Vivax Metrotech HL 6000 User manual

Water Leak Detection System

Metrotech™ HL 6000™ PC Correlator

Operations Manual

THE INFORMATION CONTAINED IN THIS DOCUMENT IS FOR INFORMATIONAL PURPOSES

ONLY AND IS SUBJECT TO CHANGE WITHOUT NOTICE. METROTECH CORPORATION

MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THE INFORMATION CONTAINED

IN THIS MANUAL, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. METROTECH SHALL NOT

BE LIABLE FOR ERRORS CONTAINED HEREIN, NOR FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES FROM THE FURNISHING OF THIS INFORMATION.

THIS MANUAL CONTAINS PROPRIETARY INFORMATION THAT IS PROTECTED BY COPYRIGHT.

NO PART OF THIS MANUAL MAY BE PHOTOCOPIED, REPRODUCED, MAGNETICALLY OR

ELECTRONICALLY STORED, TRANSMITTED, OR TRANSLATED INTO ANOTHER LANGUAGE

WITHOUT THE PRIOR WRITTEN CONSENT OF METROTECH CORPORATION.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY, BEYOND THOSE STATED HEREIN.

Metrotech warrants its equipment to be free from defects in workmanship and material under normal and

proper use and service for one year from date of purchase by original user, but not to exceed eighteen

months after date of original shipment from the factory. Metrotech assumes no obligation to repair or replace

equipment that has been altered or repaired by other than Metrotech approved procedure; been subject to

misuse, misapplication, improper maintenance, negligence or accident; had its serial number or any part

thereof altered, defaced or removed; or been used with parts other than those approved by Metrotech. Warranty

does not include batteries. Expendable items such as fuses and lamps are excluded.

Any detection product proved defective under this warranty will be repaired or replaced free of charge at the

Metrotech Corporation factory or approved Metrotech repair station. The equipment should be returned to

our factory by prepaid transportation after requesting and receiving return authorization from our Customer

Service Department. Metrotech obligations are limited to repair or replacement of broken or defective parts

which have not been abused, misused, altered or accidentally damaged, or at the option of Metrotech, to refund

of the purchase price. Metrotech assumes no liability for removal or installation costs, consequential damages,

or contingent expenses of any other nature.

Metrotech has received ISO 9001:2000 Quality Management System Certication. Metrotech adheres to the

quality standard guidelines of ISO 9001:2000 and ensures quality in its design/development, production,

installation, and servicing disciplines.

HL 6000, Metrotech, are trademarks of Metrotech Corporation. Other trademarks stated in this document are

the property of their respective owners.

© 2008 by Metrotech Corporation. All rights are reserved.

HL 6000 PC Correlator Operating Instructions | iii

Doc No. R12244 Jan/2009

Contents

1 Quick Guide 1

1.1 Quick guide for TR A / TR B amplifier-transmitters 1

1.2 Quick guide for HL 6000 PC Correlator 2

2 Operating Instructions for HL 6000 PC Correlator Transmitter 4

2.1 Controls for TR A / TR B transmitters 4

2.2 Explanation of symbols 4

2.3 Operating instructions for TR A / TR B 5

3 HL 6000 PC Correlator software 6

3.1 Correlator Display, Main Screen 6

3.1.1 Channel A and B Time Signal Display 6

3.1.2 Signal Spectrum or Coherence Display 6

3.1.3 Channel A and B Level Display 6

3.1.4 Correlation Function Display 7

3.1.5 Diagramatical Representation of Pipe 7

3.1.6 Displaying Transmitters A and B 7

3.1.7 Current Pipe Data 7

3.1.8 Start Correlation Button 7

3.1.9 Start 3D / 2D Correlation” Button 7

3.1.10 Finishing the Correlation 8

3.1.11 Changing to the Pipe Table Display 8

3.1.12 Reset Display 8

3.1.13 Playback 8

3.1.14 Automatic Frequency Analysis 9

3.1.15 Measurement Statistics 10

3.1.16 Measuring Sound Speed 11

3.1.17 Zoom In 11

3.1.18 Zoom to Pipe Length 11

3.1.19 Load Correlation 11

3.1.20 Save Correlation 11

3.1.21 Print Correlation 12

3.1.22 Help / Operating Instructions 12

3.1.23 Filter +/- 12

3.1.24 Wide Band 12

3.1.25 Coherence / Spectrum A+B 12

3.2 Pipe Table Display 13

3.2.1 Selecting the number of pipe sections 13

3.2.2 Data for the Individual Sections 14

3.2.3 Editing the Material List 15

3.2.4 Return to the Correlation Display 15

3.3 Multicorrelation Display 16

iv | HL 6000 PC Correlator Operating Instructions

Doc No. R12244 Jan/2009

3.4 Report Display 17

3.4.1 Load Background Picture 17

3.4.2 Satellite Map 17

3.4.3 Undo the Last Drawing Step 17

3.4.4 Delete a Drawing 18

3.4.5 Create a New Page 18

3.4.6 Select the Line Colour 18

3.4.7 Select the Fill Colour 18

3.4.8 Comment About a Measurement 18

3.4.9 Graphic Symbols 18

3.4.10 Drawing on the map 19

3.4.11 Loading Additional Symbols 19

3.4.12 Insert Text in the Drawing 19

3.4.13 Load Correlation 19

3.4.14 Save Correlation 19

3.4.15 Printing correlation 19

3.4.16 Help / Operating instructions 19

3.5 Configuration Display 20

3.5.1 Skins 20

3.5.2 2D / 3D 20

3.5.3 Change the Measurement Unit to Metric or Imperial 20

3.5.4 Reset Settings 21

3.5.5 Defining User Name 21

3.5.6 Choose a Logo for the Printout 21

4 Charging / Operation with external power 21

5 Technical Data 22

5.1 HL 6000 PC Correlator 22

5.2 TR A / TR B Transmitters 22

5.3 PAM CORR Sensors 23

6 Accessories 23

HL 6000 PC Correlator Operating Instructions | 1

Doc No. R12244 Jan/2009

1

Quick Guide

The HL 6000 PC Correlator uses highly developed measuring techniques and signal processing.

It has been designed to be simple to operate and to show measurement results in an informative

manner. To make the most of the equipment, however, we recommend that you read these

operating instructions carefully.

The main steps for performing a correlation are explained in the Quick Guide. A detailed

explanation follows thereafter.

1.1 Quick guide for TR A / TR B amplifier-transmitter

Function Operation

1. Put transmitter A (orange) at location 1 and

fix the sensor to the valve, rod or hydrant.

Proper contact between sensor and object is

important. Check sound with headphones.

1. Switch transmitter A on.

Align the aerial vertically and close the lid.

1. Put transmitter B (blue) at location 2 and fix

the sensor to the valve, rod or hydrant.

1. Switch transmitter B on. Align the aerial

vertically and close the lid.

2 | HL 6000 PC Correlator Operating Instructions

Doc No. R12244 Jan/2009

Fig 1: Setting up the correlator

1.2 Quick guide for HL 6000 PC Correlator

• Connect aConnect the delivered antenna to the socket of the E-Box

• Connect the USB E-Box to an unused USB port on your computer

• Turn on your computer and click the following icon once the system has started:

If necessary, select language in the Start screen, otherwise the program automatically advances.

Click into correlation window.

Start measuring with Start Correlation

After approx. 3 seconds the rst result of the correlation is displayed. When the result shows a

clear correlation curve (sometimes it can take a few more seconds before the display becomes

clearer), nish the correlation by clicking the Stop symbol.

HL 6000 PC Correlator Operating Instructions | 3

Doc No. R12244 Jan/2009

Now click the “Pipe table” symbol or the “Pipe table” tab to go to the page where the

different pipe sections can be entered. Select the number of pipe sections, pipe data and the

respective lengths here and then return to the correlation page (click tab or symbol).

You can now see the pipe sections entered underneath the correlation curve, shown

diagramatically and assigned directly to the location of the leak found.

4 | HL 6000 PC Correlator Operating Instructions

Doc No. R12244 Jan/2009

2

Operating Instructions for

HL 6000 PC Correlator Transmitter

2.1 Controls for TR A / TR B transmitters

Fig 2: Front panels of TR A / B transmitters

2.2 Explanation of symbols

Symbol Explanation

Headphone connection and charging socket

Sensor connection

Aerial connection

Transmitter buttons

HL 6000 PC Correlator Operating Instructions | 5

Doc No. R12244 Jan/2009

2.3 Operating instructions for TR A / TR B

• Positioning the transmitters

1. Put transmitter A (orange) at location 1 and fix the sensor to the valve, rod or hydrant.

2. Put transmitter B (blue) at location 2 and fix the sensor to the valve, rod or hydrant.

3. The transmitters must always be set up with the antenna pointing upwards.

( See Fig 1: Setting up the correlator)

• Transmitter on

1. Use this button to turn the transmitter on. After switching on, a message first appears

about the software version and the remaining battery capacity. This message will disap-

pear after about 3 seconds and the transmitter is then ready to use.

2. After every button push, the background illumination for the display lights up for about

1 minute and then turns itself off automatically.

3. The transmitter automatically turns itself completely off after operating for 2 hours.

• Listening to the leak noise / displaying the level

1. You can listen to the leak noise via the headphone socket on both transmitters A and B.

This means that an assessment can be made before doing the correlation and the user

can decide whether the sound picked up is due to water leaking or is due to some other

source (a pump, etc.). If necessary, the headphone volume can be adjusted using the ar-

row buttons

2. The noise level is shown on the display both as a bar and as a numerical value. This

means that you can easily compare levels at different measurement locations.

6 | HL 6000 PC Correlator Operating Instructions

Doc No. R12244 Jan/2009

3

HL 6000 PC Correlator Software

3.1 Correlator Display, Main Screen

1

23

2

3

4

6

7

891011 12

13

14 15 1617 18 5 26 19 20 2122 26

6

3

24

25

1

The individual elements of the screen are explained as follows. The number in front of the

heading is the reference to this picture.

3.1.1 Channel A and B Time Signal Display

If the time signal is at and more like a line, a correlation cannot be performed. Possible sources

of faults: signal interruptions, a bad contact between sensor and valve, etc.

3.1.2 Signal Spectrum or Coherence Display

Filters are also shown in this window. These can simply be set by clicking and dragging the

cursor in the window.

3.1.3 Channel A and B Level Display

The yellow and blue bar indicate if the E-Box is plugged into your PC and that the channels work

properly.

HL 6000 PC Correlator Operating Instructions | 7

Doc No. R12244 Jan/2009

3.1.4 Correlation Function Display

The delay time of the cursor position is shown inside the window next to the cursor (symbolised

by a red line). Left-clicking with the mouse resets the cursor (default settings to the maximum

correlation are done by the software automatically).

Right-click and drag with the mouse in this window to hide certain ranges from the correlation.

This function is called “peak suppression”.

3.1.5 Diagramatical Representation of Pipe

This diagram does not just show the pipe but also a direct reference to the position of the cursor

and hence the leak.

3.1.6 Displaying Transmitters A and B

The leak distance is shown above TR A and TR B. Both added together result in the total length

of surveyed pipe. Watching A and B also indicates radio reception from TR A and TR B.

3.1.7 Current Pipe Data

See different pipe materials in different colors including pipe parameters.

3.1.8 Start Correlation Button

You can start a correlation with this function. If no pipe data has been entered, start a so-called

“overview measurement”, as described in the Quick Guide. The advantage is to check quickly and

efciently if there is a possible leak on this pipe section.

3.1.9 Start 3D / 2D Correlation Button

With this function you can show the time constancy of a noise, just as with a data logger. In this

way, you can identify sounds that are not constant and are therefore also presumably not a leak.

8 | HL 6000 PC Correlator Operating Instructions

Doc No. R12244 Jan/2009

You can choose either a 2-dimensional or a 3-dimensional representation. The change can be

made in the “Conguration” menu.

3.1.10 Finishing the Correlation

Most of the functions are deactivated while a correlation is running. After nishing the

correlation, this functions will be available again.

3.1.11 Changing to the Pipe Table Display

By clicking the pipe data button (11) underneath the correlation window or choosing the

appropriate tab, you can also go to the pipe tables (see also Chapter 3.2).

3.1.12 Reset Display

This deletes all current correlation and pipe data and a new measurement process can be started.

3.1.13 Playback

If the sound data was also saved during a previous correlation this can be replayed with this

button after loading. A correlation is started at the same time and the result displayed in the

correlation window. Important: To be able to listen and re- correlate at the same time you need

a stereo sound card built into your PC. The “stereo- mix” sound le must be activated and the

loudspeaker symbol in the task bar in the “on” position.

HL 6000 PC Correlator Operating Instructions | 9

Doc No. R12244 Jan/2009

3.1.14 Automatic Frequency Analysis

This performs an automatic frequency analysis and analyses at which lter setting the best

correlation takes place. Ten different results are then shown.

The best result is shown in red. If you click this window, the correlation is shown in “Normal”

mode with the corresponding lter settings.

This function helps you to optimise the lter settings and to improve the correlation result. You

should, however, analyze the result very carefully to see whether it matches the actual situation.

10 | HL 6000 PC Correlator Operating Instructions

Doc No. R12244 Jan/2009

3.1.15 Measurement Statistics

First the curve shape for the correlation performed is analyzed and is allocated a quality factor

between 0 and 100. The higher the value, the clearer the correlation.

For low values, the button for frequency analysis (14) is shown in the statistics window because

an improvement might be possible by altering the lter settings.

Result statistics are also displayed.

With a measurement process that lasts longer, other louder noises (for example, water being

briey extracted) can affect the correlation and this will result in the cursor (and thereby the

distance to the leak) not staying constantly in one position. These values appear in the statistics

with low percentage values. This way, the function helps you to better identify the position of the

leak.

HL 6000 PC Correlator Operating Instructions | 11

Doc No. R12244 Jan/2009

3.1.16 Measuring Sound Speed

Measuring the “sound speed” is essential to generate an exact correlation result, especially for

unknown pipe materials and pipe characteristics (e.g. old pipes).

To measure the sound speed of the pipe, an articial leak must be created and the distance from

this leak to the transmitters must be known. A slightly opened hydrant, for example, is an articial

leak. The leak can be both within or outside the transmitters. It is recommended, however, that the

leak is produced outside the transmitters.

1. Place both sensors at suitable measuring points and open the artificial leak.

2. Start a new correlation with the “Start correlation” button (8). Finish the correlation when

you have received a suitable result.

3. Now open the “Speed measurement” dialogue by clicking button (16). Enter the correspond-

ing data in the query window.

The result is the sound speed of the pipe. Now close the articial leak and perform the correlation

again using the new data to determine the distance to the real leak.

3.1.17 Zoom In

With this function activated, the correlation curve can be enlarged in the chosen range by clicking

and dragging with the mouse in the correlation window. This is particularly useful when two

peaks are very close to one another.

3.1.18 Zoom to Pipe Length

The correlation window is automatically adjusted so that the length of the pipe lls the whole

width of the window. By pressing the button once again, the whole measurement length is

displayed again and the pipe is reduced in the middle of the measuring range.

3.1.19 Load Correlation

A saved measurement can be loaded. If sound data was saved this is also loaded at the same time.

3.1.20 Save Correlation

First you will be asked whether you would like to save the actual sounds as well. If you choose

“no”, only the correlation curve (diagram) and the report will be saved. Otherwise, the sound data

will also be stored in universal WAV format. The saved sound data can be called up at any time

again, played back and correlated once again.

12 | HL 6000 PC Correlator Operating Instructions

Doc No. R12244 Jan/2009

3.1.21 Print Correlation

Produces a printout of the correlation curve including a report.

If you have also produced a damage sketch, this can be printed out at the same time as well by

checking “Sketches”. The sketch will be printed out on a 2nd sheet.

The printer selected is always the printer that is dened in Windows as the “default printer”.

Please consult Windows Help if you wish to change the selected printer.

3.1.22 Help / Operating Instructions

The Operating Instructions supplied are called up in pdf-le form. You can therefore read about

the functions and operation at any time.

3.1.23 Filter +/-

When “+” is checked, only the selected range is used for the evaluation. When “-” is checked, this

range is excluded from the evaluation.

3.1.24 Wide Band

By clicking this button, the lter is fully opened to the maximum bandwidth.

3.1.25 Coherence / Spectrum A+B

Used to toggle between coherence representation and display of each sensor spectrum sent by the

transmitters.

HL 6000 PC Correlator Operating Instructions | 13

Doc No. R12244 Jan/2009

3.2 Pipe Table Display

3.2.1 Selecting the number of pipe sections

A maximum of ten different sections can be entered. Press the “up” arrow to increase the number

of sections. The “down” arrow reduces the number of sections.

The total length of all the pipe sections is displayed after the number of pipe sections.

The rst two sections are shown enlarged to make entry using a touchscreen PC easier.

1

2

3

14 | HL 6000 PC Correlator Operating Instructions

Doc No. R12244 Jan/2009

3.2.2 Data for the Individual Sections

The length can either be entered directly via the keyboard or with the two arrow buttons next to

the eld for the length. The material and diameter are selected from a drop-down list. Click the

small triangle directly next to the materials description and select the pipe material from the list.

The stored sound speed is displayed underneath. Select the “manual” box to enter the pipe’s

sound speed by hand. This is necessary if you have carried out sound speed measurements

for pipe sections and they do not match the listed speeds. In such cases you can improve the

correlation result. If this option is set to “manual”, the material and diameter can no longer be

selected.

HL 6000 PC Correlator Operating Instructions | 15

Doc No. R12244 Jan/2009

3.2.3 Editing the Material List

1

2

3

4

The user can add other pipe materials and sound speeds to the saved materials list, or alter the list,

as many times as they wish.

To add materials, click “+” at (1) in the left-hand part of the window. Enter a name for the

material in the following dialogue. It is advisable to clearly mark new materials (e.g. with your

town as an additional remark) so that you can distinguish them later from the standard materials.

To then add the corresponding diameters and sound speeds to the new material, press “+” at (2).

Fill in the subsequent dialogues with the corresponding values. You can measure sound speeds

using the function of the HL 6000 PC Correlator that has just been mentioned. Please also read

the chapter about this topic.

With the “Standard settings” button, you reset the pipe table back to its original state when the

equipment was delivered. CAUTION! All data that you have entered will be deleted.

Click to return to the pipe table.

3.2.4 Return to the Correlation Display

Click to return to the Correlation Display.

16 | HL 6000 PC Correlator Operating Instructions

Doc No. R12244 Jan/2009

3.3 Multicorrelation Display

1

2

1

3

4

This operation mode enables you to compare two or even several measurements on a pipe and

replaces a three-point correlation.

First carry out a correlation for a pipe section and save the measurement.

Now reposition one of the sensors and perform the correlation as normal.

To see whether both results agree select the multicorrelation mode.

In the upper screen the correlation from the main screen is shown as standard. If required, button

(1) will, however, also enable you to load a saved correlation.

The comparative measurement for lower screen (4) is loaded using the corresponding (1).

Before this, (2) must still be used to select the sensor that had the same position during both

measurements.

You can therefore use your rst measurement as a reference measurement and compare this with

a large number of other correlations in the same range.

Table of contents

Other Vivax Metrotech Measuring Instrument manuals

Vivax Metrotech

Vivax Metrotech vLoc3-9800 Instruction Manual

Vivax Metrotech

Vivax Metrotech vLoc3 Series User manual

Vivax Metrotech

Vivax Metrotech HL5000 Installation manual

Vivax Metrotech

Vivax Metrotech vLocPro2 User manual

Vivax Metrotech

Vivax Metrotech vLoc3-MLA Instruction Manual

Vivax Metrotech

Vivax Metrotech vLoc3-Cam Instruction Manual

Vivax Metrotech

Vivax Metrotech VM-540 User manual

Vivax Metrotech

Vivax Metrotech vLocPro Series Reference guide

Vivax Metrotech

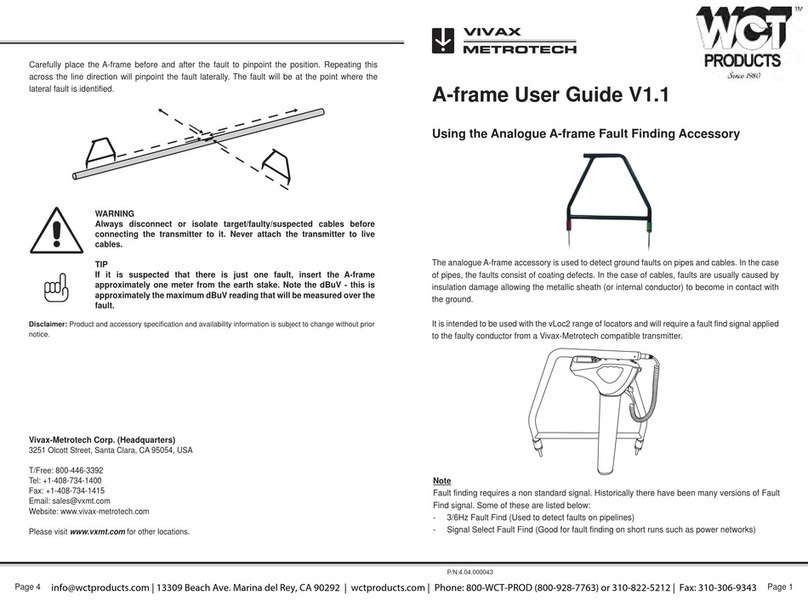

Vivax Metrotech A-frame User manual