7602030

21

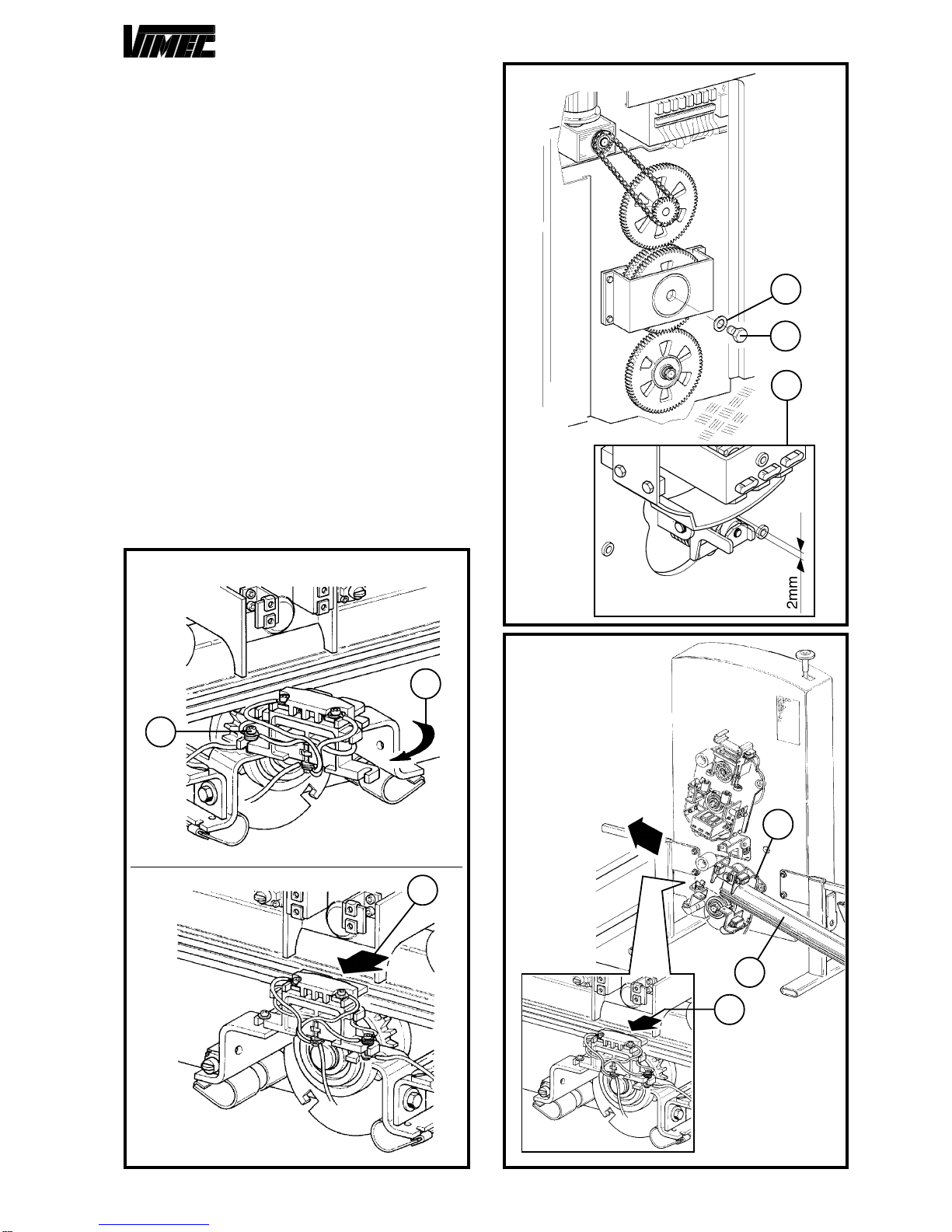

In order to facilitate the assembly operation for the wall

fastening (Fig. 10/a), it is advisable using the special

testfeet (Fig. 10/b) (ask the Vimec servicedepartment,

as they are not supplied) to insert on the guide instead

ofthe middle fastenings (almost 1-2everyramp).

NOTE: Before carrying out any machine handling test,

the connection (Fig. 10/a) must be fixed to the wall.

3) INSTALLING THE UPPER RAIL

- Position the spacing gauges (Fig. 11/a) (ask the Vimec

service department, as they are not supplied), on the

extremeedgesof thefirstpositionedguidesection (Fig.

11/b) (curve) and block them hard rotating the lever as

showninfigure (Fig.11/c).

- By loosening the handwheel (Fig. 12/a) and using a

spirit level (Fig. 12/b), position the support arm (Fig.

12/c)in perfectlyvertical position.Once theadjustment

hasbeendone,tightenthehandwheelhard(Fig.12/a).

- Position the upper guide (Fig. 13/a) on the spacing

gauges(Fig. 13/b)formerlypositioned, andafter having

checked the correct vertical sense (Fig. 13/c),

tightenthescreews(Fig.13/d)hard.

CAUTION: The couple securing the guide fixing

screws (Fig. 13/d) must be 6-7 daNm.

-Carryouttheassemblyofalltheguidesectionsremained,

proceeding in sequence as formerly described down to

thebottom of the scaleexcept the last one.If included

in the kit, insert the cable for push-button panles (Fig.

12/e)duringtheguidesconnection.

-When finished the assembly,retouch guideswithsup-

pliedblack paint andseal the screws(Fig.9/g) andthe

nuts (Fig. 9/h) of the busway junction.

FIG.10

FIG.11

FIG.13

FIG.12

a

c

ab

c

a

b

b

a

0±1

mm

ed

a

b

c