PART A: Basic machine

Granulator

H 80 Series

VIRTUS 2023, All rights reserved Page 4

8.8.1 Installation and operation ____________________________________________________ 59

Tightening torque of the screws: 395Nm _______________________________________________ 59

8.8.2 Mounting the DOKO tensioning element ________________________________________ 60

8.8.3 Dismounting the DOKO tensioning element______________________________________ 61

8.9 Mounting and dismounting TAPER-LOCK tensioning element _________________62

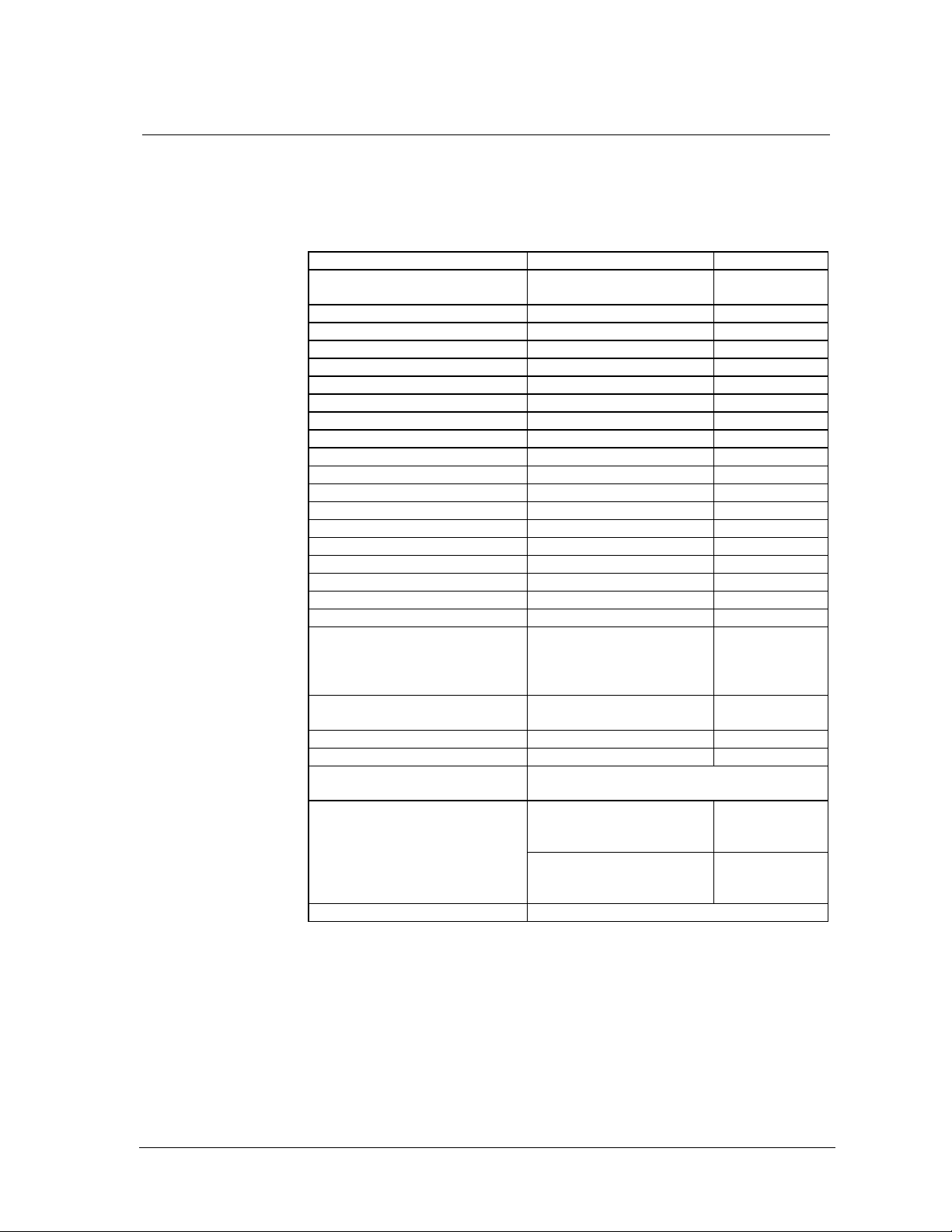

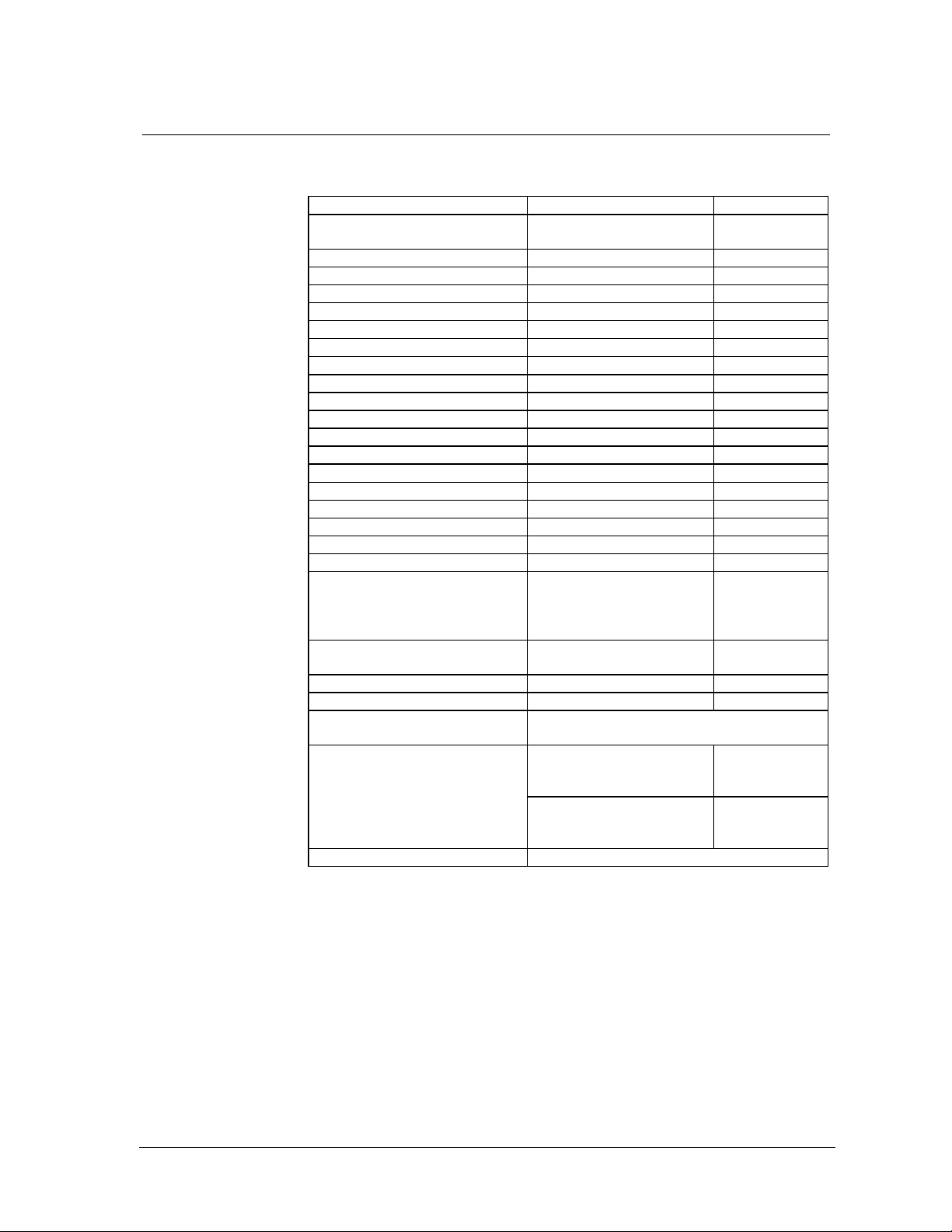

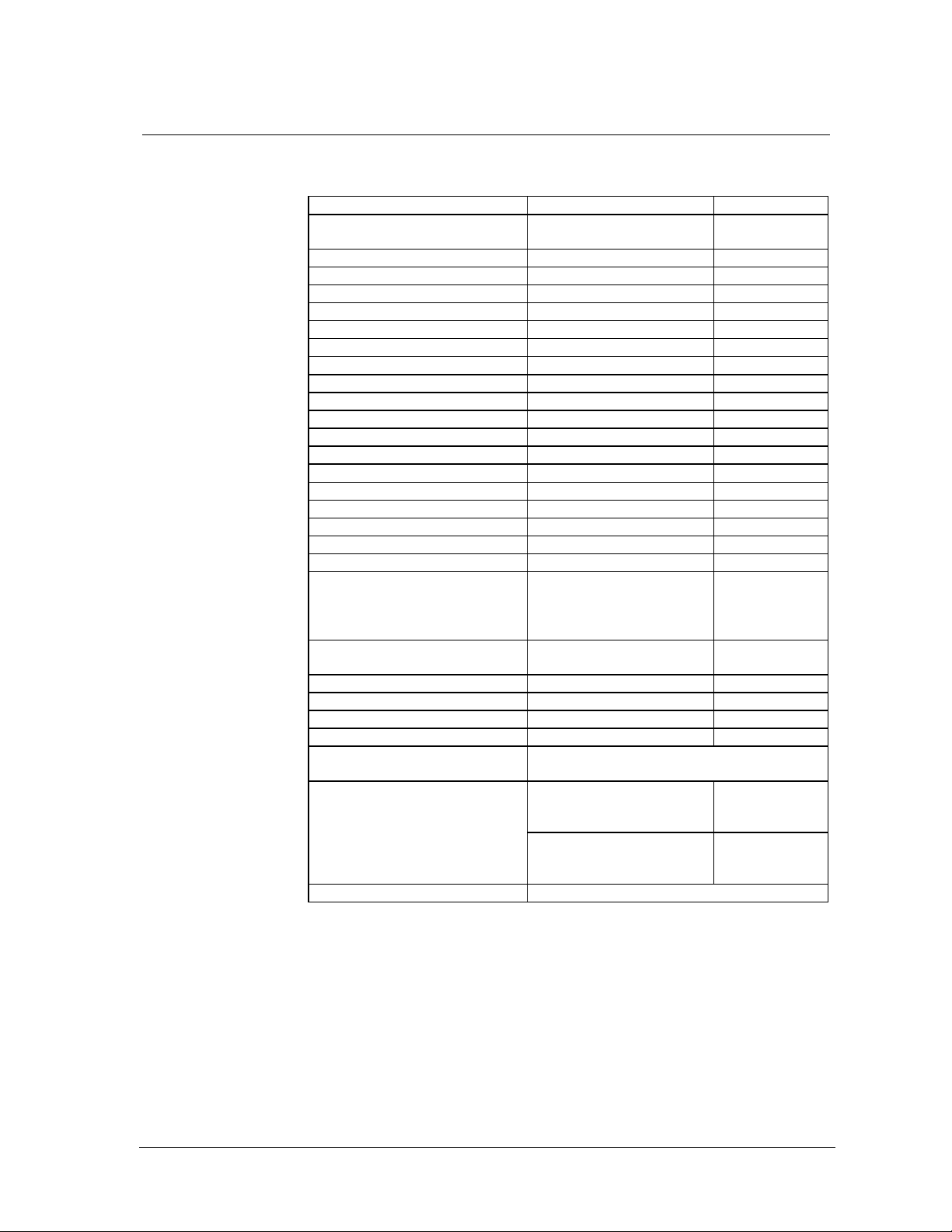

8.9.1 Table for the tightening torque of the screws _____________________________________ 62

8.9.2 Mounting the TAPER-LOCK tensioning element __________________________________ 63

8.9.3 Dismounting the TAPER-LOCK tensioning element _______________________________ 63

8.10 Replacing the screen _________________________________________________64

8.11 Work on the "V"-belts _________________________________________________66

8.11.1 Checking the tension force of the "V"-belt _______________________________________ 66

8.11.2 Retensioning and relaxing the "V"-belt__________________________________________ 67

8.11.3 Checking "V"-belt condition, replacing "V"-belt____________________________________ 67

8.12 Working on the cutting knives__________________________________________68

8.12.1 Replacing and checking the cutting knife mountings _______________________________ 68

8.12.2 Checking the condition of the cutting knives _____________________________________ 69

8.12.3 Dismounting the cutting knives________________________________________________ 69

8.12.4 Mounting the cutting knives __________________________________________________ 70

8.12.5 Sharpening cutting knives ___________________________________________________ 71

8.12.6 Setting the cutting knives ____________________________________________________ 75

8.12.7 Transporting and storing the cutting knives ______________________________________ 78

8.13 Deflection wedge removal _____________________________________________79

9Troubleshooting__________________________________________________ 81

9.1 Machine blocks or switches itself off ______________________________________81

9.2 Rotor does not grip bulky material ________________________________________81

9.3 Overheating of the grinding material ______________________________________81

9.4 Unusual vibrations _____________________________________________________82

9.5 Extreme cutter wear ____________________________________________________82

9.6 Bearings too hot _______________________________________________________82

9.7 Too many fines in grinding material_______________________________________82

9.8 Cutting gap alters during operation _______________________________________82

9.9 Screen damage ________________________________________________________83

9.10 Granulator does not start ______________________________________________83

9.11 Granulator blocks when under load _____________________________________83

9.12 Frequent switching off of grinding material in feed device __________________83

10 Storage, disposal, transportation __________________________________ 84

10.1 Storage_____________________________________________________________84

10.2 Disposal ____________________________________________________________84

10.3 Transportation_______________________________________________________84

11 Hydraulic Maintenance__________________________________________ 86

12 Customer service and spare parts orders ___________________________ 88

13 Spare Parts Lists________________________________________________ 89