4

904185 REV D 11/29/22, INST 81-87 CHEV P-UP w/ AC EVAP KIT PG 4 OF 27

Important Notice—Please Read

For Maximum System Performance, Vintage Air Recommends the Following:

New Vintage Air-Supplied Sanden Compressor: No additional oil needed (Compressor is shipped with

proper oil charge).

All Other Compressors: Consult manufacturer (Some compressors are shipped dry and will need oil

added).

NOTE: Vintage Air systems are designed to operate with R134a refrigerant only.

Use of any other refrigerant could damage your A/C system and/or vehicle, and

possibly cause a fire, in addition to potentially voiding the warranties of the A/C

system and its components.

Refrigerant Capacities:

Vintage Air System: 1.8 lbs. (28.8 oz.) or 816 grams of R134a, charged by weight with a quality charging

station or scale. NOTE: Use of the proper type and amount of refrigerant is critical to system

operation and performance.

Other Systems: Consult manufacturer’s guidelines.

Lubricant Capacities:

Safety Switches

Service Info:

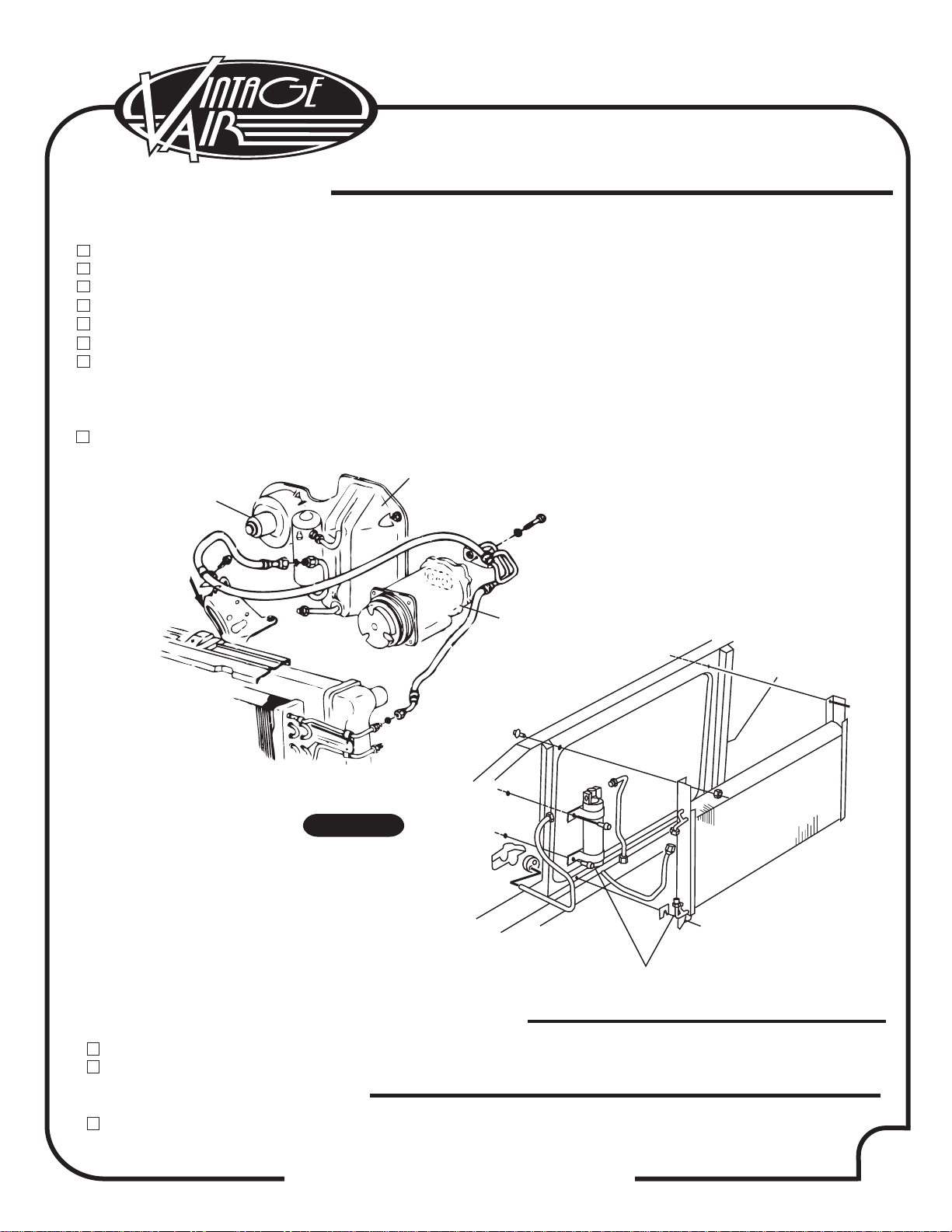

Protect Your Investment: Prior to assembly, it is critical that the compressor, evaporator, A/C hoses and

fittings, hardlines, condenser and receiver/drier remain capped. Removing caps prior to assembly will allow

moisture, insects and debris into the components, possibly leading to reduced performance and/or

premature failure of your A/C system. This is especially important with the receiver/drier.

Additionally, when caps are removed for assembly, BE CAREFUL! Some components are shipped under

pressure with dry nitrogen.

Evacuate the System for 35-45 Minutes: Ensure that system components (Drier, compressor, evaporator

and condenser) are at a temperature of at least 85°F. On a cool day, the components can be heated with a

heat gun or by running the engine with the heater on before evacuating. Leak check and charge to

specifications.

Your Vintage Air system is equipped with a binary pressure safety switch. A binary switch disengages the

compressor clutch in cases of extreme low pressure conditions (refrigerant loss) or excessively high head

pressure (406 PSI) to prevent compressor damage or hose rupture. A trinary switch combines Hi/Lo

pressure protection with an electric fan operation signal at 254 PSI, and should be substituted for use with

electric fans. Compressor safety switches are extremely important since an A/C system relies on refrigerant

to circulate lubricant.

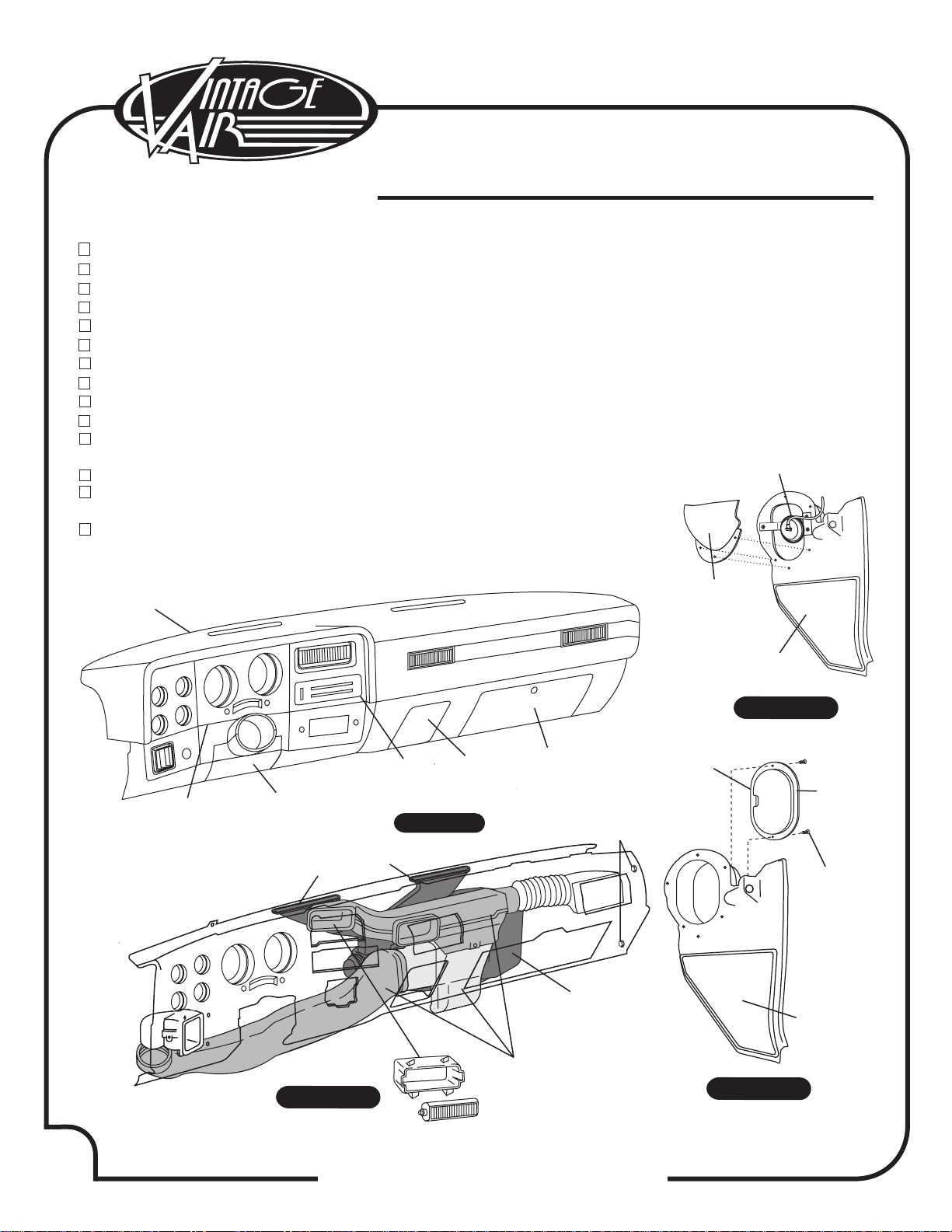

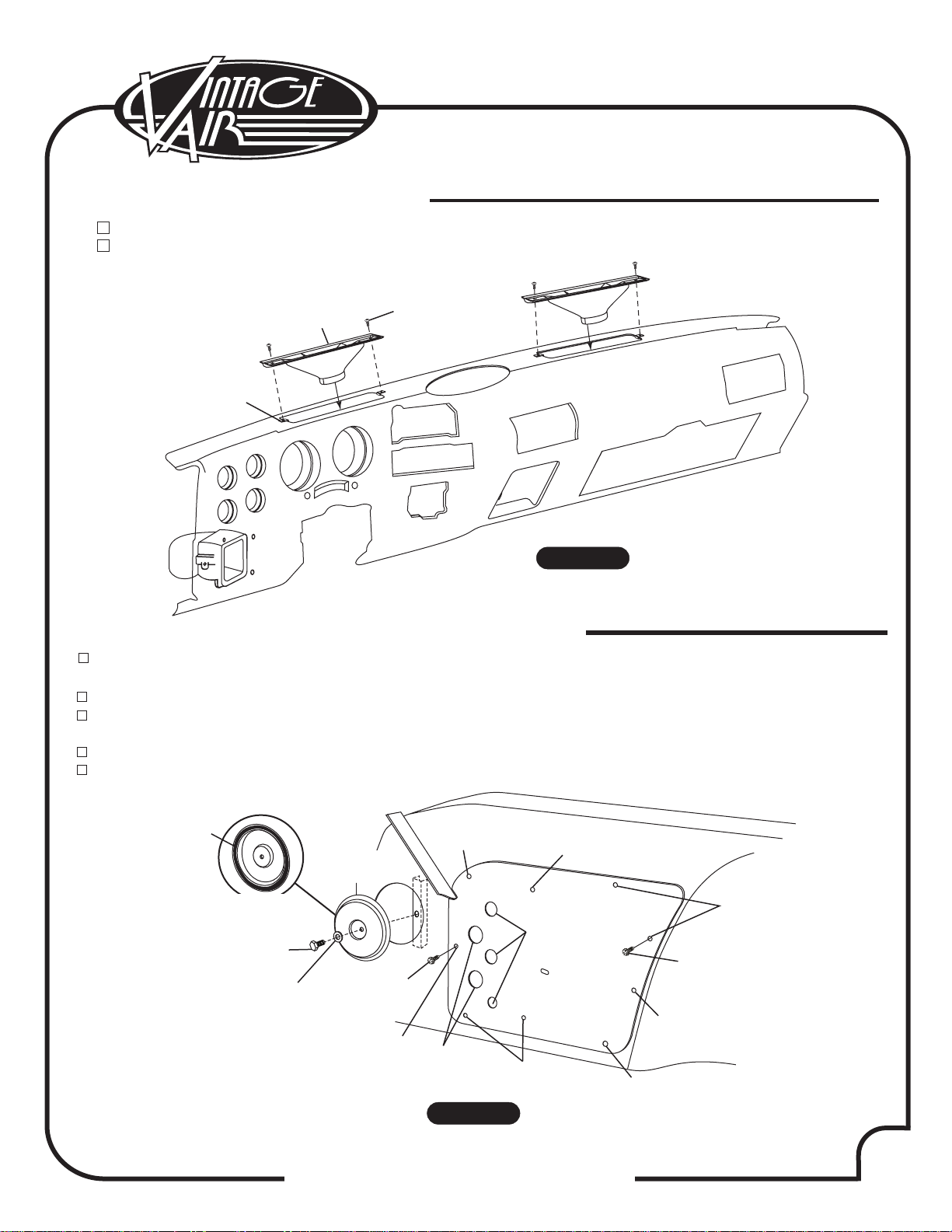

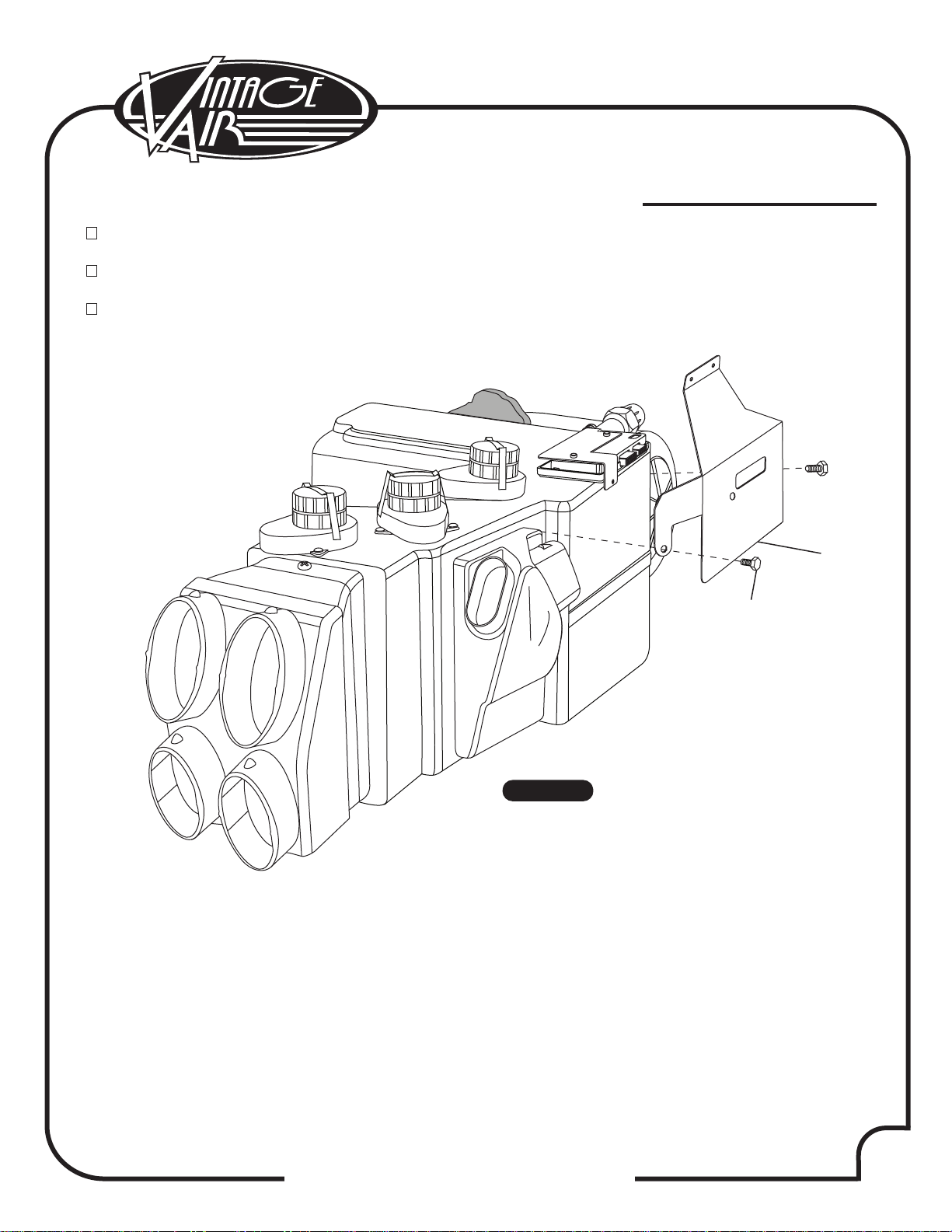

Bolts Passing Through Cowl and/or Firewall:

To ensure a watertight seal between the passenger compartment and the vehicle exterior, for all bolts

passing through the cowl and/or firewall, Vintage Air recommends coating the threads with silicone prior to

installation.

Heater Hose (not included with this kit):

Heater hose may be purchased from Vintage Air (Part#31800-VUD) or your local parts retailer. Routing and

required length will vary based on installer preference.