1- The products must be put under adequate protection and protected against impacts during shipment and storage. In case the

products are to be stored and kept prior to assembly, then indoor stockpiling areas must be formed where the ambient temperature

should not fall under 15°C.

2- The packed products must be protected from circumstances such as rainfall, water humidity, dust and fire, which might damage the

product and product packing.

3- The products should not be over - stacked on each other and the product packing must not be crushed. Precautions should be

adopted against tilting and falling.

2. Points to be taken into consideration during shipment-storage

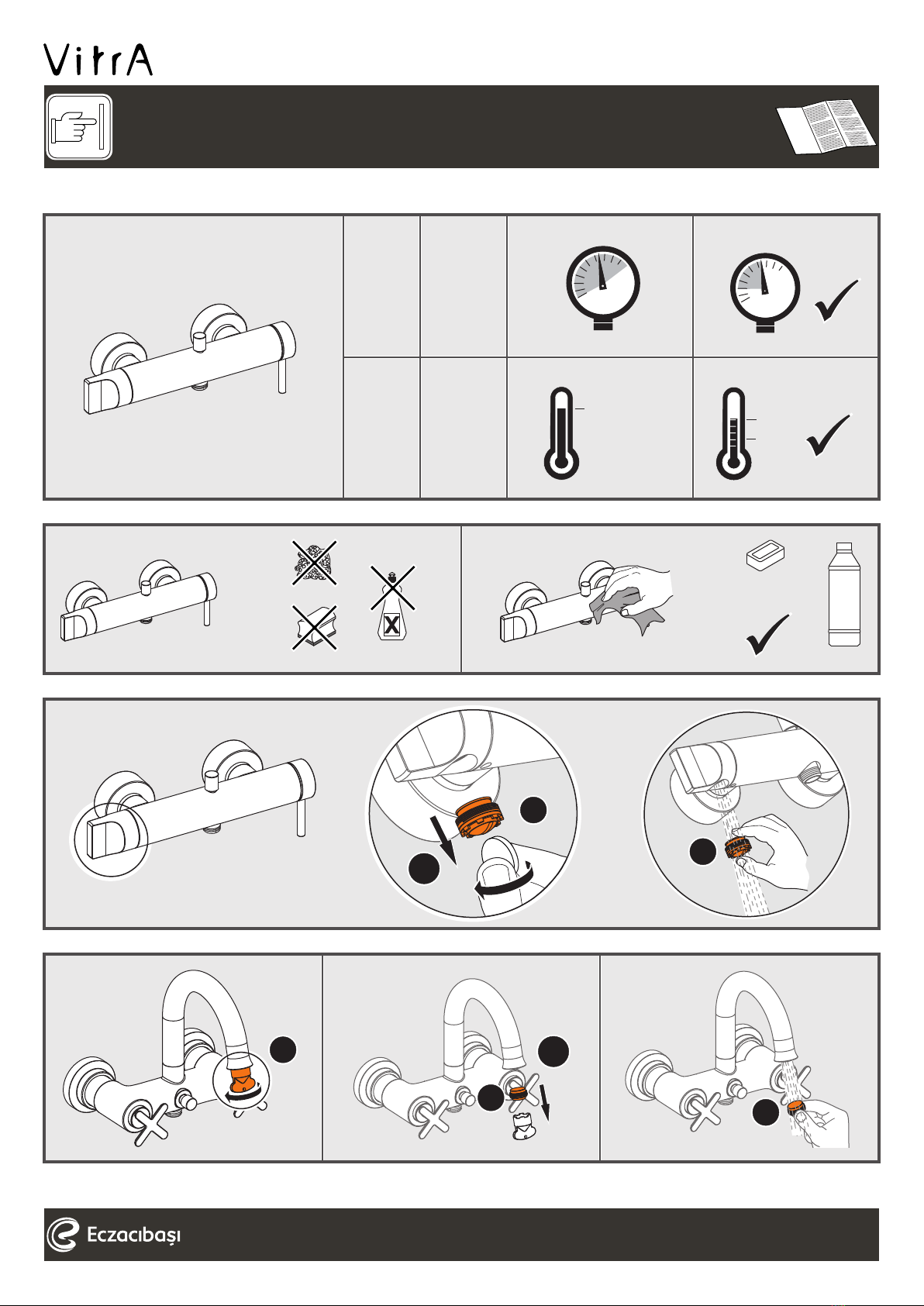

1- Liquids with acidic content and lime removers, hydrochloric acid and dust scrubbers bleach, detergents with sulfuric acid, nitric

acid, hydrochloric acid and other acids and descaling/lime remover, chlorine based bleaching agents vinegar and acetic acid must not

be used for cleaning purposes as such products damage the coating of the product. In case such type of chemicals is used at the

space where your faucet is installed for general housekeeping purposes, then the medium must be ventilated thoroughly and the

faucets must be protected against the vapor of such chemicals. Materials with abrasive / scratching effects such as steel wool, hard

cleaning sponge, etc. should not be used when cleaning your faucet. The faucet surfaces must be cleaned and dried using a soft cloth

and soap water.

3. Recommendations for use and maintenance

13- In order to ensure smooth operation of the product, the installation pressure and water temperature values must be in the range of

limits specified in the instructions for assembly.

12- After any water cut-off, the air trapped inside the pipes might become compressed and exceed the standard installation pressure

during restoration of water to the system. The most effective solution for protecting the products from such impact is to install a

pressure-reducing valve on the main intake.

11- The water intake temperature to the faucets is max. 75 °C according to the standards. Hot water with temperature exceeding such

value must not be used in terms of safety.

10- In cases where constant water quality cannot be ensured, filtered interim taps must be installed to each faucet intake, wherever

possible. The filters of the interim taps should be cleaned periodically.

9- After connecting your faucets to the installation, turn the valve on in order to observe whether there is any leaking spot at the

connection point of the faucet. If there is any leak at the connection points, then perform adequate assembly in order to seal the

connection. Do not use the faucet before conducting any tightness check.

8- Wrenches must not be used for assembling the flexible connection hoses to the body.

7- Spanner wrenches covered with plastics should be used at the time of assembly in order to avoid scratching of the products. If

plastic wrench will not be used, then the part to be assembled should be protected by covering the part with a thick piece of cloth.

6- The auxiliary products either provided together with the product, or recommended in the instructions for assembly must be used for

assembly of the product.

5- A filter valve must be installed at the main installation inlet and the inlet to the flat in order to protect the products from sand and

similar foreign participles carried by the installation and the water network. By virtue of such valve, it would be possible to preclude the

failures that might be caused by the particles such as sand, mud cotton, gravel, etc. carried by the installation.

4- Do not leave your faucet installed at buildings under construction for prolonged periods. Calcium oxide and similar chemicals

contained in the mortar, lime and cement based materials might damage your faucet by acting on the surface in combination with the

humidity of the air. If the faucet is to remain at the construction environment for long duration, please protect the product by wrapping

inside a layer of cloth bag and then a layer of plastic bag.

3- The faucets must be stored at indoor spaces in order to avoid cracking of the faucet due to freezing water. The water inside the

installation should be completely drained as a measure against the frost hazard at the new installation for the duration elapsing between

installation flushing and commissioning of the products. Likewise the main water intake should be sealed and the water inside the

installation should be completely drained also in cases where the faucets will remain unused for prolonged durations. Our faucets

are designed to be used indoors.

Thank you for preferring VitrA branded product. We hereby strongly advise you to read the present manual thoroughly before procuring

installation of your product and maintain as a reference guide for any future references.

Our distinguished customers,

EN

1. Points to be taken into consideration before and during assembly

1- The dimensions of the product to be assembled as specified in the technical catalogue should be taken into consideration when

preparing the infrastructure before the assembly. Please contact with and request from your vendor should you need such technical

data. Make sure that the installation spouts has adequate dimensions in order to enable proper installation of, and avoid damages

to, the faucet.

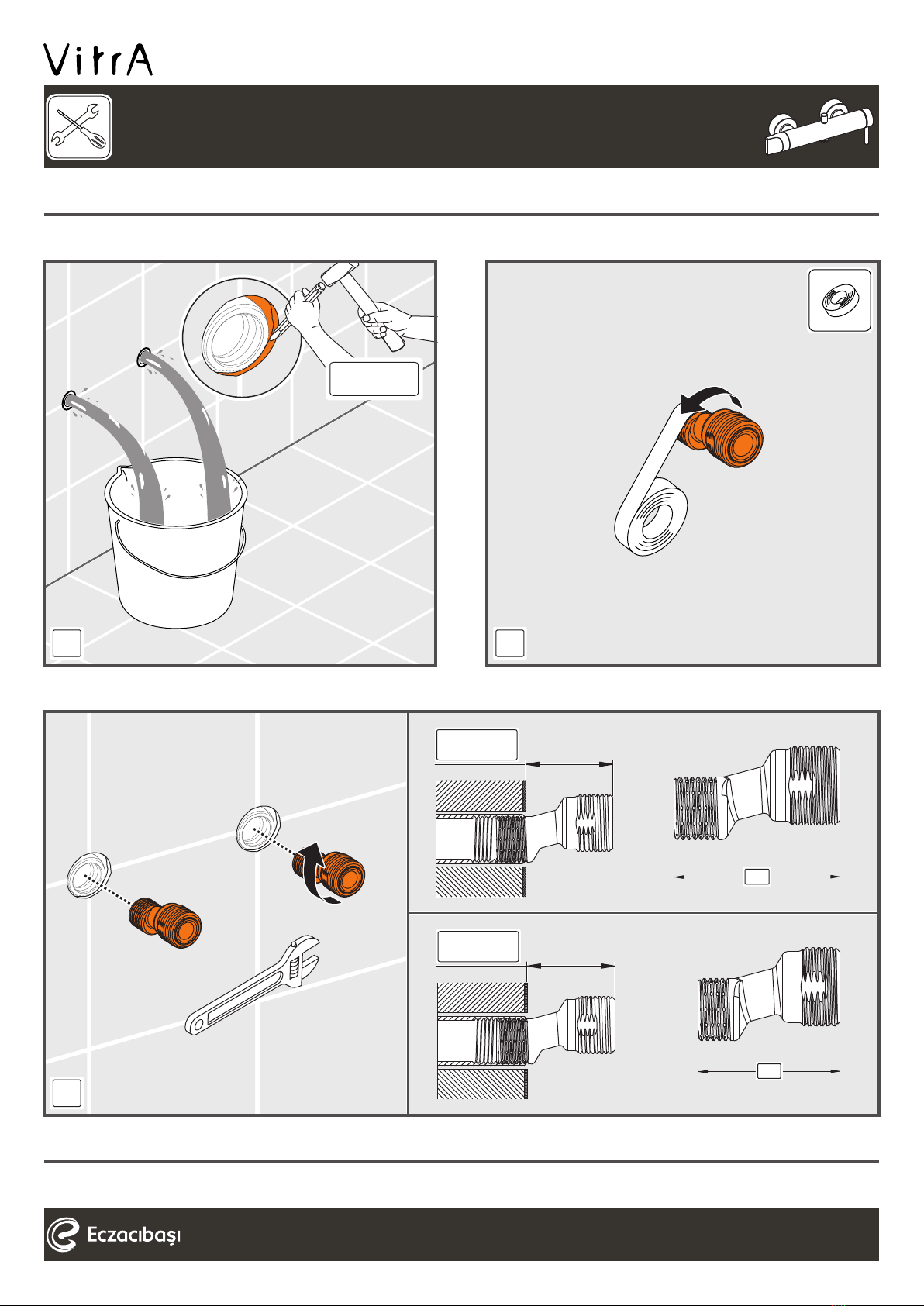

2- Any and all dirt remaining inside the piping and fittings should be flushed prior to connecting the faucets to the sanitary installation at

the new constructions and spaces where the installation is refurbished.

14- The devices connected to the water mains with detachable hose assemblies should be used with the new hose sets supplied. Old

hose sets should not be reused.

15- Class III devices powered by a detachable power supply unit must only be used with the power supply unit supplied with this device.

10