A01.01886-8 REV: 001 VALIDITY: 28.11.22

SECTION 1: INTRODUCTIONSECTION 1: INTRODUCTION

Using the wrong tire pressures has a signicant

negative impact on a vehicle's operational ability,

from increased tire wear and fuel consumption

to soil compaction and increased driver fatigue.

Driving with the proper tire pressures for load,

speed and road conditions, maximizes vehicle

mobility and performance in demanding terrain

and conditions, reduces overall operating costs,

improves fuel consumption, increases traction

and safety.

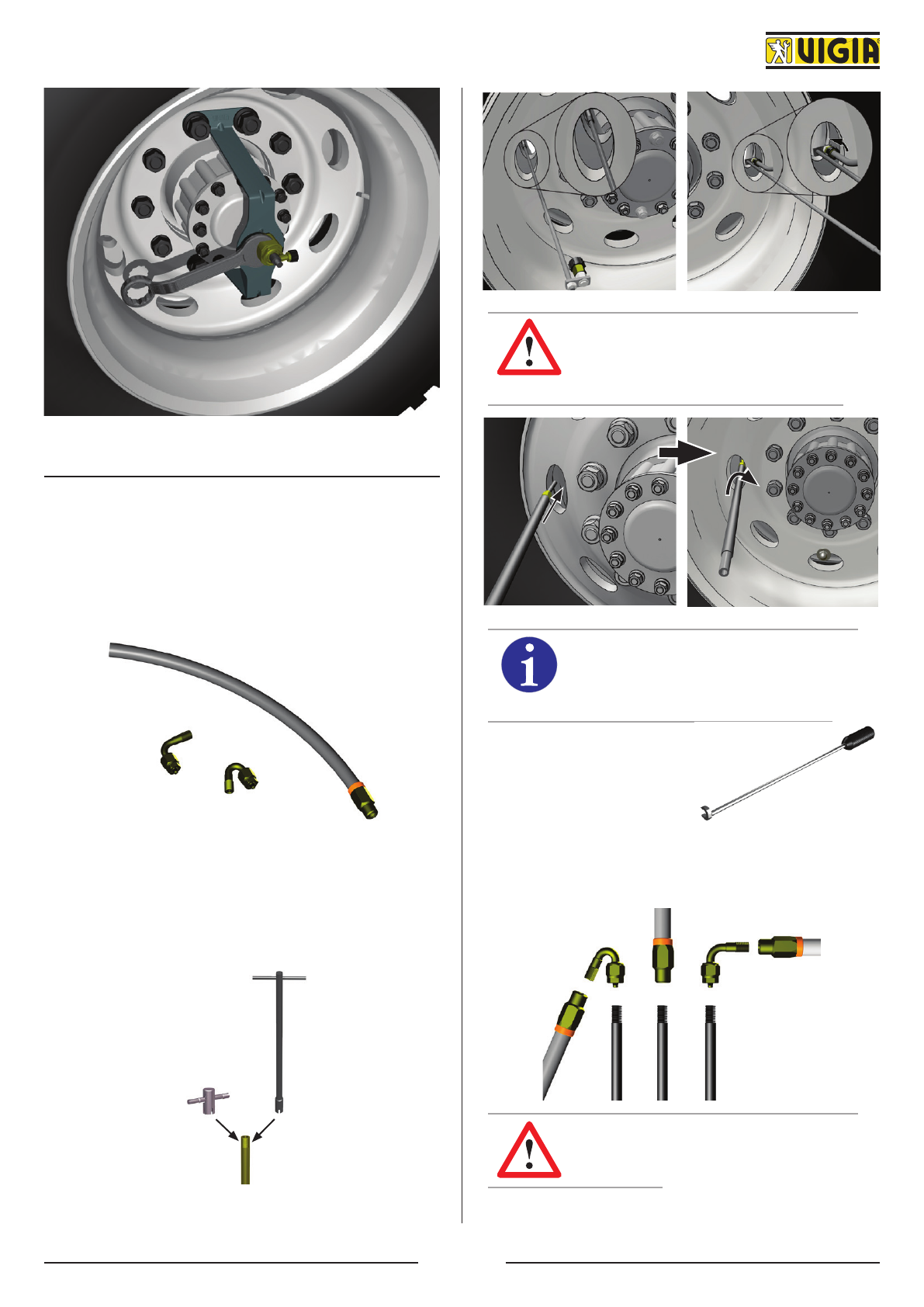

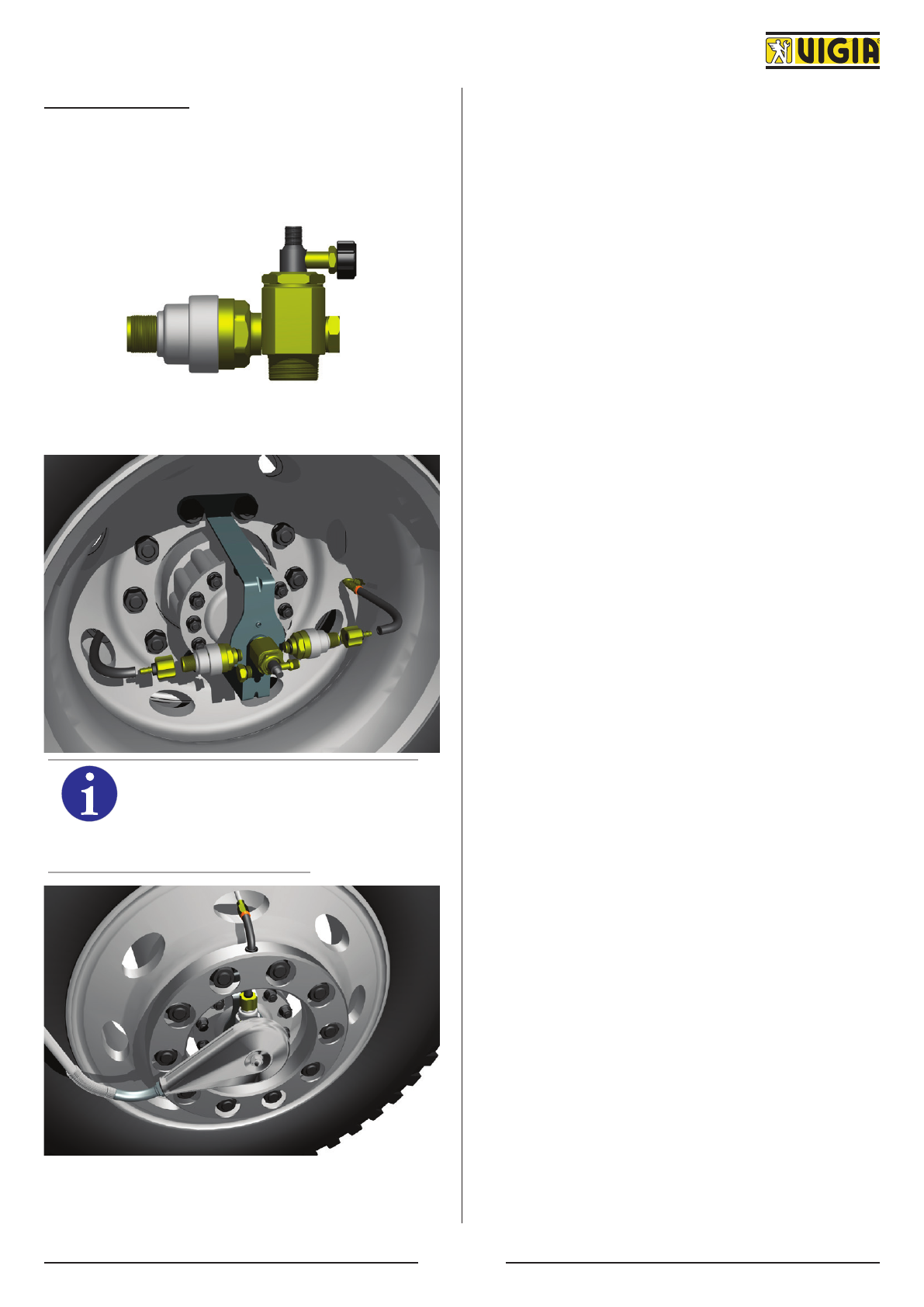

1.1: PURPOSE AND SCOPE OF THE

MANUAL

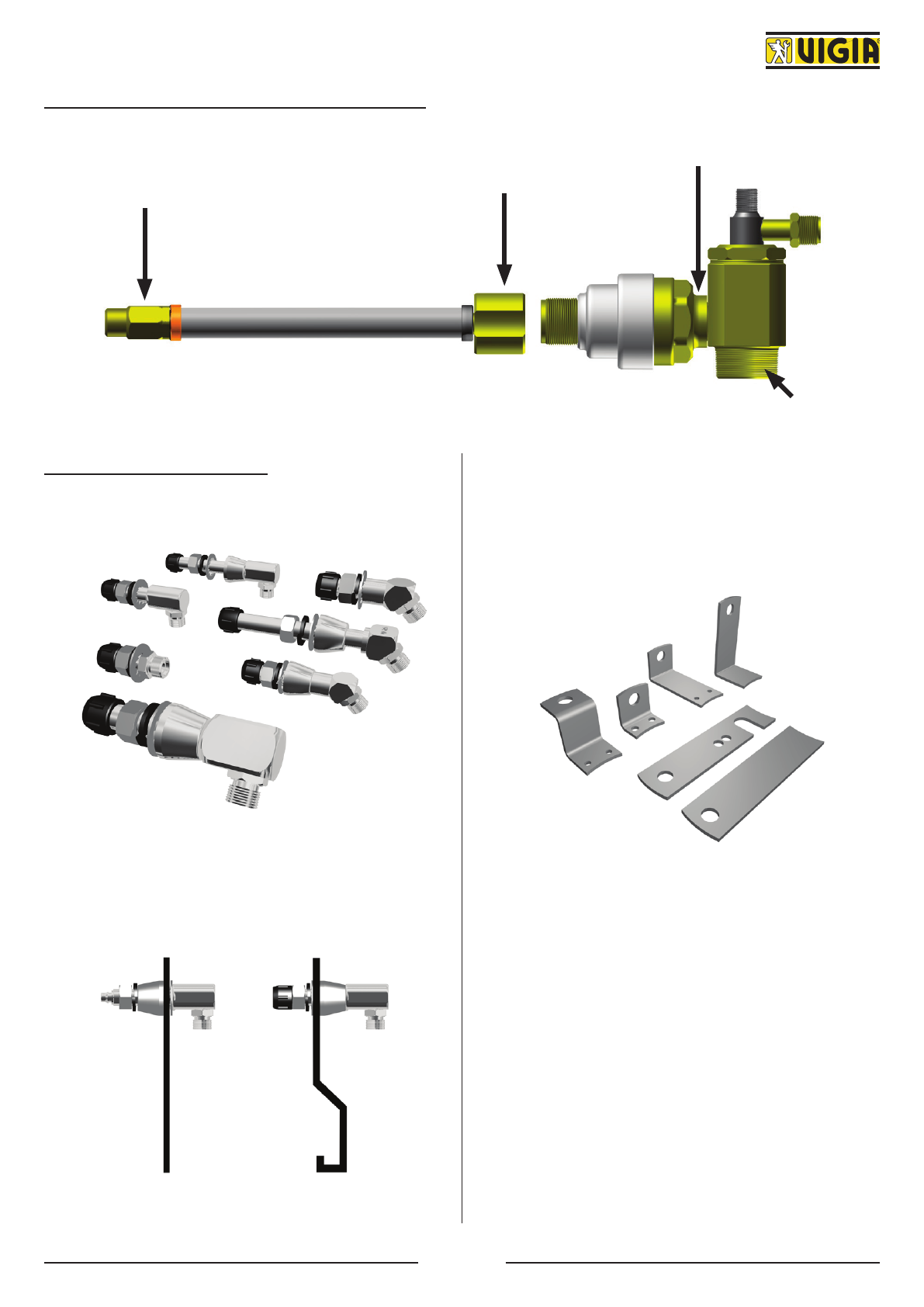

This manual explains how to install and repair

the VIGIA NM 444 ELECTRONIC TIRE

CALIBRATOR, but also includes a basic overview

of system components and operation. It also

provides the necessary information on installation,

full system operation, and troubleshooting.

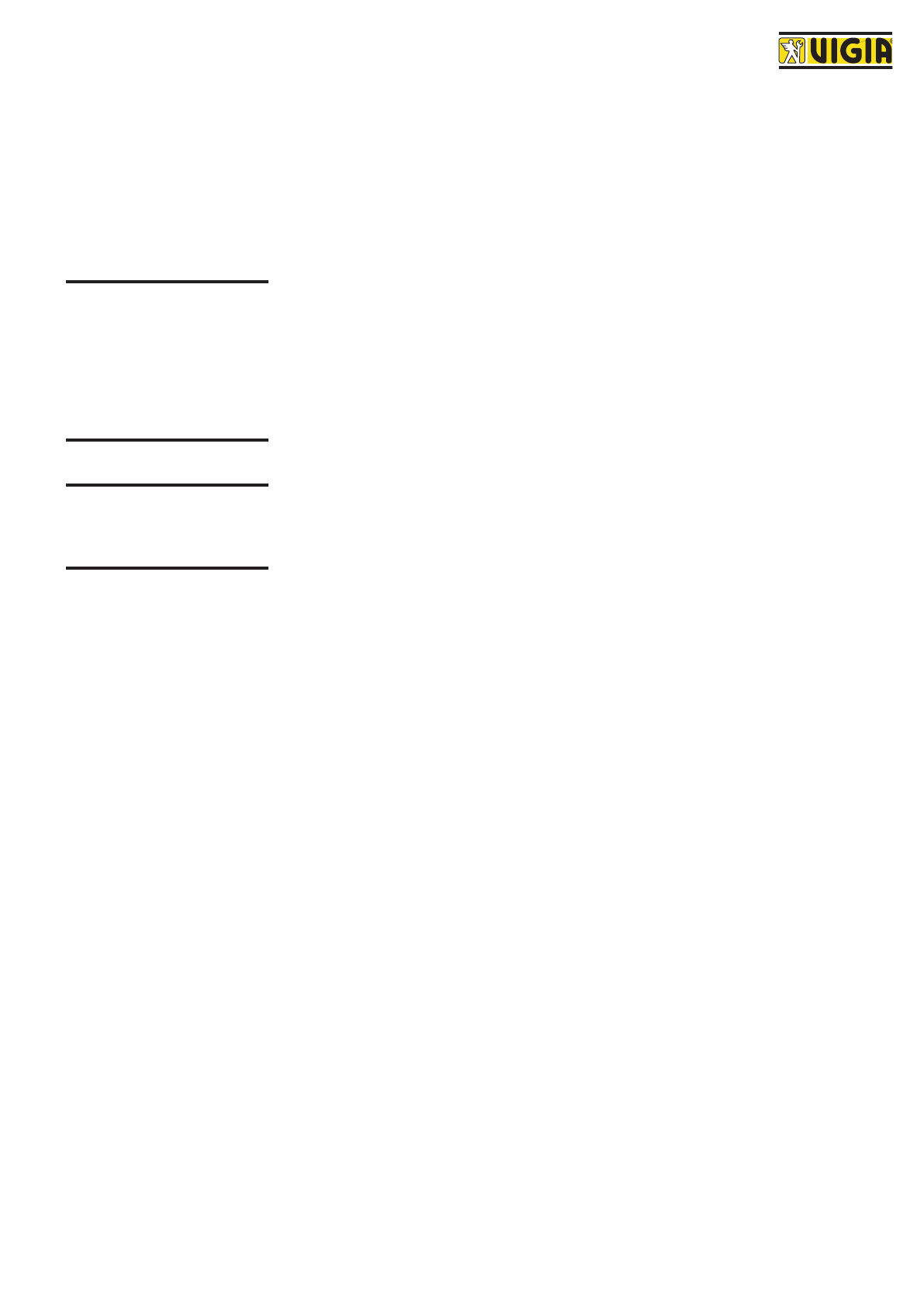

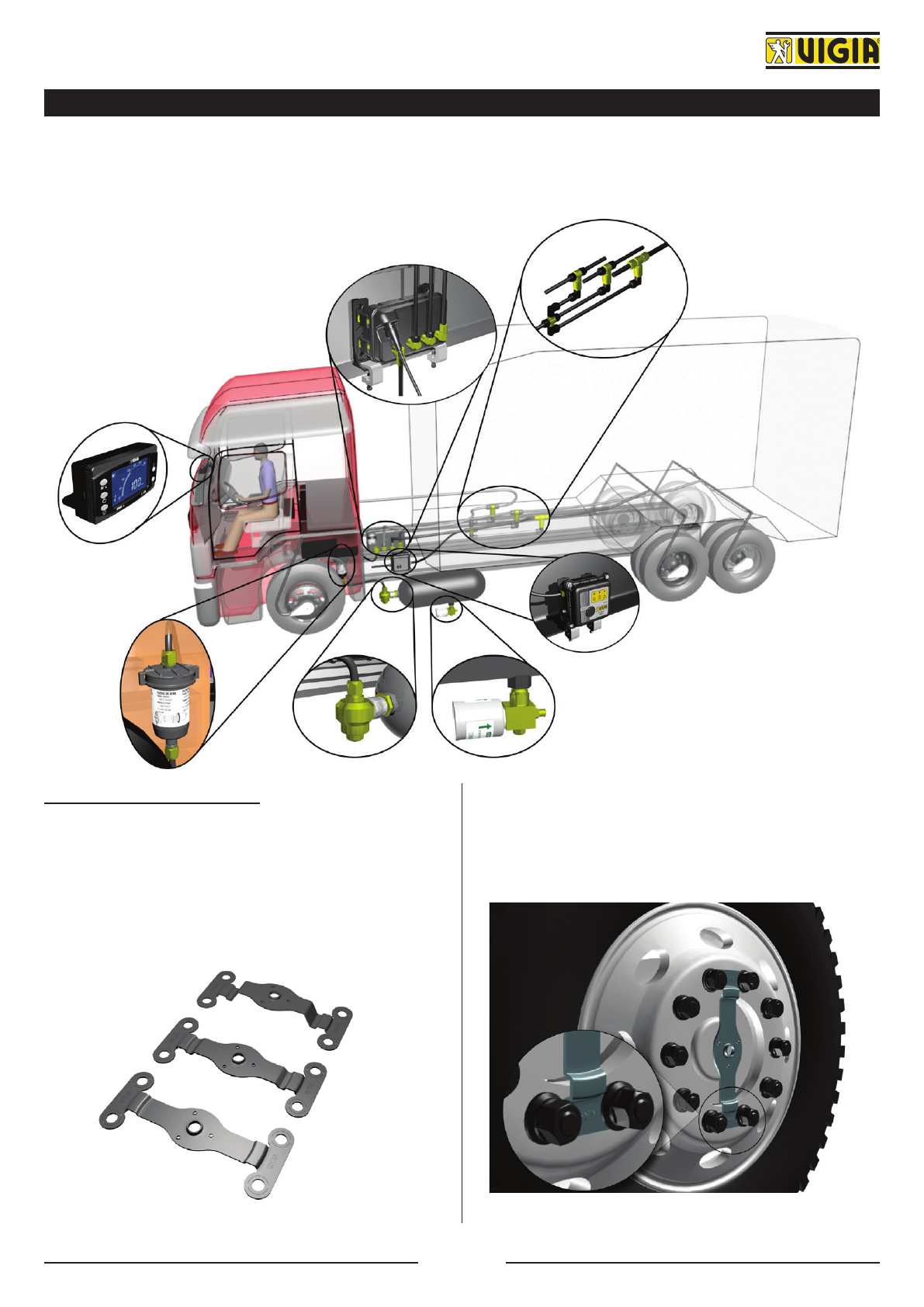

SECTION 2: ELECTRONIC TIRESECTION 2: ELECTRONIC TIRE

CALIBRATORCALIBRATOR

2.1: FUNCTION

The system allows you to calibrate the tires to a

preset maximum or minimum cold pressure, per

circuit, optimizing the tire pressure with respect

to the load and speed of your vehicle.

2.2: APPLICATION

The VIGIA NM 444 System is particularly useful

when installed on heavy transport vehicles and

especially those that are exposed to dierent

types of roads (including o-road) and conditions

of use including agriculture, livestock, forestry,

transportation fuel, mining and construction.

Very Important: The NM 444 System

can be installed in any unit that has

an air compressor and a power

supply voltage of 12 to 24 V., but its

correct operation will depend on:

• The capacity of the unit's air com-

pressor.

• The number of tires to be con-

trolled in the two pressure states.

• The pressure values at which it is

required to calibrate the tires.

PAGE. 3 OF 55