Presys TA-1200P User manual

®

Q

Y

U

T

A

L

I

E

N

T

M

S

E

Y

G

S

A

T

N

E

A

M

M

Temperature Advanced

Calibrators

TA-1200P

Technical Manual

EM0295-03

presys

presys

presys

presys

Temperature Advanced

presys

Temperature Advanced

Calibrators

presys

Calibrators

Calibrators

presys

Calibrators

TA-1200P

presys

TA-1200P

TA-1200P

presys

TA-1200P

EC Declaration of Conformity

We declare under our sole responsability that the CE marked products, are in conformity

with the essential requirements of the following EC Directives when installed in

accordance with the installation instructions contained in the product documentation:

Series

TA-1200P

Description

Dry-Block Temperature Calibrator

LVD

Low Voltage Directive

2014/35/EC

of the European Parliament and of the Council of 12 December 2006 on

the harmonization of the laws of Member States relating to Electrical Equipment

designed for use within certain voltage limits.

EN 61010-1:2011

Safety requirements for electrical equipment for measurement, control and laboratory

use

EN 61010-2:010

Safety requirements for electrical equipment for measurement, control and laboratory

use -Part 2-010: Particular requirements for laboratory equipment for the heating of

Materials.

EMC directive

2004/108/EC

of the European Parliament and of the Council of 15 December 2004

on the approximation of the laws of the Member States relating to electromagnetic

compatibility and repealing Directive 89/336/EEC

EN 61326-1:2003

Electrical equipment for measurement, control and laboratory use -EMC requirements

São Paulo, 8 September 2016

Vinicius José Gomes Nunes

Antonio Rafael Sito Antunes

CEO

Engineering Manager

presys

presys

We declare under our sole responsability that the CE marked products,

presys

We declare under our sole responsability that the CE marked products,

are in conformity

presys

are in conformity

irectives

presys

irectives

when installe

presys

when installe

d in

presys

d in

installation instructions contained in the product documentation

presys

installation instructions contained in the product documentation

:

presys

:

Block Temperature Calibrator

presys

Block Temperature Calibrator

presys

of the European Parliament and of the Council of 12 December 2006 on

presys

of the European Parliament and of the Council of 12 December 2006 on

presys

harmonization

presys

harmonization

of the laws of Member States relating to Electrical Equipment

presys

of the laws of Member States relating to Electrical Equipment

of the laws of Member States relating to Electrical Equipment

presys

of the laws of Member States relating to Electrical Equipment

presys

designed for use within certain voltage limits

presys

designed for use within certain voltage limits

.

presys

.

Safety requirements for electrical

presys

Safety requirements for electrical

equipment for measurement, control and laboratory

presys

equipment for measurement, control and laboratory

use

presys

use

:010

presys

:010

Safety requirements for electrical equipment for measurement, control and laboratory

presys

Safety requirements for electrical equipment for measurement, control and laboratory

use

presys

use

-

presys

-

Part 2

presys

Part 2

-

presys

-

010: Particular requirements for

presys

010: Particular requirements for

Materials

presys

Materials

.

presys

.

EMC directive

presys

EMC directive

2004/108/EC

presys

2004/108/EC

of the European Parliament and of the Council of 15 December 2004

presys

of the European Parliament and of the Council of 15 December 2004

on the approximation of the laws of the Member States relating to electromagnetic

presys

on the approximation of the laws of the Member States relating to electromagnetic

compatibility and repealing Directive 89/336/EEC

presys

compatibility and repealing Directive 89/336/EEC

EN

presys

EN

61326

presys

61326

-

presys

-

1:2003

presys

1:2003

Electrical equipment for measurement, control and laboratory use

presys

Electrical equipment for measurement, control and laboratory use

S

presys

S

ão Paulo

presys

ão Paulo

,

presys

,

8

presys

8

September 201

presys

September 201

presys

presys

presys

presys

presys

The warranty conditions are available in our sites:

www.presys.com.br/warranty

presys

presys

The warranty conditions are available in our sites:

presys

The warranty conditions are available in our sites:

presys

presys

presys

www.presys.com.br/warranty

presys

www.presys.com.br/warranty

presys

presys

PRESYS Instrumentos e Sistemas TA-1200P

EM0295-03

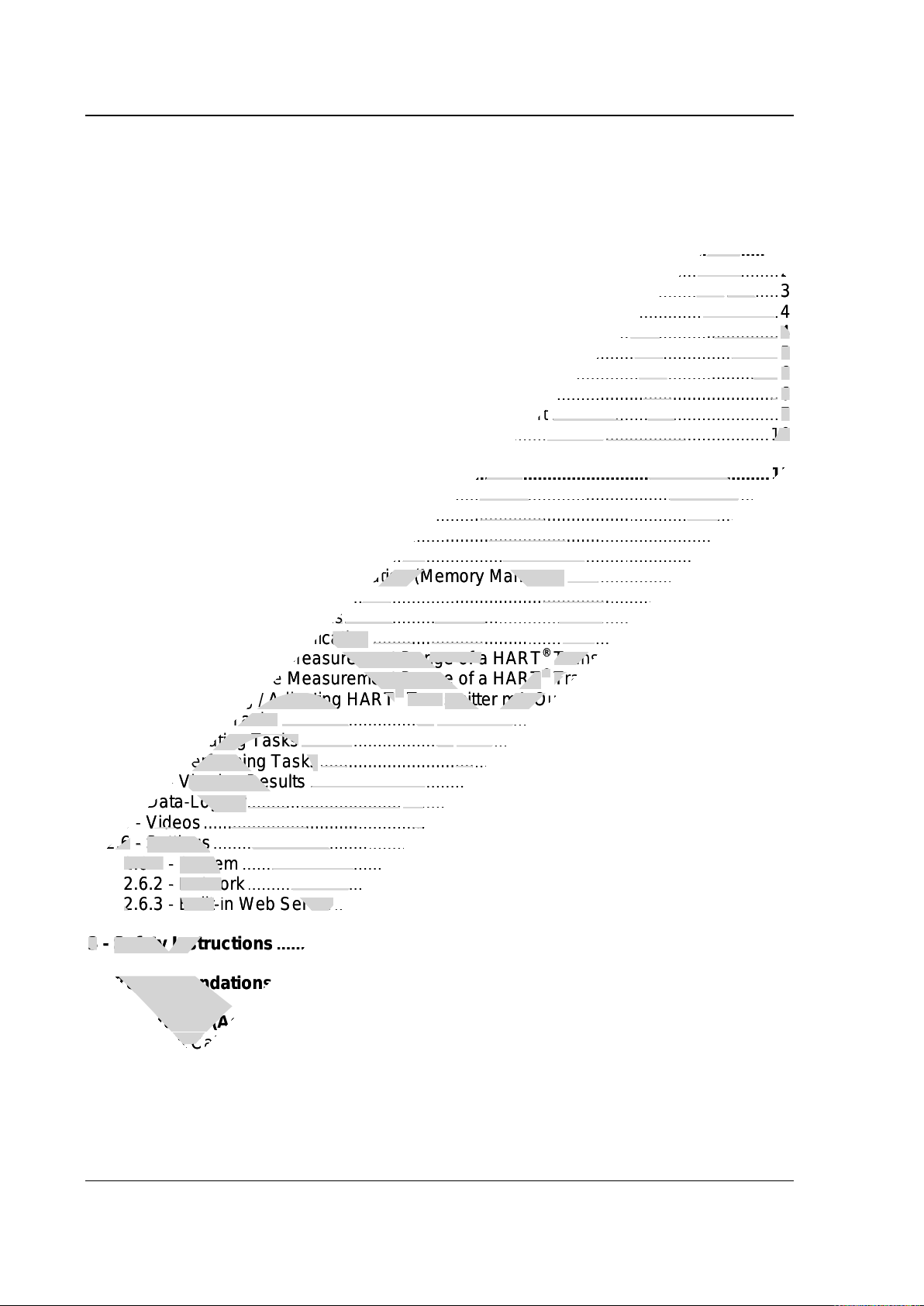

Table of Contents

1 - Introduction....................................................................................................................1

1.1 -Technical Specifications...........................................................................................2

1.1.1 -Input Technical Specifications...........................................................................3

1.1.2 -Special Software Features................................................................................4

1.2 -Order Code...............................................................................................................4

1.3 - Accessories ..............................................................................................................5

1.4 -Initial Usage..............................................................................................................6

1.5 -Mounting the insert inside the furnace.....................................................................6

1.6 -Instruction for use of the optional Black Body insert...............................................7

1.7 -Parts Identification..................................................................................................10

2 - Calibrator Operation...................................................................................................11

2.1 -Calibrator Menu......................................................................................................12

2.1.1 –Probe Reference.............................................................................................14

2.1.2 -Input Settings...................................................................................................16

2.1.3 -Special Function..............................................................................................20

2.1.4 -Saving Current Configuration (Memory Manager)..........................................21

2.2 -Hart®Configuration.................................................................................................22

2.2.1 -HART®Connections........................................................................................22

2.2.2 -Starting Communication..................................................................................23

2.2.3 -Adjusting the Measurement Range of a HART®Transmitter..........................23

2.2.4 -Adjusting the Measurement Range of a HART®Transmitter with Reference24

2.2.5 -Checking / Adjusting HART®Transmitter mA Output.....................................25

2.3 -Automatic Tasks.....................................................................................................26

2.3.1 -Creating Tasks.................................................................................................26

2.3.2 -Performing Tasks.............................................................................................29

2.3.3 -Viewing Results...............................................................................................29

2.4 -Data-Logger............................................................................................................31

2.5 -Videos.....................................................................................................................32

2.6 -Settings...................................................................................................................32

2.6.1 - System.............................................................................................................32

2.6.2 -Network............................................................................................................34

2.6.3 -Built-in Web Server..........................................................................................34

3 - Safety Instructions......................................................................................................36

4 - Recommendations as regards Accuracy of Measurements .................................36

5 - Calibration (Adjustment)............................................................................................37

5.1 -Input Calibration .....................................................................................................37

5.2 -Probe Calibration....................................................................................................38

5.3 -PID Control Parameters.........................................................................................39

6 - Maintenance.................................................................................................................39

6.1 -Instructions for Hardware Maintenance.................................................................39

presys

....................

presys

....................

...........................

presys

...........................

2

presys

2

................................

presys

................................

...........

presys

...........

3

presys

3

................................

presys

................................

................

presys

................

4

presys

4

................................

presys

................................

...............

presys

...............

4

presys

4

................................

presys

................................

..............

presys

..............

5

presys

5

................................

presys

................................

..............

presys

..............

6

presys

6

................................

presys

................................

................................

presys

................................

.....

presys

.....

6

presys

6

Instruction for use of the optional Black Body insert

presys

Instruction for use of the optional Black Body insert

................................

presys

................................

...............

presys

...............

7

presys

7

................................

presys

................................

................................

presys

................................

..

presys

..

10

presys

10

................................

presys

................................

................................

presys

................................

...

presys

...

11

presys

11

................................

presys

................................

................................

presys

................................

......

presys

......

................................

presys

................................

................................

presys

................................

.............................

presys

.............................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

..............................

presys

..............................

Saving Current Configuration (Memory Manager)

presys

Saving Current Configuration (Memory Manager)

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

Connections

presys

Connections

................................

presys

................................

................................

presys

................................

Starting Communication

presys

Starting Communication

................................

presys

................................

................................

presys

................................

Adjusting the Measurement Range of a HART

presys

Adjusting the Measurement Range of a HART

®

presys

®

Transmi

presys

Transmi

Adjusting the Measurement Range of a HART

presys

Adjusting the Measurement Range of a HART

®

presys

®

Transmitter with Reference

presys

Transmitter with Reference

Checking / Adjusting HART

presys

Checking / Adjusting HART

®

presys

®

Tran

presys

Tran

smitter mA Output

presys

smitter mA Output

Automatic Tasks

presys

Automatic Tasks

................................

presys

................................

................................

presys

................................

Creating Tasks

presys

Creating Tasks

................................

presys

................................

................................

presys

................................

Performing Tasks

presys

Performing Tasks

................................

presys

................................

................................

presys

................................

-

presys

-

Viewing Results

presys

Viewing Results

................................

presys

................................

Data

presys

Data

-

presys

-

Logger

presys

Logger

................................

presys

................................

................................

presys

................................

2.5

presys

2.5

-

presys

-

Videos

presys

Videos

................................

presys

................................

................................

presys

................................

2.6

presys

2.6

-

presys

-

Settings

presys

Settings

................................

presys

................................

................................

presys

................................

2.6.1

presys

2.6.1

-

presys

-

System

presys

System

................................

presys

................................

2.6.2

presys

2.6.2

-

presys

-

Network

presys

Network

................................

presys

................................

2.6.3

presys

2.6.3

-

presys

-

Built

presys

Built

-

presys

-

in Web Server

presys

in Web Server

................................

presys

................................

3

presys

3

-

presys

-

Safety Instructions

presys

Safety Instructions

presys

................................

presys

................................

Recommendations as regards Accuracy of Measurements

presys

Recommendations as regards Accuracy of Measurements

Calibration (Adjustment)

presys

Calibration (Adjustment)

presys

Input Cali

presys

Input Cali

Probe Calibration

presys

Probe Calibration

PRESYS Instruments TA-1200P

Page 1

1 - Introduction

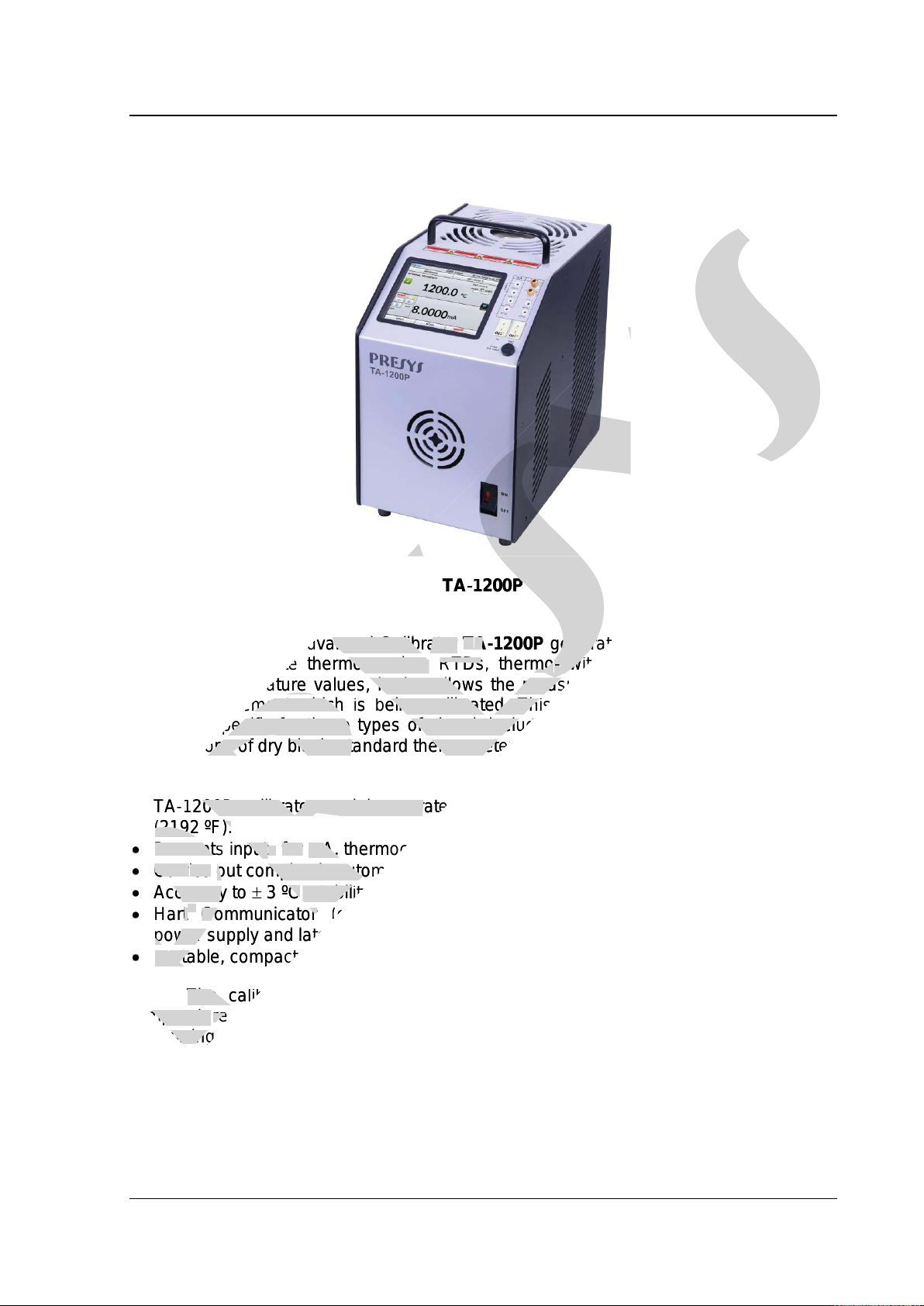

TA-1200P

Temperature Advanced Calibrator TA-1200Pgeneratestemperature in the insert

in order to calibrate thermocouples, RTDs, thermo-switches. Besides providing high

accuracy temperature values, it also allows the measurement of signals generated by

the thermo-element which is being calibrated. This is possible due to an embedded

calibrator specific for these types of signal, including 4-20 mA. Thus, they incorporate

the functions of dry block, standard thermometer and calibrator for RTD, TC and mA.

•TA-1200P calibrator model generatestemperatures from 50 ºC (122 ºF) to 1200 ºC

(2192 ºF).

•Presents inputsfor mA, thermocouples, RTDs and thermo-switches.

•Carries out completely automatic calibrations with or without the use of a computer.

•Accuracy to 3 ºC, stability of 0.2 ºC and resolution of 0.1 ºC.

•Hart®Communicator (optional) with internal resistance configurable, transmitter

power supply and latest DD as option.

•Portable, compact, provides interchangeable inserts and carrying case.

The calibrator also provides an input for an external probe to perform the

temperature measurement from a standard sensor (optional) inserted in the same

measuring zone of the sensor to be calibrated, increasing the accuracy and decreasing

loading effects. The standard sensor calibration curve follows the parameterization of

ITS-90.

It presentsa wide variety of programming resources, allowing the performance of

automatic calibrations.In this case, the sensor is placed in the insert and its electrical

presys

presys

T

presys

T

A

presys

A

-

presys

-

1200P

presys

1200P

Temperature Advanced Calibrator

presys

Temperature Advanced Calibrator

T

presys

T

A

presys

A

-

presys

-

1200

presys

1200

P

presys

P

generate

presys

generate

in order to calibrate thermocouples,

presys

in order to calibrate thermocouples,

RTDs

presys

RTDs

, thermo

presys

, thermo

-

presys

-

switches. Besides providing high

presys

switches. Besides providing high

accuracy temperature values, it also allows the measurement of signals generated by

presys

accuracy temperature values, it also allows the measurement of signals generated by

element which

presys

element which

is

presys

is

being calibrated. This is possible due to

presys

being calibrated. This is possible due to

calibrator specific for these types of signal, including 4

presys

calibrator specific for these types of signal, including 4

the functions of dry block, standard thermometer and calibrator for RTD, TC and mA.

presys

the functions of dry block, standard thermometer and calibrator for RTD, TC and mA.

TA

presys

TA

-

presys

-

1200P calibrator model generate

presys

1200P calibrator model generate

(2192

presys

(2192

ºF).

presys

ºF).

•

presys

•

Present

presys

Present

s

presys

s

input

presys

input

s

presys

s

for

presys

for

mA,

presys

mA,

thermocouples,

presys

thermocouples,

•

presys

•

Carr

presys

Carr

ies

presys

ies

out completely automatic calibrations with or without the use of a computer.

presys

out completely automatic calibrations with or without the use of a computer.

•

presys

•

Accuracy to

presys

Accuracy to

presys

3 ºC

presys

3 ºC

, stability of 0.2 ºC and resolution of 0.1 ºC

presys

, stability of 0.2 ºC and resolution of 0.1 ºC

•

presys

•

Hart

presys

Hart

®

presys

®

Communicator

presys

Communicator

(optional) with internal resistance configurable, transmitter

presys

(optional) with internal resistance configurable, transmitter

power supply and latest DD as option.

presys

power supply and latest DD as option.

•

presys

•

Portable, compact, provides interchangeable inserts and carrying case.

presys

Portable, compact, provides interchangeable inserts and carrying case.

The calibrator also provides an input for an external probe to perform the

presys

The calibrator also provides an input for an external probe to perform the

temperatu

presys

temperatu

re

presys

re

presys

measurement

presys

measurement

measuring zone of the sensor to be calibrated, increasing the accuracy and decreasing

presys

measuring zone of the sensor to be calibrated, increasing the accuracy and decreasing

loading effects. The standard sensor calibration curve follows the parameterization of

presys

loading effects. The standard sensor calibration curve follows the parameterization of

PRESYS Instruments TA-1200P

Page 2

terminals are connected to the embedded calibrator. The operator defines the calibration

points and the number of repetitions (task), then the process is started and all the

sequence is automatically accomplished. After completing the task, a Calibration Report

is issued and it can be printed directly in a USB connected printer or can be generated a

PDF document.

It has HART® communication for reading and setting parameters of field devices

that have this protocol.

TA-1200Phasalso many other features, such as:

•RTD input for 2, 3 and 4 wires. Table IEC 60751, JIS or Callendar-Van Dusen

user-configurable. Engineering units configurable to °C, °F and K.

•Built in Web Server, Ethernet communication.

•USB port for software/firmware upgrade.

•HART®Communication Protocol (optional).

•The electric signal calibrator is independent from the dry block function.

•Display indication when the temperature reaches the desired value.

•5.7 inches touchscreen display that eases the operation and configuration of the

calibrator.

•Thermo-element reading scaled to ITS-90 or IPTS-68.

•Internal regulated 24 Vdc power supply for 2-wire transmitters.

•Independent circuit for over-temperature protection and safety.

•Insert to choose, carrying case, handles and test leads included. If the insert is not

specified, it will be provided the insert type IN06.

1.1 -Technical Specifications

TA-1200P

Operating Range

50 to 1200 °C

Display Accuracy

2.2 °C

Resolution

0.1 ºC

Stability

0.1ºC

Radial Uniformity

(homogeneity)

0.05 ºC @ 50 ºC

0.15 ºC @ 650 ºC

0.20 ºC @1100 ºC

Axial Uniformity

(homogeneity) (20 mm)

0.15 ºC @ 50 ºC

0.25 ºC @ 650 ºC

0.25 ºC @1100 ºC

Heating Time

100 min (100 ºC to 1200 ºC)

Cooling Time

5 h (1200 ºC to 200 ºC)

Electric Power

800 W

Well Diameter x Depth

Ø 34 mm x 130 mm

Weight

12.6 kg

Dimension (HxWxD)

350 x 205 x 325 mm

presys

It has HART® communication for reading and setting parameters of field devices

presys

It has HART® communication for reading and setting parameters of field devices

RTD input for 2, 3 and 4 wires. Table IEC 60751, JIS or

presys

RTD input for 2, 3 and 4 wires. Table IEC 60751, JIS or

Callendar

presys

Callendar

-

presys

-

Callendar-Callendar

presys

Callendar-Callendar

Van

presys

Van

Dusen

presys

Dusen

Engineering units configurable to °C, °F

presys

Engineering units configurable to °C, °F

and

presys

and

K.

presys

K.

The electric signal calibrator is independent from the dry bloc

presys

The electric signal calibrator is independent from the dry bloc

k function.

presys

k function.

when the temperature reaches the desired value.

presys

when the temperature reaches the desired value.

that eases the operation and configuration of the

presys

that eases the operation and configuration of the

element reading scaled to ITS

presys

element reading scaled to ITS

-

presys

-

90 or IPTS

presys

90 or IPTS

-

presys

-

68.

presys

68.

supply for 2

presys

supply for 2

-

presys

-

wire transmitters.

presys

wire transmitters.

temperature protection and safety.

presys

temperature protection and safety.

Insert to choose, carrying case,

presys

Insert to choose, carrying case,

handles

presys

handles

and test leads included. If the insert is not

presys

and test leads included. If the insert is not

specified, it will be provided the insert type

presys

specified, it will be provided the insert type

IN

presys

IN

06.

presys

06.

Technical Sp

presys

Technical Sp

ecifications

presys

ecifications

Operating Range

presys

Operating Range

presys

presys

presys

presys

presys

Display

presys

Display

Accuracy

presys

Accuracy

presys

presys

presys

presys

Resolution

presys

Resolution

presys

presys

presys

presys

presys

S

presys

S

tability

presys

tability

presys

presys

presys

presys

Radial Uniformity

presys

Radial Uniformity

(homogeneity)

presys

(homogeneity)

presys

presys

presys

presys

presys

Axial

presys

Axial

Uniformity

presys

Uniformity

(homogeneity)

presys

(homogeneity)

(20 mm)

presys

(20 mm)

presys

presys

presys

presys

Heating

presys

Heating

Time

presys

Time

presys

presys

Cooling

presys

Cooling

Time

presys

Time

presys

Electric Power

presys

Electric Power

presys

presys

ameter x Depth

presys

ameter x Depth

presys

PRESYS Instruments TA-1200P

Page 3

1.1.1 - Input Technical Specifications

Input Ranges

Resolution

Accuracy

Remarks

millivolt

-150 mV to 150 mV

0.001 mV

0.01 % FS*

R

input

> 10 M

150 mV to 2450 mV

0.01 mV

0.02 % FS

auto-ranging

mA

-1 mA to 24.5 mA 0.0001 mA 0.01% FS Rinput < 120

resistance

0 to 400

400 to 2500 0.01

0.01

0.01 % FS

0.03 % FS

Excitation current

0.85 mA

auto-ranging

Pt-100

-200 to 850

C / -328 to 1562

F

0.01

C / 0.01

F

0.1

C /

0.2

F

IEC 60751

Pt-1000

-200 to 400

C / -328 to 752

F

0.1

C / 0.1

F

0.1

C /

0.2

F

IEC 60751

Cu-10

-200 to 260 C / -328 to 500 F0.1 C / 0.1 F2.0 C / 4.0 FMinco 16-9

Ni-100

-60 to 250

C / -76 to 482

F

0.1

C / 0.1

F

0.2

C /

0.4

F

DIN-43760

TC-J

-210 to 1200

C / -346 to 2192

F

0.1

C / 0.1

F

0.2

C /

0.4

F

IEC 60584

TC-K

-270 to -150

C / -454 to -238

F

0.1

C / 0.1

F

0.5

C /

1.0

F

IEC 60584

TC-K

-150 to 1370

C / -238 to 2498

F

0.1

C / 0.1

F

0.2

C /

0.4

F

IEC 60584

TC-T

-260 to -200 C / -436 to -328 F0.1 C / 0.1 F0.6 C / 1.2 FIEC 60584

TC-T

-200 to -75 C / -328 to -103 F0.1 C / 0.1 F0.4 C / 0.8 FIEC 60584

TC-T

-75 to 400 C / -103 to 752 F0.1 C / 0.1 F0.2 C / 0.4 FIEC 60584

TC-B

50 to 250 C / 122 to 482 F0.1 C / 0.1 F2.5 C / 5.0 FIEC 60584

TC-B

250 to 500

C / 482 to 932

F

0.1

C / 0.1

F

1.5

C /

3.0

F

IEC 60584

TC-B

500 to 1200 C / 932 to 2192 F0.1 C / 0.1 F1.0 C / 2.0 FIEC 60584

TC-B

1200 to 1820 C / 2192 to 3308 F0.1 C / 0.1 F0.7 C / 1.4 FIEC 60584

TC-R

-50 to 300

C / -58 to 572

F

0.1

C / 0.1

F

1.0

C /

2.0

F

IEC 60584

TC-R

300 to 1760

C / 572 to 3200

F

0.1

C / 0.1

F

0.7

C /

1.4

F

IEC 60584

TC-S

-50 to 300 C / -58 to 572 F0.1 C / 0.1 F1.0 C / 2.0 FIEC 60584

TC-S

300 to 1760

C / 572 to 3200

F

0.1

C / 0.1

F

0.7

C /

1.4

F

IEC 60584

TC-E

-270 to -150 C / -454 to -238 F0.1 C / 0.1 F0.3 C / 0.6 FIEC 60584

TC-E

-150 to 1000

C / -238 to 1832

F

0.1

C / 0.1

F

0.1

C /

0.2

F

IEC 60584

TC-N

-260 to -200 C / -436 to -328 F0.1 C / 0.1 F1.0 C / 2.0 FIEC 60584

TC-N

-200 to -20 C / -328 to -4 F0.1 C / 0.1 F0.4 C / 0.8 FIEC 60584

TC-N

-20 to 1300 C / -4 to 2372 F0.1 C / 0.1 F0.2 C / 0.4 FIEC 60584

TC-L

-200 to 900

C / -328 to 1652

F

0.1

C / 0.1

F

0.2

C /

0.4

F

DIN-43710

TC-C

0 to 1500

C / 32 to 2732

F

0.1

C / 0.1

F

0.5

C /

1.0

F

W5Re / W26Re

TC-C

1500 to 2320

C / 2732 to 4208

F

0.1

C / 0.1

F

0.7

C /

1.4

F

W5Re / W 26Re

*FS = Full Scale

Accuracy values are valid within one year and temperature range of 20 to 26 °C.

Outside these limits add 0.001 % FS / C taking 23 °C as the reference temperature.

For thermocouples, using the internal cold junction compensation add a cold junction

compensation error of 0.2 C or 0.4 F max.

presys

auto

presys

auto

-

presys

-

ranging

presys

ranging

R

presys

R

inpu

presys

inpu

t

presys

t

< 120

presys

< 120

presys

presys

Excitation current

presys

Excitation current

0.85

presys

0.85

mA

presys

mA

auto

presys

auto

-

presys

-

ranging

presys

ranging

presys

presys

presys

presys

C /

presys

C /

presys

0.2

presys

0.2

presys

F

presys

F

IEC 60751

presys

IEC 60751

presys

presys

presys

presys

presys

0.1

presys

0.1

presys

C /

presys

C /

presys

0.2

presys

0.2

presys

F

presys

F

IEC 60751

presys

IEC 60751

presys

presys

presys

presys

presys

presys

presys

2.0

presys

2.0

presys

C /

presys

C /

presys

4.0

presys

4.0

presys

F

presys

F

Minco 16

presys

Minco 16

-

presys

-

9

presys

9

presys

presys

presys

presys

presys

presys

presys

0.2

presys

0.2

presys

C /

presys

C /

presys

0.4

presys

0.4

presys

F

presys

F

DIN

presys

DIN

-

presys

-

43760

presys

43760

presys

presys

presys

presys

presys

presys

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

0.2

presys

0.2

presys

C /

presys

C /

presys

0.4

presys

0.4

presys

F

presys

F

IEC 60584

presys

IEC 60584

presys

presys

presys

presys

presys

presys

presys

presys

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

0.5

presys

0.5

presys

C /

presys

C /

presys

1.0

presys

1.0

presys

F

presys

F

IEC 60584

presys

IEC 60584

presys

presys

presys

presys

presys

presys

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

0.2

presys

0.2

presys

C /

presys

C /

presys

0.4

presys

0.4

presys

F

presys

F

IEC 60584

presys

IEC 60584

presys

presys

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

0.6

presys

0.6

presys

C /

presys

C /

presys

1.2

presys

1.2

presys

F

presys

F

IEC 60584

presys

IEC 60584

presys

presys

presys

presys

presys

presys

presys

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

0.4

presys

0.4

presys

C /

presys

C /

presys

0.8

presys

0.8

presys

F

presys

F

IEC 60584

presys

IEC 60584

presys

presys

presys

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

0.2

presys

0.2

presys

C /

presys

C /

presys

0.4

presys

0.4

presys

F

presys

F

IEC 60584

presys

IEC 60584

presys

presys

presys

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

2.5

presys

2.5

presys

C /

presys

C /

presys

5.0

presys

5.0

presys

F

presys

F

presys

presys

presys

presys

presys

presys

presys

presys

C / 482 to 932

presys

C / 482 to 932

presys

F

presys

F

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

1.5

presys

1.5

presys

C /

presys

C /

presys

3.0

presys

3.0

presys

presys

C / 932 to 2192

presys

C / 932 to 2192

presys

F

presys

F

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

1.0

presys

1.0

presys

C /

presys

C /

presys

2.0

presys

2.0

presys

presys

C / 2192 to 3308

presys

C / 2192 to 3308

presys

F

presys

F

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

0.7

presys

0.7

presys

C /

presys

C /

presys

presys

58 to 572

presys

58 to 572

presys

F

presys

F

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

1.0

presys

1.0

presys

presys

presys

presys

presys

presys

presys

presys

presys

C / 572 to 3200

presys

C / 572 to 3200

presys

F

presys

F

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

0.7

presys

0.7

presys

presys

50 to 300

presys

50 to 300

presys

C /

presys

C /

-

presys

-

58 to 572

presys

58 to 572

presys

F

presys

F

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

presys

presys

presys

presys

presys

presys

300 to 1760

presys

300 to 1760

presys

C / 572 to 3200

presys

C / 572 to 3200

presys

F

presys

F

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

F

presys

F

presys

270 to

presys

270 to

-

presys

-

150

presys

150

presys

C /

presys

C /

-

presys

-

454 to

presys

454 to

-

presys

-

238

presys

238

presys

F

presys

F

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

presys

presys

presys

-

presys

-

150 to 1000

presys

150 to 1000

presys

C /

presys

C /

-

presys

-

238 to 1832

presys

238 to 1832

presys

F

presys

F

presys

0.1

presys

0.1

presys

C / 0.1

presys

C / 0.1

presys

-

presys

-

N

presys

N

-

presys

-

260 to

presys

260 to

-

presys

-

200

presys

200

presys

C /

presys

C /

-

presys

-

436 to

presys

436 to

-

presys

-

328

presys

328

presys

F

presys

F

0.1

presys

0.1

presys

presys

presys

presys

presys

presys

presys

TC

presys

TC

-

presys

-

N

presys

N

-

presys

-

200 to

presys

200 to

-

presys

-

20

presys

20

presys

C /

presys

C /

-

presys

-

328 to

presys

328 to

-

presys

-

4

presys

4

presys

F

presys

F

0.1

presys

0.1

presys

TC

presys

TC

-

presys

-

N

presys

N

-

presys

-

20 to 1300

presys

20 to 1300

presys

C /

presys

C /

-

presys

-

4 to 2372

presys

4 to 2372

presys

F

presys

F

TC

presys

TC

-

presys

-

L

presys

L

-

presys

-

200 to 900

presys

200 to 900

presys

C /

presys

C /

-

presys

-

328 to 1652

presys

328 to 1652

presys

F

presys

F

presys

presys

presys

presys

TC

presys

TC

-

presys

-

C

presys

C

0 to 1500

presys

0 to 1500

presys

C / 32 to 2732

presys

C / 32 to 2732

presys

F

presys

F

presys

presys

presys

presys

presys

TC

presys

TC

-

presys

-

C

presys

C

1500 to 2320

presys

1500 to 2320

presys

C / 2732 to 4208

presys

C / 2732 to 4208

presys

presys

presys

presys

presys

presys

*FS = Full Scale

presys

*FS = Full Scale

Ac

presys

Ac

curacy values are valid within one

presys

curacy values are valid within one

Outside these limits add 0.001 % FS /

presys

Outside these limits add 0.001 % FS /

For thermocouples, using the internal cold junction compensation add a cold junction

presys

For thermocouples, using the internal cold junction compensation add a cold junction

presys

compensation error of

presys

compensation error of

PRESYS Instruments TA-1200P

Page 4

1.1.2 - Special Software Features

-Special Function:

SCALE:makes the scaling of mA input.

-Memory Manager: stores configuration types predefined by the user.

-Automated Tasks: creating of calibration work orders and automatic execution of

calibration services, storage of data and reporting.

-Data Logger:monitoring of input or output signals, storage and visualization of

data in chart or table.

-Videos: storage and viewing videos on the calibrator screen.

1.2 -Order Code

Notes:

*Changes can be introduced in the instrument, altering specifications in this manual.

* HART®is a FieldComm Group trademark.

presys

tores configuration types predefined by the user.

presys

tores configuration types predefined by the user.

calibration work orders and automatic execution of

presys

calibration work orders and automatic execution of

, storage and visualization of

presys

, storage and visualization of

he calibrator screen.

presys

he calibrator screen.

presys

Notes:

presys

Notes:

*

presys

*

Changes can be introduced in the instrument, altering specifications in this manual.

presys

Changes can be introduced in the instrument, altering specifications in this manual.

* HART

presys

* HART

®

presys

®

is a

presys

is a

Field

presys

Field

Comm Group

presys

Comm Group

PRESYS Instruments TA-1200P

Page 5

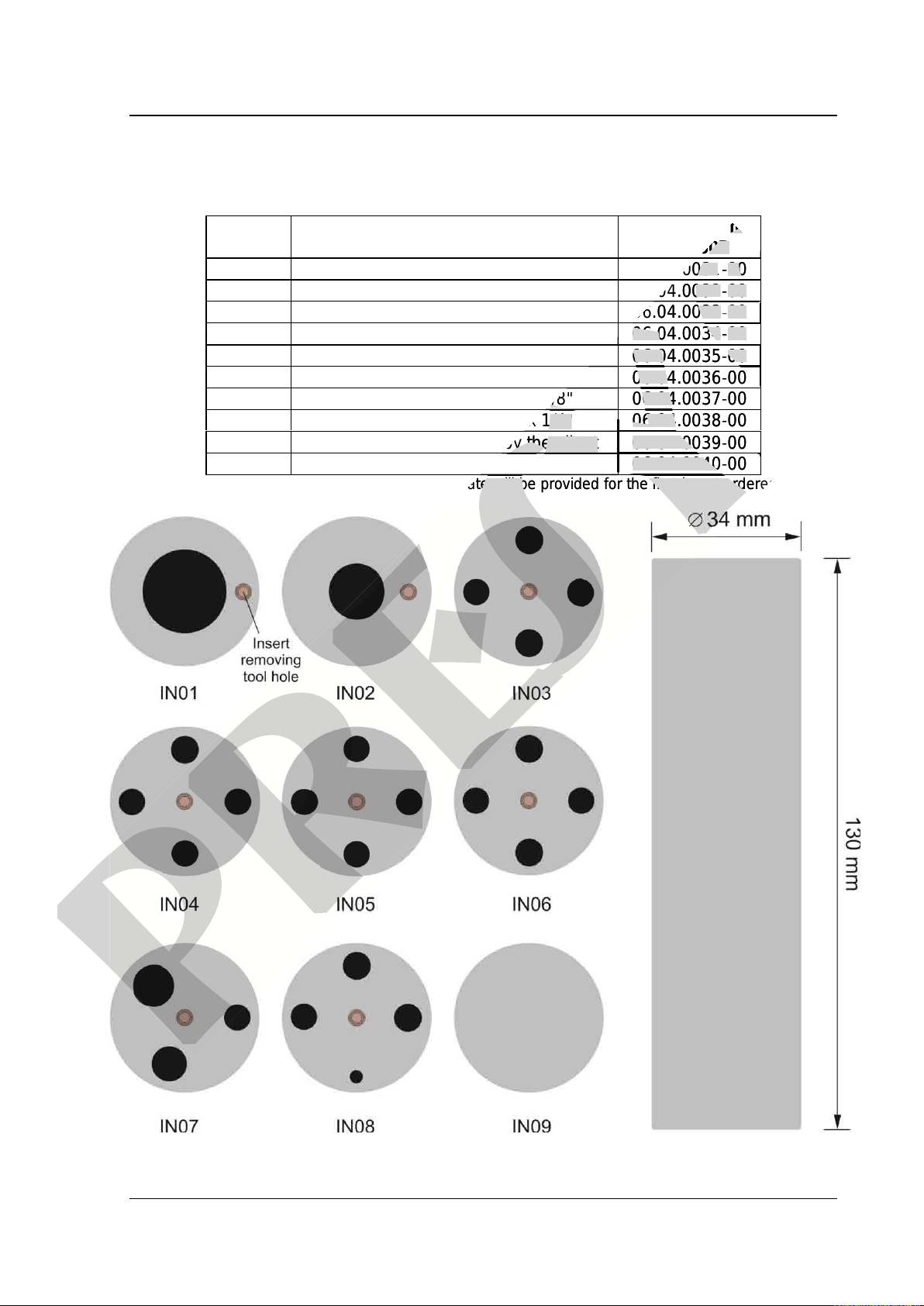

1.3 -Accessories

•Dry Block Insert:

Inserts Holes

Order Code for

TA-1200P

IN01

1 x 3/4"

06.04.0031-00

IN02

1 x 1/2"

06.04.0032-00

IN03

1 x 6.0mm and 3 x 1/4"

06.04.0033-00

IN04

3 x 6.0mm and 1 x 1/4"

06.04.0034-00

IN05

4 x 6.0mm

06.04.0035-00

IN06

2 x 6.0mm and 2 x 1/4"

06.04.0036-00

IN07

1 x 6.0mm, 1 x 8.0mm and 1 x 3/8"

06.04.0037-00

IN08

1 x 6.0mm, 1 x 3.0mm and 2 x 1/4"

06.04.0038-00

IN09

Without hole, to be drilled by the client

06.04.0039-00

IN10

Others, under ordering

06.04.0040-00

Note: When asked, the calibration certificate will be provided for the first insert ordered.

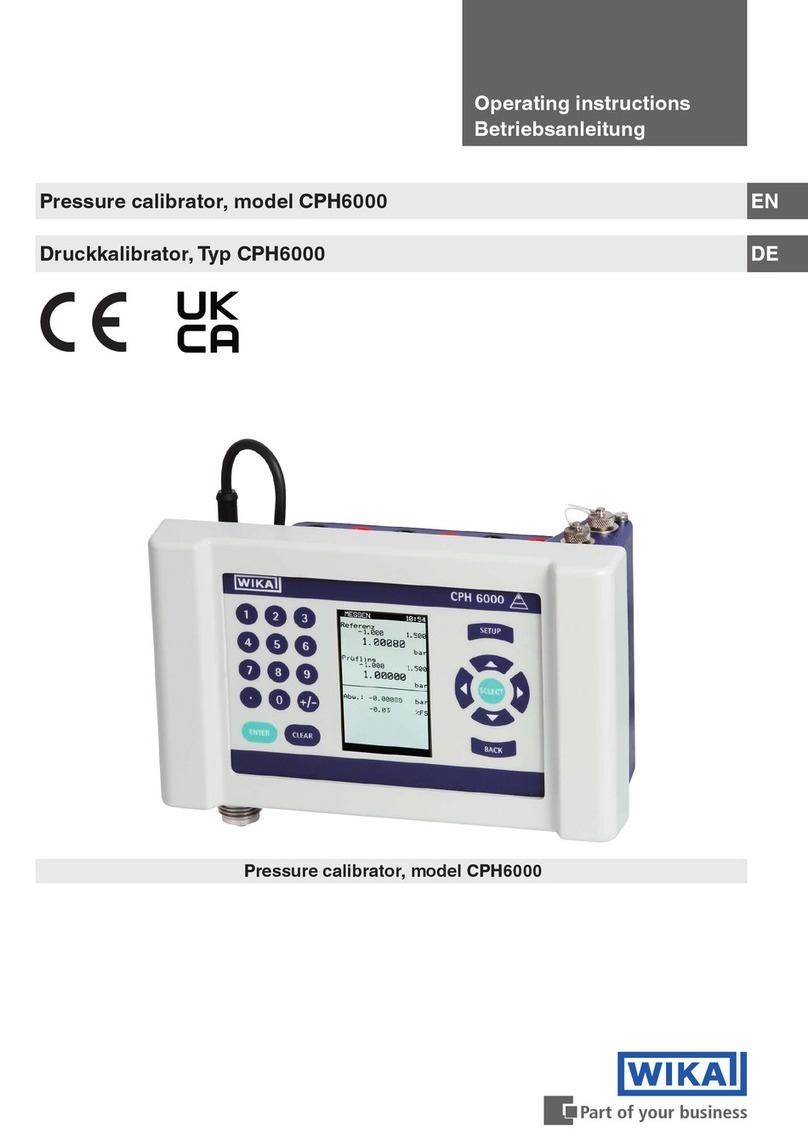

Fig. 01 -Inserts

presys

Order Code for

presys

Order Code for

120

presys

120

0P

presys

0P

presys

06.04.0031

presys

06.04.0031

-

presys

-

00

presys

00

presys

presys

presys

06.04.0032

presys

06.04.0032

-

presys

-

00

presys

00

presys

presys

presys

06.04.0033

presys

06.04.0033

-

presys

-

00

presys

00

presys

presys

presys

06.04.0034

presys

06.04.0034

-

presys

-

00

presys

00

presys

presys

presys

presys

06.04.0035

presys

06.04.0035

-

presys

-

00

presys

00

presys

presys

presys

presys

presys

presys

06.04.0036

presys

06.04.0036

-

presys

-

00

presys

00

presys

presys

presys

presys

presys

presys

1 x 6.0mm, 1 x 8.0mm and 1 x 3/8"

presys

1 x 6.0mm, 1 x 8.0mm and 1 x 3/8"

06.04.0037

presys

06.04.0037

-

presys

-

00

presys

00

presys

presys

presys

presys

presys

presys

1 x 6.0mm, 1 x 3.0mm and 2 x 1/4"

presys

1 x 6.0mm, 1 x 3.0mm and 2 x 1/4"

06.04.0038

presys

06.04.0038

-

presys

-

00

presys

00

presys

presys

presys

presys

presys

presys

Without hole, to be drilled by the client

presys

Without hole, to be drilled by the client

06.04.0039

presys

06.04.0039

-

presys

-

00

presys

00

presys

presys

presys

presys

presys

presys

06.04.0040

presys

06.04.0040

-

presys

-

00

presys

00

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

Note: When asked, the calibration certificate will be provided for the first insert ordered.

presys

Note: When asked, the calibration certificate will be provided for the first insert ordered.

presys

PRESYS Instruments TA-1200P

Page 6

Description

Order Code

Soft Carrying Case for TA-1200P model

06.01.1032-00

Insert Extractor

02.06.0087-20

Lead Cable Kit

06.07.0018-00

Power Cable Type J –Brazil 01.14.0008-21

Power Cable Type B –US 01.14.0100-21

Power Cable Type F –Europe Universal 01.14.0089-21

Power Cable Type J –UK 01.14.0117-21

1.4 -Initial Usage

Identify if the following parts are present:

•TA-1200P Calibrator;

•Metallic insert;

•Inferior insulator of the insert (only one central hole);

•Superior insulator of the insert (same holes of the metallic insert);

•Power cable.

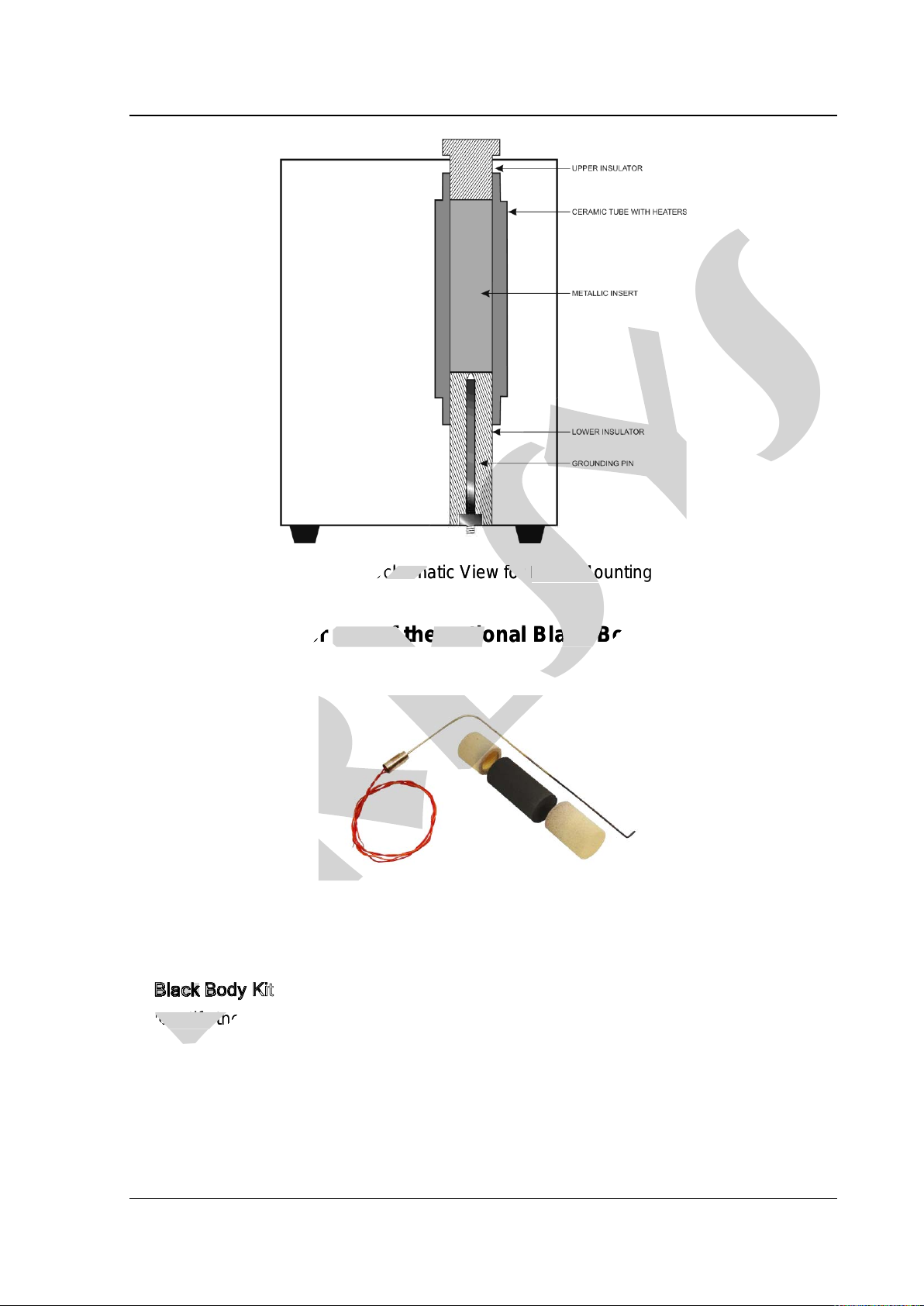

1.5 - Mounting the insert inside the furnace

In the core of the dry block TA-1200P there is a ceramic tube. Therefore, for

safety purposes, the insert and the insulators are separated. Asupport is sent to protect

the block. Remove the screws indicated by the arrows and remove the support. Store it

and use it whenever you need to transport the dry block.

To mount the set, one should first slide gently the inferior insulator inside the

ceramic tube. Do not let it free, slide it inside the tube. Afterwards, hold the metallic insert

by using the insert extractor tool and lower it inside the ceramic tube.

Finally, place the superior insulator above the insert. Note that the sensor to be

tested should go through the insulator and the metallic insert to achieve a correct

temperature measurement.

presys

01.14.0008

presys

01.14.0008

-

presys

-

21

presys

21

presys

presys

01.14.0100

presys

01.14.0100

-

presys

-

21

presys

21

presys

presys

presys

presys

presys

01.14.0089

presys

01.14.0089

-

presys

-

21

presys

21

presys

presys

presys

presys

presys

presys

presys

01.14.0117

presys

01.14.0117

-

presys

-

21

presys

21

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

Identify if the following parts are

presys

Identify if the following parts are

present:

presys

present:

1200P Calibrator;

presys

1200P Calibrator;

Inferior insulator of the insert (only one central hole);

presys

Inferior insulator of the insert (only one central hole);

Superior insulator of the insert (same holes of the metallic insert);

presys

Superior insulator of the insert (same holes of the metallic insert);

Power cable.

presys

Power cable.

1.

presys

1.

5

presys

5

-

presys

-

Mounting the insert inside the furnace

presys

Mounting the insert inside the furnace

In the core of the

presys

In the core of the

dry block TA

presys

dry block TA

safety purposes, the insert and the insulators are separated.

presys

safety purposes, the insert and the insulators are separated.

the block. Remove the screws indicated by the arrows and remove the support. Store it

presys

the block. Remove the screws indicated by the arrows and remove the support. Store it

and use it whenever

presys

and use it whenever

you

presys

you

need to transport the dry

presys

need to transport the dry

To mount the set, one should first slide gently the inferior insulator inside the

presys

To mount the set, one should first slide gently the inferior insulator inside the

ceramic tube. Do not let it free, slide it inside the tube. Afterwards, hold the metallic insert

presys

ceramic tube. Do not let it free, slide it inside the tube. Afterwards, hold the metallic insert

by using the insert extractor tool and

presys

by using the insert extractor tool and

presys

Finally, place the superior insulator above the insert. Note that the sensor to be

presys

Finally, place the superior insulator above the insert. Note that the sensor to be

tested should go through the insulator and the metallic insert to achieve a correct

presys

tested should go through the insulator and the metallic insert to achieve a correct

PRESYS Instruments TA-1200P

Page 7

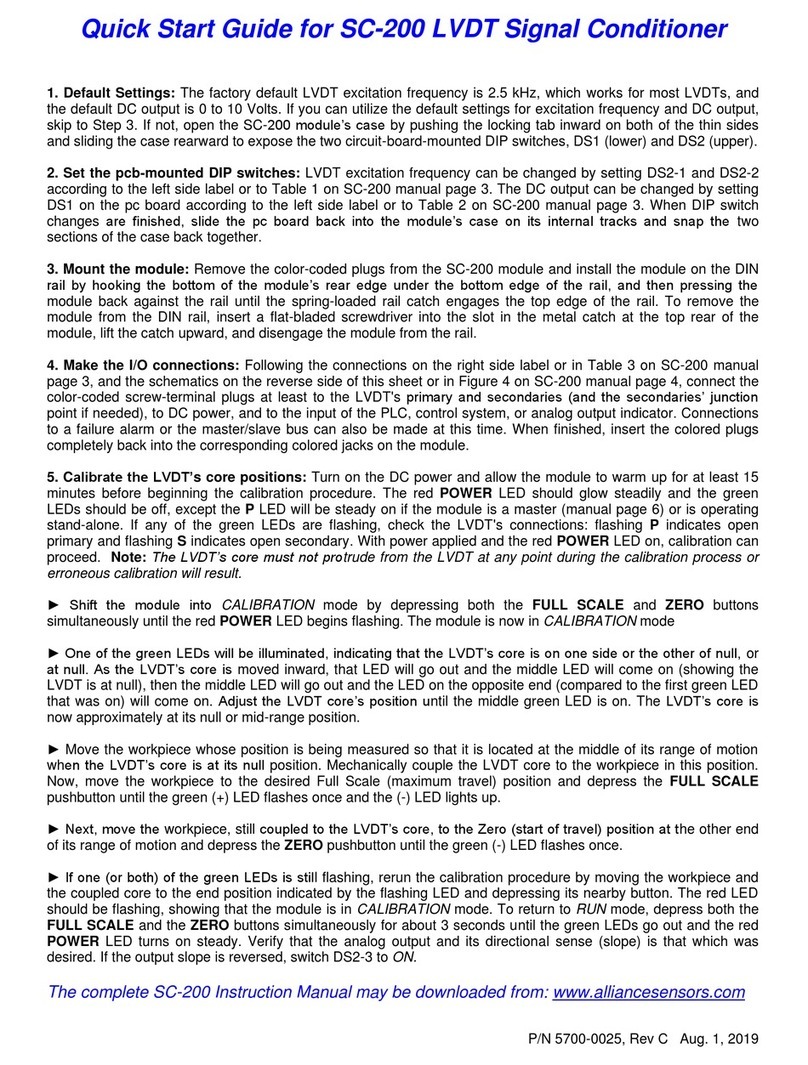

Fig 2 -Schematic View for Insert Mounting

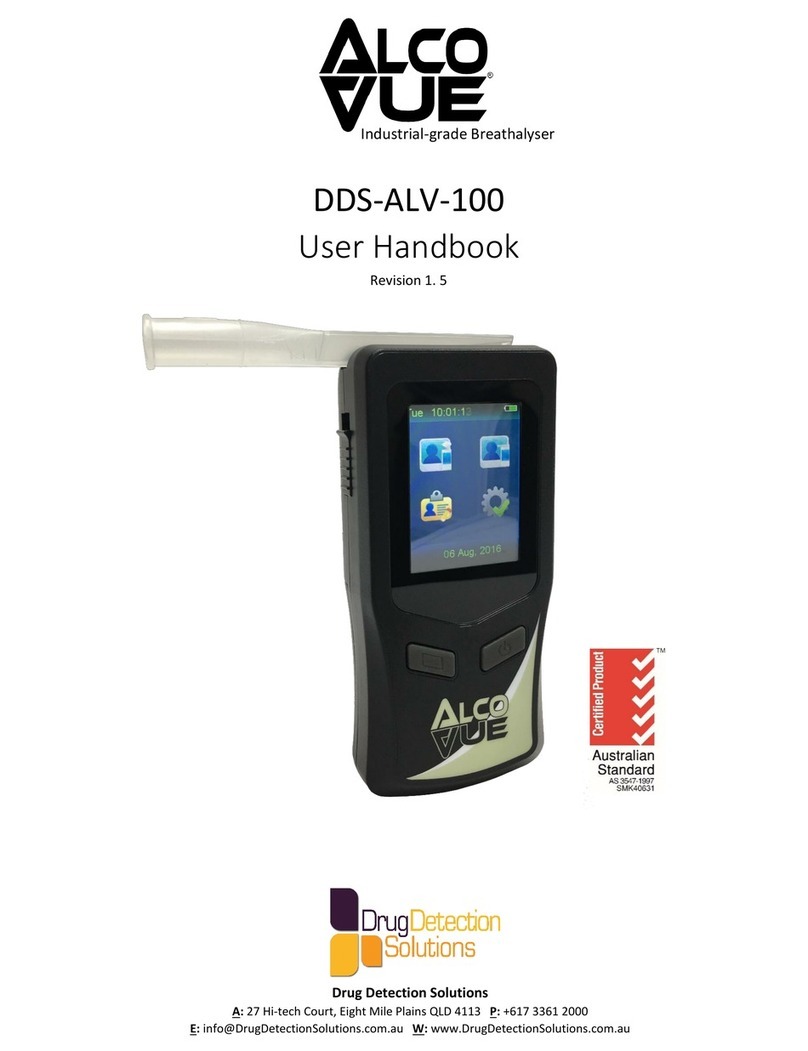

1.6 -Instruction for use of the optional Black Body insert

Fig 3 - Black Body Kit

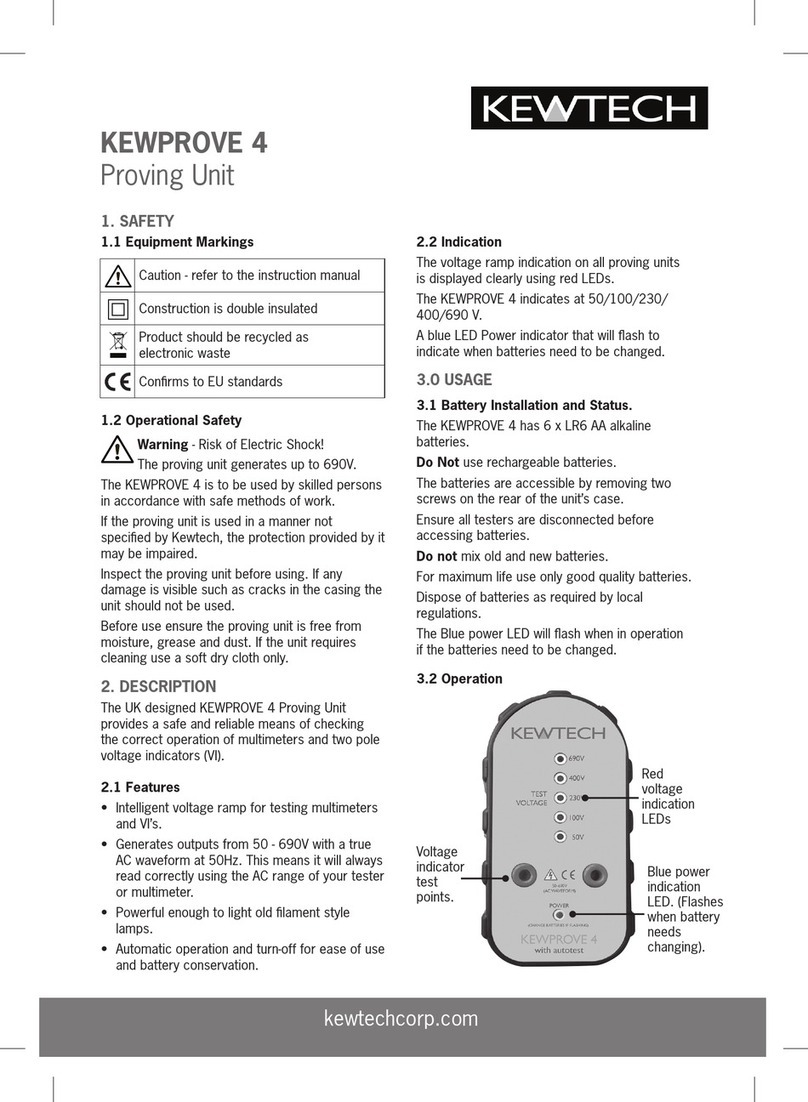

Black Body Kit

Identify the following parts and proceed to the mounting as explained:

•Cylindrical Thermal insulator –Mounted in the lower part of the pit of the

furnace.

•Metallic Insert type Black Body cavity –Must be introduced in the pit joined

with a thermocouple type N mounted laterally.

presys

presys

Schema

presys

Schema

tic View for

presys

tic View for

Insert Mounting

presys

Insert Mounting

Instruction for use of the optional Black Body insert

presys

Instruction for use of the optional Black Body insert

presys

B

presys

B

presys

l

presys

l

presys

a

presys

a

presys

c

presys

c

presys

k

presys

k

presys

B

presys

B

presys

o

presys

o

presys

d

presys

d

presys

y

presys

y

presys

presys

K

presys

K

presys

i

presys

i

presys

presys

Identify the following parts and proceed to the mounting as explained:

presys

Identify the following parts and proceed to the mounting as explained:

PRESYS Instruments TA-1200P

Page 8

Careful when entering the thermocouple in the cavity to not force the fragile

ceramic wall pit.

•Ring-shaped cylindrical Insulator -mounted on top of the pit of the furnace

Note that the position of the slit of insulation should match the type N

thermocouple sheath laterally.

•Connect the terminals of the thermocouple type N to the auxiliary input side of

the furnace TA-1200P and set the reading of the input to N type thermocouple

(CJC internal).

The combination constitutes an excellent mounted cavity blackbody with

emissivity of (0,95 0,02) and an effective target of Ø 20 mm well suited for calibration of

infrared thermometers.

Align the thermometer to be calibrated with a black body cavity in the furnace

in a vertical position.

Observe the distance of the infrared thermometer to be calibrated against the

background of the black body cavity and the size of the actual target (Ø 20 mm) as

specified in the technical manual of the thermometer.

Remember that the area targeted by the thermometer to be calibrated must be

less than or equal to the effective target spot size of the blackbody in order to not

introduce measurement errors.

Use the certificate of calibration of the thermocouple type N to correct the

readings from the input of the calibrator and comparing the reading of the thermometer.

presys

Note that the position of the slit of insulation should match the type N

presys

Note that the position of the slit of insulation should match the type N

Connect the terminals of the thermocouple type N to the auxiliary input side of

presys

Connect the terminals of the thermocouple type N to the auxiliary input side of

1200P and set the reading of the input to N type thermocouple

presys

1200P and set the reading of the input to N type thermocouple

The combination constitutes an excellent mounted cavity blackbody with

presys

The combination constitutes an excellent mounted cavity blackbody with

Ø 20 mm

presys

Ø 20 mm

well suited for calibration of

presys

well suited for calibration of

to be calibrated with a black body cavity in the furnace

presys

to be calibrated with a black body cavity in the furnace

infrared thermometer

presys

infrared thermometer

to be calibrated against the

presys

to be calibrated against the

background of the black body cavity and the size of the ac

presys

background of the black body cavity and the size of the ac

tual target (Ø 20 mm) as

presys

tual target (Ø 20 mm) as

specified in the technical manual of the

presys

specified in the technical manual of the

thermometer

presys

thermometer

.

presys

.

Remember that the area targeted by the

presys

Remember that the area targeted by the

thermometer

presys

thermometer

to be calibrated must be

presys

to be calibrated must be

less than or equal to the effective target spot size of the blackbody in order to not

presys

less than or equal to the effective target spot size of the blackbody in order to not

rement errors

presys

rement errors

.

presys

.

Use the certificate of calibration of the thermocouple type N to correct the

presys

Use the certificate of calibration of the thermocouple type N to correct the

readings from the input of the calibrator and comparing the reading of the

presys

readings from the input of the calibrator and comparing the reading of the

PRESYS Instruments TA-1200P

Page 9

Fig 4 -Schematic view for mounting of the black body cavity

presys

presys

Fig 4

presys

Fig 4

-

presys

-

Schematic view for mounting of the black body cavity

presys

Schematic view for mounting of the black body cavity

PRESYS Instruments TA-1200P

Page 10

1.7 - Parts Identification

Fig. 05-Parts Identification

presys

presys

PRESYS Instruments TA-1200P

Page 11

2 - Calibrator Operation

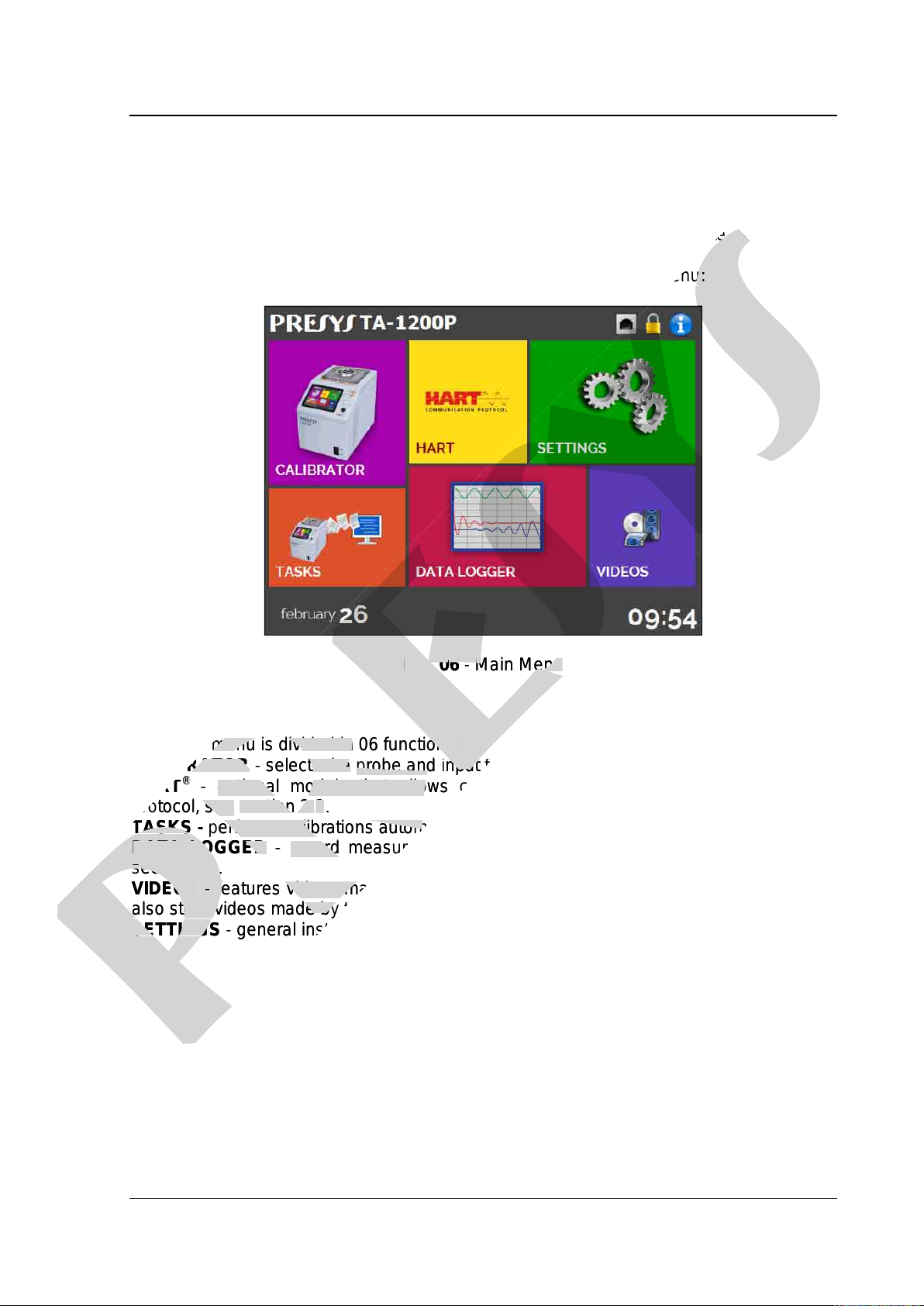

When powered on, the calibrator goes through a self-test routine and shows the

last adjustment date. In case of failure, it displays a message to indicate error; if that

occurs, the instrument should be sent to manufacturer for repair.

After the self-test is completed, the display shows the main menu:

Fig. 06-Main Menu

The main menu is divided in 06 functions:

CALIBRATOR -selects the probe and input functions, see section 2.1

HART®-optional module that allows communication with devices that have Hart®

protocol, see section 2.2.

TASKS -performs calibrations automatically, see section 2.3.

DATA LOGGER -record measurements, enabling visualization in chart or table, see

section 2.4.

VIDEOS -features videos made by Presys to assist in the use of the calibrator, and can

also store videos made by the user, see section 2.5.

SETTINGS -general instrument settings, see section 2.6.

presys

last adjustment date. In case of failure, it displays a message to indicate error; if that

presys

last adjustment date. In case of failure, it displays a message to indicate error; if that

test is completed, the display shows the main menu

presys

test is completed, the display shows the main menu

:

presys

:

presys

Fig. 0

presys

Fig. 0

6

presys

6

-

presys

-

Main Menu

presys

Main Menu

The main menu is divided in 06 functions:

presys

The main menu is divided in 06 functions:

CALIBRATOR

presys

CALIBRATOR

-

presys

-

selects the

presys

selects the

probe and

presys

probe and

input functions, see

presys

input functions, see

HART

presys

HART

®

presys

®

-

presys

-

optional module that allows communication with devices that have Hart

presys

optional module that allows communication with devices that have Hart

protocol, see

presys

protocol, see

section 2.

presys

section 2.

2

presys

2

.

presys

.

TASKS

presys

TASKS

-

presys

-

performs calibrations automatically, see

presys

performs calibrations automatically, see

DATA LOGGER

presys

DATA LOGGER

-

presys

-

record measurements, enabling visualization in chart or table, see

presys

record measurements, enabling visualization in chart or table, see

s

presys

s

ection 2.

presys

ection 2.

4

presys

4

.

presys

.

VIDEOS

presys

VIDEOS

-

presys

-

features videos made by Presys to assist in the use of the calibrator, and can

presys

features videos made by Presys to assist in the use of the calibrator, and can

also store videos made by the user, see

presys

also store videos made by the user, see

SETTINGS

presys

SETTINGS

-

presys

-

general instrument settings, see

presys

general instrument settings, see

PRESYS Instruments TA-1200P

Page 12

2.1 -Calibrator Menu

To select the probe set point or electrical input functions, from the main menu,

press the CALIBRATOR button. The following screen is displayed.

Fig. 07-Calibrator Function

At the top is shown the probe settings and values.

The centered value shows the block temperature. The GREEN color indicates that

the temperature is stable, otherwise it is RED.

The set point value appears on the top. Touch in the SET bar to change it.

Pressing on the temperature unit it can be changed between °C (Celsius), °F

(Fahrenheit) or K (Kelvin).

Fig. 08-Calibrator Mode

presys

presys

Calibrator Function

presys

Calibrator Function

probe settings and values.

presys

probe settings and values.

The centered value shows the block temperature.

presys

The centered value shows the block temperature.

The

presys

The

GREEN

presys

GREEN

color indicates that

presys

color indicates that

the temperature is stable, otherwise it is

presys

the temperature is stable, otherwise it is

RED

presys

RED

.

presys

.

The set point value appears on the top. Touch in the

presys

The set point value appears on the top. Touch in the

presys

SET

presys

SET

Pressing on the temperature unit it can be changed between °C (Celsius), °F

presys

Pressing on the temperature unit it can be changed between °C (Celsius), °F

K (Kelvi

presys

K (Kelvi

n).

presys

n).

presys

PRESYS Instruments TA-1200P

Page 13

In the STEP function, a step value can be configured, and the steps can be

changed through the up and down arrows.

In REFERENCE menu, you can configure the type of probe reference (see

section 2.1.1 –Probe Reference). The chosen reference appears just below the

REFERENCE button.

At the bottom, an input can be configured.When the input is selected, the screen

will split automatically. To select an input, just touch the INPUT bar (see section 2.1.2 -

INPUT MENU).

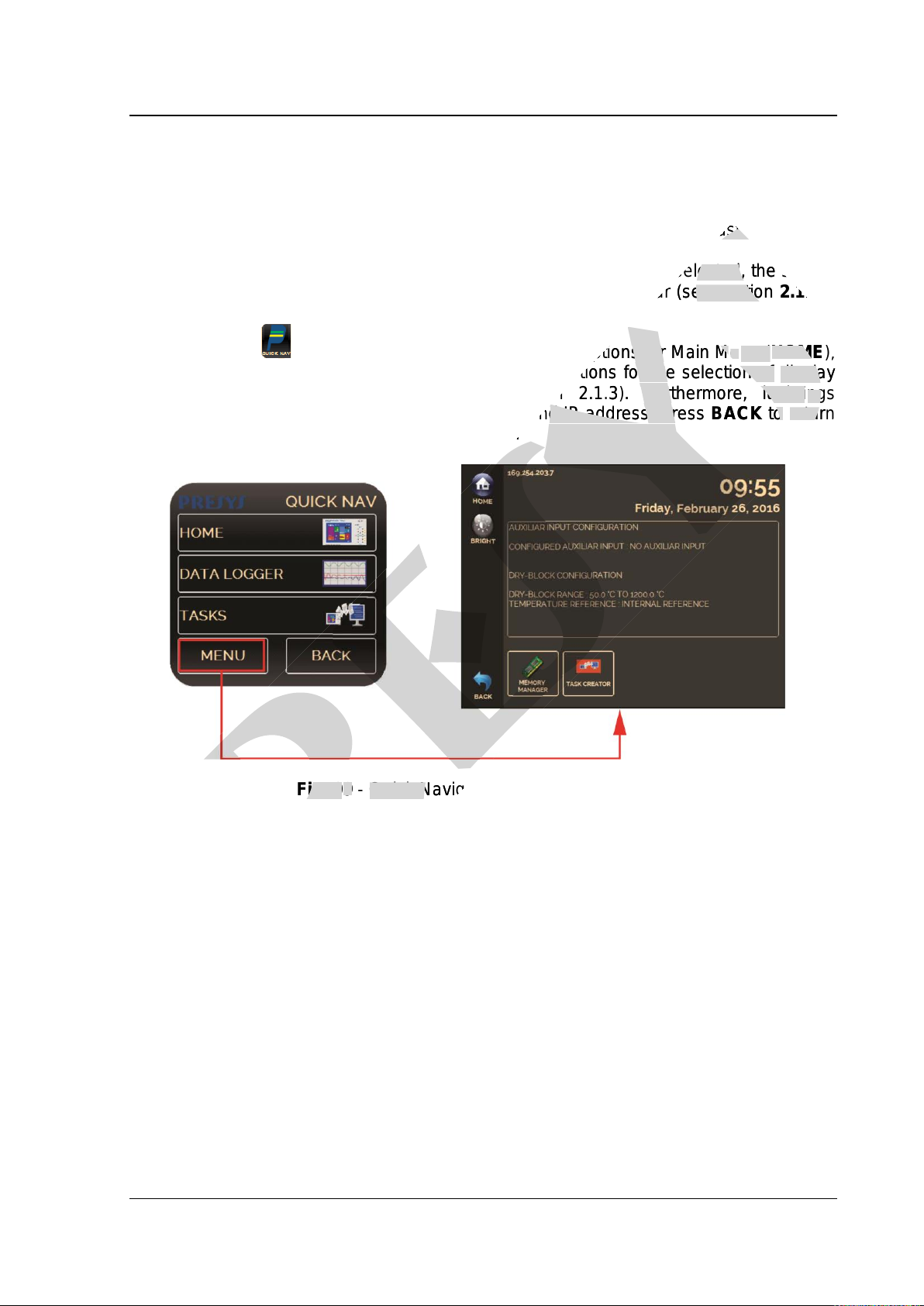

The icon shows a Quick Navigator, with the options for Main Menu (HOME),

Data-Logger and Tasks.Pressing MENU,there are options for the selection of display

Brightness and Memory Manager (see section 2.1.3). Furthermore, it brings

information about the auxiliary input configuration and IP address. Press BACK to return

to Calibrator Mode or HOME to go to Main Menu.

Fig. 09-Quick Navigator and Secondary Menu

presys

e chosen reference appears just below the

presys

e chosen reference appears just below the

When the input is selected, the screen

presys

When the input is selected, the screen

bar (see section

presys

bar (see section

2.1.2

presys

2.1.2

he options for Main M

presys

he options for Main M

e

presys

e

nu (

presys

nu (

HOME

presys

HOME

)

presys

)

,

presys

,

there are options for the selection of

presys

there are options for the selection of

display

presys

display

(see section 2.1.

presys

(see section 2.1.

3

presys

3

presys

). Furthermore, it bri

presys

). Furthermore, it bri

ngs

presys

ngs

y input configuration and IP address. Press

presys

y input configuration and IP address. Press

BACK

presys

BACK

to

presys

to

return

presys

return

to go to Main Menu.

presys

to go to Main Menu.

presys

Fig. 0

presys

Fig. 0

9

presys

9

-

presys

-

Quick Navigator and Secondary Menu

presys

Quick Navigator and Secondary Menu

PRESYS Instruments TA-1200P

Page 14

2.1.1 –Probe Reference

There are two different references to the thermal block:Internal Reference and

External Reference.

The Internal Reference is a sensor built into the block.

The External Reference is an option for more accurate measurements. The

reference comes from a Standard Thermocouple Sensor placed inside the insert, among

the DUT (devices under test). This Standard Sensor should be a noble metal

thermocouple (R, S or B type). To increase accuracy to the measurements, ITS-90

parameters can be used to correct the thermocouple electromotive force in reference to

the IEC-60751 table.

When used External reference, the probe indication is displayed on the screen

and the control is made by the internal probe.

Fig. 10 -Choosing the Type of Temperature Reference

To select the Reference between Internal and External, touch the REFERENCE

bar. Select a reference between the registered sensors. To add a new sensor select

MANAGER and ADD. When selecting External Reference, the ITS-90 parameters must

be set. If the sensor does not have parameters, use the value “zero” for all the

coefficients.

ID: Sensor Identification

TYPE: Thermocouple type (R, S, B)

Scale: Reference table for the thermocouple

MIN and MAX: Operating range for the thermocouple

CJC: Type of Cold Junction Compensation. If MANUAL is chosen, inform the

temperature.

C0,C1,C2 and C3: Thermocouple coefficients.

The coefficient values can be found in the Reference Sensor Certificate.

presys

is an option for more accurate measurements. The

presys

is an option for more accurate measurements. The

Sensor placed inside the insert, among

presys

Sensor placed inside the insert, among

should be a

presys

should be a

noble metal

presys

noble metal

(R, S or B type). To increase accuracy to the measurements,

presys

(R, S or B type). To increase accuracy to the measurements,

ITS

presys

ITS

-

presys

-

90

presys

90

can be used to correct the thermocouple electromotive force in reference to

presys

can be used to correct the thermocouple electromotive force in reference to

the probe indication is displayed on the screen

presys

the probe indication is displayed on the screen

presys

Fig.

presys

Fig.

10

presys

10

-

presys

-

Choosing the Type of Temperature Reference

presys

Choosing the Type of Temperature Reference

To select the Reference between Internal and External, touch the

presys

To select the Reference between Internal and External, touch the

bar.

presys

bar.

Sel

presys

Sel

ect a reference between the registered sensors. To add a new sensor select

presys

ect a reference between the registered sensors. To add a new sensor select

MANAGER

presys

MANAGER

and

presys

and

ADD.

presys

ADD.

When selecting External Reference, the ITS

presys

When selecting External Reference, the ITS

be set. If the sensor does not have parameters, use the value “zero” for all the

presys

be set. If the sensor does not have parameters, use the value “zero” for all the

coefficients.

presys

coefficients.

ID:

presys

ID:

S

presys

S

ensor Identification

presys

ensor Identification

TYPE:

presys

TYPE:

Thermocouple type (R, S, B)

presys

Thermocouple type (R, S, B)

Scale:

presys

Scale:

Reference table for the thermocouple

presys

Reference table for the thermocouple

MIN

presys

MIN

and

presys

and

MAX

presys

MAX

CJC

presys

CJC

: Type of Cold Junction Compensation. If MANUAL is chosen, inform the

presys

: Type of Cold Junction Compensation. If MANUAL is chosen, inform the

temperature.

presys

temperature.

PRESYS Instruments TA-1200P

Page 15

Fig. 11 -Adding a new Reference Sensor

After filling the blanks, click on SAVE button and confirm. The new sensor is now

available to be chosen in the list. To edit data from a sensor, select it and press

MANAGER button. To remove a sensor, select it and press REMOVE

Fig. 12-Connecting the Standard Sensor for the External Reference

Note: the values corresponding to controlled temperatures appear in GREEN /RED.

Values that show only the sensor indication appear in BLACK.

presys

presys

Adding a new Reference Sensor

presys

Adding a new Reference Sensor

SAVE

presys

SAVE

button and confirm. The new sensor is now

presys

button and confirm. The new sensor is now

the list. To edit data from a sensor, select it and press

presys

the list. To edit data from a sensor, select it and press

button. To remove a sensor, select it and press

presys

button. To remove a sensor, select it and press

presys

REMOVE

presys

REMOVE

presys

Table of contents

Other Presys Test Equipment manuals

Presys

Presys MCS-XV User manual

Presys

Presys T-1200PH User manual

Presys

Presys TA-1200PLAB User manual

Presys

Presys T-350P User manual

Presys

Presys PCON-Y18-LP User manual

Presys

Presys T-500PIR User manual

Presys

Presys PCA-570-RM User manual

Presys

Presys MCS-12-IS User manual

Presys

Presys T-1200PIR User manual

Presys

Presys PC-507-IS User manual

Popular Test Equipment manuals by other brands

Tektronix

Tektronix MDO4104 Technical reference

Oakton

Oakton Eutech Instruments TDSTestr11+ instruction manual

Martindale Electric

Martindale Electric HPAT600/2 HANDYPAT instruction manual

SIGLENT

SIGLENT SDS1000X-E Series Service manual

Kewtech

Kewtech KEWPROVE 4 manual

Hioki

Hioki MEMORY HiCORDER 8855 instruction manual