VITO OILTESTER User manual

OILTESTER - Deep-frying Oil Tester

Instruction manual

2

1 Contents

3

1 Contents

1 Contents ................................................................................................... 3

2 Safety and the environment .................................................................... 4

2.1. About this document ........................................................................ 4

2.2. Ensure safety ................................................................................... 5

2.3. Protecting the environment .............................................................. 5

3 Specifications .......................................................................................... 6

3.1. Use .................................................................................................. 6

3.2. Technical data ................................................................................. 6

4 Product description ................................................................................. 8

4.1. Overview.......................................................................................... 8

4.2. Basic properties ............................................................................. 10

5 First steps .............................................................................................. 11

5.1. Commissioning .............................................................................. 11

5.2. Getting to know the product ........................................................... 13

5.2.1. Switching the instrument on/off ...................................................................... 13

5.2.2. Description of important functions and displays ............................................. 14

5.2.2.1. Alarm indicator ................................................................................ 14

5.2.2.2. Setting the TPM limit values ............................................................ 14

5.2.2.3. Hold function ................................................................................... 15

5.2.2.4. Auto-Hold function ........................................................................... 15

5.2.2.5. Auto-off function .............................................................................. 15

5.2.2.6. Battery capacity ............................................................................... 16

5.2.3. Configuring the instrument ............................................................................. 16

5.2.4. Locking / unlocking configurations ................................................................. 18

6 Using the product .................................................................................. 20

6.1. General measurement information ................................................ 20

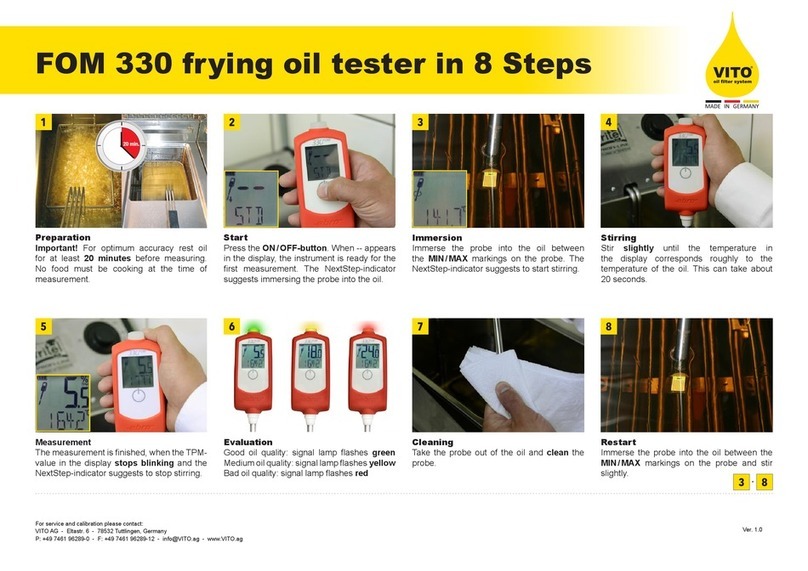

6.2. Carrying out measurements .......................................................... 21

6.3. Function test .................................................................................. 23

7 Maintaining the product ........................................................................ 24

7.1. Changing batteries ........................................................................ 24

7.2. Cleaning the sensor ....................................................................... 24

7.3. Cleaning the housing ..................................................................... 25

7.4. Cleaning the plastic case ............................................................... 25

7.5. Calibrating/adjusting the instrument .............................................. 25

8 Tips and assistance ............................................................................... 26

8.1. Questions and answers ................................................................. 26

2 Safety and the environment

4

2 Safety and the environment

2.1. About this document

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

product.

Warnings

Always pay attention to information that is marked by the following

warnings with warning pictograms. Implement the specified

precautionary measures.

Representation Explanation

WARNING Indicates potential serious injuries

NOTICE indicates circumstances that may lead to

damage to the products

Symbols and writing standards

Represen-

tation

Explanation

Note: Basic or further information.

1. ...

2. ...

Action: more steps, the sequence must be followed.

> ... Action: a step or an optional step.

- ... Result of an action.

Menu Elements of the instrument, the instrument displays

or the program interface.

2 Safety and the environment

5

[OK] Control keys of the instrument or buttons of the

program interface.

... | ... Functions/paths within a menu.

“...” Example entries

2.2. Ensure safety

> Only operate the product properly, for its intended purpose and

within the parameters specified in the technical data. Do not

use any force.

> Do not operate the instrument if there are signs of damage at

the housing, mains unit or feed lines.

> The objects to be measured or the measurement environment

may also pose risks: Note the safety regulations valid in your

area when performing the measurements.

> Temperatures given on probes/sensors relate only to the

measuring range of the sensors. Do not expose handles and

feed lines to any temperatures in excess of 70 °C unless they

are expressly permitted for higher temperatures.

> Do not perform contact measurements on non-insulated, live

parts.

> Transport and store the instrument exclusively in the aluminium

case provided in order to avoid damage to the sensor.

> Do not store the product together with solvents. Do not use any

desiccants.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts from

Vito AG.

2.3. Protecting the environment

> Dispose of faulty rechargeable batteries/spent batteries in

accordance with the valid legal specifications.

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

regulations) or return the product to Vito AG for disposal.

3 Specifications

6

3 Specifications

3.1. Use

The OILTESTER is a handy measuring instrument for the fast

inspection of deep-frying oils and is designed in equal measure for

left and right handers.

The TPM value (total polar materials) enables a statement on the

ageing of deep-frying oils due to the effects of heat.

The following measuring tasks can be performed:

• Display temperature of the deep-frying oil:

Indicator for correct setting of the deep-fryer, inspection of

integrated temperature displays.

• Display TPM value:

Indicator for the ageing of the deep-frying oil.

The sensor works on a capacitive basis and determines the total

amount of polar materials in % as the reading.

The free fatty acids that are determined above all for the evaluation

of unloaded oils (rancidity) cannot be detected.

The temperature of the deep-frying oil to be measured must

be at least 40 °C. The maximum operating temperature is

200 °C.

The sensor and the probe tube are designed to come into

contact with oil used in deep fat fryers for the typical

duration of a spot check measurement. The materials used

in these components meet the relevant requirements in the

Regulation (EC)1935/2004.

3.2. Technical data

Feature Values

Measuring range Temperature: 40.0 to 200.0 °C /

104.0 to 392.0°F

TPM: 0 to 40%

Accuracy Temperature: ± 1.5 °C

TPM1: ±2% (40.0 to 190.0 °C / 104 to 374 °F)

1 typical, referred to internal reference, at an ambient temperature of 25 °C.

3 Specifications

7

Feature Values

Resolution Temperature: 0.1 °C / 0.1 °F

TPM: 0.5%

Power supply Batteries: 2x micro (type AAA)

Battery (micro AAA) Designation according to IEC: LR03

Chem. composition: Zn-MnO2 (alkaline)

Battery life at 20 °C Approx. 25 hrs continuous operation

(corresponds to 500 measurements) without

display illumination

Temperature

sensor

PTC

TPM sensor Capacitive sensor

Operating

temperature

0 to 50 °C / 32 to 122 °F

Ambient humidity 0 to 90%RH

Storage/transport

temperature

-20 to 70 °C / -4 to 158 °F

Display LCD, 2-line, display illumination

Weight 255 g

Housing material Top part: ABS

Lower part: ABS-PC glass fibre 10%

Dimensions Approx. 50 mm x 170 mm x 300 mm

(WxHxD)

TPM response time Approx. 30 secs

Protection class IP65

Warranty 24 months

EC Directive 2014/30/EC

4 Product description

8

4 Product description

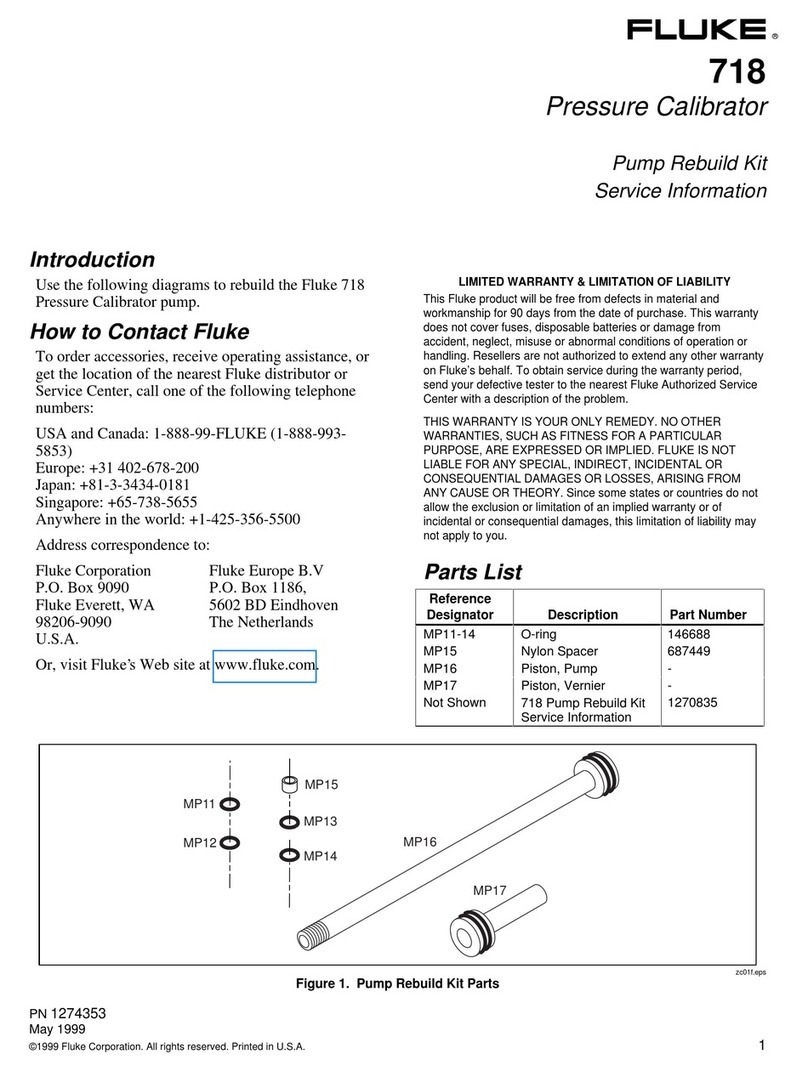

4.1. Overview

1 Display

2 Control keys

3 Battery compartment

4 Probe shaft

5 Oil quality (%TPM) and temperature sensor

6 Min. immersion depth

7 Max. immersion depth

4 Product description

9

Items shown on the display:

Items shown Function/property

200 (flashing

temperature value

> 200 °C)

Temperature measuring range exceeded

40 (flashing

temperature value

< 40 °C)

Temperature measuring range undershot

Alarm Alarm indicator activated

PIN Configuration mode locked

Battery capacity 100 %

Battery capacity 66 %

Battery capacity 33 %

Battery capacity < 10 %

Alarm Upper TPM limit value exceeded

Alarm Lower TPM limit value exceeded

Hold Readings held (manually)

Auto-Hold Readings held (automatically)

°C / °F Temperature in °C or °F

Important display messages

Item shown on the

display

Explanation

000 lights up Instrument is ready to measure, sensor is not

in oil.

Reading >190

flashes

Measured temperature is above 190 °C

(374 °F). The reading flashes in the range

from 190.1 °C (374 °F) to 200 °C (392 °F).

4 Product description

10

Control keys

Buttons Function/property

[] • Switch instrument on/off

• Configure instrument

[Hold] • Hold measuring values manually

• Switch to the measuring mode

• Configure instrument

[] • on/off; yes/no - Configure instrument

[] • on/off; yes/no - Configure instrument

Battery compartment

4.2. Basic properties

Power supply

The power is supplied to the instrument via two micro batteries

(type AAA). The batteries are included in the delivery.

5 First steps

11

5 First steps

5.1. Commissioning

Inserting batteries

CAUTION

Incorrectly inserted batteries can damage the instrument!

> Adhere to the polarity when inserting the batteries.

1. Undo the screw on the battery compartment.

2. Remove the battery holder.

5 First steps

12

3. Insert batteries. Adhere to the polarity.

4. Insert the battery holder into the battery compartment.

5. Secure battery compartment with screw.

6. Switch instrument on: Press [].

- Display test is carried out: all segments light up.

- The instrument switches to the measuring mode.

- 000 lights up on the display, the instrument is ready for use.

7. If necessary, switch instrument off.

5 First steps

13

For storage of the instrument

Suspension attachment

> The integrated suspension attachment can be used to hang the

instrument on a hook.

Plastic case

- The instrument is securely stored in a plastic case for protection

against contamination and for transport.

5.2. Getting to know the product

5.2.1. Switching the instrument on/off

To switch on

> Press [] until the indicator elements appear in the display.

- Display test is carried out: all segments light up.

- The instrument switches to the measuring mode and is ready

for operation.

To switch off

> Press and hold [] for approx. 2 secs.

- Display goes off, instrument switches off.

5 First steps

14

5.2.2. Description of important functions and displays

5.2.2.1. Alarm indicator

The alarm indicator uses the following display colours to show what

range the measured TPM value is in:

Green TPM value < lower limit value

Orange TPM value is between the lower and the upper limit value

Red TPM value > upper limit value

The alarm indicator is switched on when the instrument is

delivered. The TPM limit values are set as follows:

Lower limit value 20%

Upper limit value 24%

To activate/deactivate the alarm indicator, see Configuring the

instrument, page 16.

To set the TPM limit values, see Setting the TPM limit values, page

14.

5.2.2.2. Setting the TPM limit values

The TPM limit values can be between 0 and 40%. The

upper limit value (Alarm ) must be at least 1% higher than

the lower limit value (Alarm ).

In order to apply the settings of the lower and upper TPM

limit value, you must make sure you confirm the input of the

upper TPM limit value with [Hold].

Setting the lower TPM limit value

Requirement: Instrument is in configuration mode, see Carrying out

the configuration, page 17

1. Alarm and the set lower limit value appear on the display.

- When alarm indicator is activated: the display lights up orange.

2. Set the lower limit value with [] or [].

3. Confirm with [Hold].

- New lower limit value is applied.

- The instrument switches to the upper TPM limit value (Alarm ).

5 First steps

15

Setting the upper TPM limit value

Requirement: Instrument is in configuration mode,

lower TPM limit value has been set and confirmed with [Hold] .

1. Alarm and the set upper limit value appear on the display.

- When alarm indicator is activated: the display lights up red.

2. Set the upper limit value with [] or [].

3. Confirm with [Hold].

- New upper limit value is applied.

> Carry out further settings in the configuration menu or quit the

configuration menu with [].

5.2.2.3. Hold function

Measured values can be held manually.

Requirement: Sensor is in the oil.

1. Briefly press [Hold] (< 1 sec).

- Hold appears in the display.

- Readings are held.

2. To switch to the measuring mode: Briefly press [Hold] (<

1 sec).

- Hold function is deactivated.

- Current readings are displayed.

5.2.2.4. Auto-Hold function

When the Auto-Hold function is activated, the measured values

are automatically held by the instrument after the equalization

period.

To activate/deactivate the Auto-Hold function, see Carrying out the

configuration, page 17

5.2.2.5. Auto-off function

When the Auto-off function is activated, the instrument

automatically switches off after a certain time

• If the instrument is in measuring mode: automatic switch-off

after 2 mins.

• If the instrument is in hold or configuration mode: automatic

switch-off after 10 mins.

To activate/deactivate the Auto-off function, see Configuring the

instrument, page 16

5 First steps

16

5.2.2.6. Battery capacity

With decreasing battery capacity, a symbol lights up in the display (

). If the empty battery symbol ( ) flashes in the display, the

remaining capacity is only approx. 30 min.

If the battery voltage is too low, the instrument automatically

switches off.

> Change batteries, see Changing batteries, page 24

5.2.3. Configuring the instrument

Setting options in the configuration mode

Configurations Setting options

Setting the TPM limit values

Alarm , Alarm

Lower TPM limit value Alarm

Upper TPM limit value Alarm

Carry out calibration

CAL

no: Do not carry out calibration.

yes: Carry out calibration.

Automatically hold readings

Auto-Hold

on: Readings are automatically

held by the instrument.

off: Readings are not

automatically held.

Automatically switch off the

instrument Auto-off

on: Instrument switches off

automatically after 2 or 10 mins.

off: No automatic switch-off.

Set alarm indicator

Alarm

on: Alarm indicator activated

off: Alarm indicator deactivated

Set temperature unit

°C, °F

°C or °F

Lock configuration, including

TPM limit values

PIN

no: Do not lock configuration.

yes: Lock configuration

Carry out reset

rst

no: Do not reset the adjustment

value to the factory setting.

yes: Reset the adjustment value

to the factory settings.

Firmware version Firmware versions of the product

components are shown.

5 First steps

17

Carrying out the configuration

Requirement: The instrument is switched off.

1. Switch the instrument on.

> Switch the instrument on, press [Hold] during the display

test and hold down for approx. 2 secs.

- When the configuration menu is locked, PIN lights up.

> To unlock, set the last two figures of the serial number with [

] or [].

If an incorrect PIN is entered, the instrument switches into

measuring mode.

- When the configuration menu is not locked, you can gain

access by setting the limit values.

2. Set the alarm limit values.

- Alarm lights up in the display.

> Set lower limit value (Alarm ): [] or [] and confirm with

[Hold].

- Alarm lights up in the display.

> Set upper limit value (Alarm ): [] or [] and confirm with

[Hold].

3. Carry out / do not carry out calibration.

- CAL and no or yes light up in the display.

> Activate / deactivate calibration / adjustment function (no is

the standard setting): [] or [] and confirm with [Hold].

- Selection of yes: The instrument can be calibrated /

adjusted,

- Selection of no: No calibration / adjustment possible

4. Automatically hold readings.

- Auto-Hold and on or off light up in the display.

> Switch Auto-Hold on or off: [] or [] and confirm with

[Hold].

5. Automatically switch the instrument off.

- Auto-off and on or off light up in the display.

> Switch Auto-off on or off: [] or [] and confirm with

[Hold].

5 First steps

18

6. Set alarm indicator

- Alarm and on or off light up in the display.

> Switch alarm indicator on or off: [] or [] and confirm with

[Hold].

7. Set the temperature unit.

- °C or °F lights up in the display.

> Set the temperature unit (°C/°F): [] or [] and confirm

with [Hold].

8. Enable / disable PIN.

- PIN and yes or no light up in the display.

> Activate PIN (yes) or deactivate it (no is the standard

setting).

9. Carry out reset.

- rst and yes or no light up.

> Activate or deactivate rst: [] or [].

- Selection of yes: Delete adjustment value, is reset to the

factory setting.)

- Selection of no: no reset, adjustment value is retained).

Quitting configuration mode early and saving

You can quit the configuration mode early.

The configuration mode cannot be stopped in the

adjustment / calibration process.

> Quit configuration mode early: Press and hold [] for approx.

1 sec.

- Configuration mode is stopped.

- The values which have so far been set and confirmed with

[Hold] are applied.

- The instrument switches to the measuring mode.

5.2.4. Locking / unlocking configurations

You can lock/unlock the set values, including TPM limit values,

from the configuration mode. The instrument is delivered with the

configuration mode unlocked (PIN is deactivated, no).

Requirements: Instrument is in configuration mode.

> Go through the configuration mode with [Hold], until PIN

and yes or no light up in the display.

Lock configuration mode

> Activate PIN: Select yes with [] or [].

- PIN is activated and the configuration mode is locked.

5 First steps

19

The last two figures of the instrument's serial number are

automatically set as the PIN (see sticker on the instrument).

Unlock configuration mode

Requirement: PIN is activated and the instrument is in configuration

mode.

Enter PIN:

> Select first figure: [] or [] and confirm with [Hold].

> Select second figure: [] or [] and confirm with [Hold].

If an incorrect PIN is entered, the instrument switches into

measuring mode.

- The configuration mode is enabled for the duration of the

settings being carried out.

Deactivate PIN:

> Go through the configuration mode with [Hold], until PIN

and yes or no light up in the display.

> Deactivate PIN: Select no with [] or [].

- Settings can be carried out without entering the PIN.

6 Using the product

20

6 Using the product

6.1. General measurement information

The instrument enables several measurements to be carried out

one immediately after the other without any waiting times.

Which oils/cooking fats can be measured?

In principle, all oils and fats intended for deep fat frying can be

measured.

This includes, for example, rapeseed, soya bean, sesame, palm,

olive, cotton seed or groundnut oil. Fats from animal sources can

also be measured. There may be a variation of several percentage

points in the % TPM value for fresh cooking oils, depending on the

type.

The maximum service life for the cooking oil cannot be derived

from this.

Example: Fresh palm oil has a higher % TPM value than other

cooking oils, but ages considerably more slowly.

Use of additives

The instrument is designed for the use of pure fats/oils. If additives

are used, deviations may occur.

Comparison of laboratory methods / OILTESTER

Cooking oil is a mixture of substances with a wide variety of

polarities. During ageing, the proportion of more highly polar

components increases. The laboratory method of column

chromatography separates the fat into a polar and a non-polar

group. The proportion of the polar group compared to the total

amount of cooking oil being investigated is described as the

% TPM value (total polar materials).

The % TPM value established by column chromatography may

vary slightly depending on the setting of the separation limit

between the polar and the non-polar group.

Depending on the type of fat, slight variations of the polarity in both

groups (polar/non-polar) may occur which are not however

identified by the chromatography.

On the other hand, the instrument records the entire polarity of the

cooking oil and thus the actual polarity of both groups (polar/non-

polar). This means the reading of the instrument may be higher or

lower than that of the column chromatography in individual cases.

Table of contents

Other VITO Test Equipment manuals

Popular Test Equipment manuals by other brands

Fluke

Fluke NX1 Pocket Toner user guide

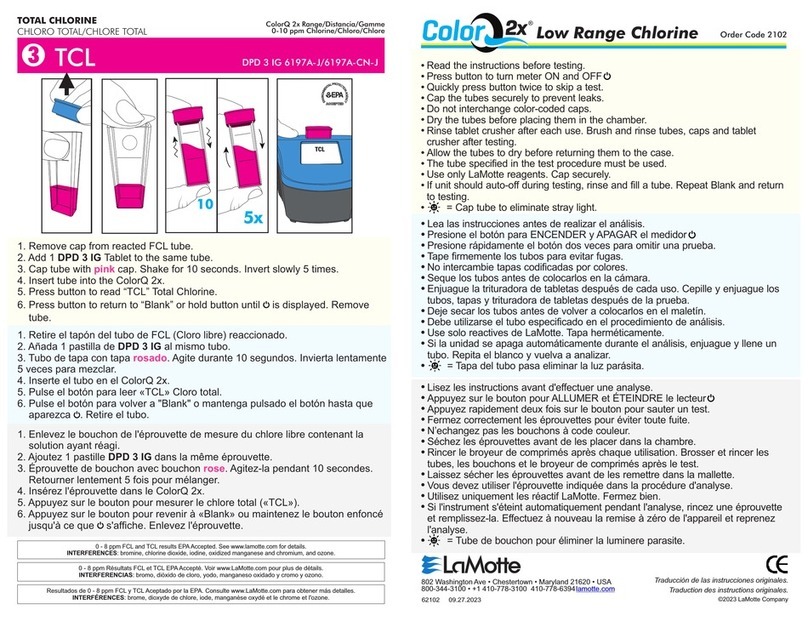

TCL

TCL HLORO TOTAL quick start guide

Presys

Presys TA-1200P Technical manual

Psiber Data Systems

Psiber Data Systems NETWORK IP TESTER user guide

Keithley

Keithley Interactive SourceMeter 2450 Declassification and security instructions

Additel

Additel ADT209 user manual