3

GENERAL INFORMATION

UUnnppaakk

1. Remove banding from bottom of arton. Lift arton up and off of the wine ellar

2. Remove all tape and pa kaging material from the outside and inside of the abinet.

3. Keep all arton pa kaging until your wine ellar has been thoroughly inspe ted and found to be in good ondition.

AARREEAA RREEQQUUIIRREEMMEENNTTSS

1. Pla e unit so the front side will be ompletely unobstru ted to provide proper air flow. The unit may be losed in

on the top and three sides, but the front MMUUSSTT BBEEunobstru ted for air ir ulation and proper operation.

Installation should be su h that the abinet an be moved for servi ing if ne essary.

2. Unit should be in a well ventilated area with temperature above 55°F (13°C) and below 110°F (43°C). Best results

are obtained at temperatures between 65°F (18°C) and 80°F (27°C) for built-in models and 65°F (18°C) and 90°F

(32°C) for freestanding models.

3. Provisions for ele tri ity should be determined before pla ing unit in proper pla e.

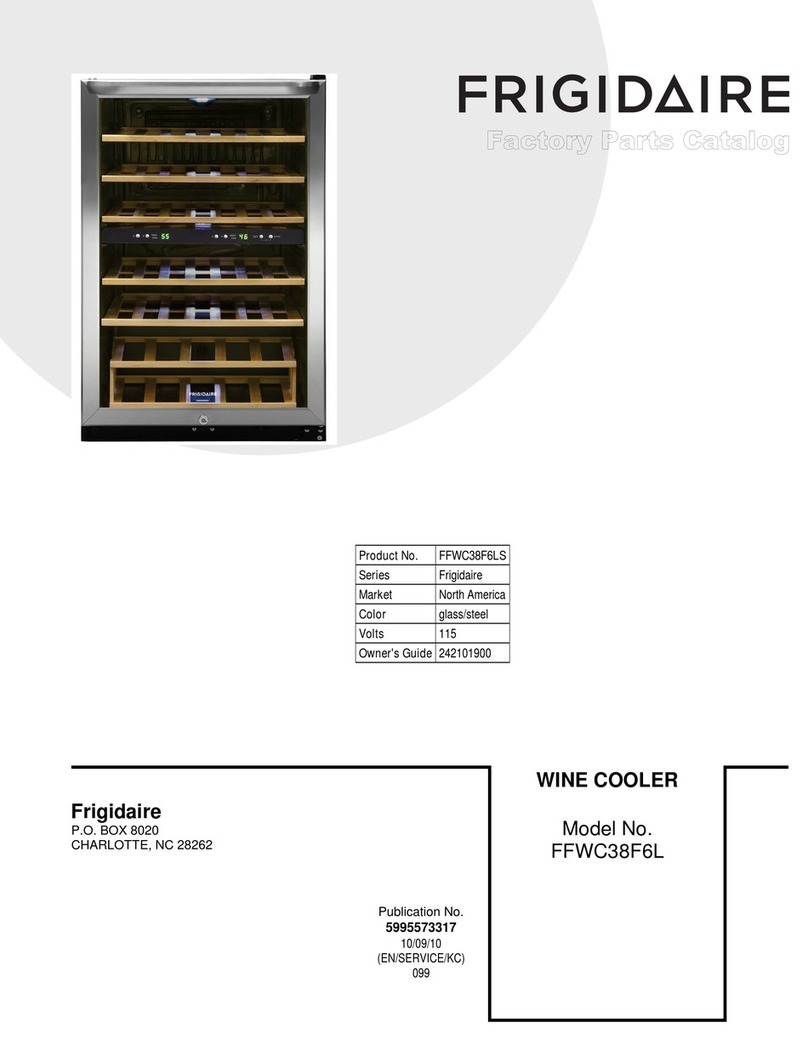

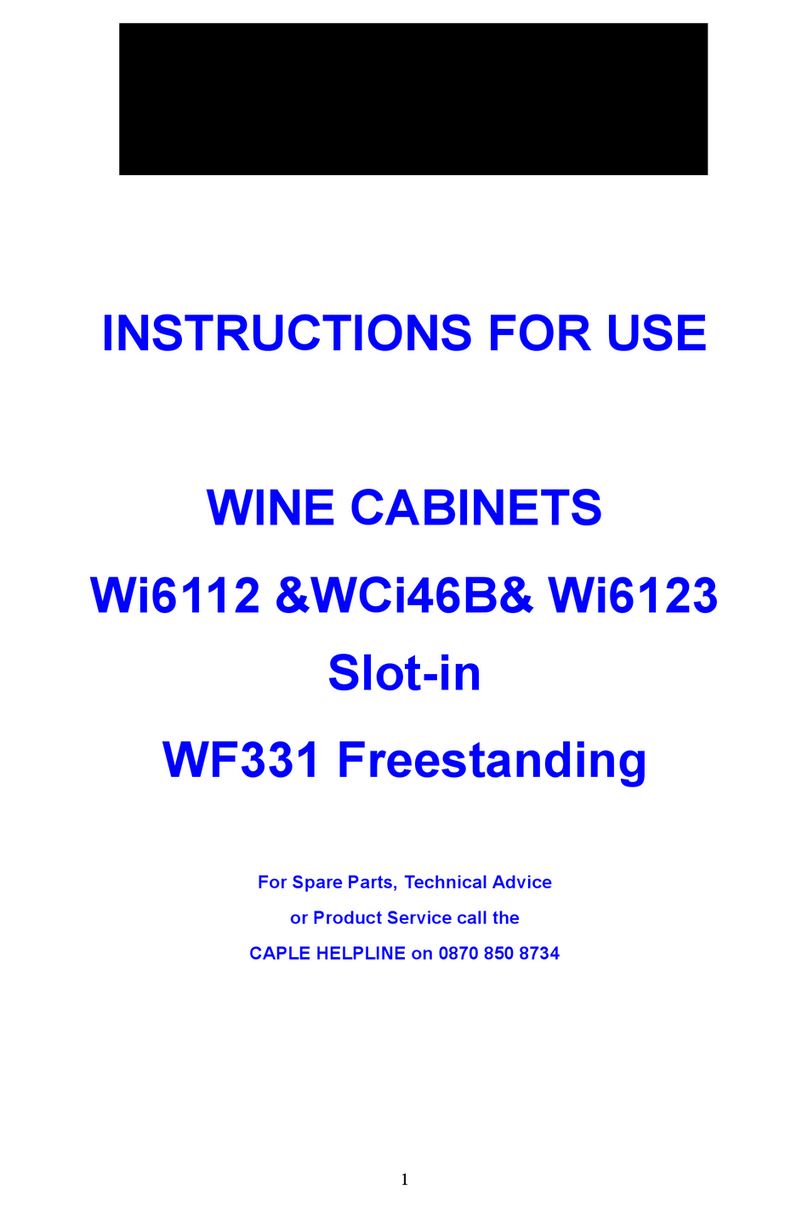

A

B

C

UUNNDDEERRCCOOUUNNTTEERR CCAABBIINNEETT CCUUTTOOUUTT

IMPORTANT - PLEASE READ AND FOLLOW

•• Before beginning, please read these instru tions ompletely and arefully.

• Do not remove permanently affixed labels, warnings, or plates from the produ t. This may void the warranty.

• Please observe all lo al and national odes and ordinan es.

• Please ensure that this produ t is properly grounded.

• The installer should leave these instru tions with the onsumer who should retain for lo al inspe tor’s use and for

future referen e.

WARNING::

TToo rreedduuee tthhee rriisskk ooff ffiirree,, eelleettrriiaall sshhookk,, oorr iinnjjuurryy wwhheenn uussiinngg yyoouurr wwiinnee eellllaarr,, ffoollllooww bbaassii pprreeaauuttiioonnss iinnlluuddiinngg tthhee

ffoolllloowwiinngg::•FOR YOUR SAFETY•

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCE. THE FUMES CAN CREATE A FIRE HAZARD OR EXPLOSION.

IItt iiss yyoouurr rreessppoonnssiibbiilliittyy ttoo bbee ssuurree yyoouurr wwiinnee eellllaarr iiss::

•lo ated so the front is not blo ked to restri t in oming or dis harge air flow.

•properly leveled.

•lo ated in a well ventilated area.

• onne ted to the proper kind of outlet, with the orre t ele tri supply and grounding. A 115 volt, 60 Hz, 15 amp

fused ele tri al supply is required. NNOOTTEE::Time delay fuse or ir uit breaker is re ommended.

•not used by anyone unable to operate it properly.

•used only for its intended purpose.

•properly maintained.

•SAVE THESE INSTRUCTIONS•

SUFFOCATION HAZARD

Remove door from your old refrigeration unit.

Failure to do o can re ult in child entrapment,

which can cau e death or brain damage.

IMPORTANT: Child entrapment and uffocation are not problem of the

pa t. Junked or abandoned refrigeration product are till dangerou ,

even if they will it for “ju t a few day .” If you are getting rid of your

refrigeration product, plea e follow the in truction below to help prevent

accident .

BEFORE YOU THROW AWAY YOUR OLD REFRIGERATION UNIT:

•Take off the doors.

•Leave the shelves in pla e so that hildren may not easily limb inside.

PROPER DISPOSAL OF YOUR OLD REFRIGERATION UNIT

2

DANGER

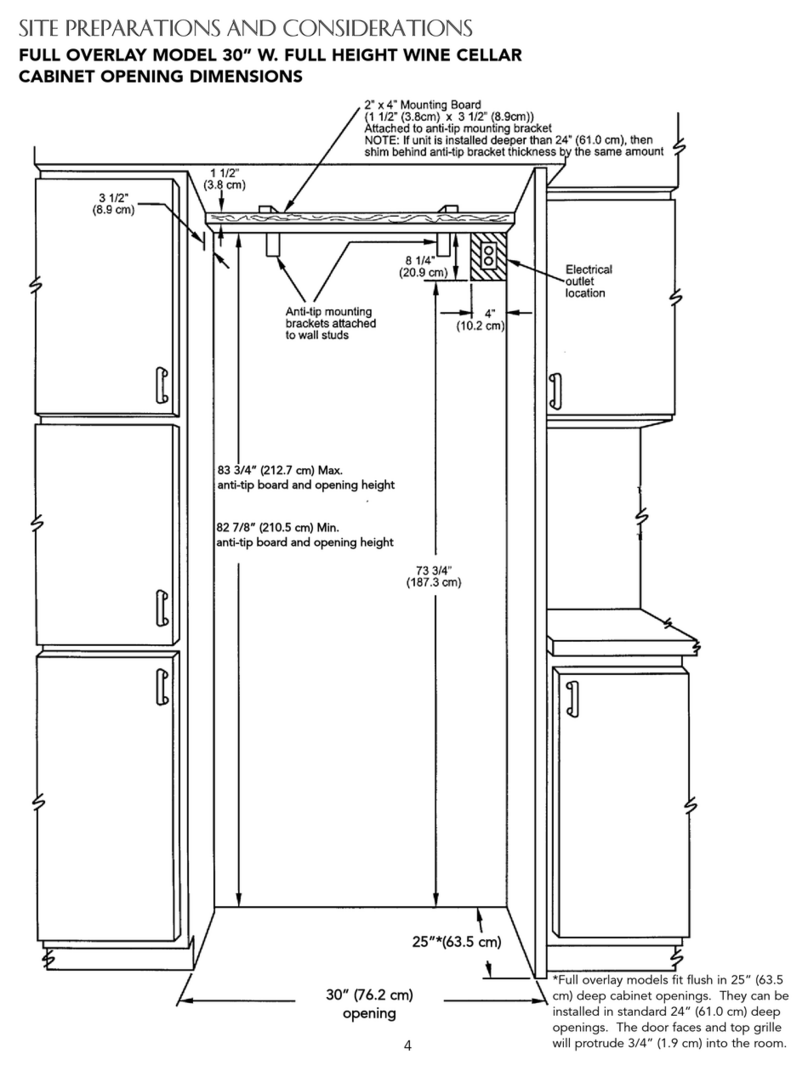

24” W. Models

15” W. Models

*Add 1/4” (.64 m) to utout width if door is re essed between

abinets.

A 15” (38.1 m)* 24” (61.0 m)*

BMin. 34 1/2” (87.6 m)

Max. 35 1/8” (89.2 m)

Min. 34 1/2” (87.6 m)

Max. 35 1/8” (89.2 m)

C 24” (61.0 m) 24” (61.0 m)

UUnniittss CCeerrttiiffiieedd ffoorr OOuuttddoooorr UUssee -- ((ssttaaiinnlleessss sstteeeell oouutteerr aabbiinneett))

1. Pla e unit so the front side will be ompletely unobstru ted to provide proper air flow. The unit may be losed in

on the top and three sides, but the front MMUUSSTT BBEEunobstru ted for air ir ulation and proper operation.

Installation should be su h that the abinet an be moved for servi ing if ne essary.

2. Unit should be in a well ventilated area with temperature above 40°F (4.4°C) and below 110°F (43°C). Best results

are obtained at temperatures between 60°F (16°C) and 100°F (38°C).

3. Provisions for ele tri ity should be determined before pla ing unit in proper pla e.