Viking Designer DGVU260-5B User manual

Other Viking Cooktop manuals

Viking

Viking Designer DECU105 User manual

Viking

Viking F20679C User manual

Viking

Viking VGRT421-4G Series User manual

Viking

Viking VECU1064BSB User manual

Viking

Viking Designer DETU200-4B User manual

Viking

Viking Designer DGRT300-4B User manual

Viking

Viking Professional Custom VGCC5486G User manual

Viking

Viking VECU1064BSB User manual

Viking

Viking Designer DERT362-5B User manual

Viking

Viking RDGSU2005BSS User manual

Viking

Viking RVEC330 User manual

Viking

Viking CNVGSU User manual

Viking

Viking RVGC3365BSS User manual

Viking

Viking RDGSU2005BSS User manual

Viking

Viking 3 Series Troubleshooting guide

Viking

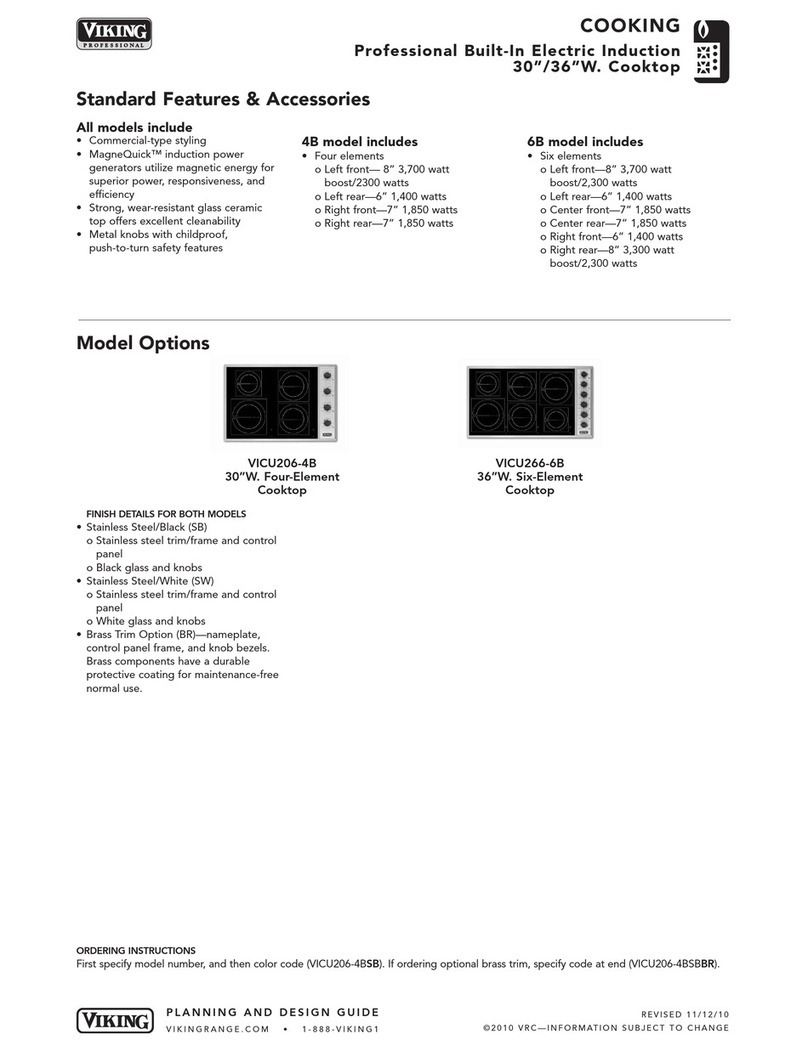

Viking Professional VICU266-6B User manual

Viking

Viking VCCU105-4B Service manual

Viking

Viking F20333A User manual

Viking

Viking Built-In Electric Cooktops User manual

Viking

Viking RDGSU2005B User manual

Popular Cooktop manuals by other brands

Bonnet

Bonnet OPTIMUM 700 Technical instructions

Jenn-Air

Jenn-Air JGCP430 installation instructions

Frigidaire

Frigidaire FES367FCC Wiring diagram

Ztove

Ztove EZ2 DUO instruction manual

Kleenmaid

Kleenmaid cooking GCTK9011 Instructions for use and warranty details

Jenn-Air

Jenn-Air JGC2536EB00 Use & care guide