Basic Knowledge

5www.vinylsystems.com

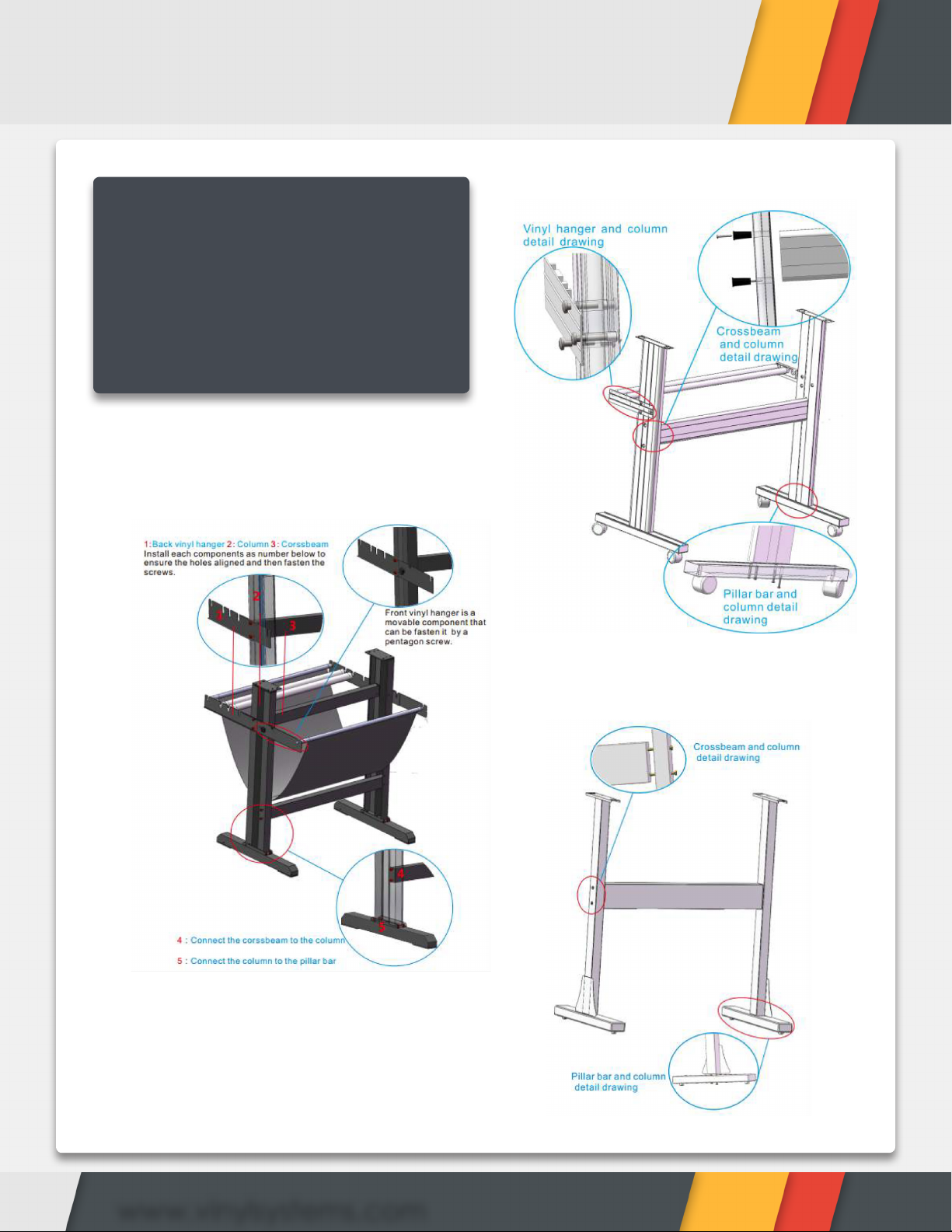

Installing Vinyl Material

All Vinyl Systems cutters will have a 1” white tabs that are labeled on the cutter. These

tabs are the areas your pinch rollers will need to be placed in. If you look underneath

these white tabs, you will see that the metal roller will have traction which allows the

vinyl to be fed with proper grip. If your pinch rollers are set up outside of these white

tabs and clamped onto your vinyl, it is subject to shift when it is cutting since it will not

have any grip. Try your best to make sure the pinch rollers are placed at the edge

of your vinyl material. Sometimes if you have the pinch rollers too closely into the

material, your vinyl will get bunched and possibly jammed.

Straighten Your Vinyl

Vinyl can be installed straight using the ruler that is labeled on the front of your machine.

It is recommended to manually track out your vinyl forward using the control buttons

before sending the job to ensure that it will be completely straight while it is cutting

the entire size of your design. The last thing you’ll want is your entire cut image to be

ruined towards the end of the job just because you didn’t measure it correctly!

Placing Your Cutter

If you are not using the included stand, make sure you place it on a sturdy tabletop

or surface that will be able to support the weight and dimensions of your cutter. You

will also need to make sure your vinyl roll will be able to feed correctly as improper

feeding to the cutter will cause cut and tracking issues.

Power On Your Cutter

These vinyl cutters require a standard US electrical outlet. They can draw up to 5 amps

so make sure it is plugged into an outlet with enough power available. Connect the

power plug to the wall socket when the machine is switched “OFF.” Do not overload

the circuit with any other electrical appliances. Most homes can hold anywhere from

15 to 20 amperages per breaker.