6 English User Manuel - 1.0

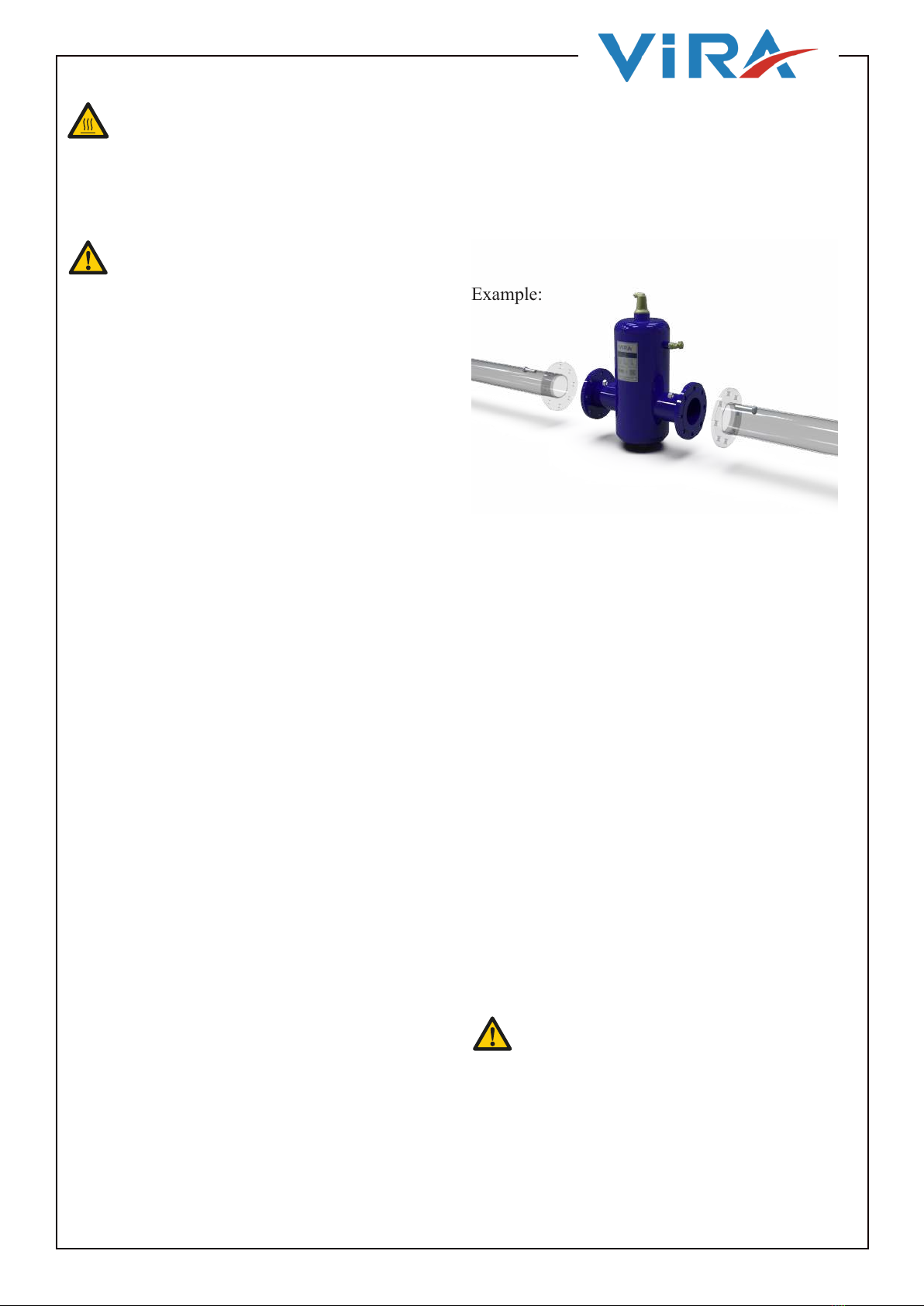

5.2. Install the unit

5.2.1. Mount The Unit

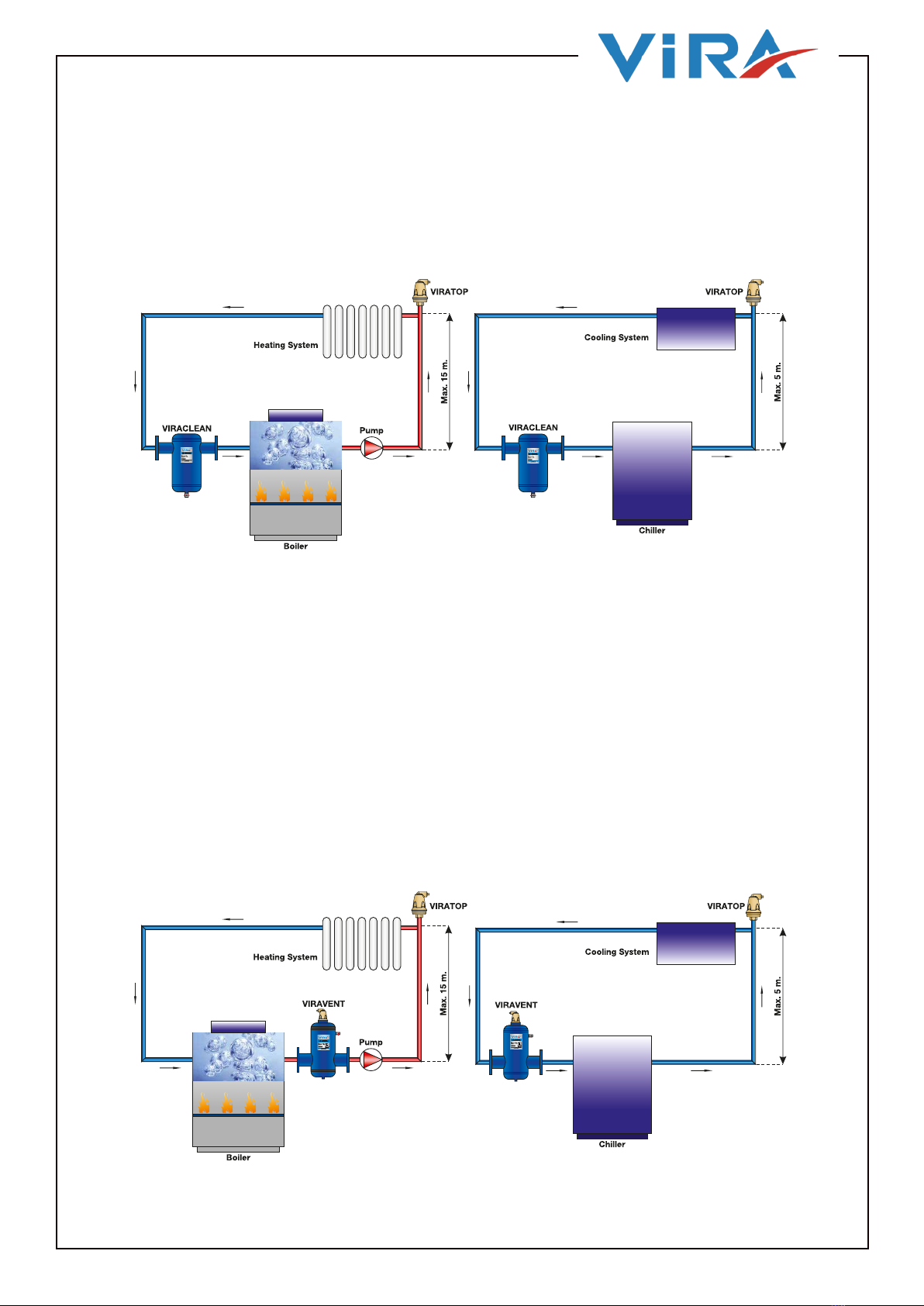

Example:

• The scum valve and the manual air valve are

designed to blow o and let in large quantities of air

during the filling and emptying of the installation and

to remove oating dirt.

5. INSTALLATION AND COMMISSIONING

5.1. Installation Conditions

• Install the unit in a frost-free, well-ventilated

place.

• Install the unit in accordance with the local

guidelines and rules.

• Install the unit stress free and with the body in

vertical position.

• Do not use the unit as a support for pipework.

• It is not allowed to weld the unit to the pipework

or other external items unless the unit is specifically

designed to be welded into the pipework.

• It is not allowed to modify the unit.

• Apply the separately supplied product labels if

the labels on the product are not visible; for instance

after the unit has been insulated.

• The lifting lugs may only be used during the

installation.

• The unit operates independent of the ow

direction.

• Do not obstruct the automatic air vent (if

available) and make sure that the automatic air vent is

always easily accessible.

• A tube can be fitted to the air vent (1/2” female

thread on the outlet) to lead away the released

(smelly) air. Excessive dirt particles or foam forming

might cause a temporary leakage of

the automatic air vent.

• If a drain pipe is fitted, make sure that this pipe

is fitted stress and vibration free to the drain valve.

Preferably, a exible pipe or pipe parts should be

used (e.g. a hose).

• Do not obstruct the vent valve and keep all valves

accessible.

5.3. Commissioning

CAUTION

If a cap R½ was installed on the automatic air

vent for the system test, make sure that cap

R½ is removed before the commissioning of

the system.

WARNING

Do not touch the unit or the pipework when the

system is in operation. The surfaces may be hot

and touching them may cause burns.

CAUTION

• Do not use the scum valve or drain valve for

(re)filling.

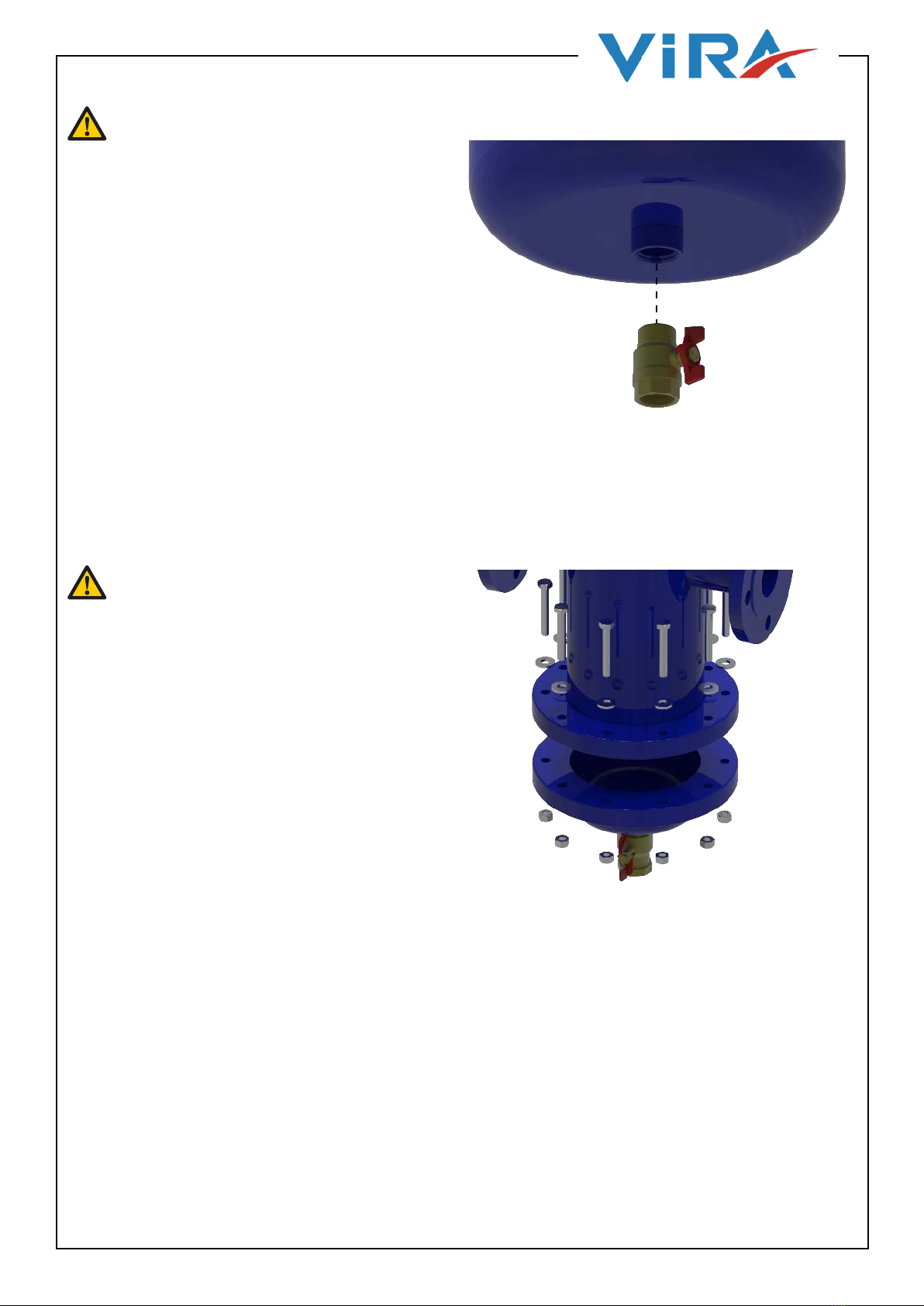

• Always install the unit body vertically, with

the automatic air vent (if available) on top and

the dry pocket or drain valve (if available) at the

bottom.

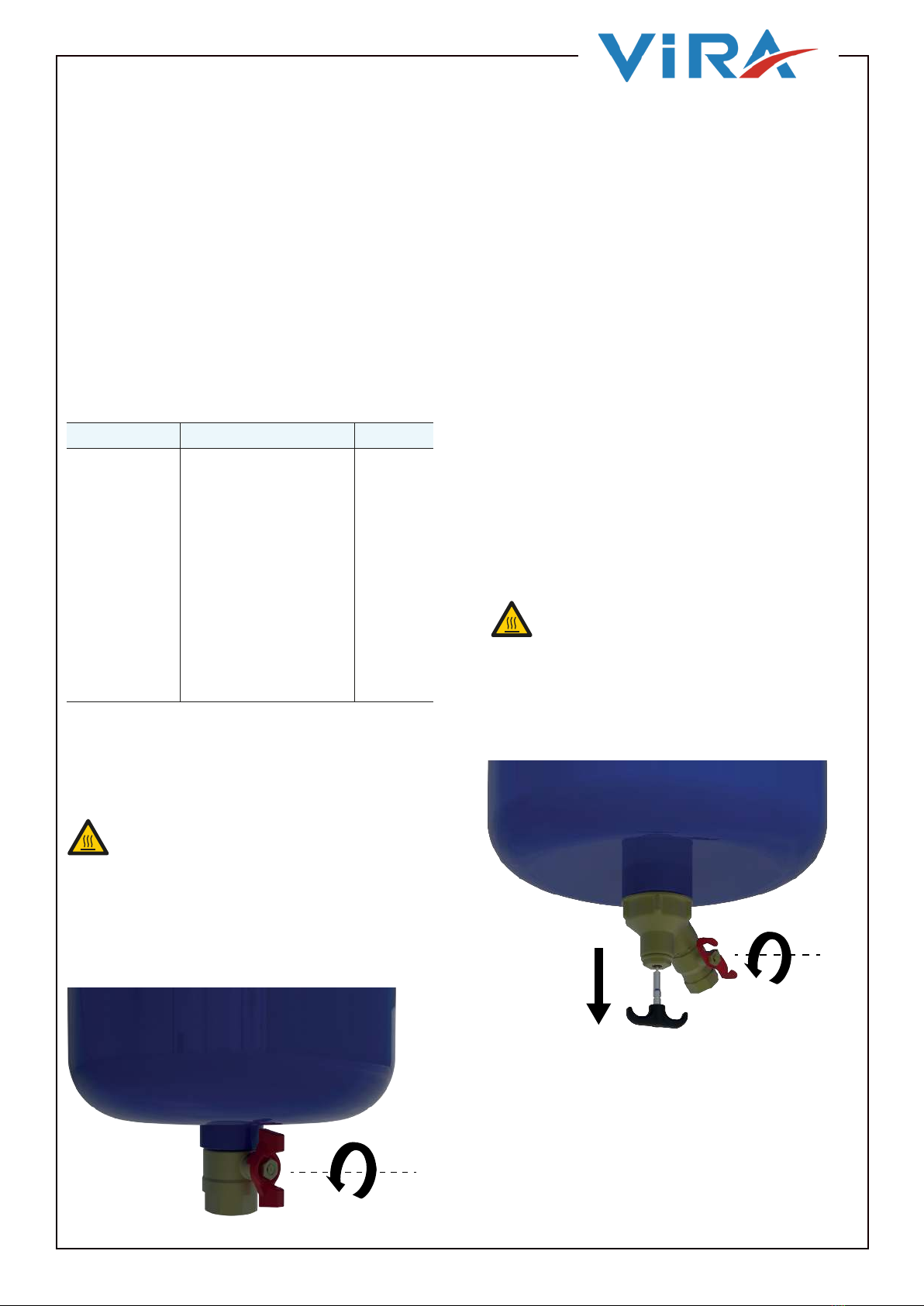

5.2.2. Install The Drain Valve (Not For SV / SVH

Units)

NOTE

For units with a drain valve and / or magnetic dirt

separator: Make sure that there is enough space to

operate the valve. In case there is not enough space

and the unit has a rotatable dirt separator, rotate the

dry pocket.

• Attach the pipework to the to the unit. Make

sure that the unit is installed stress free.

NOTE

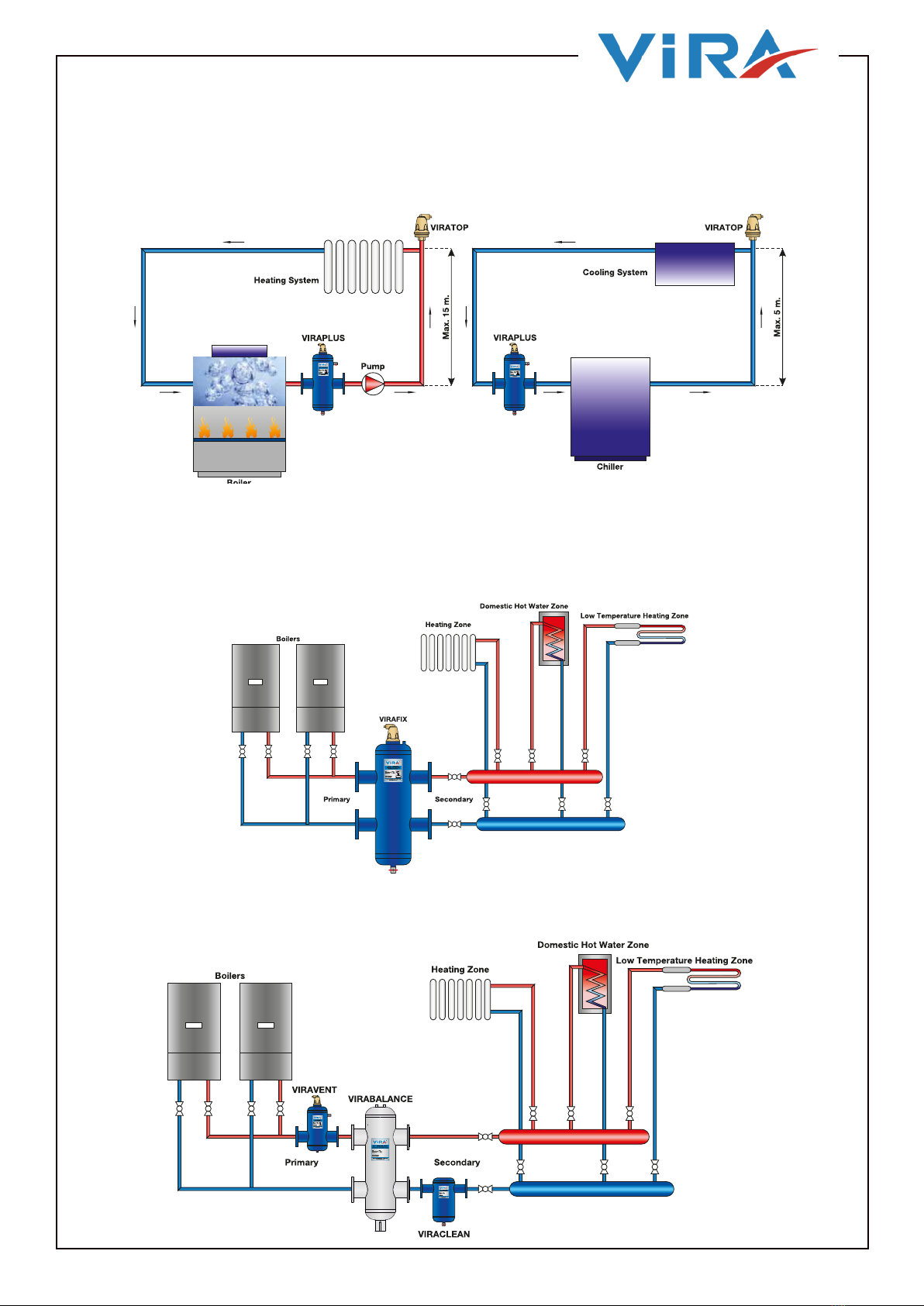

For ViraFix and ViraBalance (SCX and SB) : Make

sure that the warmest water enters the unit at the

top anges. The coldest water should enter the unit

at the lower anges. This is necessary to prevent

unwanted mixing of warm and cold water.

• Tighten the fasteners to the correct torque value

of the pipework.