TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

T

elephone:

269-945-9501

T

echnical

Services:

877-384-5464

Fax:

269-818-1680

Email:

[email protected]SPRINKLER OVERVIEW

Page 1 of 3

Form No. F_080814 18.12.06 Rev 14.1.P65

1. DESCRIPTION

Viking fire sprinklers consist of a threaded frame with a specific waterway or orifice size and a deflector for distributing water in a

specified pattern. A closed or sealed sprinkler refers to a complete assembly, including the thermosensitive operating element. An

open sprinkler does not use an operating element and is open at all times. The distribution of water is intended to extinguish a fire

or to control its spread.

Viking sprinklers are available in several models and styles. Refer to specific sprinkler technical data pages for available styles,

finishes, temperature ratings, thread sizes, and nominal K-Factors for the particular model selected.

2. LISTINGS AND APPROVALS

Refer to the Approval Charts on the appropriate sprinkler technical data page(s) and/or

approval agency listings.

3. TECHNICAL DATA

Pressure Ratings:

Maximum allowable water working pressure is 175 psig (12 Bar) unless rated and specified for high water working pressure [250

psig (17.2 bar)].

Sprinkler Identication:

Viking sprinklers are identified and marked with the word “Viking”, the sprinkler identification number (SIN) consisting of “VK” plus

a three digit number*, the model letter, and the year of manufacture.

Available Finishes:

Viking sprinklers are available in several decorative finishes. Some models are available with corrosion-resistant coatings or are

fabricated from non-corrosive material. Refer to the sprinkler technical data page for additional information.

Available Temperature Ratings:

Viking sprinklers are available in several temperature ratings that relate to a specific temperature classification. Applicable installa-

tion rules mandate the use and limitations of each temperature classification. In selecting the appropriate temperature classifica-

tion, the maximum expected ceiling temperature must be known. When there is doubt as to the maximum temperature at the

sprinkler location, a maximum-reading thermometer should be used to determine the temperature under conditions that would

show the highest readings to be expected. In addition, recognized installation rules may require a higher temperature classifica-

tion, depending upon sprinkler location, occupancy classification, commodity classification, storage height, and other hazards. In

all cases, the maximum expected ceiling temperature dictates the lowest allowable temperature classification. Sprinklers located

immediately adjacent to a heat source may require a higher temperature rating.

K-Factors:

Viking sprinklers are available in several orifice sizes with related K-Factors. The orifice is a tapered waterway and, therefore, the

K-Factor given is nominal. Nominal U.S. K-Factors are provided in accordance with the 1999 edition of NFPA 13, Section 3-2.3.

Refer to the specific data page for appropriate K-Factor information.

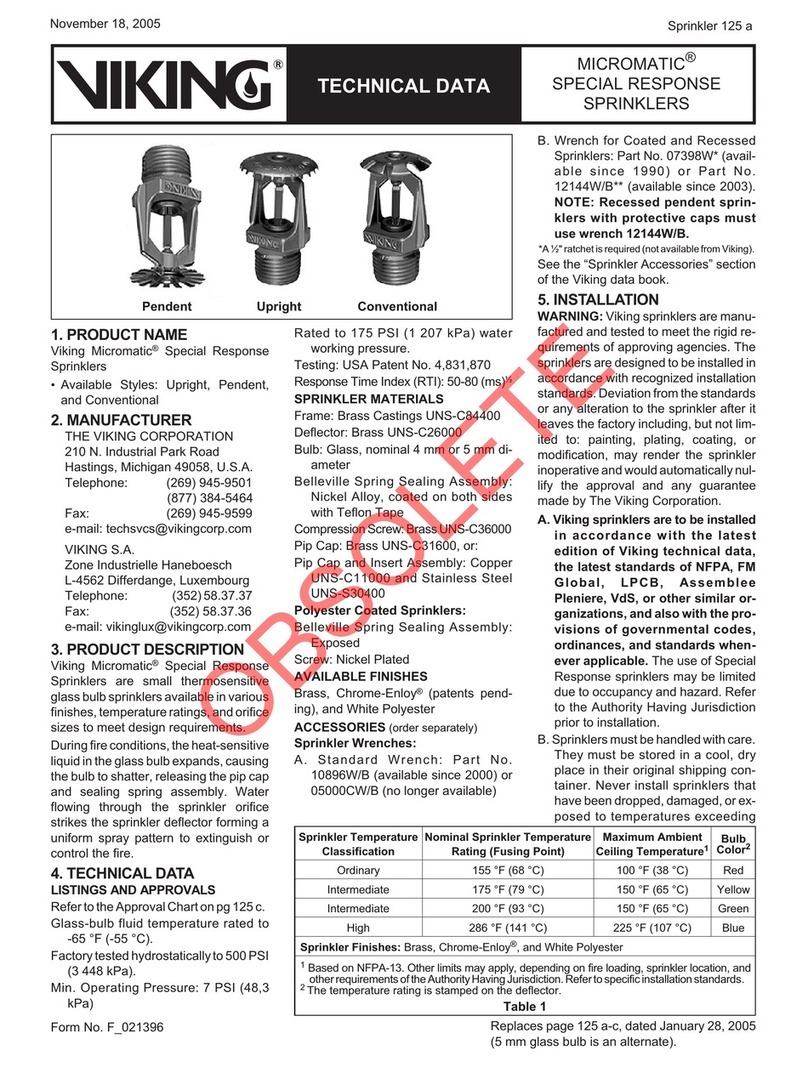

Available Styles:

Viking sprinklers are available for installation in several positions as indicated by a stamping on the deflector. The deflector style

dictates the appropriate installation position of the sprinkler; it breaks the solid stream of water issuing from the sprinkler orifice to

form a specific spray pattern. The following list indicates the various styles and identification of Viking sprinklers.

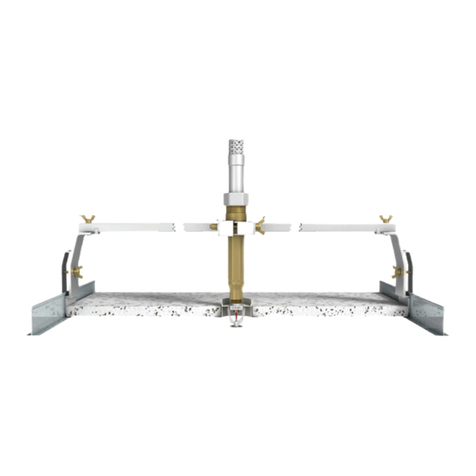

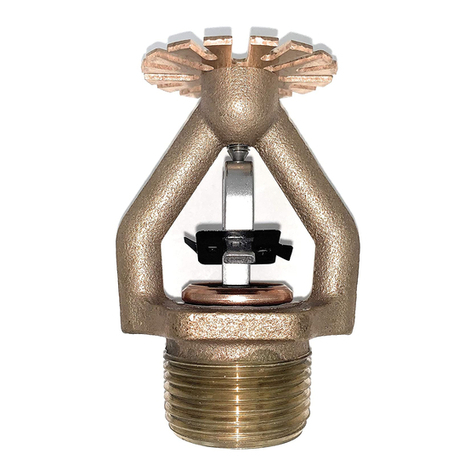

UPRIGHT SPRINKLER:A sprinkler intended to be installed with the deflector above the frame so water flows upward through the

orifice, striking the deflector and forming an umbrella-shaped spray pat-

tern downward. Marked “SSU” (Standard Sprinkler Upright) or “UPRIGHT”

on the deflector.

PENDENT SPRINKLER:A sprinkler intended to be oriented with the deflec-

tor below the frame so water flows downward through the orifice, striking

the deflector and forming an umbrella-shaped spray pattern downward.

Marked “SSP” (Standard Sprinkler Pendent) or “PENDENT” on the de-

flector.

CONVENTIONAL SPRINKLER:An “old style” sprinkler intended to be installed with the deflector in either the upright or pendent

position. The deflector provides a spherical type pattern with 40 to 60 percent of the water initially directed downward and a

proportion directed upward. Must be installed in accordance with installation rules for conventional or old style sprinklers. DO

NOT USE AS A REPLACEMENT FOR STANDARD SPRAY SPRINKLERS. Marked “C U/P” (Conventional Upright/Pendent) on

the deflector.

Viking Technical Data may be found on

The Viking Corporation’s Web site at

http://www.vikinggroupinc.com.

The Web site may include a more recent

edition of this Technical Data Page.

Replaces Form No. F_080814 Rev 14.1

(Added P65 Warning.)