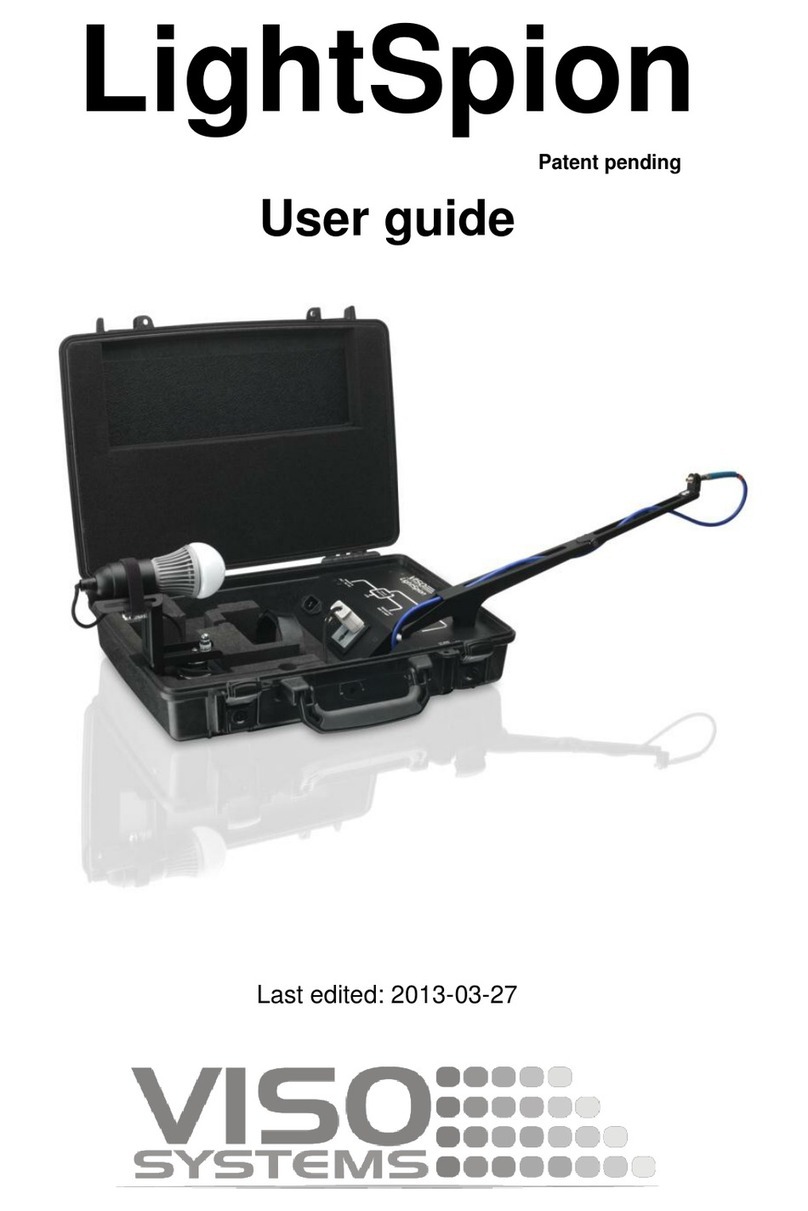

Viso Systems LightSpion LIGSP001 User manual

VISO SYSTEMS LightSpion

User Manual

Revision: 3 September 2020

2

Congratulations on purchasing your new Viso Systems LightSpion. Before using this

product, please read the Safety Information.

This manual contains descriptions and troubleshooting necessary to install and

operate your new Viso Systems product. Please review this manual thoroughly to

ensure proper installation and operation.

For news, Q&A and support at Viso Systems, visit our website at

www.visosystems.com

Other manuals in this series for which the latest version can be downloaded from

www.visosystem.com, include:

▪Light Inspector User Guide (Software)

▪LabFlicker User Manual (optional equipment)

▪VISO Reference CALI-T50 User guide (optional calibration light source)

3

Contents

Safety Information........................................................................................................4

Preventing electric shocks ........................................................................................4

Disposing of this Product ..............................................................................................4

Introduction..................................................................................................................4

About this document ................................................................................................4

These guidelines describe the installation process of the LightSpion followed by

the typical measurements of various light sources...................................................4

About the LightSpion ................................................................................................4

Product Dimensions......................................................................................................5

Shipping packages.........................................................................................................5

Installation ....................................................................................................................5

Software installation.................................................................................................5

Connecting power.........................................................................................................6

AC power supply cable plug......................................................................................6

Connecting USB.............................................................................................................6

Room Considerations....................................................................................................7

Laboratory environment...........................................................................................7

Making measurements .................................................................................................7

Bulbs and Spots.........................................................................................................7

Strips and Tubes............................................................................................................9

LightPort Installation.................................................................................................9

Linear Light Holder Installation...............................................................................10

Check for light overspill...........................................................................................11

Advanced setup ..........................................................................................................12

Checking the calibration status...............................................................................12

Custom calibration..................................................................................................12

Accuracy......................................................................................................................15

Photo spectrometer accuracy.................................................................................15

Optical sensor accuracy ..........................................................................................15

Circular field accuracy.............................................................................................16

Specifications..............................................................................................................19

4

Safety Information

Warning! This product is not for household use.

Read this manual before installing and operating the LightSpion, follow the safety

warnings listed below, and study all the cautions in the manual.

Preventing electric shocks

Make sure the power supply is always grounded.

Use a source of AC power that complies with the local building and electrical codes,

that has both overload and ground-fault protection.

If the controller or the power supply are in any way damaged, defective, wet, or

show signs of overheating, disconnect the power supply from the AC power and

contact Viso Service for assistance.

Do not install or use the device outdoors. Do not spray with or immerse in water or

any other liquid.

Do not remove any covers or attempt to repair the controller or the power supply.

Refer any service to Viso.

Disposing of this Product

Viso Systems products are supplied in compliance with Directive 2012/19/EU on

waste - electrical and electronic equipment (WEEE) together with the RoHS Directive

2011/65/EU with amendments 2015/863. Help preserve the environment! Ensure

that this product is recycled at the end of its lifetime. Your supplier can give details of

local arrangements for the disposal of Viso Systems products.

Introduction

About this document

These guidelines describe the installation process of the LightSpion followed by the

typical measurements of various light sources.

About the LightSpion

The LightSpion is a portable far field goniometer system with a spectrometer sensor

that makes it possible to get all photometric measurements quickly and efficiently.

The Light Inspector software enables to quickly measure, save and export the newly

obtained data.

© 2007 Viso Systems ApS, Denmark

All rights reserved. No part of this manual may be reproduced, in any form or by any means,

without permission in writing from Viso Systems ApS, Denmark. Information subject to change

without notice. Viso Systems ApS and all affiliated companies disclaim liability for any injury,

damage, direct or indirect loss, consequential or economic loss or any other loss occasioned by

the use of, inability to use or reliance on the information contained in this manual.

5

Product Dimensions

Shipping packages

Shipping Dimensions

Shipping

Volume

Weight

1. LightSpion

450 x 350 x 160 mm

0.025 m3

(net 6 kg)

7 kg

Installation

Software installation

Before you can start using the LightSpion, the Viso Light Inspector software must be

installed. It is supported on all windows platforms.

Use the following link to download the latest version:

http://www.lightdataserver.com/software/Viso%20Systems/LightInspector.htm

Please make sure the LightSpion is not connected to the computer during software

installation.

Run the .msi file and follow the installation instruction.

USB drivers are automatically installed.

6

Your measurements are not lost when installing newer versions or uninstalling. All

measurements will always remain in your document folder. If you want to remove all

your measurements go to the ‘Light Inspector’ folder and delete them manually.

Typical folder location:

C:\Users\’Username’\Documents\Viso Systems\Light Inspector

Or if stored in dropbox:

C:\Users\’username’\Dropbox

Connecting power

The LightSpion comes with a standard IEC power-in connector and with a standard

euro power cable, but any power cable can be used as the LightSpion supports any

outlet voltage from 90-260VAC.

The power-in connector supplies power both to the goniometer motor and to the

power analyzer and then subsequently to the measured light source. It means that

the power is identical to the one of the measured light source (unless the latter is

power with an external power supply).

AC power supply cable plug

Warning: Risk of an electric shock! Plug installation shall be performed by a qualified

electrician.

A grounding-type (earthed) power plug that fits the local power outlet must be used.

You can acquire an IEC power cable with a suitable grounding-type plug from most of

consumer electronics stores.

When installing the plug connect pins as follows:

•Blue wire to neutral

•Yellow and green wire to grounding (earth)

•Brown wire to live

Connecting USB

The LightSpion is connected to the computer using a USB connector type B.

A 2 m USB cable type A to B is included in the LightSpion case, however any USB

cable supporting USB2.0 can be used.

The USB provides communication and power to the LightSpion’s main board

processor, power analyzer and photo spectrometer, meaning that the photo

spectrometer can be used only with the connected USB.

Start the Viso Light Inspector software after having connected the USB; the

connection to the LightSpion will be established automatically. A successful

connection is shown with a green “Connected” icon in the upper right corner of the

Viso Light Inspector software.

You can connect and disconnect the USB without restarting the Viso Light Inspector

software, as the connection is always established automatically as soon as the USB

connector is plugged in and vice versa.

Neutral

Ground/Earth

Live

7

Room Considerations

Laboratory environment

▪The LightSpion can be used outside of the laboratory and compensates

automatically for steady ambient light. However, for the most precise

measurements, a dark room/laboratory is recommended. You can find

guidance in

▪Always keep your laboratory clean from dust and particles. Dust may

interfere with measurement if it accumulates on and around the sensor by

introducing straylight and disturbing translucence. Dust and particles in the

mechanical parts of the goniometer may disturb functionality and may

cause wear on motors, belts and bearings. Disconnect all USB cables and

power supplies, and vacuum clean your goniometer regularly (normally

every month) to remove dust. Mount a brush on the vacuum cleaner

handle. Dry off all external surfaces with a clean, dry, cotton cloth (avoid

statics).

▪Avoiding air currents is necessary to minimize cooling of devices under

test. Limit air flow (e.g. from air conditioning systems or draught) around

the system (may alter light source intensity).

▪Limit heat transmission from light source through mounting system. Should

be mounted as realistically as possible

The standard test conditions and

tolerance intervals of CIE DIS 025

(laboratory conditions)

Standard test

condition

Tolerance interval

Ambient temperature

25.0 °C

±1.2 °C

Surface temperature for device

under test

Nominal operating

temperature tp

±2.5 °C

Air movement

Stationary air

0 m/s to 0.25 m/s

Making measurements

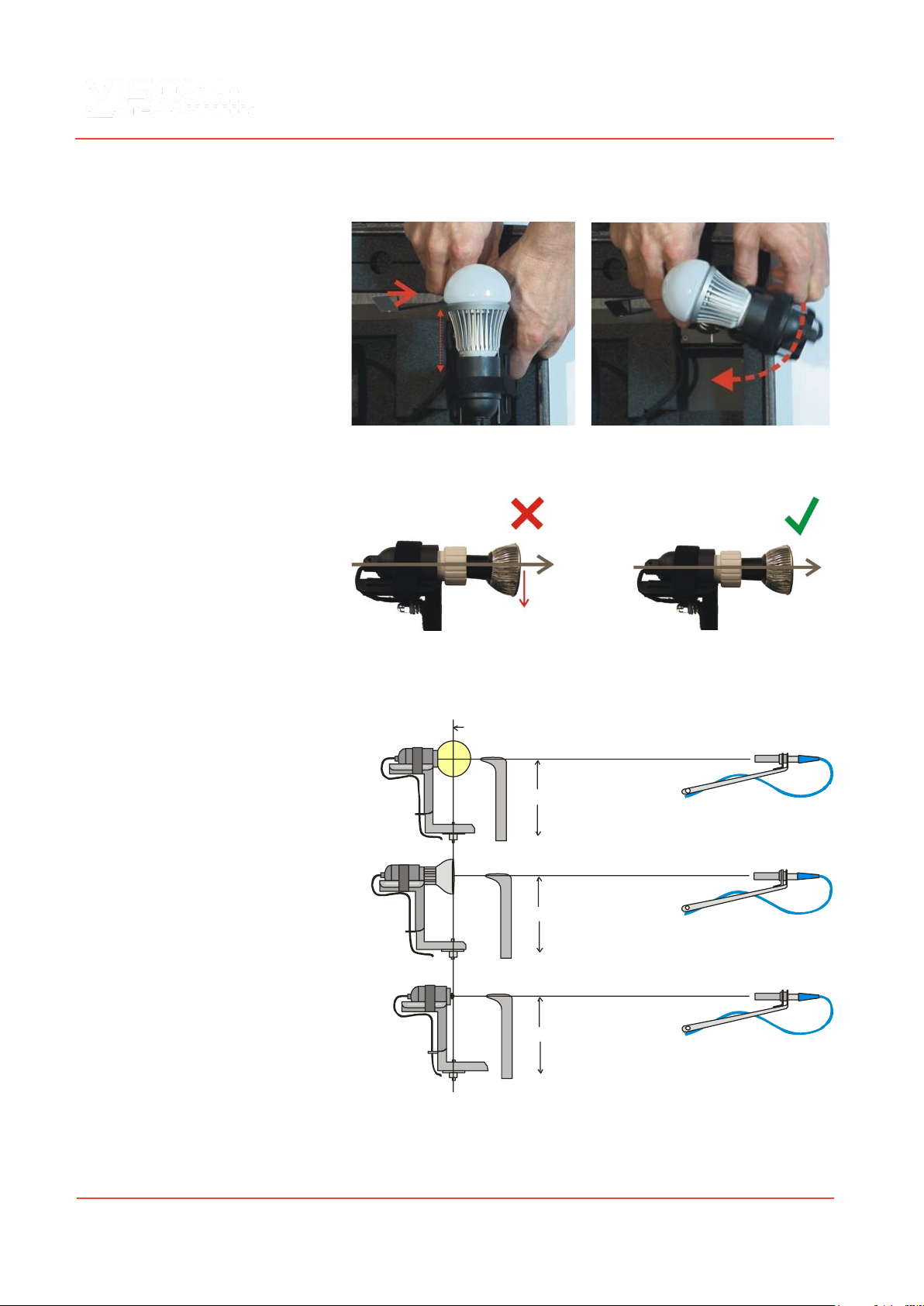

Bulbs and Spots

Before making any measurements, it is

important to align the investigated light

source. Use the alignment tool located in the

front compartment of the LightSpion case

and place it in front of the light source.

Then adjust the height by sliding the lamp

holder bracket up and down.

8

Turn the lamp holder 90 degrees and set the center of rotation by sliding the lamp

forward and backward, so that the center of the illumination part of the lamp is

aligned with the alignment tool.

When measuring light sources with narrow beam angles it is important to ensure

that the light is pointing straight horizontally to make certain that the centre of the

beam is scanned at the correct point as shown below.

After alignment turn the light source back pointing straight towards the optical

sensor.

Different alignment examples are shown below:

Center hight

Center hight

Center hight

Center of rotation

Light bulb

Spot light

LED chip

9

Strips and Tubes

The LightSpion can also measure linear light sources such as LED strips or tubes. The

width of the linear tubes cannot exceed half of the maximal diameter, which is 8 cm.

That means the maximum width of the linear tube is 4 cm.

To measure a linear light source a “light port bracket” can be used to ensure that

only a fixed portion of the linear light sources is being measured as shown below.

The “light port bracket” ensures that light from only 8 cm of the linear light source is

captured. The actual length of the light source is then typed into the software after

the measuring process is finished. An alternative to the bracket is to effective mask

off directly on the light source to ensure that only 8 cm contributes to the light

output.

Click Edit -> Photometric -> Linear sources to insert the real length of the source to

the software. The complete light output of the linear light sources is then calculated.

For linear light sources of flexible lengths such as LED strips it is also possible to get

the light output information specified in lumen per meter or foot.

NB: The bracket is not intended for use with “LightSpion Extender”.

LightPort Installation

The “light port bracket” should be place in the LightSpion case to ensure the correct

measurement as shown below:

1) The LightPort is stored in the lid

2) Place the lid in the slot in front of the

arm

Linear light

holder

Light port

bracket

8 cm

10

3) A magnet keeps it in place

4) Push it in, to the end of the slot

Linear Light Holder Installation

The “linear light holder” is set and used as shown in the pictures below:

1) Take holder from the lid

2) Push to the end

3) Erect holder

4) Use Velcro straps to hold fixture

5) Center the light source

11

Check for light overspill

Light overspill, which is the light retrieved by the detector outside of the light port

bracket area, can increase the measured value of the luminous flux.

An extension plate for the light port bracket will prevent the light overspill. The

extension is smoothly attached on top of the port bracket as shown in the pictures

below.

Light

overspill

12

Advanced setup

Checking the calibration status

A special Viso reference light source (Reference 800) is included in the package. The

light source has its own power supply, and both parts are labelled with identical

calibration date and numbers. Never measure without the original power supply.

Right after factory calibration of your system, the refence light source was measured

and a certificate was issued. The certificate is part of the delivery. The certificate can

also be downloaded from Viso’s website using the calibration number on the labels.

With the reference lamp you can quickly check your calibration status:

•Check whether the total flux in lumen and peak candela is close to the

original values

•Check whether the shape of the spectrum is close to the original shape.

•Check whether the spectrum looks spiky or jagged.

If you are not happy with the result, the system needs to be calibrated. Viso

recommends calibration every year, or minimum every 2 years. Viso provides

calibration service, or you may do your own calibrations following the ‘Custom

Calibration’procedure.

Check-up Procedure

•Place the Reference 800 with the indicator (the oblong hole in the base)

upwards

•Do not preheat the light source before measurement

•Centre the light source in the gonio (measuring distance 66 cm)

•Start measurement normal measurement. In the stabilization window,

choose “1,0% in 15 min.” and let the measurement finish by itself.

Custom calibration

The LightSpion is delivered in a pre-calibrated condition. It is also possible to make a

custom calibration of the photo spectrometer if desired. This could be necessary if

the LightSpion is to be certified by an official agency, which will perform its own

calibration and afterwards issue certification documents.

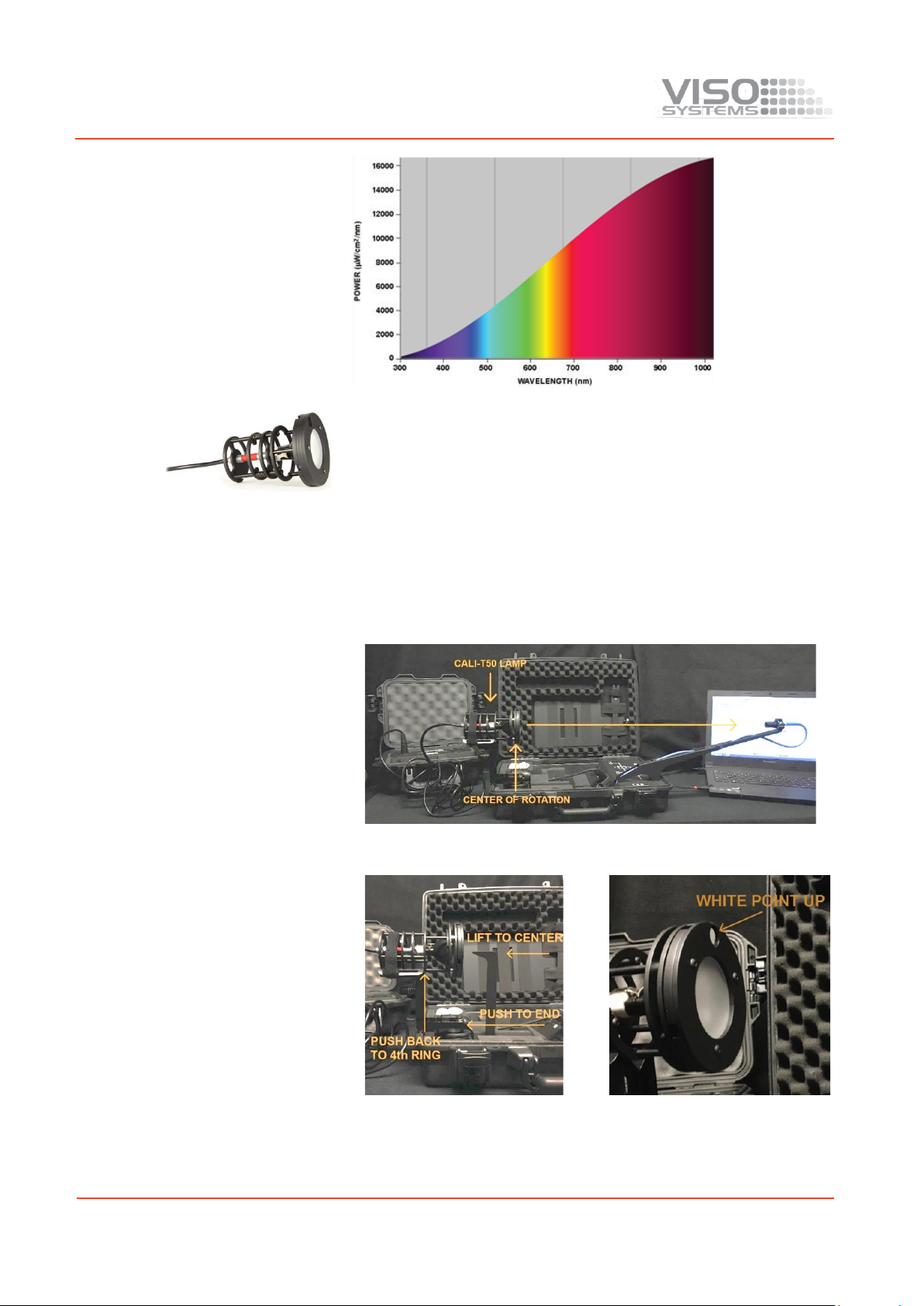

To make a custom calibration a calibration source must be used, the spectrum of

which in a directional point at a certain distance is known. Such a spectrum is usually

specified as power in μW/cm2/nm, as shown below.

13

Calibration sources can be obtained from a number of suppliers, in this example will

we use the CALI-T50 from Viso Systems which is a tungsten irradiance lamp. The

spectrum of the calibration source is usually provided in a .lmp file (lamp file).

NOTE! Making a custom calibration does not delete the Viso factory calibration. You

can always switch between factory and custom calibration at any time.

IMPORTANT: Calibration must be made in a dark environment, with non-reflective

surfaces.

These steps show how to make a custom calibration.

1

Place the calibration lamp at the center of the rotation motor and make sure it is

lifted to the right height by using the alignment tool.

The lamp must be pointed directly towards the sensor. Sometime is might be

necessary to unplug RJ45 cable to the motor to enabling precise alignment

14

2

Open the Viso Light Inspector software

connected to the LightSpion via USB and

select Setup - Spectrometer calibration.

Then select custom calibration and click

on the new button. Note: The primary

factory calibration will not be lost, and

you can always return it.

3

Select “Load lamp file” to load the

calibration source spectrum. The system

will automatically calculate the intensity

of the source in candela based on the

lamp file at a distance of 0.5 m. If the

measurements are done at a different

distance, then click on the re-calculate

button. If you don’t know the lamp

distance but know the intensity value in

candela, simply insert it directly into the

candela box.

4

Make sure the calibration source has

been turned on for at least 30 min, so the

output is stable.

5

Click next and set the integration time to

a maximum possible value to ensure the

highest resolution, and therefore the best

calibration quality.

15

6

Click next and cover the sensor or turn off

the calibration source so the dark

reference spectra can be measured

7

Click next –and the calibration is then

finished.

When you close the calibration dialog will you be asked if you want to save the

calibration to the device. When selecting yes, the custom calibration will be saved

inside the device you can always switch back to the factory calibration at any time.

Accuracy

The accuracy of the LightSpion device consists of the sum of individual accuracies of

the involving parts as follows:

▪Photo spectrometer accuracy

▪Optical sensor accuracy

▪Circular field accuracy

The accuracies of these devices are described below.

Photo spectrometer accuracy

The spectrometer used in the LightSpion is Ocean Optics STS-VIS.

The accuracy of the spectrometer has been previously tested in a wide temperature

range from -10 to +50 degrees, therefore the device is adjusted for a temperature

drift.

The linearity of the photo spectrometer is corrected to have an error < +/- 0.5% from

15-95% full scale (2,500 –14,000 counts net).

The effect of the linearity error will also affect the color and CRI measurements so

the complete series of measurement errors are as follows:

▪Intensity error < +/- 0.5%

▪Color temperature error < +/- 35 Kelvin

▪CRI error < +/- 0.7%

Optical sensor accuracy

The accuracy of the sensor depends on a change of a sensitivity field as a function of

position (it is also called the sensitivity span). The measurement setup with an

indicated sensitivity span of less than 8.5% is presented below.

16

The system is constructed for measuring light sources with a maximum diameter of

100 mm. It is calibrated with the help of a calibration source with an aperture

diameter of 35 mm with constant field of light output. Thus, subsequently measured

light sources with the same aperture and a constant field will have an error of 0%,

whereas light sources smaller than 35 mm will have a positive error and vice versa.

The errors can occur due to differences in sizes of apertures of light fixtures. The

largest error is then calculated according to the minimum and a maximum aperture

sizes.

Max positive error +0.49% Max negative error -2.55%

In most cases the maximum error would be smaller than 2.55%, as the light radiated

from a large aperture would be highest in the center.

The inaccuracy of the sensor is rounded off to < +/- 2%.

Sensor intensity error < +/- 2%

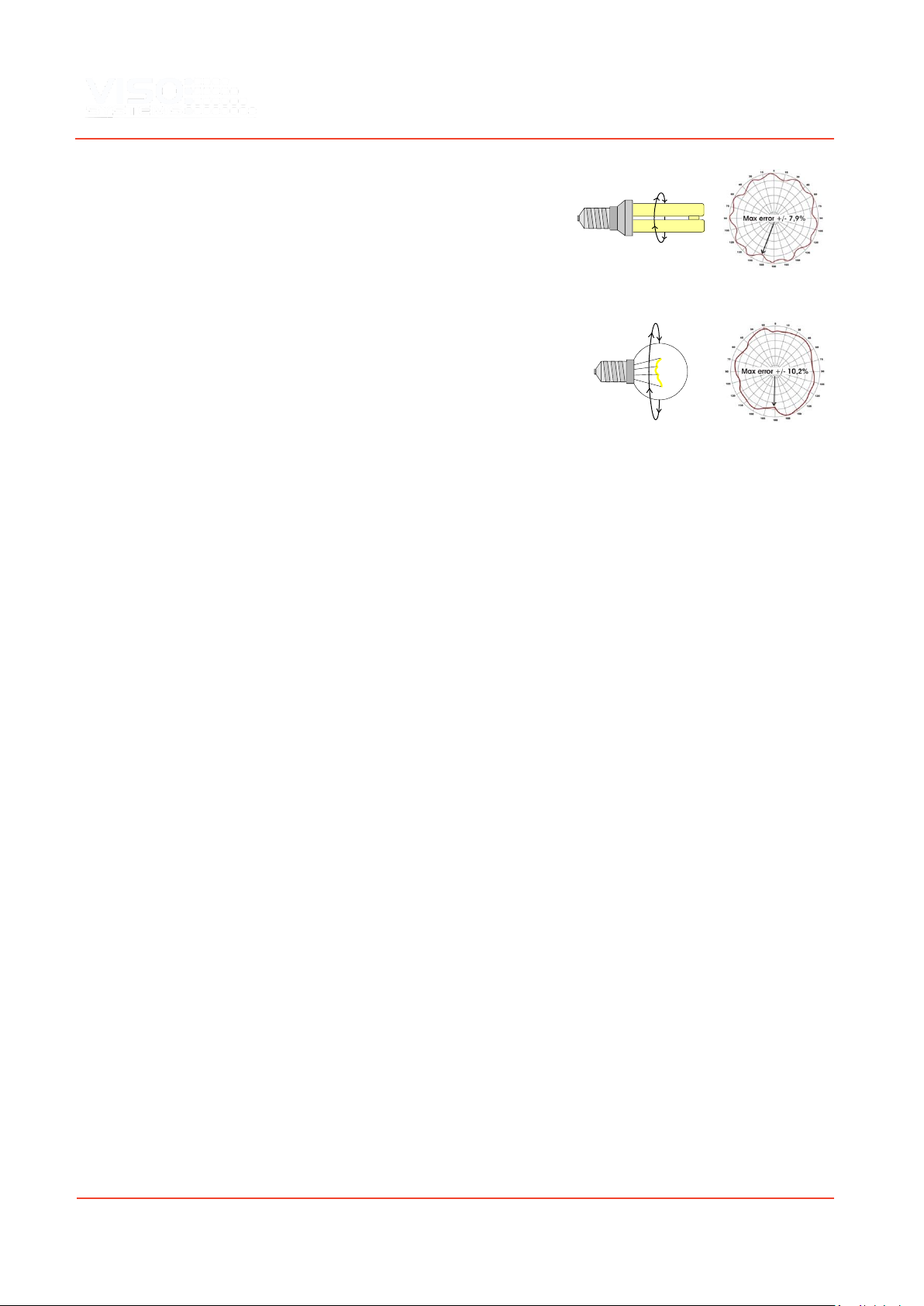

Circular field accuracy

The LightSpion measures the luminous flux in lumen, which accounts for light

radiated in all directions. Lumen measurement is generally done with the help of an

integrating sphere, which allows to collect light radiated in all direction into one

point.

The LightSpion uses goniometer technology to obtain this measurement. It captures

light from one section of the light source and afterwards calculates the complete flux

value based on this section, as shown below (section “A” is presented in green).

17

The principle behind it is based on a consideration that the opposite field “B” is

circular (see in the picture above). Most of the light sources and fixtures have

nonuniform circular “A” and “B” fields.

In some particular cases the deviation from a circular uniformity of the “B” field is

caused by a physical geometry of the light source.

A series of test measurements of different types of light sources was made to account

for such errors.

The total flux accuracy is calculated for each type of light sources by summation of the

3 kinds of errors: Spectrometer Intensity Error + Sensor Error + Circular Field Error =

Total Lumen Accuracy

1.

A LED bulb with a frosted glass

cone.

For this type of light source the

“B” field is almost completely

circular and therefore it has a

small error when measured only

using the “A” field.

Accuracy = 0.5% + 2% + 1.6% < +/- 4.1%

2.

A LED bulb with a frosted

plastic cone.

The plastic cone exposes the

led. Thus it has a slightly

deviated distribution of the “B”

field, which results in a higher

error value

Accuracy = 0.5% + 2% + 2.3% < +/- 4.8%

3.

Fluorescent bulb with a frosted

cone.

The large field of light from a

fluorescent bulb and a

nonuniform wearing of the glass

tubes increase the error

compared to LED.

Accuracy = 0.5% + 2% + 4.6% < +/- 7.1%

18

4.

Fluorescent open bulb.

A non-frosted coned fluorescent

bulb exposes the glass tube

completely therefore producing

an oscillating “B” field, which

depends on the number of

tubes.

Accuracy = 0.5% + 2% + 7.9% < +/- 10.4%

5.

Incandescent clear glass.

Old-fashioned incandescent

bulb gives the largest error due

to a non-circular tungsten

thread.

Accuracy = 0.5% + 2% + 10.2% < +/- 12.7%

Based on the above, the average accuracy is then calculated as follows:

Total Average Lumen Error

= spectrometer intensity error + sensor error + (circular field error

type1 + type2 + type3 + type4+ type5) / 5

= 0.5% + 2% + (1.6% + 2.3% + 4.6% + 7.9% + 10.2%) / 5

= < +/- 7.82%

19

Specifications

Measurement method

Far Field, Type C

Physical Dimensions

Shipping dimensions (L x W x H)

(L x W x H) 46 x 17.5 x 37.5 cm

Shipping weight

6 kg

Dimensions (L x W x H)

43 x 11.5 x 33.5 cm

Weight

5 kg

Sensor distance

66 cm

Lamp diameter range

0 –80 mm

Lamp maximum weight

(tower in upright position)

4 kg

Electrical

Power supply input

90 - 260 VAC, 50/60 Hz

Power consumption

15 W

USB current consumption

200 mA

Power analyzer voltage range

30 VAC - 400 VAC <+/- 0.2V

Power analyzer current range

0 –3 A (Avg: +/- 0.1 mA)

Power analyzer power range

0 –300 W (Avg: +/- 0.001 W)

Power analyzer sample rate

70,000 samples/sec

Photometric

Flux, lumen @ 0.66 m

10 - 50,000 +/- 7.8%

(see “Lumen Accuracy)

Intensity, candela

0.05 –50,000 <+/- 2.5%

Color temperature

1,000 K-10,000 K <+/- 35 K

Color rendering index

0-100 <+/- 0.7

Angular resolution BASIC MODE

5-degree step (About 20 sec

measurement time per C-plane)

Angular resolution HIGH MODE

1-degree step (About 1 min

measurement time per C-plane)

Angular resolution - highest resolution

0.1-degree step (About 5 min

measurement time per C-plane)

Spectrometer type

STS Ocean Optics

Calibration

Fully calibrated with certificate

Re-calibration

Every 1 year (Maximum 2 years)

Control and interface

Control interface

USB 2.0

Control connector

USB-B

Connections

AC power in (power supply

IEC 3-pin

Control connector

Universal socket

Light source adaptors

E27, E14, B22, GU10

PC

USB B

20

Approvals

Power supply

cUL/UL, CE, CCC, TUV, FCC

Power analyzer - photometer

CE

Warranty

Warranty period

2 years

Ordering information

LightSpion

P/N LIGSP001

Table of contents

Other Viso Systems Measuring Instrument manuals

Viso Systems

Viso Systems LabFlicker User manual

Viso Systems

Viso Systems LabSpion User manual

Viso Systems

Viso Systems VISO SYSTEMS Labarazzi User manual

Viso Systems

Viso Systems LightSpion User manual

Viso Systems

Viso Systems BaseSpion User manual

Viso Systems

Viso Systems LabSpion User manual

Viso Systems

Viso Systems LabSpion User manual

Popular Measuring Instrument manuals by other brands

Hilti

Hilti PD 5 Original operating instructions

Measurement Computing

Measurement Computing 15200B quick start guide

Sears

Sears 161.2124 owner's manual

Shimadzu

Shimadzu MOC63u instruction manual

Endress+Hauser

Endress+Hauser Flexdip CYA112 operating instructions

Logitech

Logitech 200 MKIII Series user guide