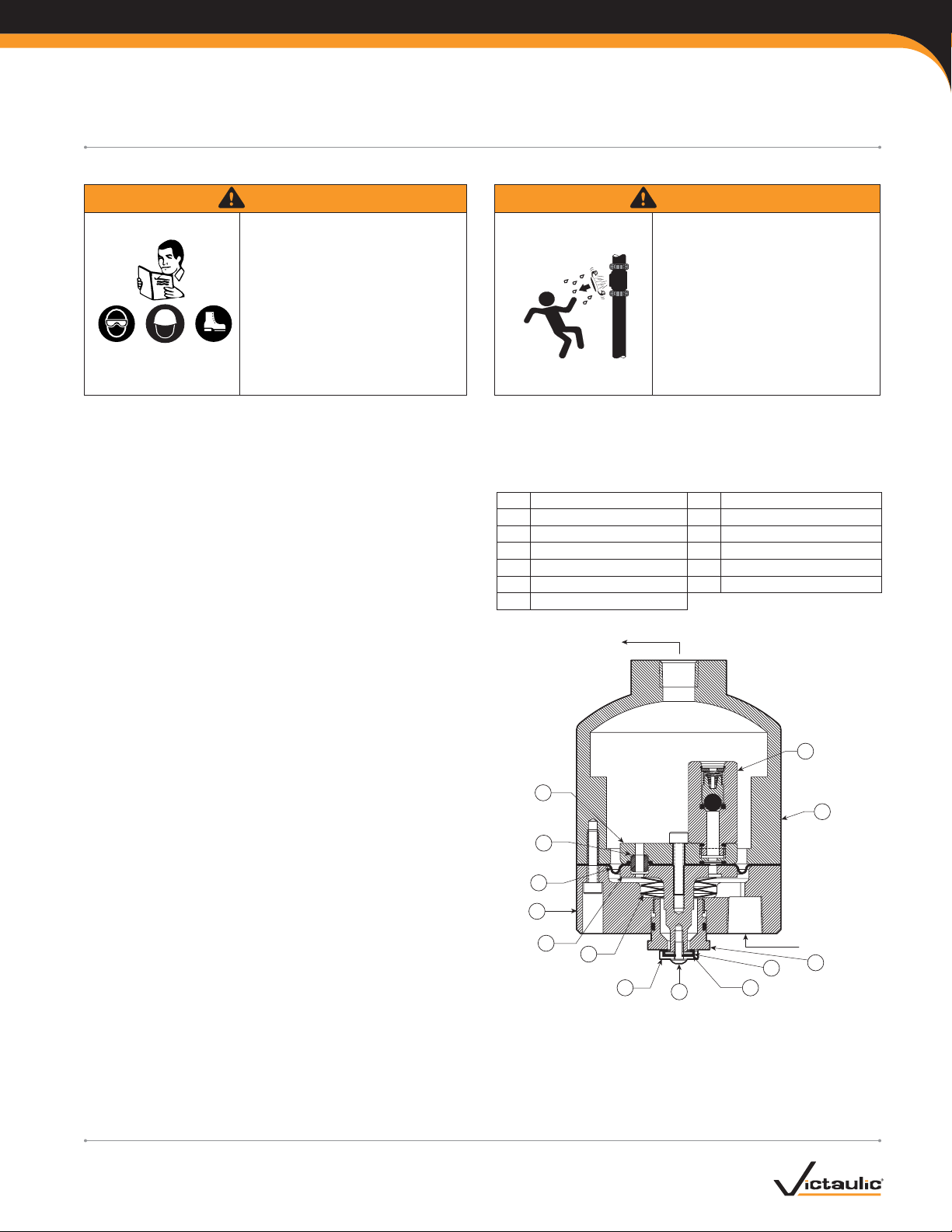

SECTION VIEW DRAWING AND DESCRIPTION –

SERIES 746-LPA DRY ACCELERATOR

The Series 746-LPA Dry Accelerator is a quick-opening device, which

exhausts air from Series 767/776/798 Actuators to speed valve

operation.

A diaphragm separates the Series 746-LPA Dry Accelerator into two

chambers. The closing chamber contains a compression spring, which

maintains the chamber in the closed position. The closed position is

maintained as long as the pressure differential between the opening and

closing chambers is less than 3 psi/21kPa.

When the system introduces air pressure into the dry accelerator, air

enters the closing chamber and passes through a check valve to the

opening chamber. The check valve, which allows flow into the open-

ing chamber, prevents pressure from escaping the opening chamber.

Therefore, air can escape only through the restrictor.

When a rapid loss of system air pressure occurs, such as an open

sprinkler, air escapes from the closing chamber faster than it escapes

from the opening chamber. As the sprinkler system’s pressure continues

to decay, a differential pressure develops across the diaphragm. When

this differential pressure reaches 3 – 5 psi/21 – 34 kPa, the opening

chamber’s pressure overcomes the compression spring’s closing force,

causing the closing chamber to open to the atmosphere. The closing

chamber opens immediately and releases pressure from the actuator,

resulting in valve operation.

BILL OF MATERIALS

1 Opening/Air Chamber 8 Seal Support

2 Piston 9 Button-Head Cap Screw

3Restrictor 10ClosingChamberSeal

4Diaphragm 11Washer

5 Closing Chamber 12 Adjustable Seat

6 Actuator Shaft 13 Check Valve

7 Compression Spring

To Pressure

Gauge

Air Inlet

13

1

12

11

10

9

7

6

5

8

3

2

4

CROSS SECTION WITH UPPER CHAMBER ROTATED

45° AND BOLT REMOVED FOR CLARITY

Exaggerated for clarity

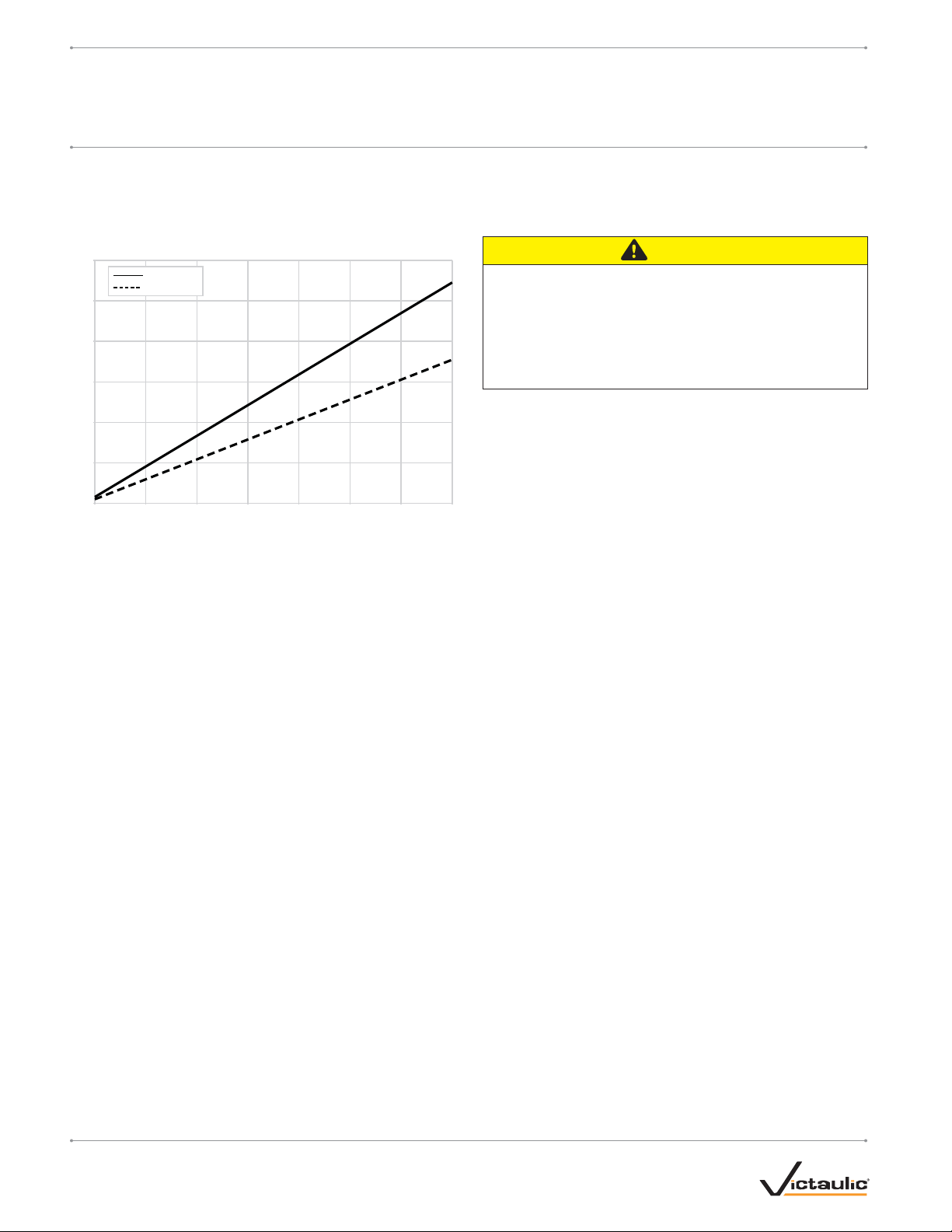

IMPORTANT INFORMATION

WARNING WARNING

Read and understand all instruc-

tions before attempting to perform

maintenance on any Victaulic

piping products.

Wear safety glasses, hardhat, and

foot protection.

Failure to follow these instructions

could result in serious personal

injury, property damage, and/or

product failure.

•

•

Depressurize and drain the piping

system before attempting to

remove, adjust, or perform main-

tenance on any Victaulic piping

products.

Failure to follow this instruction

could result in serious personal injury

and/or property damage.

•

The following information is a guide for proper installation of Victaulic Series 746-LPA Dry Accelerators. Always refer to the installation,

maintenance, and testing manual for the applicable valve for detailed system setup, operation, and maintenance instructions.

I-746.LPA_1

Series 746-LPA

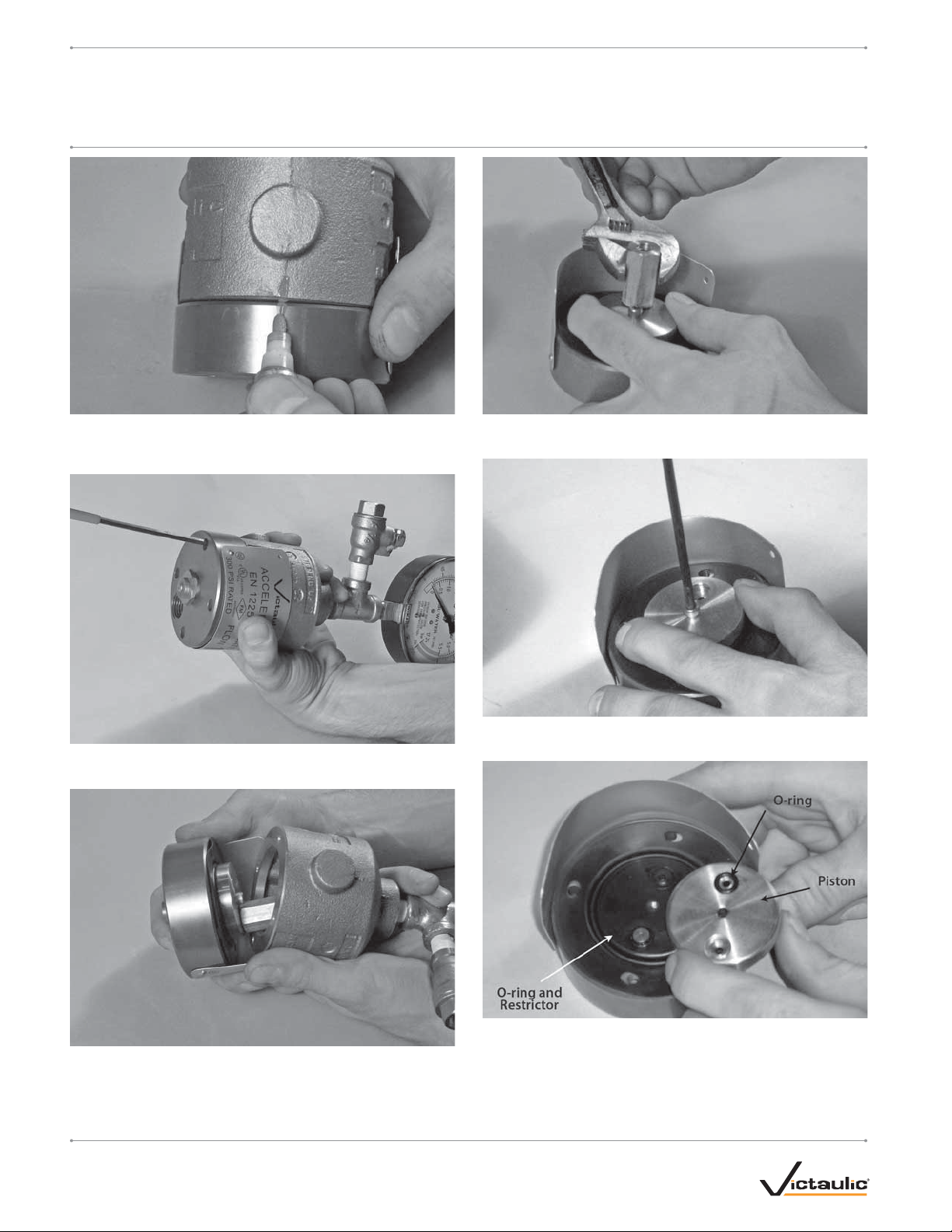

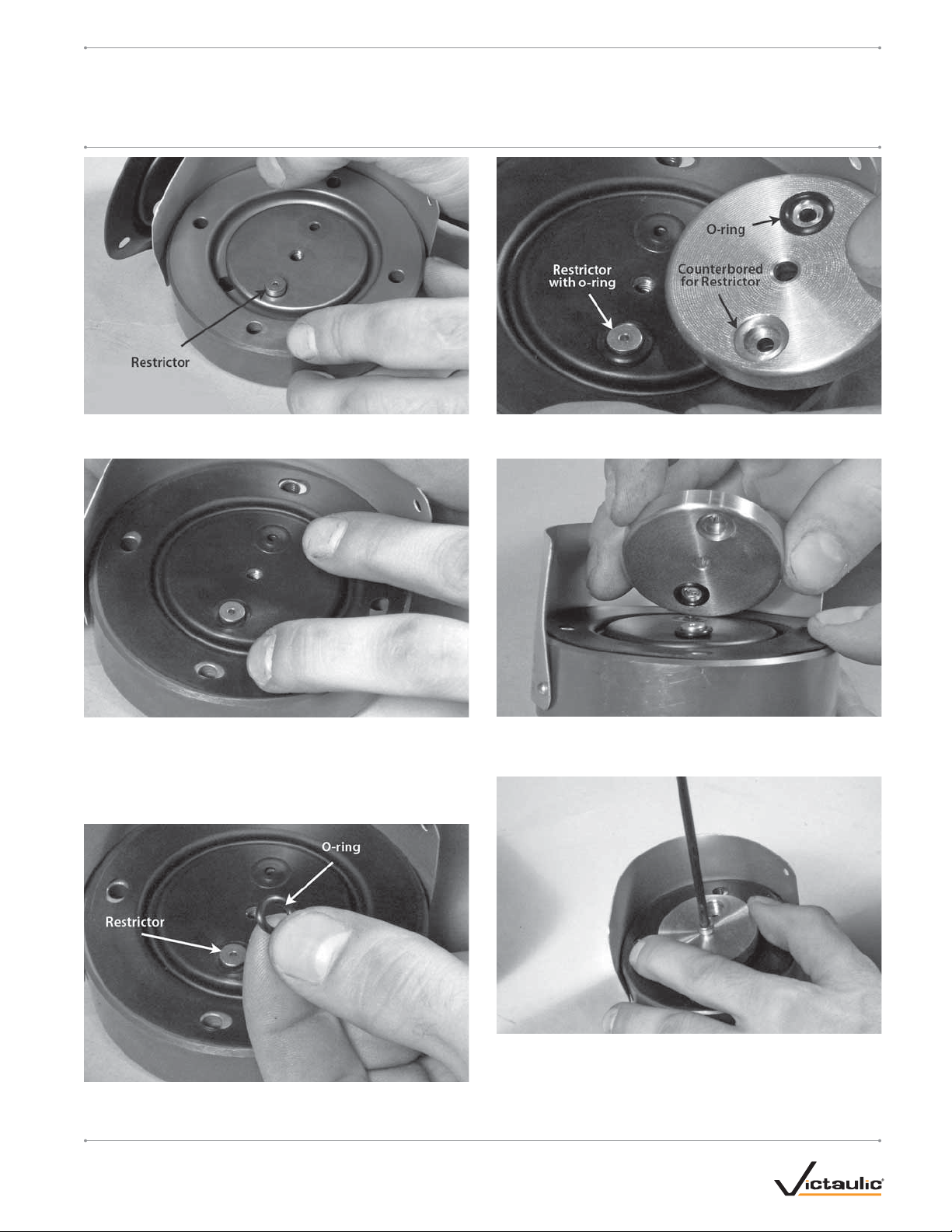

INSTRUCTIONS FOR INSTALLING AND REPAIRING SERIES 746-LPA DRY ACCELERATORS

I-746.LPAINSTALLATION AND REPAIR KIT INSTRUCTIONS

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2006 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_A