Single Wide Modular Proofer

Construction:

The cabinet interior and exterior are

constructed of heavy gauge polished

stainless steel to maintain an attractive

appearance for years of heavy use. The 2”

thick polyurethane panels throughout

ensure the ultimate in energy efficiency.

The cam-lock modular panel construction

adapts to different rack configurations and

makes assembly easy.

Controls:

The digital control panel is conveniently

mounted at eye level. The heat and relative

humidity levels can be adjusted independently,

and offers a six-program time set countdown

function.

Doors:

The self-closing door is securely mounted on

3 rugged cam-lift hinges, which have a

lifetime guarantee. The door has a self-

adjusting magnetic gasket to prevent the

humidity from escaping. An interior vapor-

proof incandescent light fixture is provided.

Capacity:

The door opening will accommodate a 75”

high rack for 18” x 26” or 20” x 30”pans.

Humidification System:

Internally mounted, energy efficient heat

and humidity system is virtually maintenance

free. Fine nozzle air-wash system controls

humidity, no flush cleaning required.

Cabinets are provided with both front and

rear drain capabilities.

Standard Features (all models)

• Stainless Steel Doors

• Stainless Steel Interior and Exterior

Construction

• Eye-Level Digital Control Conveniently

Located on Door Corner Post

-- Independently Controls Heat and Relative

Humidity Levels

-- Six-Program Time Set Countdown Function

• Internally Mounted Energy Efficient Fine

Nozzle Air-Wash System to Control Heat and

Humidity

-- No Flush Cleaning Required

• Cam-lock Modular Panel Construction

• Stainless Steel Rack Guides

• Accommodates 75” High End-Load, Side

Load, and Double Racks

• Insulation - 2” Thick Polyurethane Panels

• The Door has 3 Heavy-Duty Hinges

• Self-Closing Camlift Hinges with Stay-Open

Feature

• Independent Door Closer

• Standard Exterior Depth Ranges from 34” to

123”

• Temperature Range of 70° - 120°F (21° -

49°C)

• Humidity Range from Room Ambient to 95%

RH

• All Models Include an Interior Vapor-Proof

Incandescent Light Fixture

Optional Features and Accessories

• Side and Rear Trim Panels

• Roll-Thru Models Available

• Correctional Package

• Door Vision Panel

• Heavy-Duty Stainless Steel Floor

• One-Door Unit can be Shipped Assembled,

(028/038/048) Consult Factory for Details

VP-1W-028 VP-1W-058

VP-1W-038 VP-1W-068

VP-1W-048 VP-1W-078

VP-1W-118

VP-1W MODELS —

Stainless Steel

Exterior and Interior.

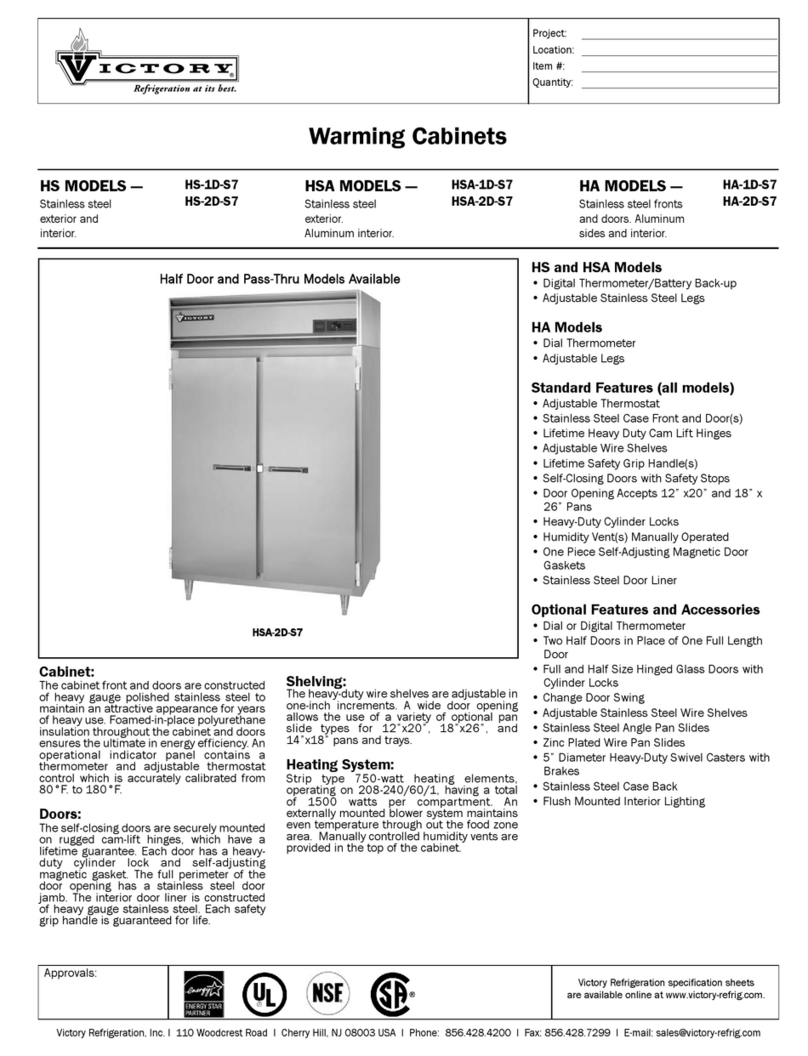

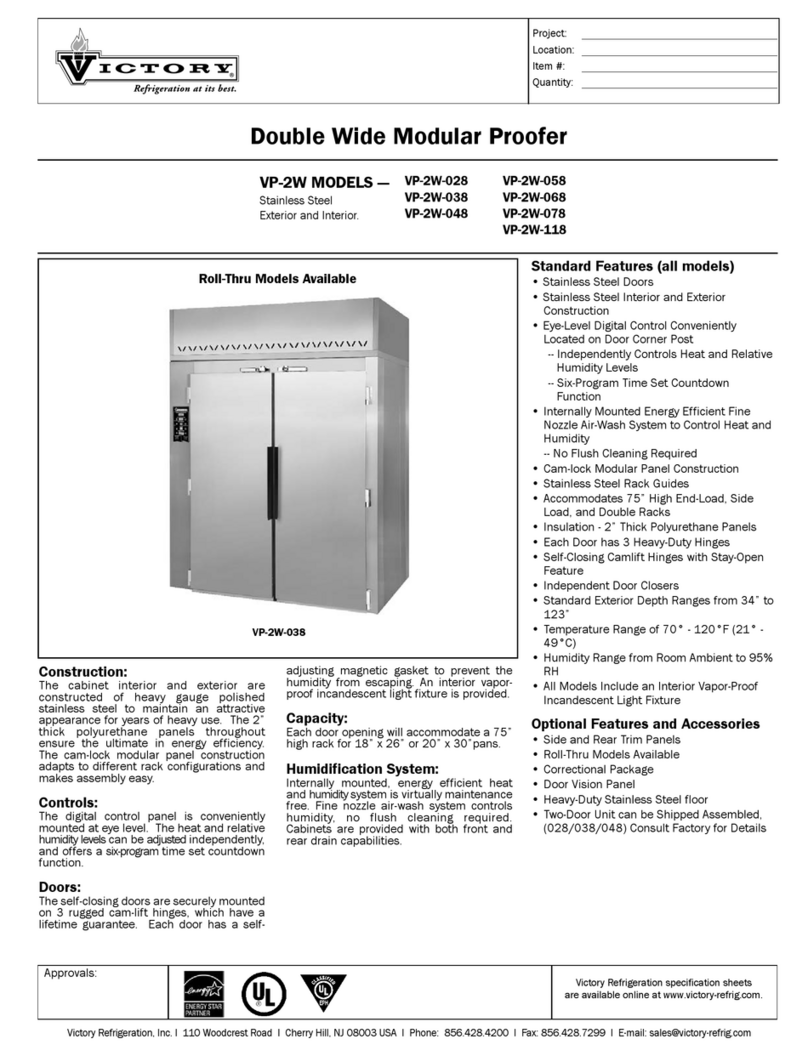

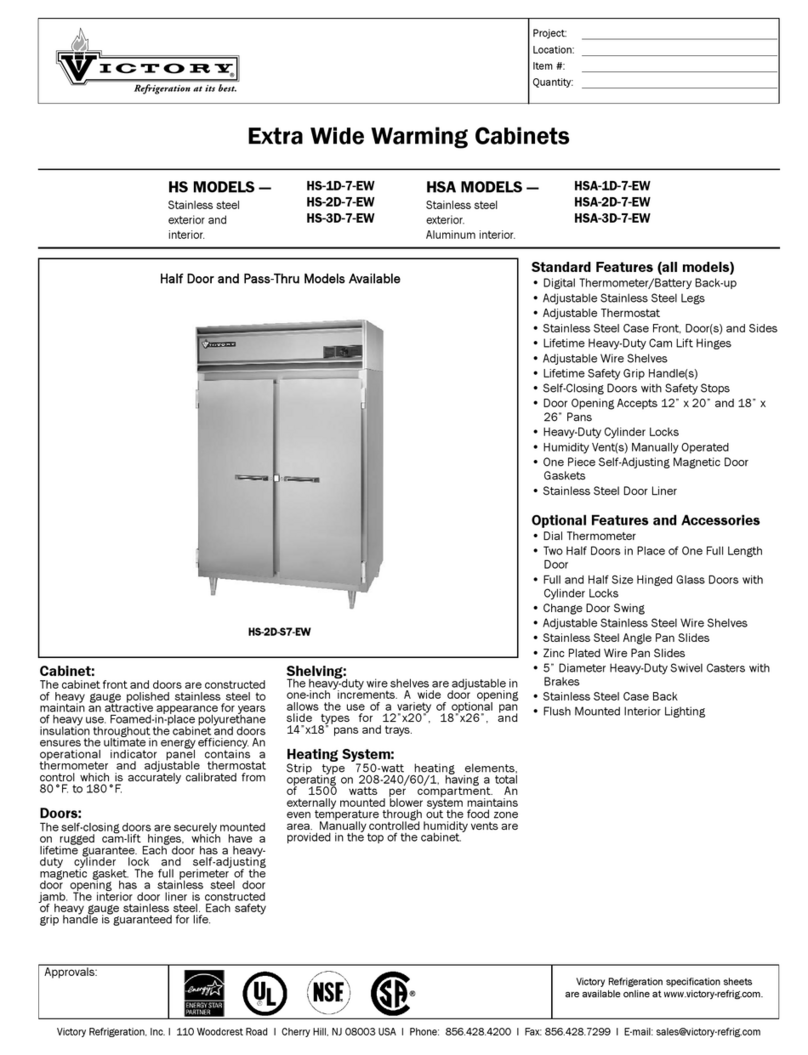

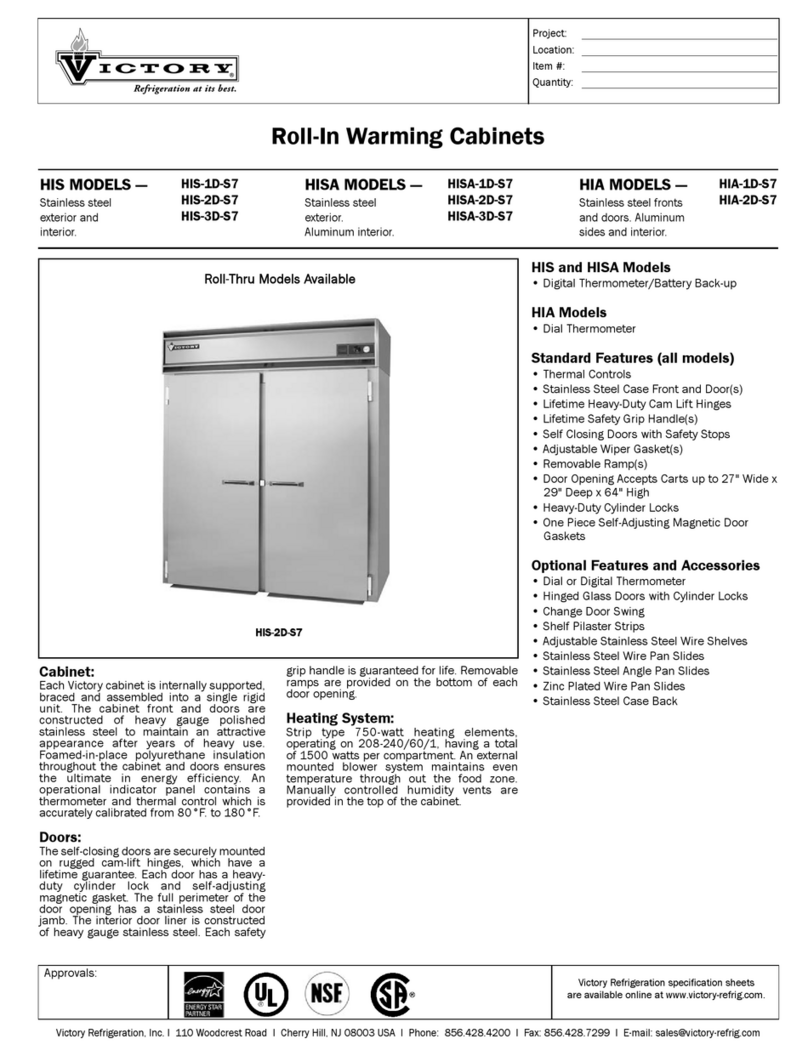

VP-1W-038

Roll-Thru Models Available

Victory Refrigeration, Inc. I 110 Woodcrest Road I Cherry Hill, NJ 08003 USA I Phone: 856.428.4200 I Fax: 856.428.7299 I E-mail: sales@victory-refrig.com

Victory Refrigeration specification sheets

are available online at www.victory-refrig.com.

Approvals:

Project:

Location:

Item #:

Quantity: