Operation

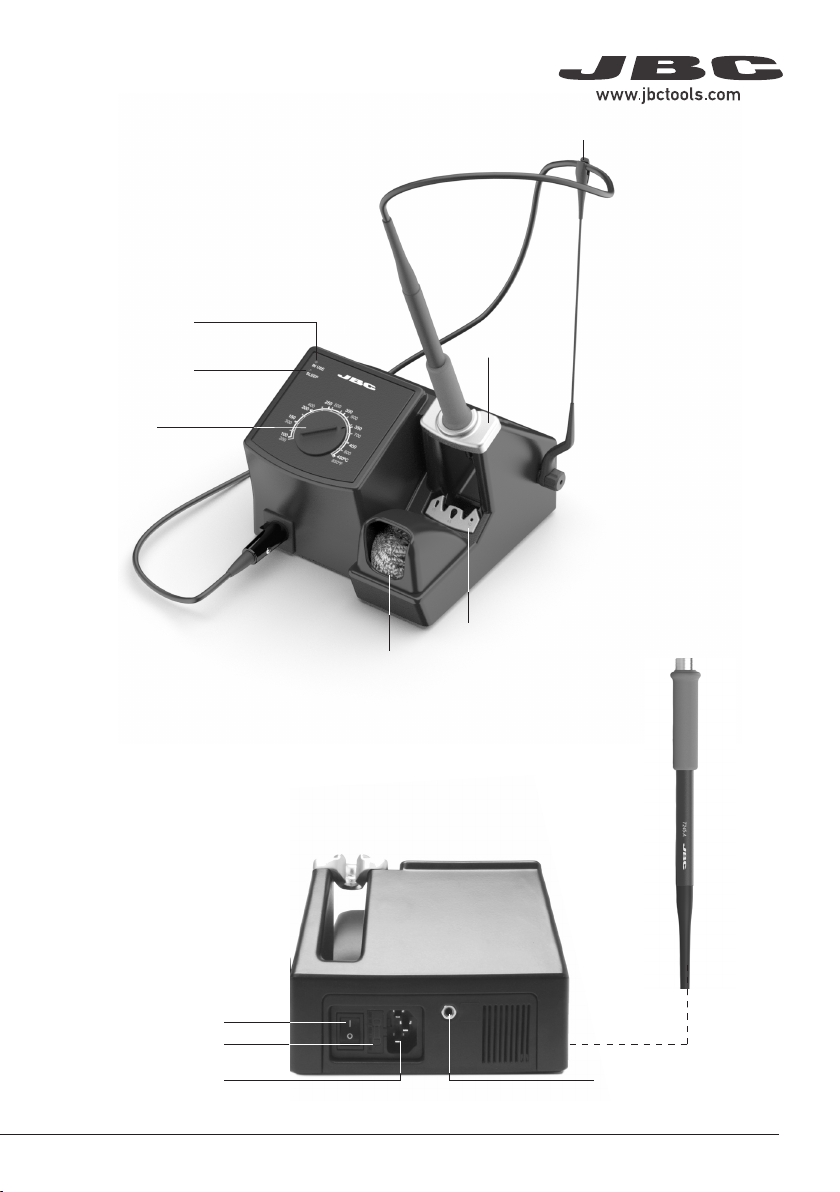

AC Console

The LEDs indicate the station’s different work-

ing modes.

1. Station without a tool connected: The

green IN USE light flashes with the sequence

(- - -- --).

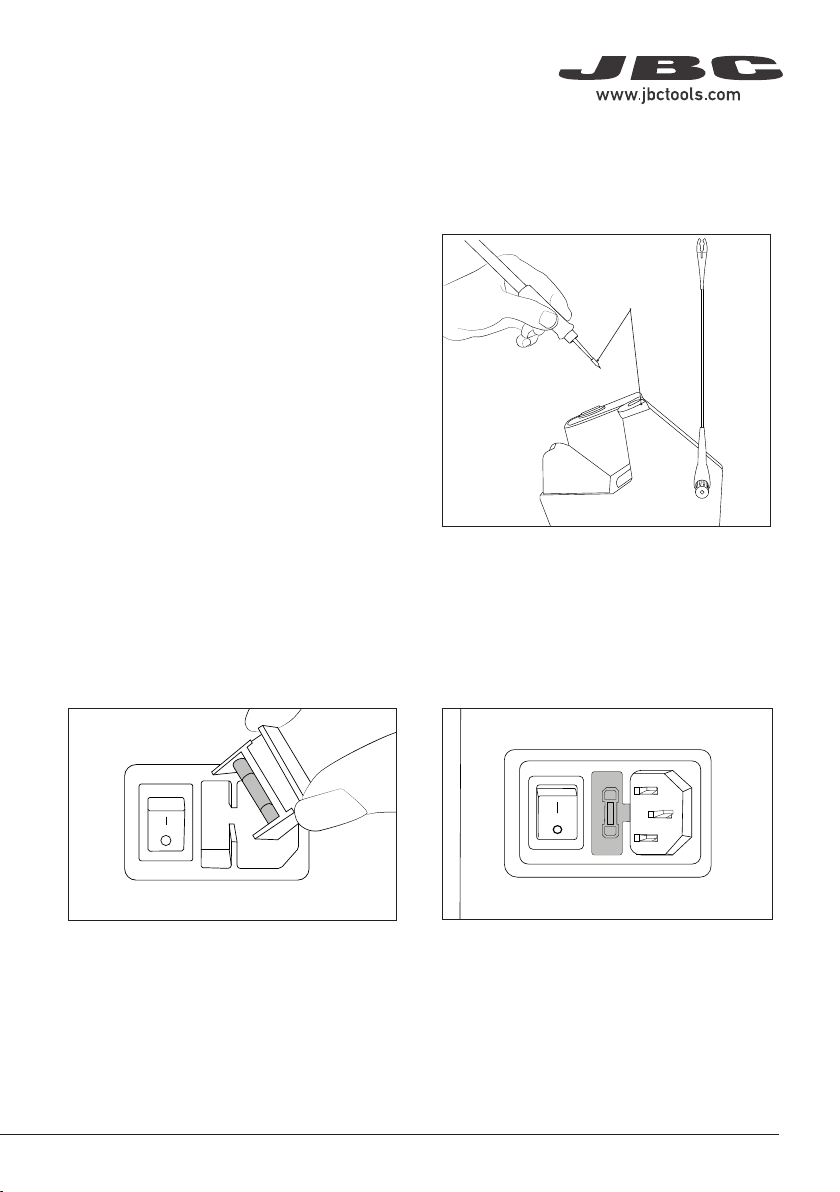

2. Tool out of the support: The green IN

USE light is permanently lit, indicating that the

soldering iron tip is at working temperature.

3. Tool in the support (sleep mode): The yel-

low SLEEP light is permanently lit. In order that

the tool goes into sleep mode, the tool must

be in its support and the programmed sleep

temperature must be less than the temp. on the

dial or the prefixed temperature.

4. Station with previously fixed temperature.

(Only for users of the AC console).

Soldering iron out of support:

- If the dial is above the prefixed temperature,

the green IN USE light is lit the majority of the

time, switching off briefly at regular intervals

(___ ___).

- If the dial is below the prefixed temperature,

the green IN USE light is off the majority of

the time, lighting up briefly at regular intervals

(- - -).

- If the dial is at the prefixed temperature, the

green light is permanently lit.

Errors

When the handpiece or the cartridge is in an

open circuit, the green IN USE light flashes with

the sequence (- - - - - -).

When the handpiece or the cartridge is in a

short circuit, the green IN USE light flashes with

the sequence (--- --- ---).

If any of the above mentioned causes is corrected,

the station will start working automatically.

If the station is used continually in a overloaded

condition for a period of time, the system will

stop and both leds will flash simultaniusly.

Switch station off and on to reset and review

the soldering application.

Yellow LED

(SLEEP)

Green LED (IN USE)

Dial

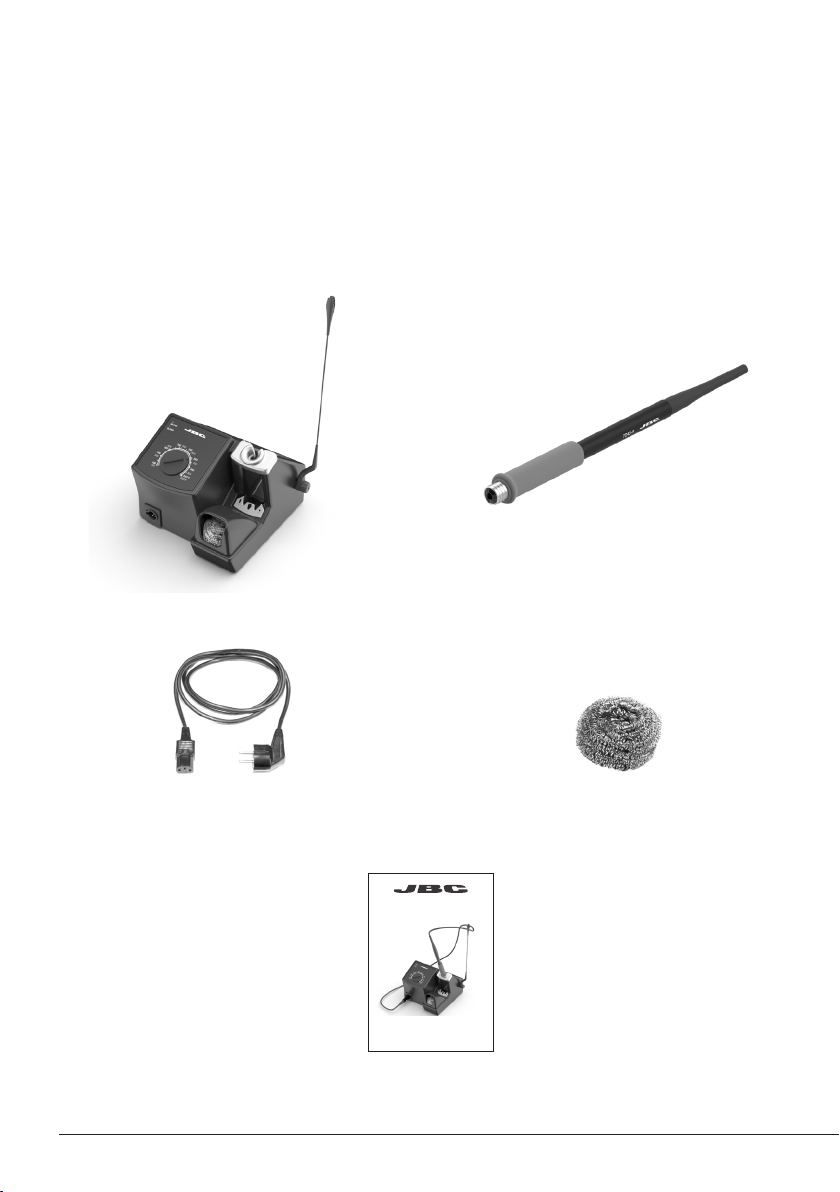

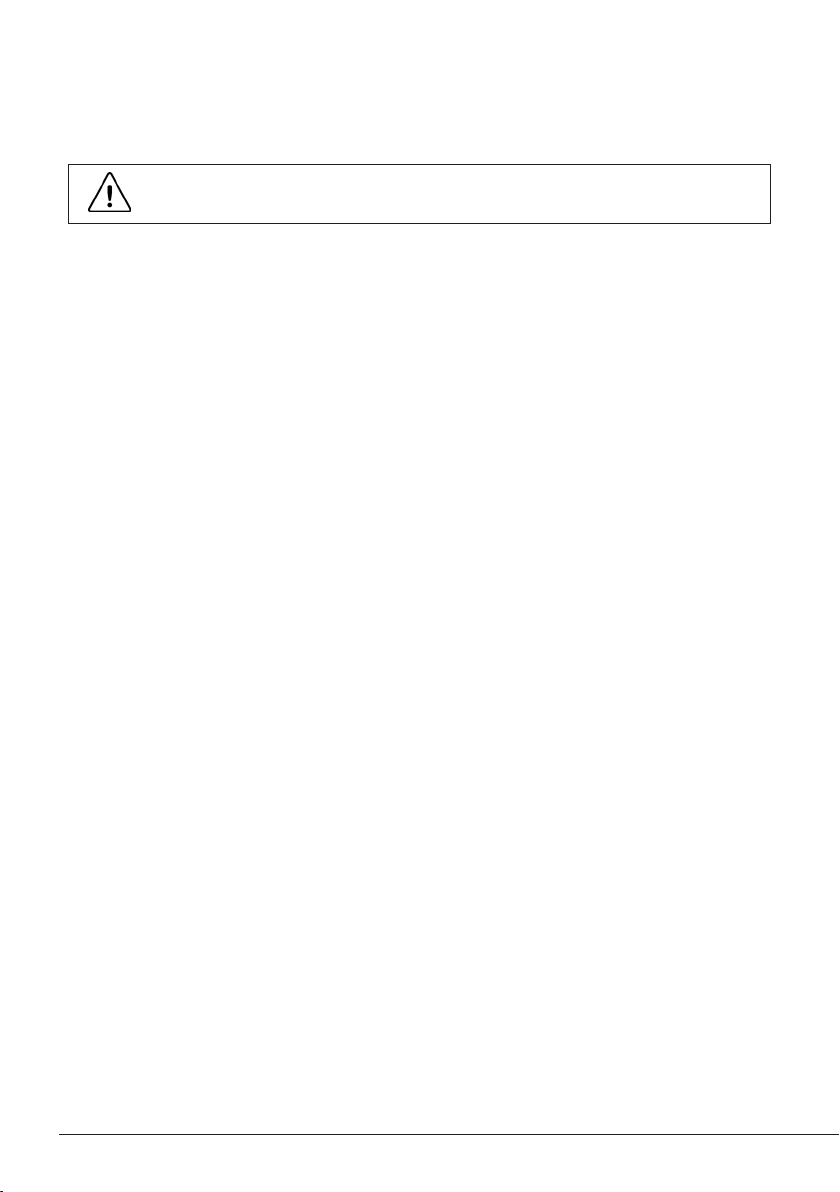

The original parameters of control unit can be

modified using the AC console.

It is necessary to connect the console AC with

software revision 7.0 or later to the BT in order to

configure it (consult JBC for console software updates).

Previous versions only allow for reading of

counters and do not allow for modification of

parameters.

Configuration possible:

- Fixing the working temperature.

- Selection of temperature units ºC or ºF.

- Modification of sleep temperatures and standby

times.

- Adjustment of temperature.

- Reset the parameters back to factory settings.

- Read-out data:

- Working hours.

- Sleep cycles and sleep hours.

- Cartridge and iron changes.

- Program version.

6