TECHNICAL DATA

June 1, 2011

6” MODEL G-6000 DRY VALVE

RISER ASSEMBLY

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

T

elephone:

269-945-9501

T

echnical

Services:

877-384-5464

Fax:

269-818-1680

Email:

[email protected]Dry 138a

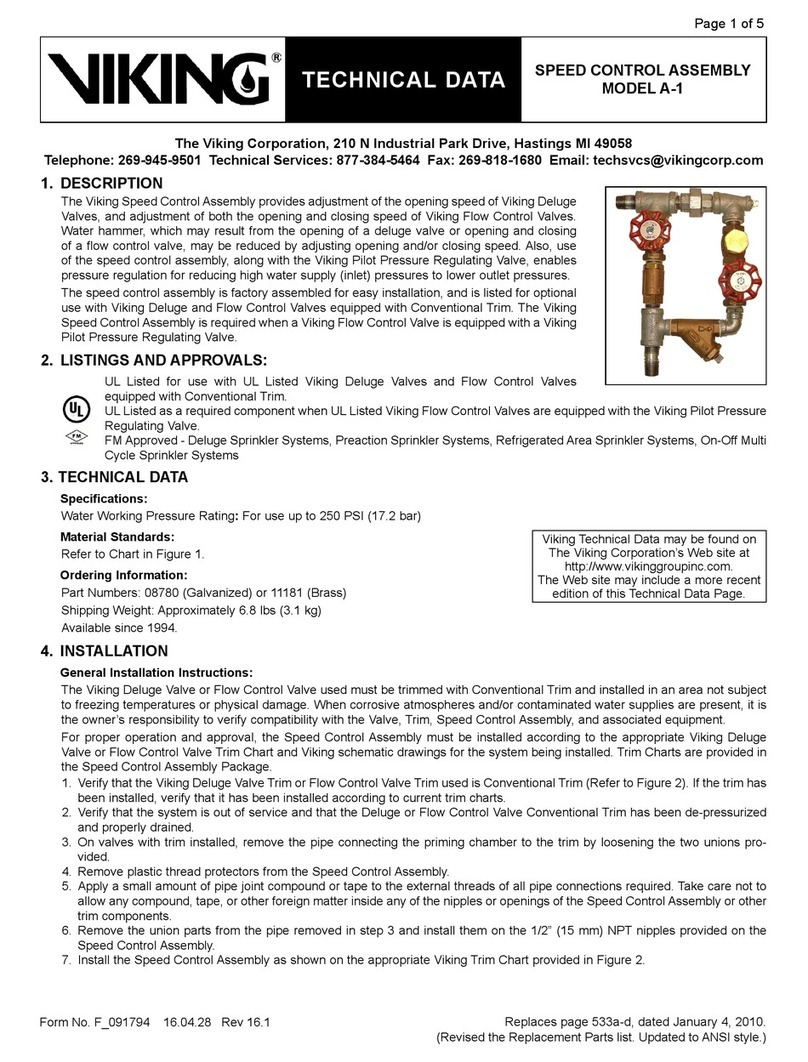

1. DESCRIPTION

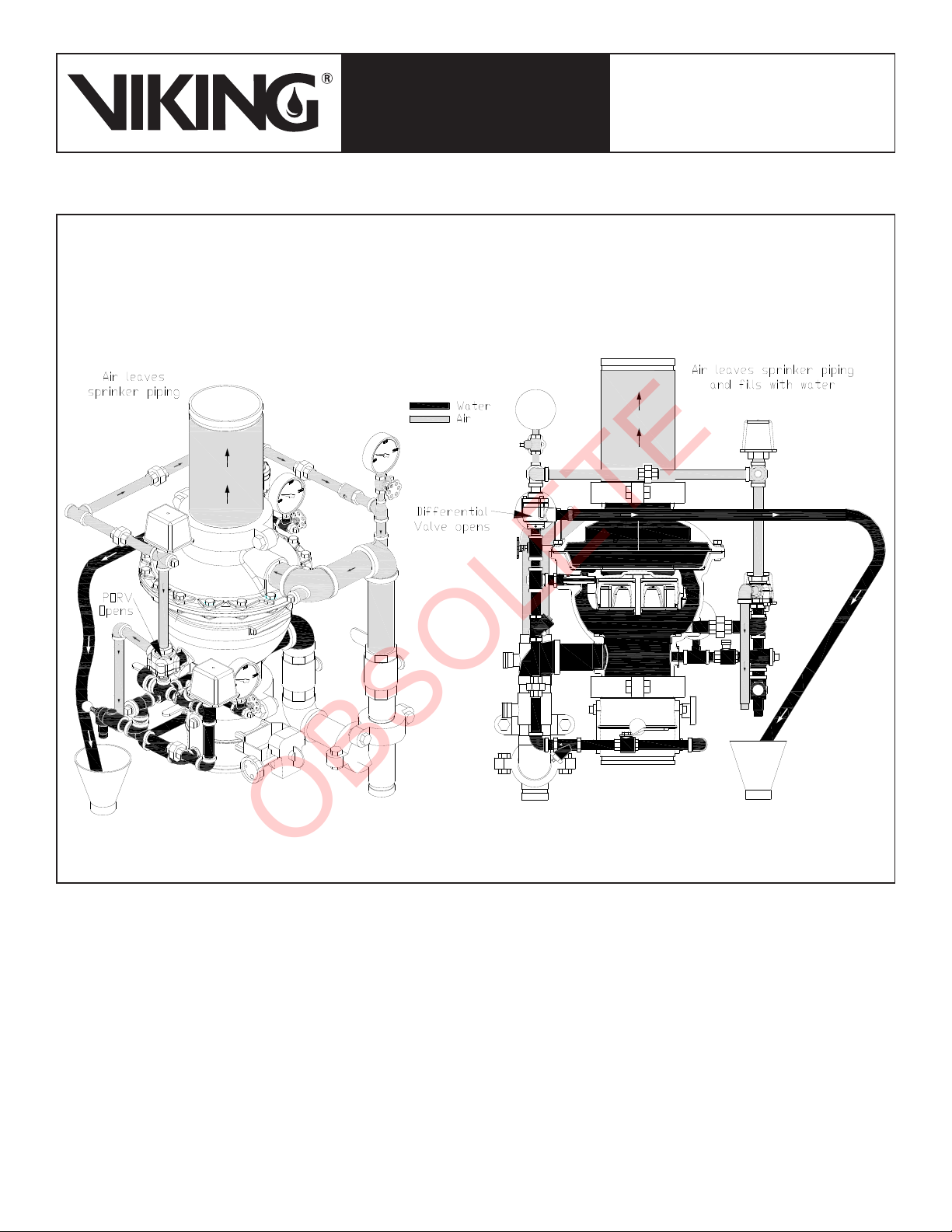

The Viking 6” Model G-6000 Dry Valve Riser Assembly consists of a small prole, light

weight, pilot operated valve that is used to separate the water supply from the dry

sprinkler piping, which is pressurized with air. The pilot operated valve combines an

internal diaphragm assembly that is pressurized closed with priming water, an internal

check valve to isolate the sprinkler system piping, and the Model A-1 Differential Valve

located on the valve trim that allows the valve to operate upon loss of air pressure. The

differential design of the Differential Valve allows an air supply of moderate pressure to

control a higher water supply pressure. When the air pressure in the dry pipe system

is reduced sufciently upon the differential valve due to a sprinkler head operation to

destroy the pressure differential, the differential valve will open and relieve the prim-

ing pressure from the internal diaphragm assembly. The internal diaphragm assembly

will compress, which will allow water to pass through the body of the valve and center

of the internal check valve, entering the sprinkler system piping. The Viking Model

G-6000 Valve is designed to be used with a water ow pressure switch and/or water

motor gong. For systems that require an accelerator to increase the speed of water

delivery, the Viking Model E-1 Accelerator shall be used.

2. LISTING AND APPROVALS

cULus Listed - VPZV

FM Approved - Dry Pipe Valves

3. TECHNICAL DATA

Specifications:

Pressure Rating: 250 PSI (17.2 bar) Water Working Pressure

Factory Hydrostatically Tested to: 500 PSI (34.5 bar)

Air to water differential: Approximately 5.75 to 1

Friction Loss (Given in feet of Schedule 40 pipe based on Hazen & Williams formula: C = 120):feet of Schedule 40 pipe based on Hazen & Williams formula: C = 120)::

G-6000 Valve: 44.88’G-6000 Valve: 44.88’

12” Section of Pipe: 1’

Water Supply Control Valve: 14.7’

Model G-6000P Valve CvFactor: 811

Valve Color: Black

Material Specifications:

Refer to Figure 11.

Ordering Information:

Available since 2011.

Part Number: G-6000 Dry Valve Riser Assembly (See Figure 8) - 17048-1

Accessories:

Model E-1 Accelerator: 08055

Drain Manifold: 17056 (See Figure 9.)

Model LD-1 Anti-Column Device: 14800

4. INSTALLATION:

A. General Installation Instructions

1. For proper operation and approval, the valve must be installed in the vertical position as trimmed from the factory. DO NOT

install horizontally or modify the factory assembled trim except as described in this technical data page.

2. Viking recommends installing a 12” section of pipe directly above the G-6000 Dry Valve. Prior to valve maintenance, this sec-

tion of pipe may be removed to provide clearance for lifting the cover from the body.

3. The dry valve must be installed in an area not subject to freezing temperatures or physical damage. If required, provide a

valve house (enclosure) with adequate heat around the dry valve and trim. Freezing temperatures and/or excessive pressure

will damage the dry valve. When corrosive atmospheres and/or contaminated water supplies are present, it is the owner’s

responsibility to verify compatibility with the Model G-6000 Dry Valve and associated equipment.

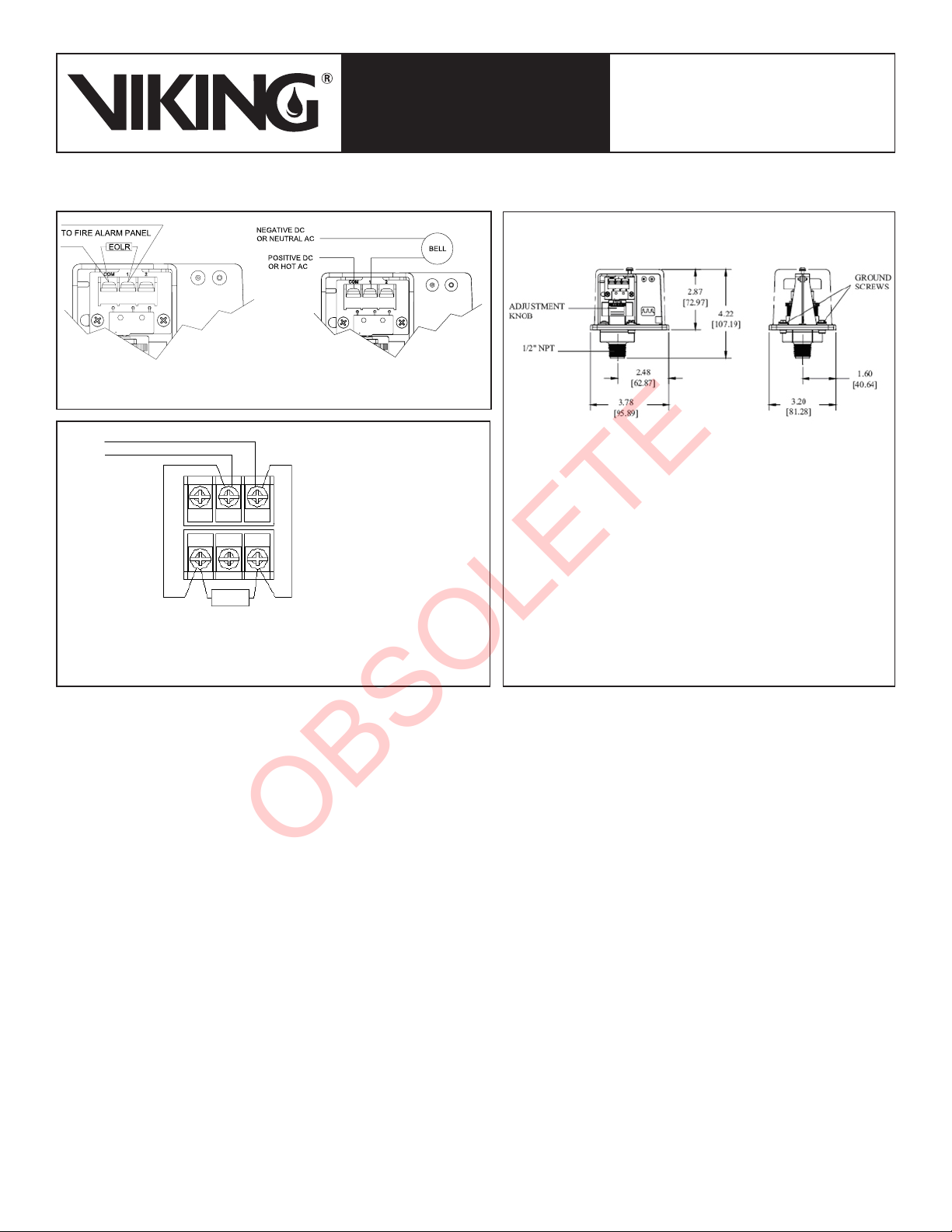

4. The Viking Model E-1 Accelerator should be installed at the location indicated in Figure 1 when required by the installation

standard or local Authority Having Jurisdiction.

Form No. F_022111 New page 138a-m, issued June 1, 2011.

Viking Technical Data may be found on

The Viking Corporation’s Web site at

http://www.vikinggroupinc.com.

The Web site may include a more recent

edition of this Technical Data Page.

Q= Cv√∆P

S

Q = Flow

Cv = Flow Factor (GPM/1 PSI ∆P)

∆P = Pressure Loss through Valve

S = Specic Gravity of Fluid