6 7

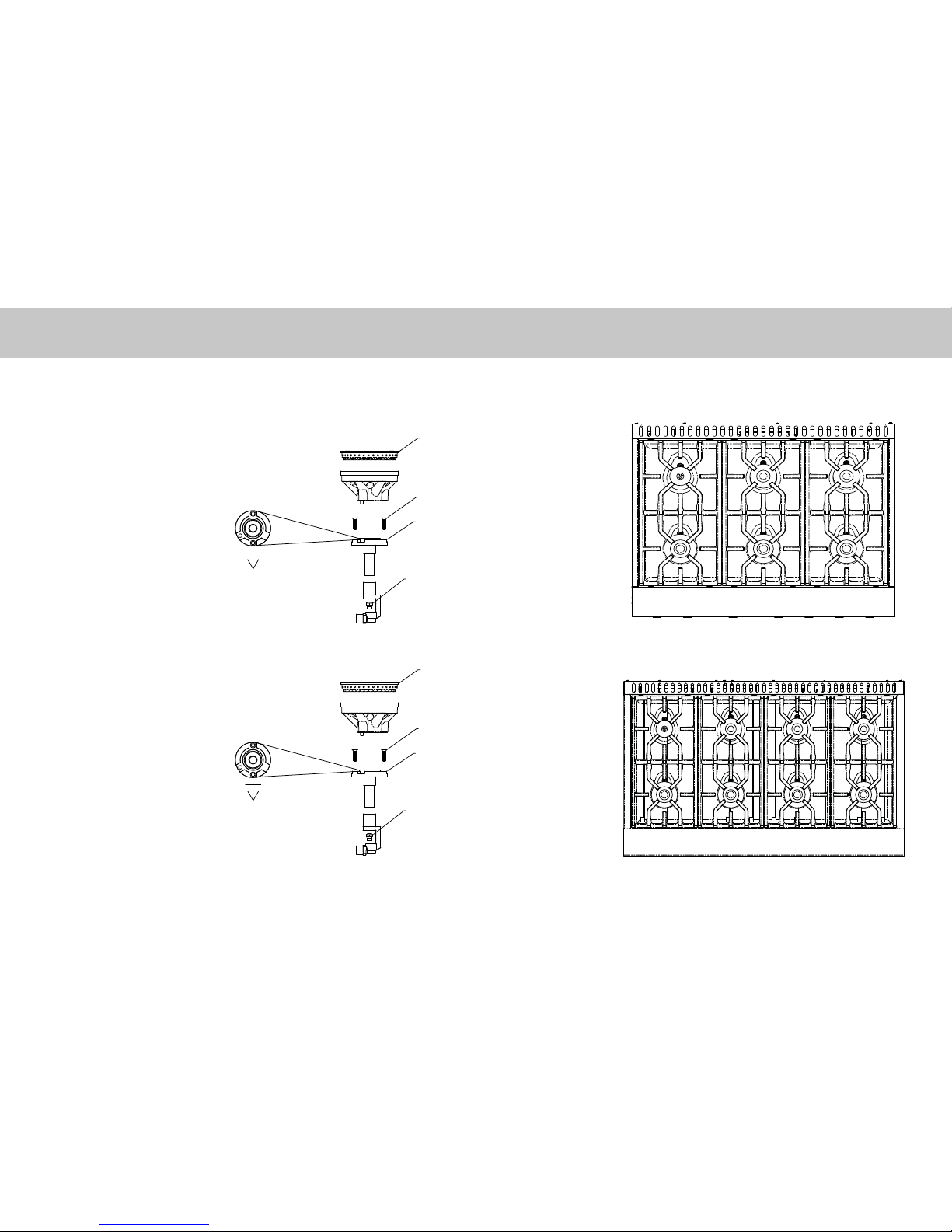

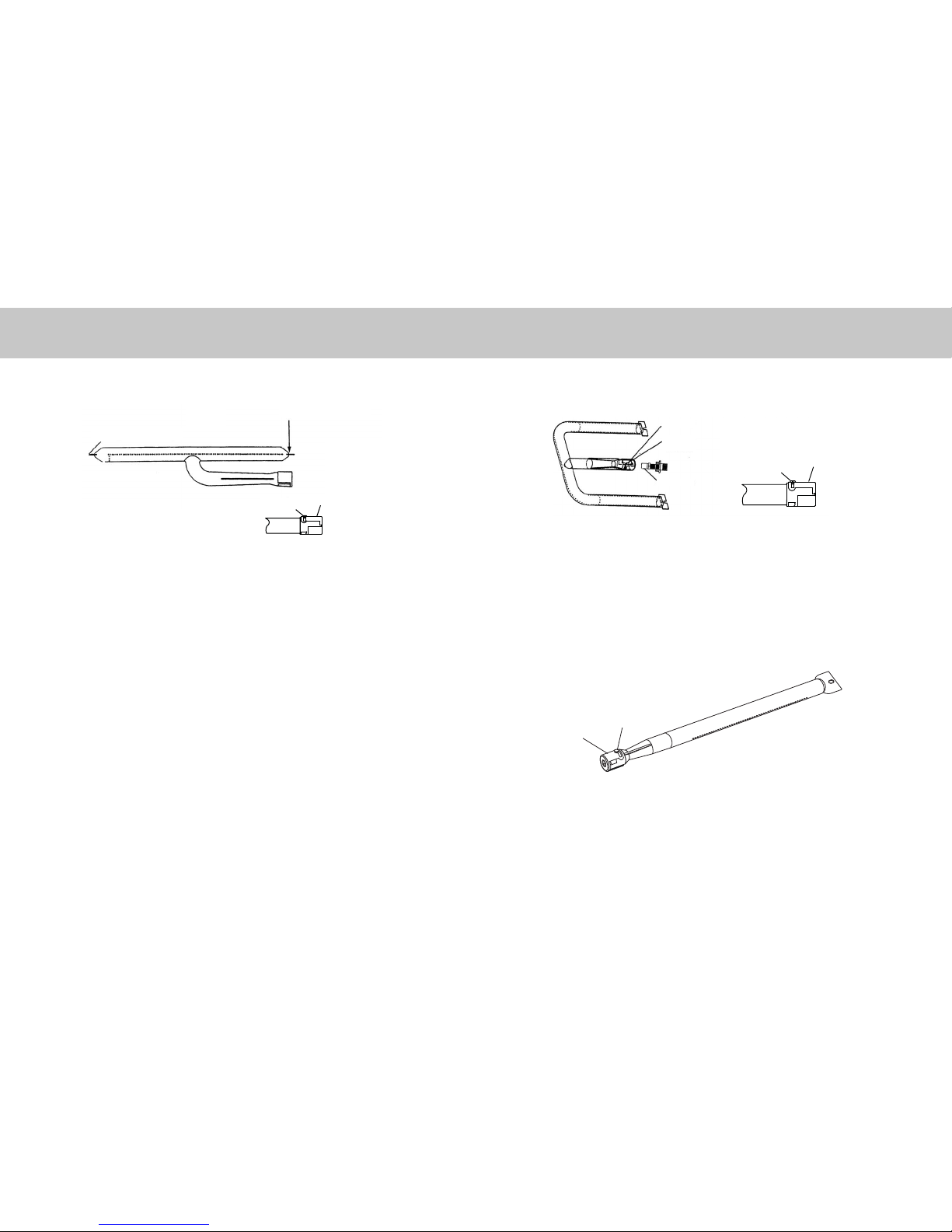

Surface Burner Conversion

AA*A

BB*

C

Burner A #55 (1.32 mm)

Burner B #58 (1.07 mm)

Burner C #67 (.813 mm)

36” Surface Burner Orifice Locations

AA

B

C

Burner A #55 (1.32 mm)

Burner B #58 (1.07 mm)

Burner C #67 (.813 mm)

48” Surface Burner Orifice Locations

A

B

Surface Burner Conversion

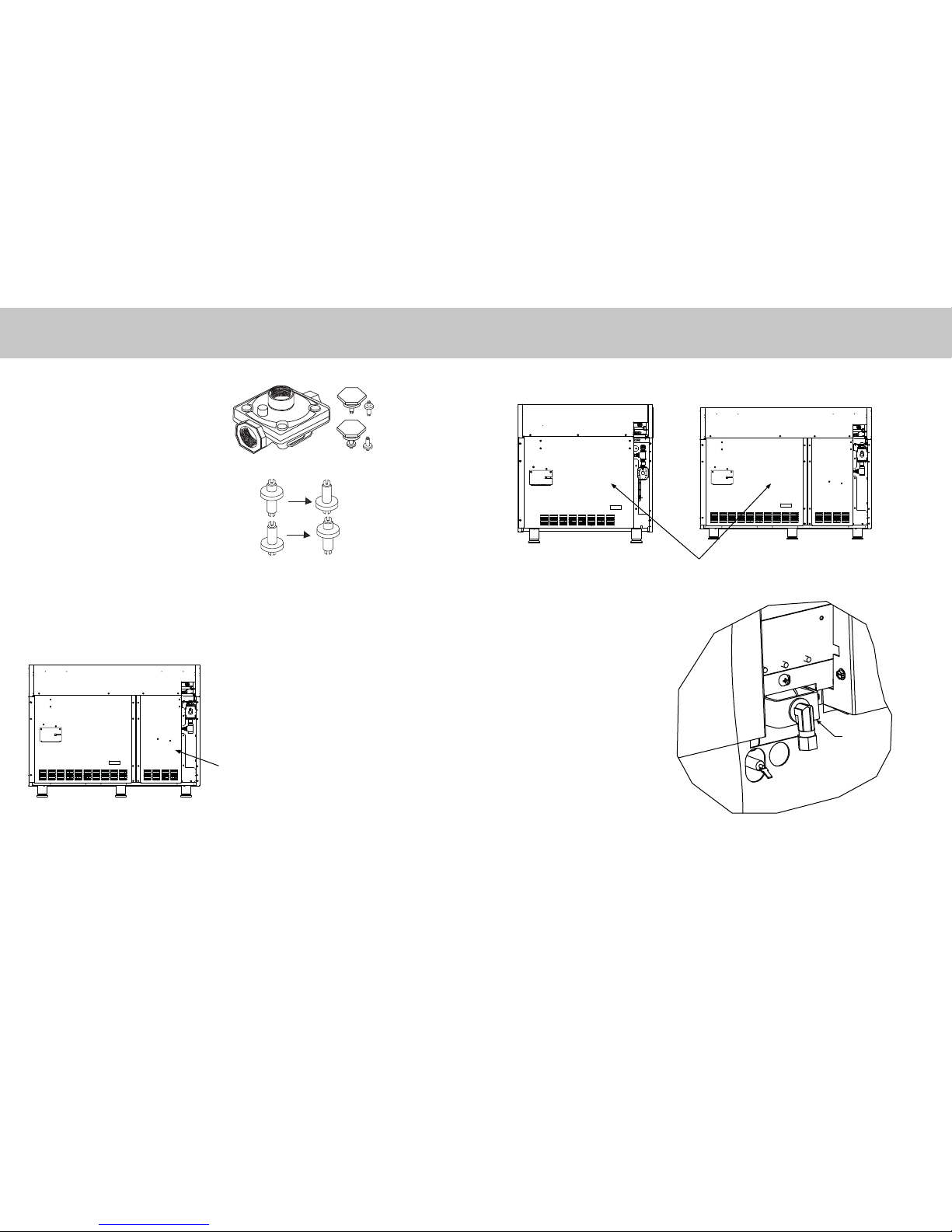

Front Surface Burner Conversion

Item #1

Item #2

Item #3

Front of unit

Top View of

Venturi flange

Burner

Head

-Locate bag labeled 050299-000

-Remove screws (Item #1) with a T-20 Torx bit.

-Remove venturi flange (Item #2).

-Use a metric 10mm nut driver to remove orifice (Item

#3).

-Replace orifice with #55 from 050299-000 bag. The

orifice will have a red color code ink and 052 stamped

on the orifice.

Tech tip: Tape can be applied to the inside of the

socked to assist in the removal of the surface

burne orifices. This can prevent the orifices

from falling into the range during removal.

-After replacing the orifice, replace Item#2 venturi flange

with LP venturi flange labeled 050306-000. Note

orientation of venturi flange (refer to Top view of Venturi

flange).

-Reinstall screws and reverse procedure to reassemble.

NOTE: For proper placement of the burner head, rotate until burner head seats into groove.

Rear Surface Burner Conversion

Item #1

Item #2

Item #3

Front of unit

Top View of

Venturi flange

Burner

Head

-Locate bag labeled 050299-000

-Remove screws (Item #1) with a T-20 Torx bit.

-Remove venturi flange (Item #2).

-Use a metric 10mm nut driver to remove orifice (Item #3).

-Replace left rear orifice with #67 from 050299-000 bag.

The orifice will have a blue color code ink and 032

stamped on the orifice.

-Replace all other rear orifices with #58 from 050299-000

bag. The orifice will have a black color code ink and 042

stamped on the orifice.

Tech tip: Tape can be applied to the inside of the socked

to assist in the removal of the surface burne

orifices. This can prevent the orifices from falling

into the range during removal.

-After replacing the orifice, reinstall the current Item#2

venturi flange (it will not be replaced). Note orientation of

venturi flange (refer to Top view of Venturi flange).

-Reinstall screws and reverse procedure to reassemble.

NOTE: For proper placement of the burner head, rotate until burner head seats into groove.

(*Not applicable on

griddle models)

(*Not applicable on

griddle models)

B*

A*

(*Not applicable on

griddle models)

(*Not applicable on

griddle models)

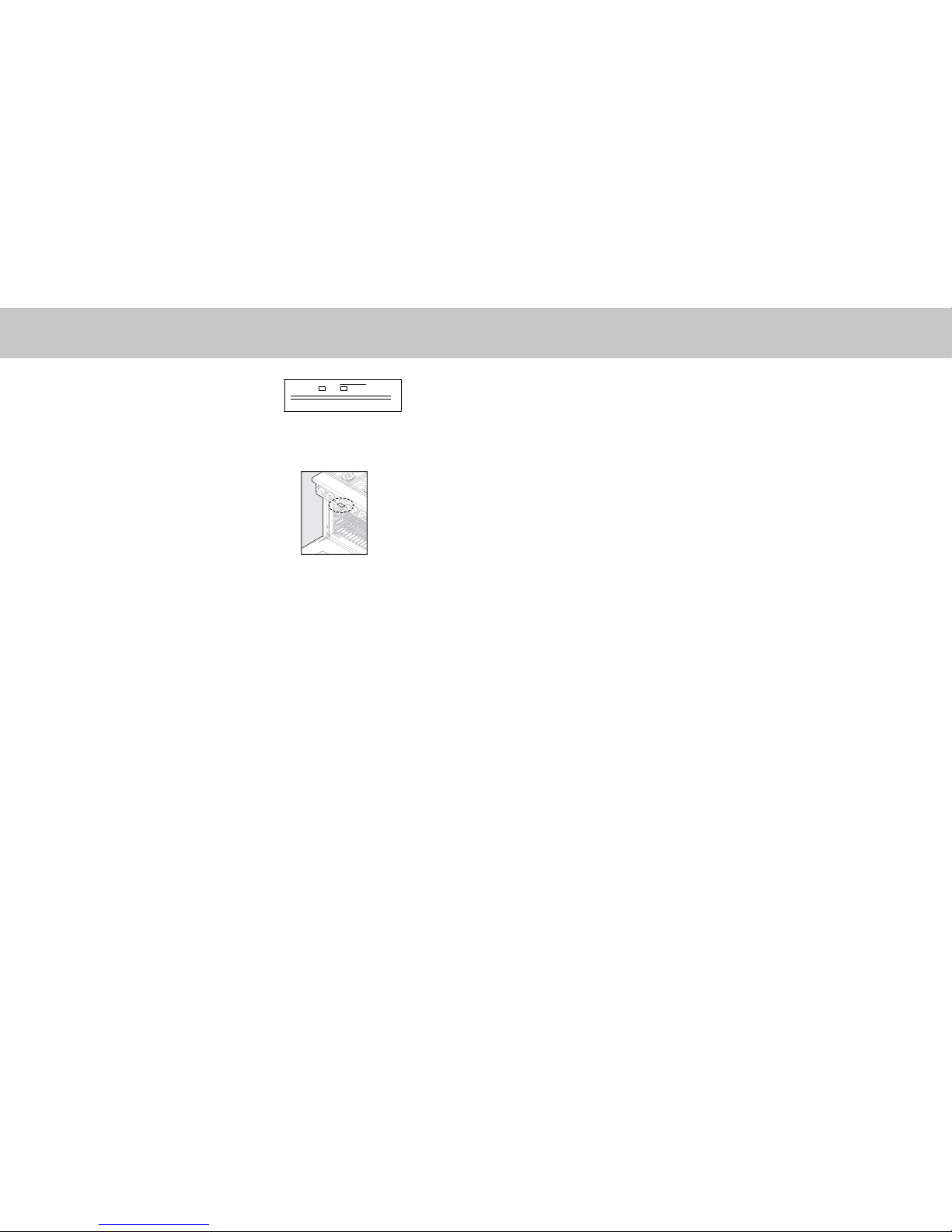

Preparing for Top Surface Conversion

Remove all grates, grate supports, surface burner caps, and griddle

NOTE: Some models may not be equipped with all parts mentioned above.

IMPORTANT: For models equipped with griddles, notice position of griddle temperature probe for

proper reinstallation. Failure to properly reinstall could result in damage to griddle temperature probe.