Overview'of'the'Hydrosense'Water'Detection'System'..............................................'2!

Detection'Components'.........................................................................................................'3!

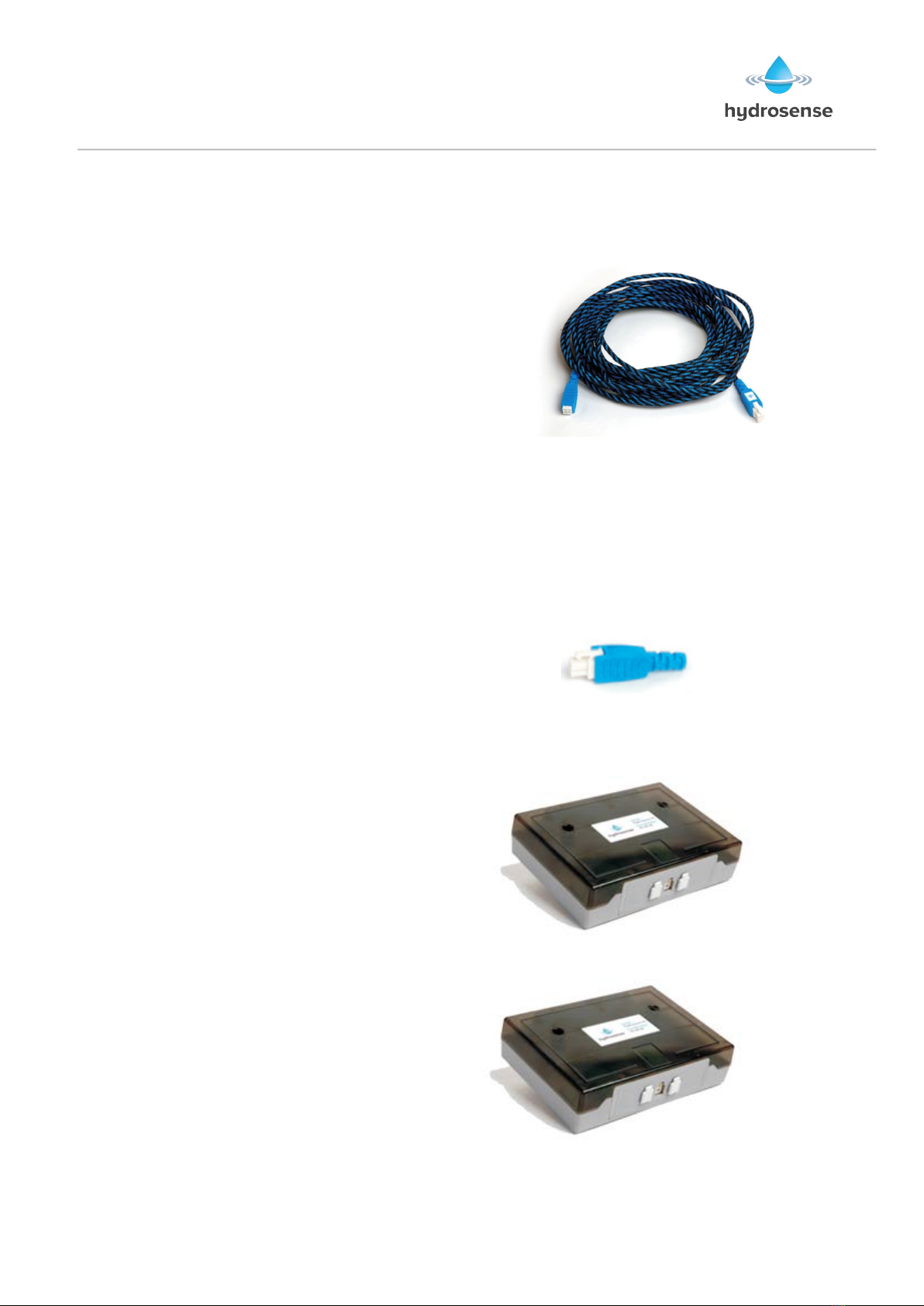

Linear!Detection-!Hydrowire!Cable!.........................................................................................................!3!

Linear!Detection!EOL!.....................................................................................................................................!3!

Linear!Detection!Connection!Interface!...................................................................................................!3!

Floor!Probe!Junction!Box!..............................................................................................................................!3!

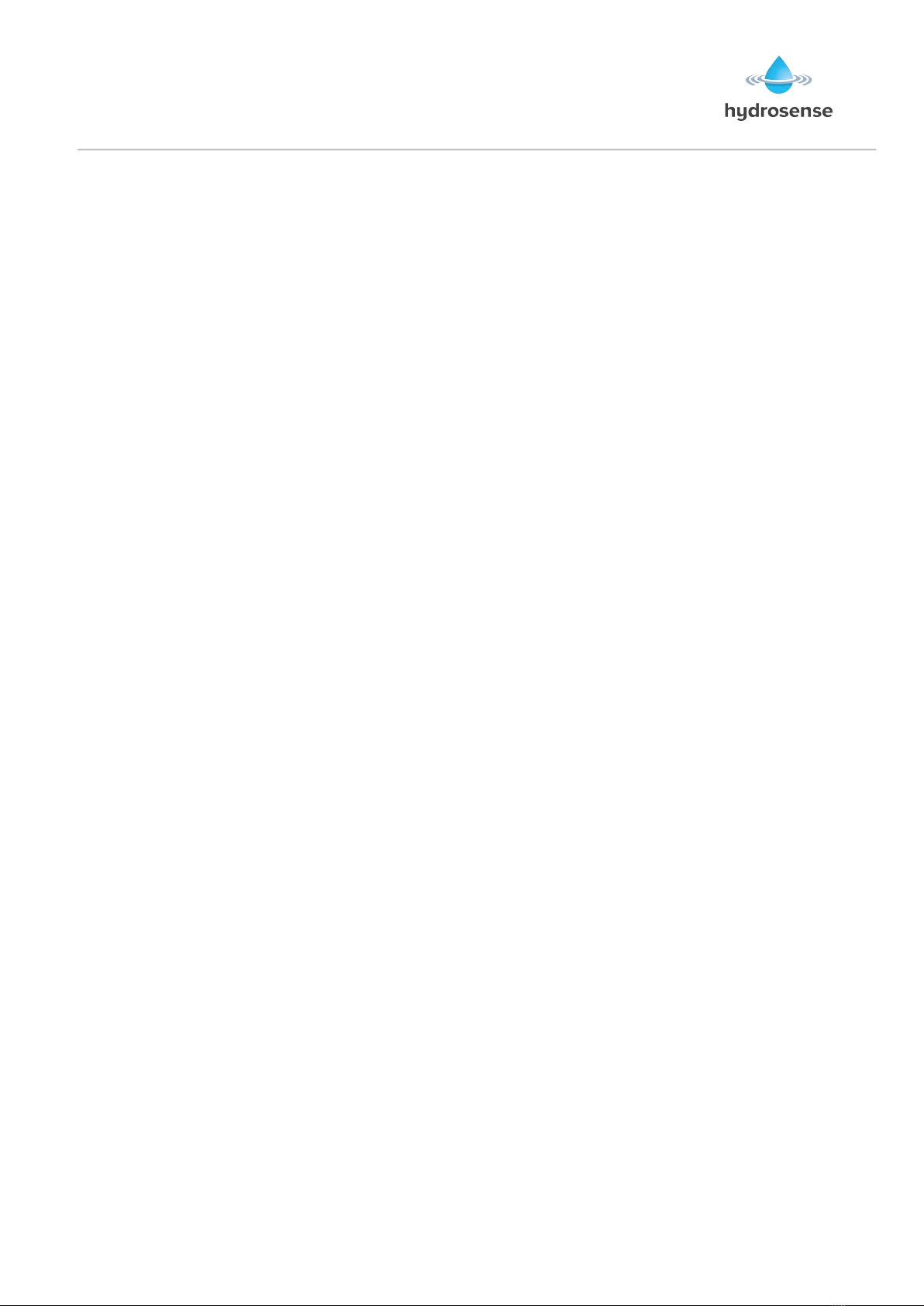

Point!Detection!Floor!Probe!........................................................................................................................!4!

Control'and'Indicating'Equipment'of'a'Hydrosense'System'...................................'4!

Control!Panel!(2!to!8!Zones)!.......................................................................................................................!4!

Hydrosense!Mimic!Panels!............................................................................................................................!4!

System!components:!.......................................................................................................................................!5!

System!Options!.................................................................................................................................................!5!

Design'&'Planning'..................................................................................................................'5!

Design!Notes!......................................................................................................................................................!5!

Design!Guidelines!............................................................................................................................................!6!

Hydrosense!Floor!Probe:!..............................................................................................................................!6!

Hydrowire!Cable:!.............................................................................................................................................!6!

System!Installation!Notes!.............................................................................................................................!6!

Panel'Installation'...................................................................................................................'7!

Safety!.....................................................................................................................................................................!7!

Panel!Mounting!.................................................................................................................................................!7!

Removing!the!front!facia!...............................................................................................................................!8!

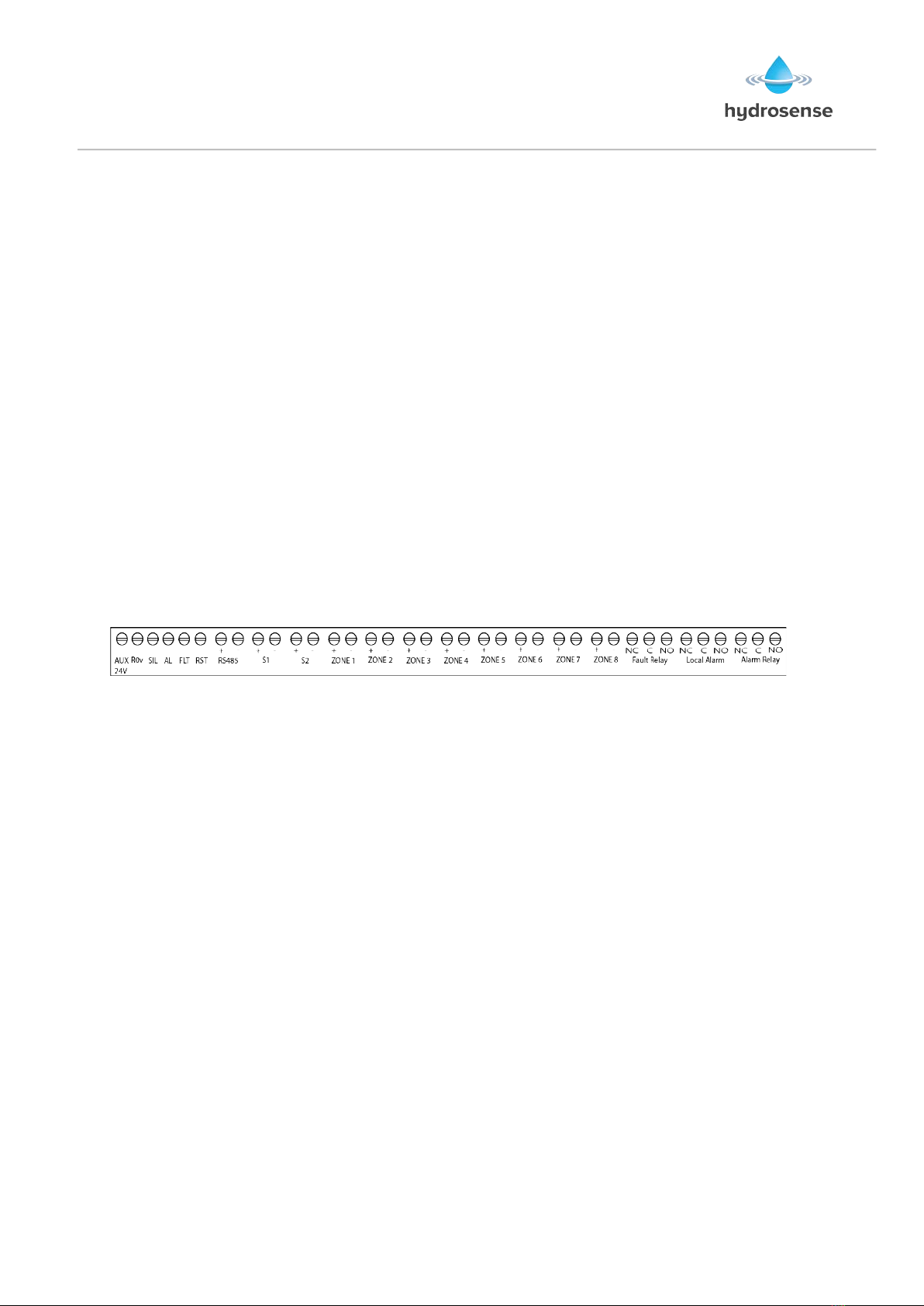

Control!relays!.................................................................................................................................................!12!

Access!level!2!configuration!options!....................................................................................................!13!

Access!level!3!configuration!options!....................................................................................................!14!

Internal!Switches!..........................................................................................................................................!16!

Watchdog!Reset!switch!(W/Dog!Reset)!..............................................................................................!16!

Processor!Reset!.............................................................................................................................................!16!

Internal!Indicators!........................................................................................................................................!17!

Hydrowire'Installation'and'Commissioning'...............................................................'18!

Hydrowire!Installation!HSHWI-100!.....................................................................................................!18!

Hydrowire'Wiring'................................................................................................................'19!

Hydrowire!Remote!Lamp!Connection!.................................................................................................!19!

Hydrowire!Commissioning!–!HSHWC-100!........................................................................................!20!

Hydrowire!Layout!.........................................................................................................................................!21!

Floor'Probes'Installation'and'Commissioning'...........................................................'22!

Floor!Probe!Installation!HSFPI!-100!.....................................................................................................!22!

Floor!Probe!Wiring!.......................................................................................................................................!23!

Floor!Probe!Remote!Lamp!Connection!...............................................................................................!23!

Floor!Probe!Testing!.....................................................................................................................................!24!

Probe!Layout!...................................................................................................................................................!25!

Hydrosense'Commissioning'Record'..............................................................................'26!