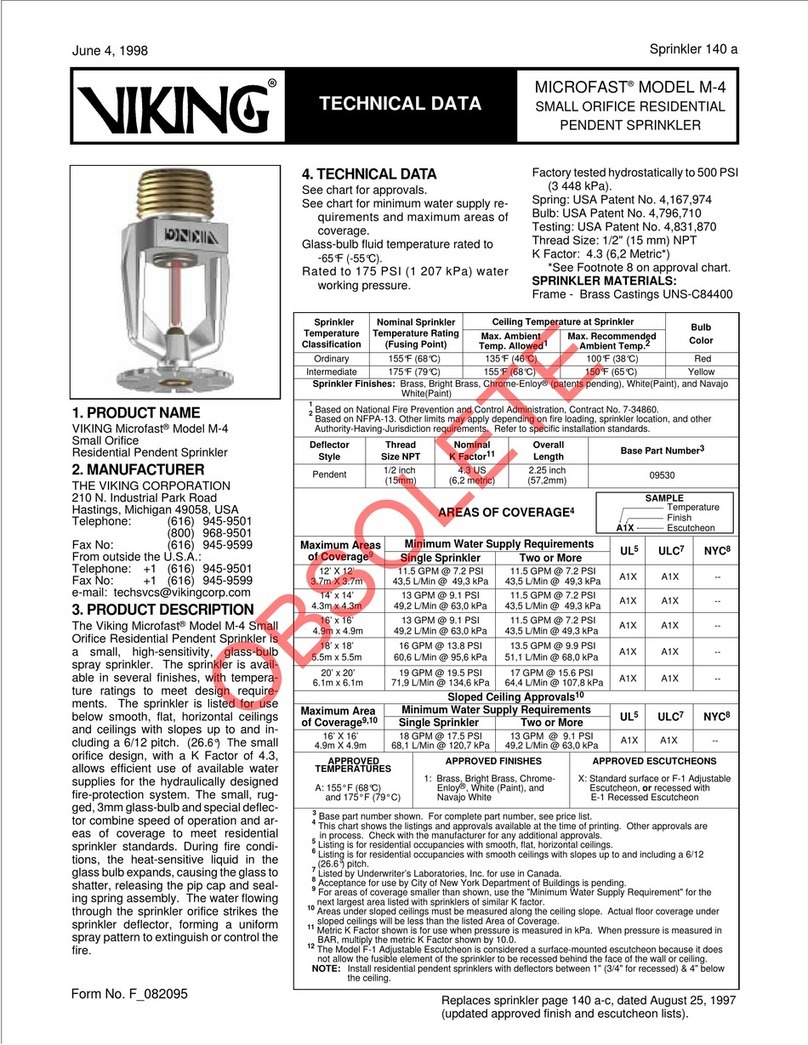

1. PRODUCT NAME

VikingMicrofast®ModelM-5Residential

Pendent Sprinkler, 5.5 K-factor

•Base Part Number 10050

•Available since 1997.

2. MANUFACTURER

The Viking Corporation

210 N. Industrial Park Road

Hastings, Michigan 49058, U.S.A.

Telephone:(616) 945-9501

(877) 384-5464

Fax:(616) 945-9599

3. PRODUCT DESCRIPTION

The Viking Microfast ® Model M-5 Resi-

dential Pendent Sprinkler is a small,

high-sensitivity, glass-bulb spray sprin-

kler. The sprinkler is available in several

finishesandtemperatureratingstomeet

design requirements.

The sprinkler is listed for use below

smooth, flat, horizontal ceilings and

ceilings with slopes up to and includ-

ing a 6/12 (26.6°) pitch, with spacings

up to 20’ x 20’.

The sprinkler design, with a K-factor of

5.5, allows efficient use of available wa-

ter supplies for the hydraulically de-

signed fire-protection system. The

small, rugged 3 mm glass bulb and spe-

cial deflector combine speed of opera-

tion and areas of coverage to meet the

residential sprinkler standards. During

fire conditions, the heat-sensitive liquid

in the glass bulb expands, causing the

bulb to shatter, releasing the pip-cap

and sealing spring assembly. The water

flowing through the sprinkler orifice

strikes the sprinkler deflector, forming a

uniform spray pattern to extinguish or

control the fire.

4. TECHNICAL DATA

LISTINGS AND APPROVALS

Refer to Table 1 on pages 141 c and

Table 2 on page 141 d.

Ratedto175psi(1207kPa)waterwork-

ing pressure.

Factory tested pneumatically to 95 psi

(655 kPa).

See approval charts for minimum water

supply requirements and maximum

areas of coverage.

Glass-bulb fluid temperature rated to

-65 °F (-55 °C).

Spring: USA Patent No. 4,570,720

Seepages141cand141dfortempera-

ture ratings.

ThreadSize:Nominal1/2"(15mm)NPT

K-factor: 5.5 U.S. (7,9 metric*)

* Metric K-factor shown is for use when pressure is

measuredinkPa.Whenpressure is measured in

BAR, multiply the metric K-factor shown by 10.0.

SPRINKLER MATERIALS

Frame: Brass Castings UNS-C84400

Deflector: Brass UNS-C26000

Bulb: Glass, nominal 3 mm diameter

Seal: Teflon®Tape

Spring: Nickel Alloy

Screw: Brass UNS-C36000

Pip Cap: Copper UNS-C11000 and

Stainless Steel UNS-S30400

SPRINKLER FINISHES

Bright Brass, Chrome-Enloy ®(patents

pending), White (Paint), and Navajo

White (Paint)

ACCESSORIES

Refer to the “SPRINKLER ACCES-

SORIES” section of the Viking Engi-

neering and Design Databook for tech-

nical data on approved sprinkler wrench

and other accessories.

5. AVAILABILITY AND SERVICE

Vikingsprinklers are available through a

network of domestic, Canadian, and in-

ternational distributors. See the Yellow

Pagesofthetelephonedirectoryforalo-

cal distributor (listed under “Sprin-

klers-Automatic-Fire”)orcontactViking.

Viking Technical Data may be found on

The Viking Corporation’s Web site at

http://www.vikingcorp.com.

The Web site may include a more recent

edition of this Technical Data page.

6. GUARANTEES

For details of warranty, refer to Viking’s

currentlistpricescheduleorcontactThe

Viking Corporation directly.

7. INSTALLATION

WARNING:Viking sprinklers are manu-

factured and tested to meet the rigid re-

quirements of the approving agency.

The sprinklers are designed to be in-

stalled in accordance with recognized

installation standards. Deviation from

the standards or any alteration to the

sprinkler after it leaves the factory in-

cluding, but not limited to: painting, plat-

ing,coating,ormodification,mayrender

the sprinkler inoperative and will auto-

matically nullify the approval and any

guaranteemadebyTheVikingCorpora-

tion.

A.Sprinklersare tobeinstalledinaccor-

dance with the latest published stan-

dards of the National Fire Protection

Association, Factory Mutual, Loss

Prevention Council, Assemblee

Pleniere, Verband der

Sachversicherer or other similar or-

ganizations,andalso with provisions

of governmental codes, ordinances,

and standards whenever applicable.

For conditions not specifically cov-

ered by the standards, refer to the

“Viking Residential Installation

Guide”. Final approval and accep-

tance of all Residential Sprinkler In-

stallationsmust be obtained fromthe

Authority Having Jurisdiction. Resi-

dential sprinklers are special-service

sprinklers for use in one- and

two-family dwellings, mobile homes,

and residential portions of other oc-

cupancies, where allowed. The use

of residential sprinklers may be lim-

ited due to occupancy and hazard.

The minimum flow rate indicated for

a listed area of coverage must be

provided at the sprinkler. Therefore,

thesystem must be hydraulicallycal-

culated. Refer to the Authority Hav-

ing Jurisdiction prior to installation.

B. Sprinklers must be handled with care.

They must be stored in a cool, dry

place in their original container.

Never install sprinklers that have

been dropped or damaged in any

way. Never install any glass-bulb

sprinkler if the bulb is cracked or if

there is a loss of liquid from the bulb.

If a glass bulb lacks the appropriate

amountof fluid, itshouldbe set aside

and returned to Viking (or an autho-

rized Viking distributor) for analysis

assoonaspossible.Ifthe sprinkleris

not returned to Viking, it should be

destroyed immediately. Never install

sprinklers which have been exposed

to temperatures in excess of maxi-

Sprinkler 141 a

May 27, 1999

FormNo.F_060697Replaces sprinkler page 141 a-e, dated May 21, 1998

(revised pip-cap materials).

Units of measure in parentheses may be approximations.

TECHNICAL DATAMicrofast®MODEL M-5

RESIDENTIAL PENDENT

SPRINKLER, 5.5 K-FACTOR