8

a

a

b

b

7511001

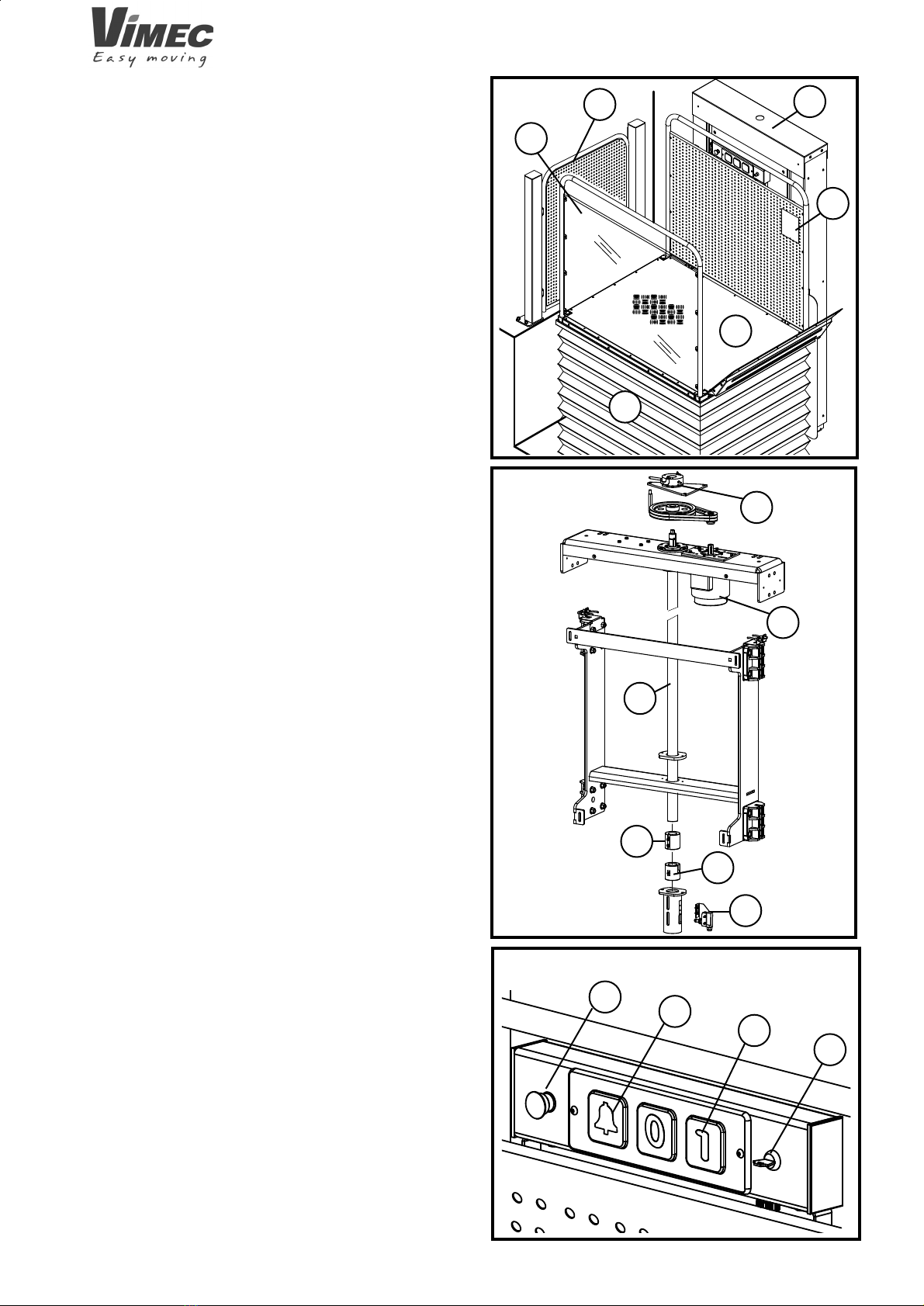

6) PREPARING THE LIFT FOR OPERATION

6.1) Electrical panel and installation

The customer is required to make all necessary mo-

difications required to the stairwell (before deliv¬ery),

providing a water drain in outdoor installations if requi-

red, and also to arrange for the handling of the parts

delivered.

The customer is also responsible, at his own expense,

for construction of the dedicated electricity supply line

to our panel, with conductors having gauge of at least

2.5 mm2 and differential security circuit breaker with

rated load 16A and sensitivity 0.03A installed in a box

with padlock fixture close to the unit control panel,

having IP54 protection and earthed by means of 2.5

mm2 cable. All expenses for making-good after instal-

lation and any testing procedures shall also be for the

customer’s account.

The Customer shall ensure lighting of at least 50 LUX

for the landings and lift platform, with switch adjacent

to the platform.

Automatic emergency light in lift shaft 1Wx1 hour, 24

VDC emergency alarm with independent power supply

to be connected to the circuit (emergency button).

The customer shall be responsible for ensuring the

strength and finishing of walls where necessary (dise-

mbarkation side).

The customer is also responsible for ensuring the

strength of the floors.

N.B.: Data are guideline and not binding.

The manufacturer reserves the right to make any chan-

ges it considers appropriate.

7) CORRECT USE OF THE PLATFORM LIFT

WARNING: READ THIS MANUAL CAREFULLY

BEFORE USING THE PLATFORM LIFT.

7.1) Start-up

- The platform lift is started up by simply powering up the

control panel, after connecting all the cable sheaths

between the unit and the gate.

- The lift can be left constantly powered up.

Checks to be performed before using the

platform lift:

Skill level required: O - Trained operator

Frequency: Before use

7.2) Check that the load to be lifted does not exceed

the payload stated on the nameplate and is evenly

distributed over the platform surface.

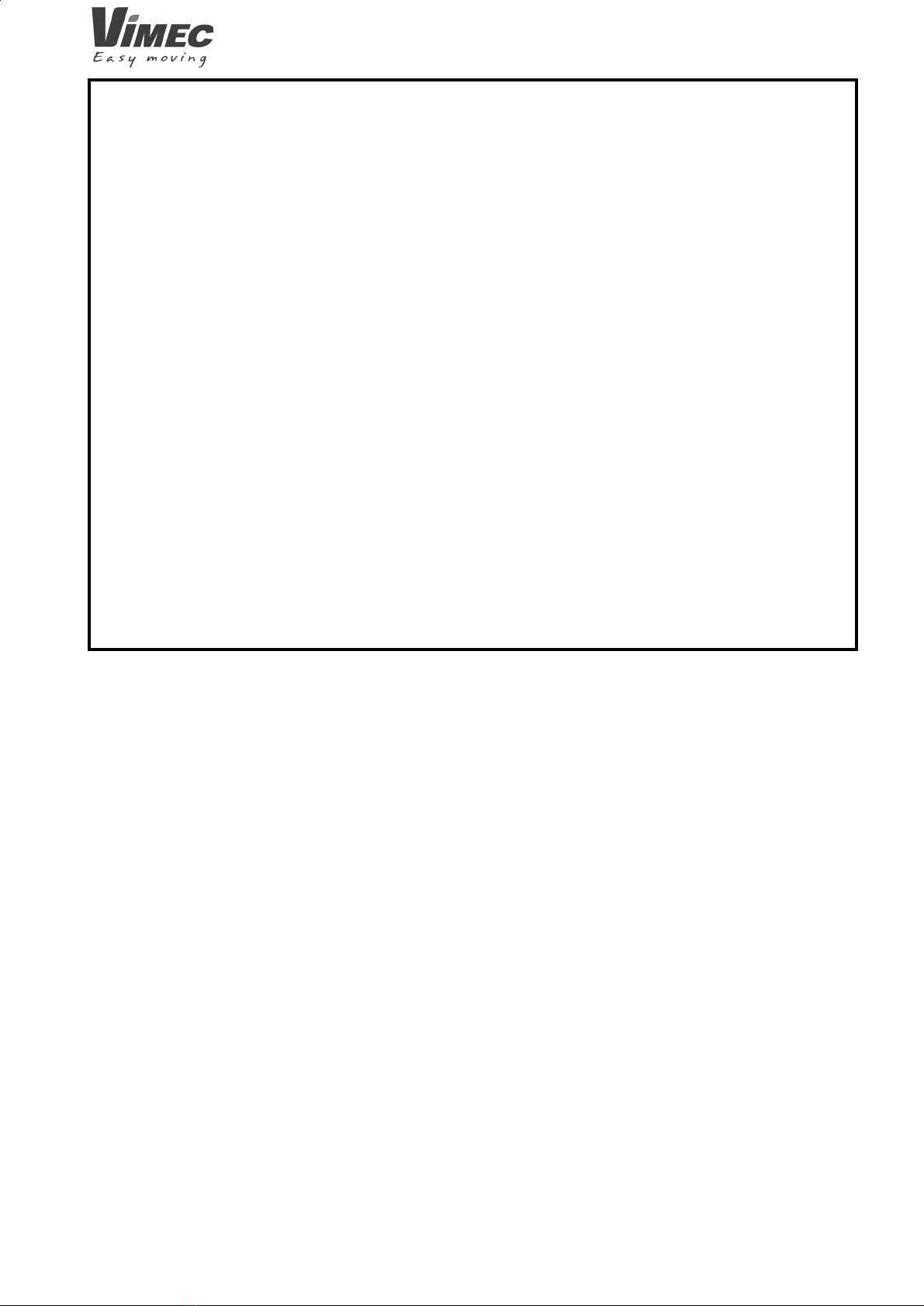

FIG.5

7.3) Ensure that the load is stable.

7.4) Check that there are no foreign bodies underneath

the platform.

7.5) Check that the platform is not working in a

hazard¬ous environment (dust, salt, flammable or

explosive substances).

7.6) Controls at the floors

The control panel on the gate or the rear of the unit

contains the following devices (Fig. 5):

- Control board master key-switch (Fig. 5/a).

- Call button (Fig. 5/b).

7512001