1.1 PREMESSA

Manual identified by code No. 03/2013- UK -

REV B- 07 - MH90 has 44 pages.

IMPORTANT

At the delivery of this manual checks all

data and for possible incongruities.

VIME reserves the right to improve its

products through changes in designed or ma-

terials as it may seem desirable without being

obligated to incorporate such changes in this

manual.

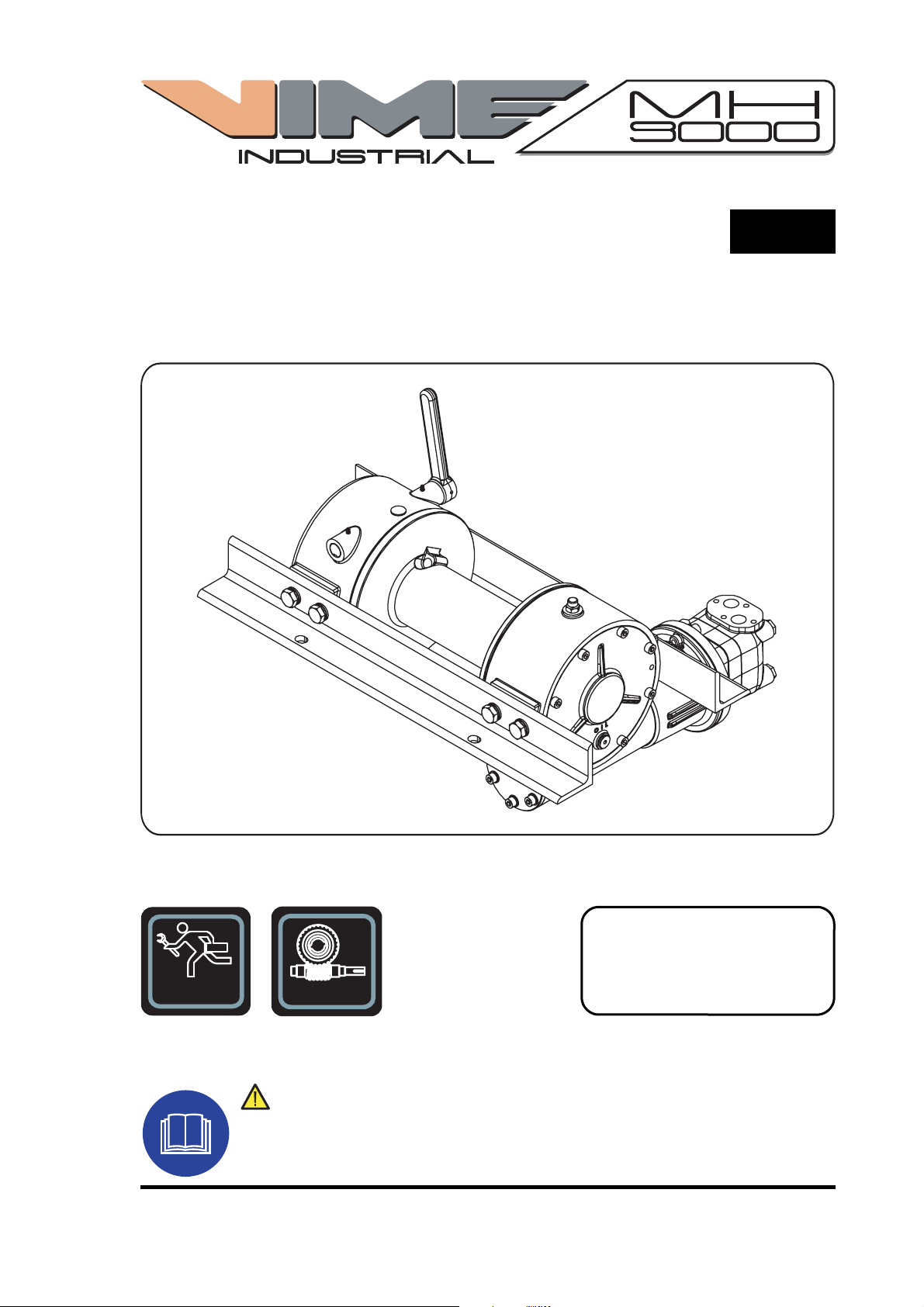

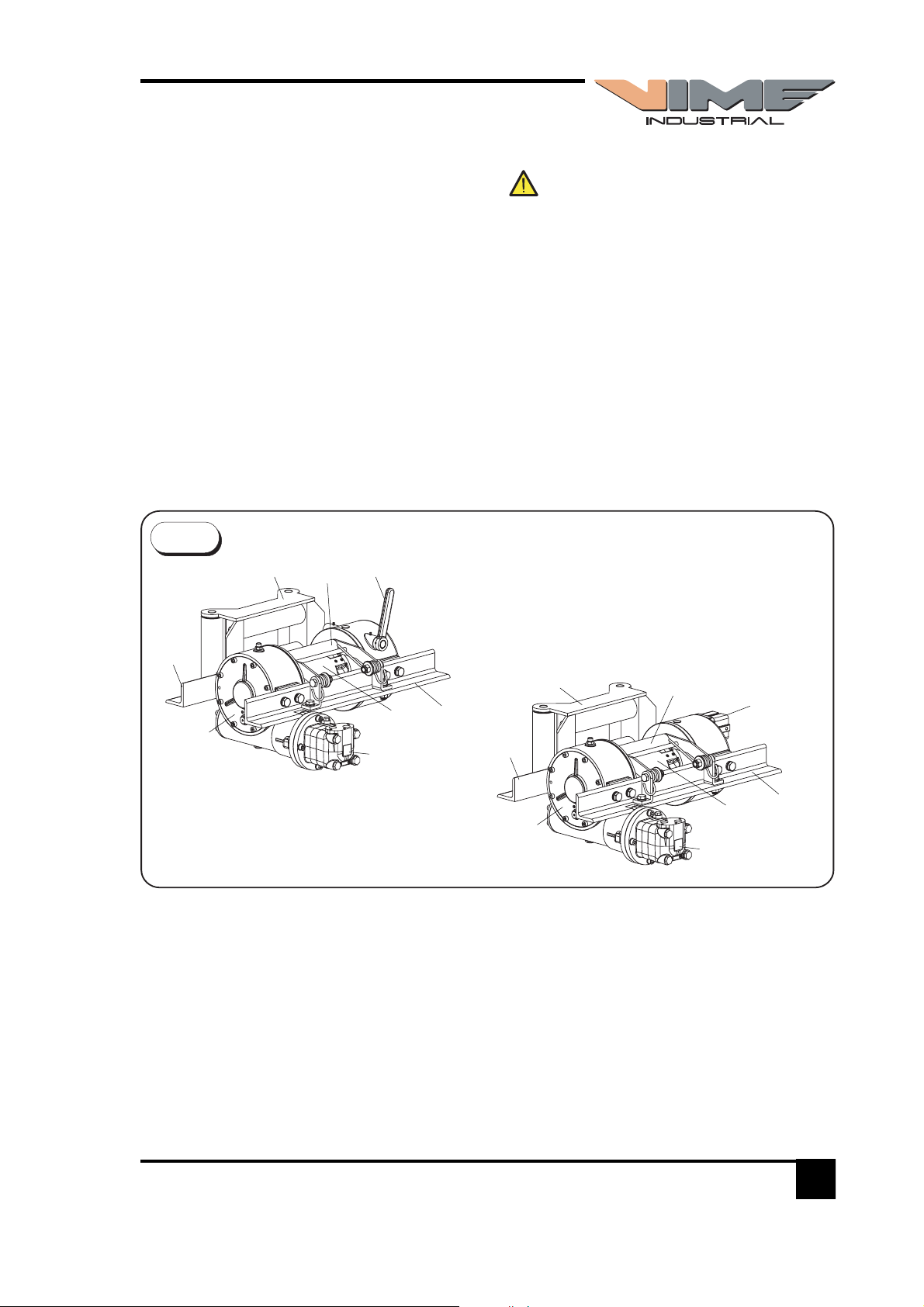

This manual contains useful ideas in obtaining

the most efficient operation and maintenance

from the winch and safety procedures one

need to know before operating a winch.

For safety procedures, read carefully safety

procedures in chapter 1.7.

Manual has to be kept intact and near to the

winch for a prompt reading and consultation.

WARNING

In case of misunderstanding of this

manual or parts of it, please contact

VIME. For repair service contact VIME.

For a rapid consultations, manual is being

shared in 7 sections:

Section 1 Safety procedures

Section 2 Mounting

Section 3 Operation

Section 4 Accessories

Section 1 Safety procedures

Section 5 Maintenance

Section 6 Trouble shooting guide

Section 7 Parts list

Section 1contains warning symbols, winch

description and alls data for SAFETY

PROCEDURES. Section 2contains note about

road traffic, hydraulic system, winch and ca-

ble drum installations. Section 3 contains alls

data for winch operations. Section 4accesso-

ries description. Section 5is referred to the

operator in charge of the winch maintenance.

In this section are indicated all procedures as

well as the maintenance must be executed in

winch life. Section 6is a guide for a trouble

shooting should verify in winching operation.

Section 7contains parts list codes and parts

drawing. All sections are shared in chapters

progressive numbered. Chapters are shared in

subsections progressive numbered.

IMPORTANT

For a rapid reading see table of contents.

SECTION 1

SAFETY PROCEDURES

4

The Quality is Transparent