Document: LT0109 Vigilant MICROVAC Owners Manual

Issue 1.31 5 April 2000 Page iii

TABLE OF CONTENTS

CHAPTER 1 SYSTEM DESCRIPTION & SPECIFICATION.................... 1-1

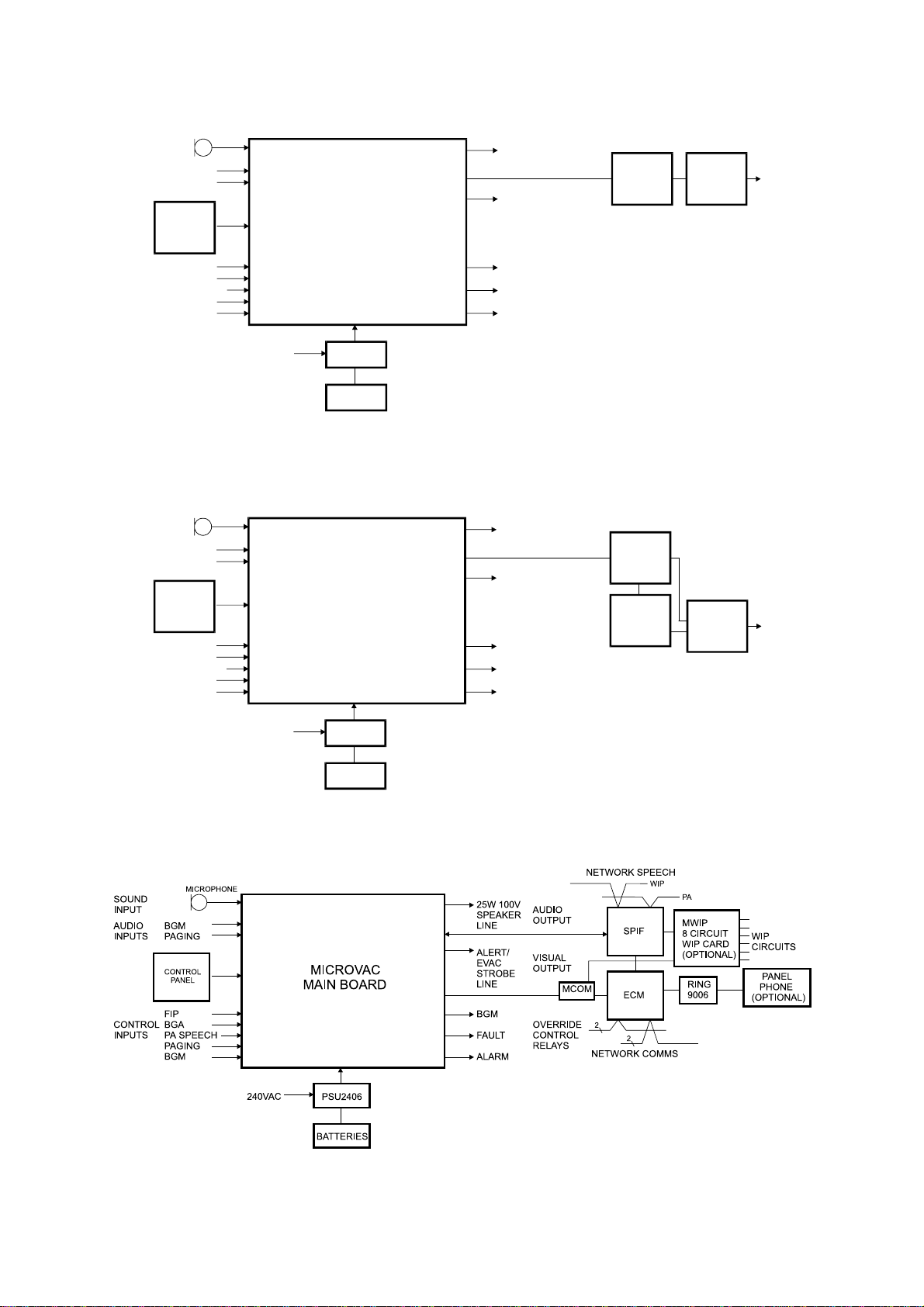

1.1 OVERVIEW.............................................................................................................1-1

1.2 SYSTEM CONCEPT ...............................................................................................1-2

1.2.1 OPERATOR FUNCTIONS................................................................................1-4

1.2.2 EMERGENCY WARNING AND AUXILIARY FUNCTIONS...............................1-4

1.2.3 POWER SUPPLY.............................................................................................1-4

1.3 SPECIFICATIONS...................................................................................................1-5

1.3.1 GENERAL........................................................................................................1-5

1.3.2 CABINET..........................................................................................................1-6

1.3.3 INPUTS & OUTPUTS.......................................................................................1-7

1.3.4 AMPLIFIER CHARACTERISTICS....................................................................1-8

CHAPTER 2 INSTALLATION, WIRING, SETUP & COMMISSIONING. 2-1

2.1 INSTALLATION ......................................................................................................2-1

2.2 WIRING...................................................................................................................2-1

2.2.1 MAINS..............................................................................................................2-1

2.2.2 BATTERIES......................................................................................................2-1

2.2.3 AUXILIARY 24V OUTPUT................................................................................2-1

2.2.4 FAULT RELAY OUTPUT..................................................................................2-2

2.2.5 STROBE OUTPUT...........................................................................................2-2

2.2.6 BGM OVERRIDE RELAY OUTPUT..................................................................2-3

2.2.7 ALARM RELAY OUTPUT.................................................................................2-3

2.2.8 FIP AND BGA INPUTS.....................................................................................2-4

2.2.9 PAGING CONTROL INPUT..............................................................................2-5

2.2.10 BGM / AFTER HOURS CONTROL INPUT.......................................................2-5

2.2.11 BGM, PAGING AND AUX AUDIO INPUTS.......................................................2-6

2.2.12 100V SPEAKER LINE ......................................................................................2-6

2.2.13 EXTERNAL DC POWER INPUT.......................................................................2-7

2.2.14 VIGILANT HIGH POWER AMPLIFIER WIRING...............................................2-8

2.2.15 THIRD PARTY BOOSTER AMPLIFIER WIRING..............................................2-8

2.2.16 NETWORK WIRING.......................................................................................2-10

2.2.17 MASTER WIP WIRING...................................................................................2-10

2.2.18 FIELD WIP WIRING .......................................................................................2-10

2.3 SETUP - DIP SWITCH SETTINGS........................................................................2-11

2.3.1 NETWORKED MODE.....................................................................................2-11

2.3.2 ALERT TO EVACUATE DELAY (NON NETWORKED MODE).......................2-11

2.3.3 INITIAL DELAY BEFORE ALERT (NON NETWORKED MODE)....................2-11

2.3.4 PTT / PA MODE .............................................................................................2-12

2.3.5 FIP / BGA SHORT CIRCUIT FAULT MONITORING.......................................2-12

2.3.6 25W OR 100W/200W .....................................................................................2-12

2.3.7 NUMBER OF EVACUATE MESSAGES.........................................................2-12

2.3.8 NUMBER OF ALERT MESSAGES.................................................................2-12

2.3.9 USE OF BGM CONTROL INPUT : BGM OR AFTER-HOURS........................2-12

2.3.10 DISABLE MAINS AND CHARGER FAULT MONITORING.............................2-13

2.3.11 SPEECH IN MANUAL MODE.........................................................................2-13

2.4 COMMISSIONING.................................................................................................2-13

2.4.1 POWERING UP..............................................................................................2-13