chanical damage. Viking Institutional

Style Quick Response Flush Hori-

zontal Sidewall Sprinklers must be

installed below smooth, flat, horizon-

tal ceilings. The sprinklers must be

installed with the deflectors located

4" to 12" (102 mm to 304 mm) below

the ceiling, and flush with the wall in

which they are installed.

Always install horizontal sidewall

sprinklers with the top of the deflector

oriented parallel with the ceiling. The

wrench ear on the top of the Viking

Institutional Style Quick Response

Flush Horizontal Sidewall Sprinkler

is marked with the word “top”.

Before installing, be sure to have the

appropriate sprinkler model and

style, with the correct orifice size,

temperature rating, and response

characteristics. Install the sprinklers

accordingto thefollowingsequence:

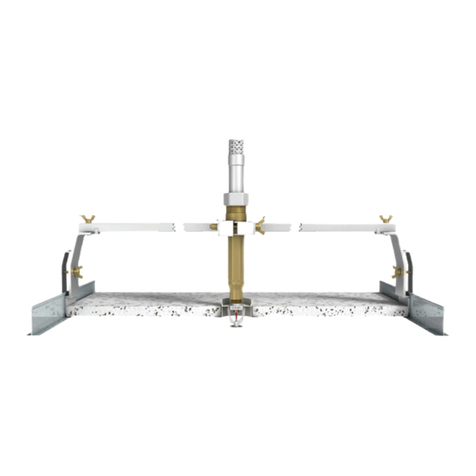

1. Install all piping and cut the sprin-

kler nipple so that the ½" (15 mm)

NPT outlet of the reducing cou-

pling is at the desired location and

centered in a 2-1/4" (57,22 mm)

diameter opening in the wall (due

to the lockring).

Note: If the retaining flange as

-

sembly is to be used, slide the

flange over the sprinkler nipple

prior to threading the nipple into

the tee, as shown in Figure 3A.

2.The internal diameterof thespecial

Flush/Concealed Sprinkler Wrench

is designed for use with the sprin-

kler contained in the protective

plastic shell. With the sprinkler in

the shell, apply a small amount of

pipe-joint compound or tape to the

external threads of the sprinkler

only, taking care not to allow a

build-up of compound in the sprin-

kler inlet.

3. Refer to Figure 3B and use only

the special Flush/Concealed

Sprinkler Wrench, which is de-

signed for installing Viking Institu-

tional Style Quick Response

Flush Horizontal Sidewall Sprin-

klers. With the sprinkler in the

plastic protective shell, place the

unit into the wrench. DO NOT use

the fusible link to start or thread

the sprinkler into a fitting. Turn the

unit clockwise to thread the sprin-

kler into the coupling, taking care

not to over-tighten or damage the

sprinkler operating parts.

G. After installation, the entire sprinkler

system must be tested. The test must

be conducted to comply with the in-

stallation standards.

Make sure the sprinkler has been

properly tightened. If a thread leak

occurs, normally the sprinkler must

be removed, new pipe-joint com-

pound or tape applied, and then rein

-

stalled. This is due to the fact that

when the joint seal is damaged, the

sealing compound or tape is washed

out of the joint.

H. After testing, repairing all leaks, and

installing and painting the wall, re

-

move the plasticprotective shell from

the sprinkler.

INSTALLATION TIP: Do not install the

lockring onto the sprinkler until after the

sprinkler nipple has been cut back to en-

sure desired placement of the sprinkler

in relation to the outer surface of the

wall. The lockring will prove difficult to

remove from the sprinkler once it has

been installed behind the face of the

wall. Check finished product by tempo-

rarily installing the escutcheon plate

onto the sprinkler without the lockring,

using the Institutional Escutcheon In

-

stallation Wrench. If necessary, re-cut

the sprinkler nipple as required.

Once satisfied with sprinkler location

compared to the front of the wall, install

the lockring and the escutcheon plate

following steps I through K on this page.

The escutcheon plate cannot be re-

moved after it has been installed with

the lockring, so do not install the es-

cutcheon plate with the lockring until af-

ter the system has been tested.

I. As shown in Figures 3C and 3D, fit the

lockring over the open end of the pro-

tective sprinkler shell and use the

shell to gently press the lockring over

the threads of the sprinkler. The ring

must rest against the two wrench

ears of the sprinkler body with the

four arms of the lockring pointing out-

ward.

J. REMOVE THE PLASTIC PROTEC-

TIVE SHELL from the sprinkler.

(Recommendation: retain a protec

-

tive shell in the spare sprinkler cabi

-

net.)

K. As depicted in Figure 3E, use the In-

stitutional Escutcheon Installation

Wrench to screw on the escutcheon

plate clockwise. The face of the es

-

cutcheon plate is equipped with four

indentations to complement the de-

sign of the Institutional Escutcheon

Installation Wrench and facilitate in-

stallation of the escutcheon plate.

As the escutcheon plate is threaded

onto the sprinkler body, the four arms

of the lockring must fully engage with

the radialgrooves onthe inside of the

escutcheon plate. Continueto thread

the escutcheon plate onto the sprin-

kler body until the plate’s flange fits

tightly against the surface of the wall.

Then, proceed to turn the escutch

-

eon plate another ½ turn clockwiseto

ensure that it is secured to the wall.

The arms of the lockring are angled

and designed to wedge into the

coined radial grooves on the inside

face of the escutcheon plate to keep

the escutcheon plate from being un-

screwed. Thus, an attempt to remove

the escutcheon plate is prevented af-

ter it is installed with the lockring. DO

NOT MODIFY THE UNIT.

L. The retaining flange, located behind

the wall, must fit snug against the in

-

ner surface of the wall to prevent ver-

tical movement of the assembly. Use

a 1/8" hex wrench to tighten the re-

taining flange screw and secure the

assembly into place to prevent it from

being pulled through the wall.

M. DISASSEMBLY: Refer to section 9.

MAINTENANCE, paragraph D. and

follow all warnings and instructions.

9. MAINTENANCE

(Refer to Figures 1, 2, and 3.)

NOTICE: The owner is responsible for

maintaining the fire protection system

and devices in proper operating condi-

tion. For minimum maintenance and in

-

spection requirements, refer to the ap-

propriate National Fire Protection Asso

-

ciationstandardthatdescribes care and

maintenance of sprinkler systems. In

addition, the Authority Having Jurisdic-

tion may have additional maintenance

requirements that must be followed.

A. The sprinklers must be inspected on

a regular basis for corrosion, me-

chanical damage, obstructions,

paint, etc. The frequency of inspec

-

tions may vary due to corrosive at

-

mospheres, water supplies, and ac-

tivity around the device.

B. Sprinklers that have been painted or

mechanically damaged must be re-

placed immediately. Sprinklers

showing signs of corrosion shall be

tested and/or replaced immediately

as required. Installation standards

require sprinklers to be tested and, if

necessary,replaced after a specified

term of service. Refer to the installa

-

tion standards (e.g., NFPA 25) and

the Authority Having Jurisdiction for

the specified period of time after

which testing and/or replacement is

required. Sprinklers that have oper-

ated cannot be reassembled or re

-

used, but must be replaced. When

replacing sprinklers, use only new

sprinklers.

C. The sprinkler discharge pattern is

critical for proper fire protection.

Nothing should be hung from the

sprinkler, attached to it, or otherwise

obstruct the discharge pattern. All

obstructions must be immediately re-

moved or, if necessary, additional

sprinklers installed.

D. When replacing existing sprinklers,

the system must be removed from

service. Refer to the appropriate

Sprinkler 126 n

TECHNICAL DATA INSTITUTIONAL STYLE

QUICK RESPONSE FLUSH

SIDEWALL SPRINKLER

August 29, 2003