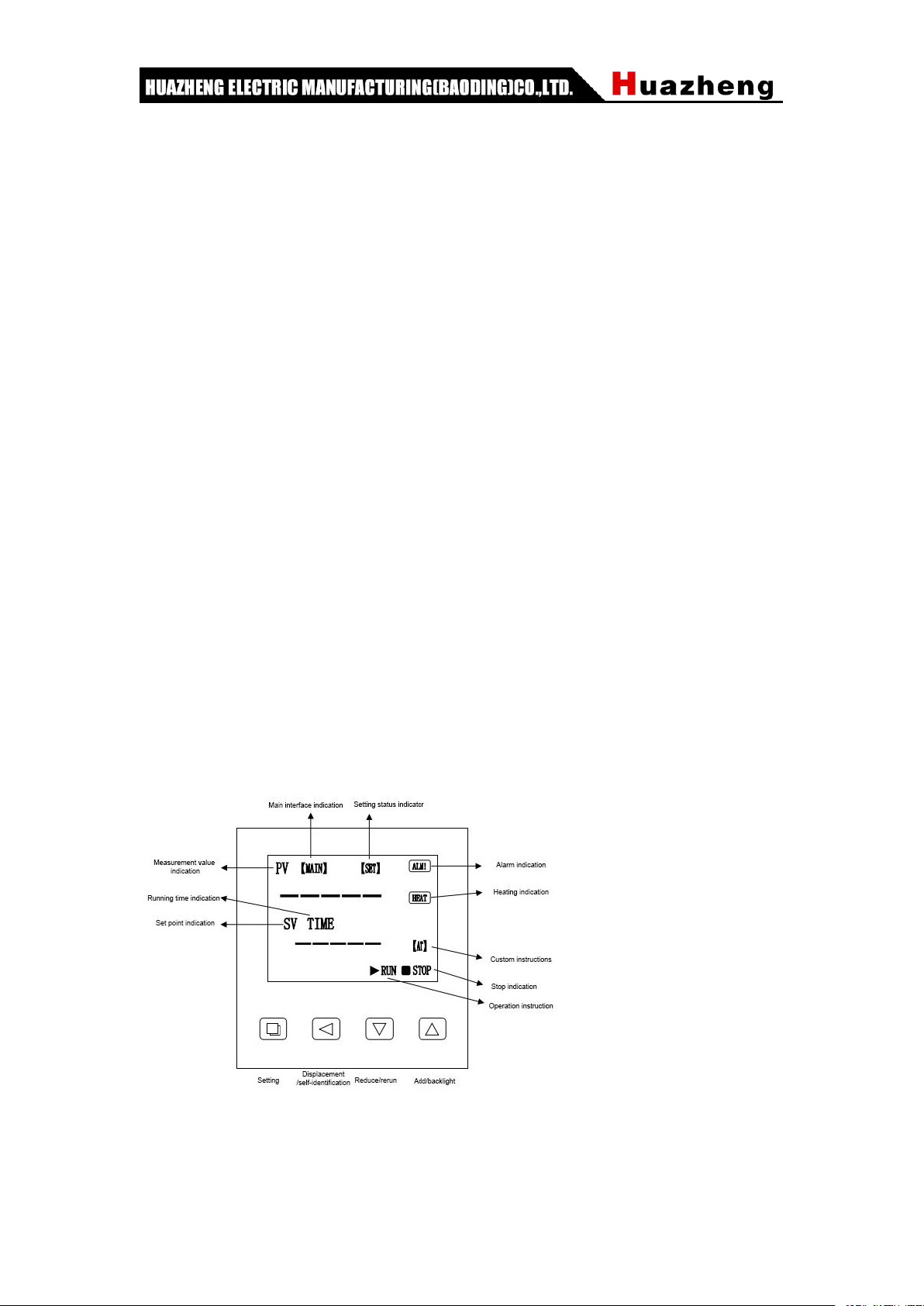

auto-tuning state, the [AT] indicator flashes, after the auto-tuning is completed, [AT] When

the indicator light stops flashing, the controller will get a better set of PID parameters, and

the parameter values will be saved automatically. In the process of system

auto-tuning, press and hold the "shift" key for 6 seconds to stop the auto-tuning program.

In the process of system self-tuning, if there is an upper deviation over-temperature alarm,

the "ALM" alarm light will not light up and the buzzer will not sound, but the heating alarm

relay will be automatically disconnected. The "Set" key is invalid during system

auto-tuning. In the process of system self-tuning, regardless of whether there is a constant

temperature time setting, the lower row of the controller display window always displays

the temperature setting value.

4.Reference and setting of temperature internal parameters

Long press the setting key for about 3 seconds, the upper row of the indicator display

window displays the password prompt "Lc", and the lower row displays the password

value. Use the increase, decrease and shift keys to modify the required password value.

Click the set button again, if the password value is incorrect, the meter will automatically

return to the normal display state; if the password value is correct, it will enter the

temperature internal parameter setting state, and then click the set button to modify each

parameter in turn. Long press the set button for 3 seconds to exit this state, and the

parameter value is automatically saved.

5.Matters needing attention:

1. The shell of the drying box must be grounded effectively to ensure safe use.

2. The drying box should be placed in a well-ventilated room, and no flammable and

explosive materials should be placed around it.

3. The drying box has no explosion-proof device, and flammable and explosive materials

are not allowed to be dried in the drying box.

4. Do not overcrowd the items in the box, and leave space to facilitate the circulation of hot

air.

5. The inside and outside of the box should always be kept clean. If it is not used for a long