Spe ifi ations

9

Spe ifi ations

8

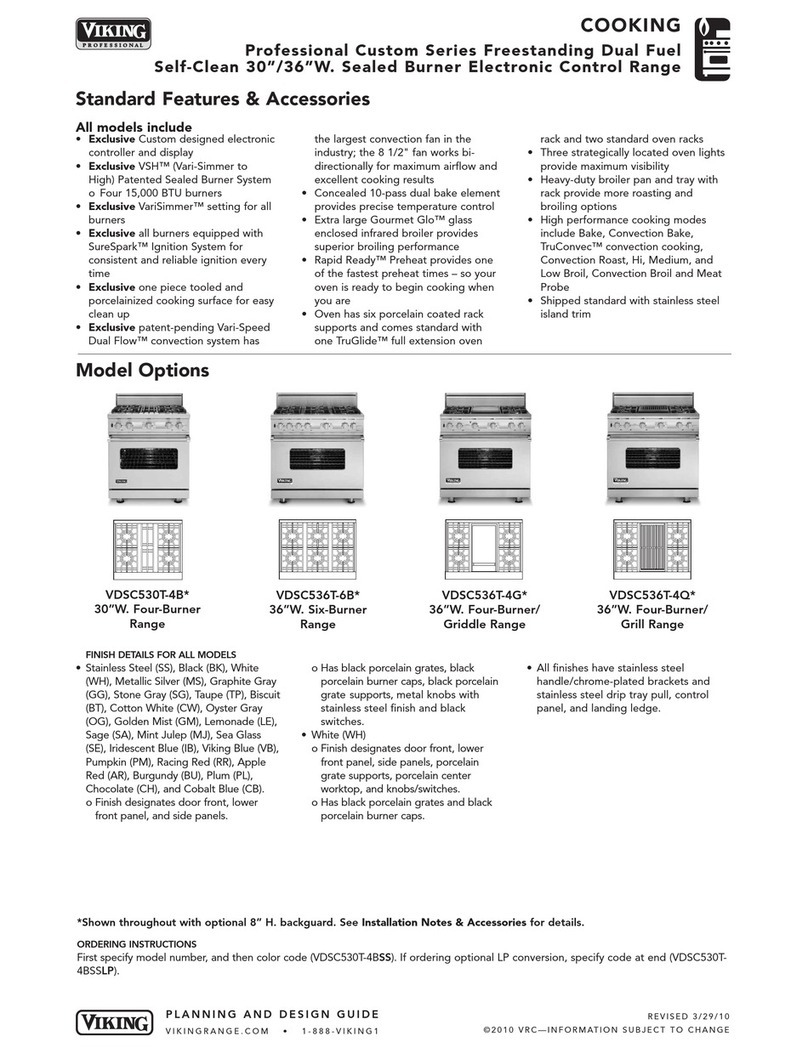

Dual Fuel 30” and 36” W. Ranges

Description

30” W. Models 36” W. Models

Overall width 29-7/8”

(75.9 m)

35-7/8”

(91.1 m)

Overall height To top of side trim - 35-7/8” (91.1 m) min. 37” (94.0 m) max.

Legs adjust - 1-1/8” (2.9 m)

Overall depth

from rear

To end of side panel - 24-5/16” (61.8 m)

To front of door - 25-3/4” (65.4 m)

To end of landing ledge - 28-1/16” (71.2 m)

To end of door handle - 28-11/16” (72.9 m)

Additions to Base

Height

To top of island trim - add 1” (2.5 m)

To top of ba kguard - add 8” (20.3 m)

To top of high shelf - add 23-1/2” (59.7 m)

Gas Requirements Shipped Natural or LP/Propane, field onvert with onversion kit (pur hased separately);

a epts standard residential 1/2” (1.3 m) ID gas servi e line

Gas Manifold Pressure Natural 5.0” W.C.P./ Liquid Propane L/P 10.0” W.C.P.

Ele tri al Requirements See Ele tri al Requirements information.

Max Amp Usage 240V - 25.4 amps

208V - 22.9 amps

240V - 28.5 amps

208V - 24.7 amps

Surfa e Burner Rating

Natural/LP 18,500 BTU (5.4 kW)/16,600 BTU (4.9 kW)

15,000 BTU (4.4 kW)/12,500 BTU (3.7 kW)

Griddle Burner Rating NA 15,000 BTU Nat./12,500 BTU LP/Propane

(4.4 kW Nat/ 3.7 kW LP)

Grill Burner Rating NA 18,000 BTU Nat./16,000 BTU LP/Propane

(5.3 kW Nat/ 4.7 kW LP)

Oven(s) Interior Width 25-5/16” (64.6 m) 30-5/16” (76.9 m)

Oven(s) Interior Height 16-1/2” (41.9 m)

Oven(s) Interior Depth Overall - 19-1/2” (49.5 m) AHAM 16-13/16” (42.7 m)

Oven(s) Volume

Overall

AHAM

4.7 u. ft.

4.1 u. ft.

5.6 u. ft.

4.9 u. ft.

Approximate

shipping weight

410 lbs.

(184.5 kg)

500 lbs.

(225 kg)

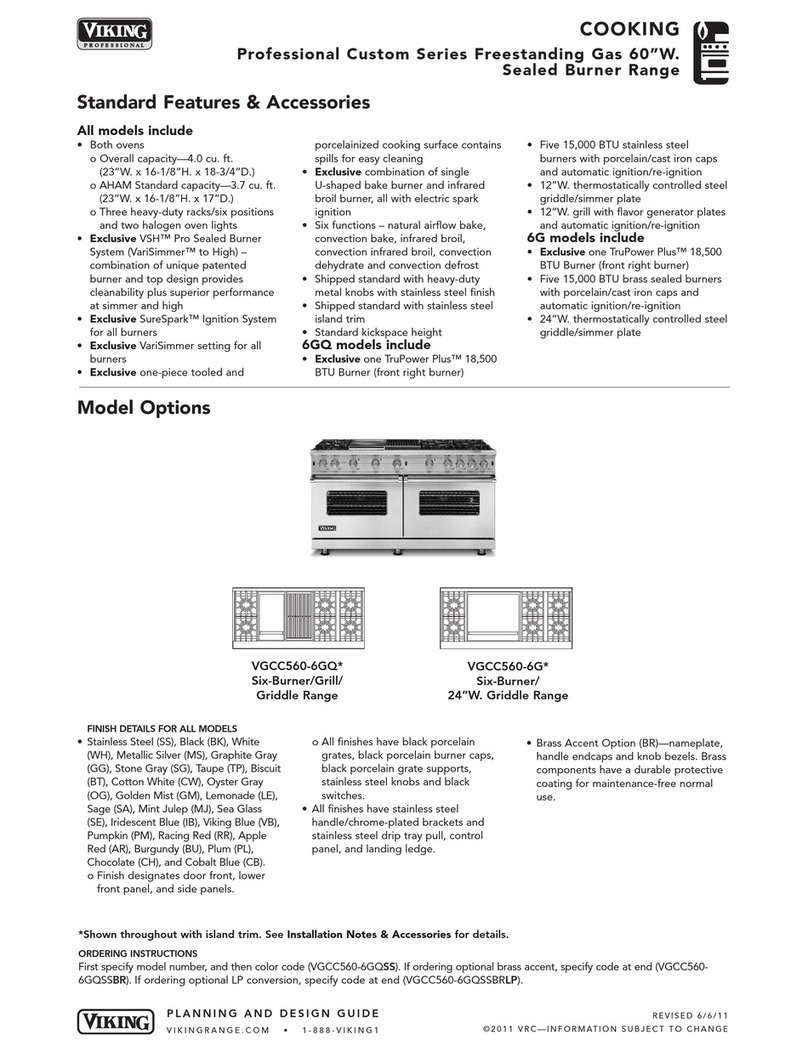

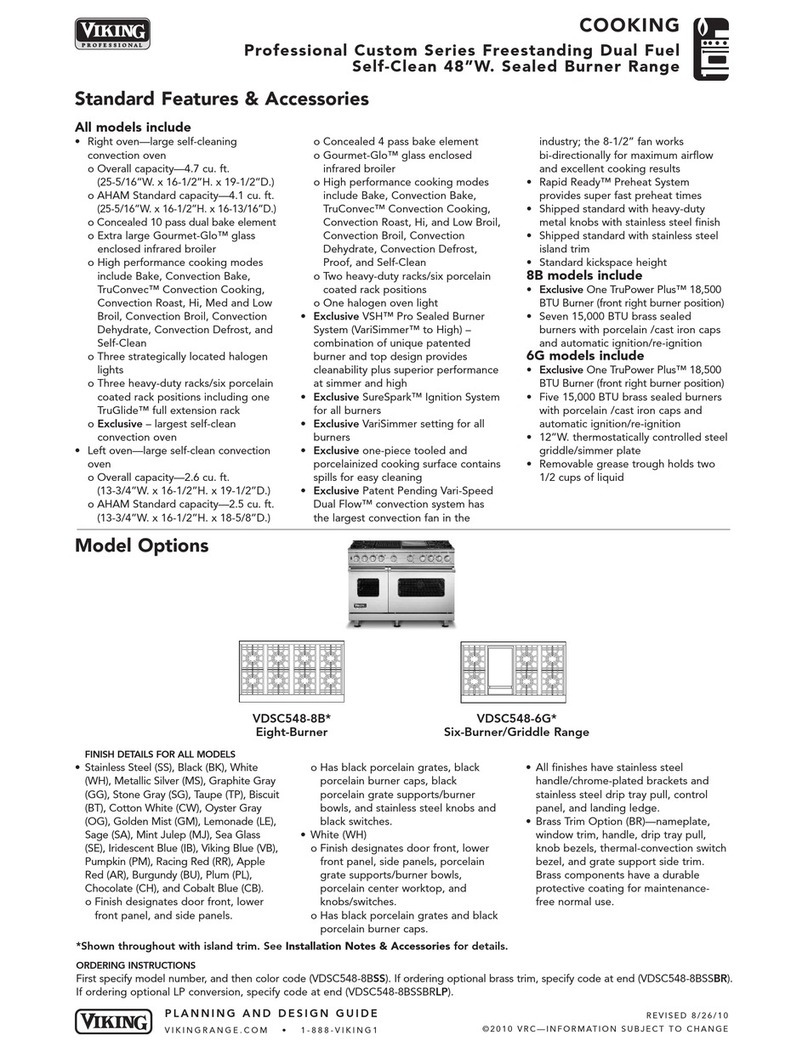

Dual Fuel 48” and 60” W. Ranges

Description

48” W. Models 60” W. Models

Overall width 47-7/8”

(121.6 m)

60”

(152.4 m)

Overall height To top of side trim - 35-7/8” (91.1 m) min. 37” (94.0 m) max.

Legs adjust - 1-1/8” (2.9 m)

Overall depth

from rear*

To end of side panel - 24-5/16” (61.8 m)

To front of door - 25-3/4” (65.4 m)

To end of landing ledge - 28-1/16” (71.2 m)

To end of door handle - 28-11/16” (72.9 m)

*Add 3/4” (1.9 m) to overall depth for 48” and 60”W. VDSC models installed against a

ombustible wall.

Additions to Base

Height

To top of island trim - add 1” (2.5 m)

To top of ba kguard - add 8” (20.3 m)

To top of high shelf - add 23-1/2” (59.7 m)

Gas Requirements Shipped Natural or LP/Propane, field onvert with onversion kit (pur hased separately);

a epts standard residential 1/2” (1.3 m) ID gas servi e line

Gas Manifold Pressure Natural 5.0” W.C.P./ Liquid Propane L/P 10.0” W.C.P.

Ele tri al Requirements See Ele tri al Requirements information.

Max Amp Usage 240V - 37 amps

208V - 32 amps

240V - 40 amps

208V - 34.7 amps

Surfa e Burner Rating

Natural/LP

18,500 BTU (5.4 kW)/16,600 BTU (4.9 kW)

15,000 BTU (4.4 kW)/12,500 BTU (3.7 kW)

Griddle Burner Rating 15,000 BTU Nat./12,500 BTU LP/Propane

(4.4 kW Nat/ 3.7 kW LP)

Grill Burner Rating 18,000 BTU Nat./16,000 BTU LP/Propane

(5.3 kW Nat/ 4.7 kW LP)

Oven(s) Interior Width Right - 25-5/16” (64.6 m)

Left - 13-3/4” (34.9 m)

25-5/16” (64.6 m)

Oven(s) Interior Height 16-1/2” (41.9 m)

Oven(s) Interior Depth Overall - 19-1/2” (49.5 m) AHAM 16-13/16” (42.7 m)

Oven(s) Volume

Overall

AHAM

Right - 4.7 u. ft. Left - 2.6 u. ft.

Right - 4.1 u. ft. Left - 2.2 u. ft.

Both Ovens 4.7 u. ft.

Both Ovens 4.1 u. ft.

Approximate

shipping weight

575 lbs.

(258.8 kg)

750 lbs.

(337.5 kg)

Minimum learan es from adja ent ombustible onstru tion:

Below ooking surfa e (36” [91.4 m] and below)

• Sides - 0”

• Top grate support - 36” (91.4 m)

Above ooking surfa e (above 36” [91.4 m])

• Sides - 6” (15.2 m)

• Within 6” (15.2 m) side learan e, wall abinets no deeper than 13” (33.0 m) must be minimum 18” (45.7 m)

above ooking surfa e

• Wall abinets dire tly above produ t must be a minimum of 42” (106.7 m) above ooking surfa e

• Rear - 0” with 8” ba kguard or high shelf; 0” with island trim and non- ombustible rear wall;

• 6” (15.2 m) with island trim and ombustible rear wall

Minimum learan es from adja ent ombustible onstru tion:

Below ooking surfa e (36” [91.4 m] and below)

• Sides - 0”

• Top grate support - 36” (91.4 m)

Above ooking surfa e (above 36” [91.4 m])

• Sides - 6” (15.2 m)

• Within 6” (15.2 m) side learan e, wall abinets no deeper than 13” (33.0 m) must be minimum 18” (45.7 m)

above ooking surfa e

• Wall abinets dire tly above produ t must be a minimum of 42” (106.7 m) above ooking surfa e

• Rear - 0” with 8” ba kguard or high shelf; 0” with island trim and non- ombustible rear wall;

• 6” (15.2 m) with island trim and ombustible rear wall