Stainless Steel Care & Maintenance

All grades of stainless steel will stain and discolour due to surface deposits and

cannot be considered completely maintenance-free. In order to retain

maximum corrosion resistance and aesthec appeal, the surface of stainless

steel must be kept clean. Cleaning schedules should be carried out on a

regular basis then good performance and long service life are assured.

GENERAL CLEANING METHODS

Stainless steel is easy to clean. Washing with soap or a mild detergent and

warm water, followed by a clear water rinse, is usually quite adequate for

domesc and architectural equipment. An enhanced aesthec appearance will

be achieved if the cleaned surface is wiped dry. Where stainless steel has

become extremely dirty with signs of surface discolouraon, (perhaps

following a period of neglect or misuse), methods of cleaning are detailed in

the chart provided below:-

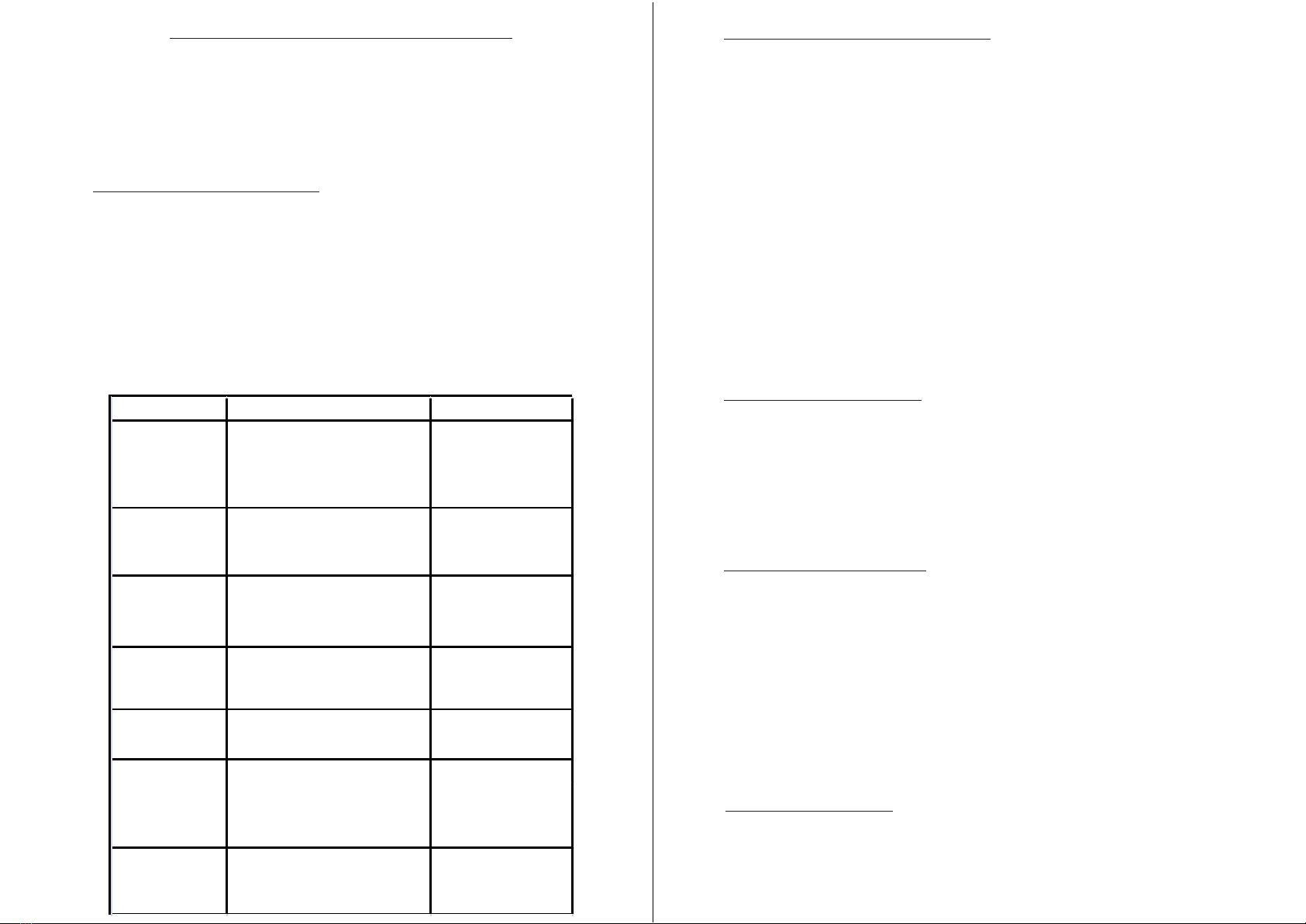

Requirement Suggested Method Comments

Roune cleaning of

light soiling

Soap, detergent or dilute (1%)

ammonia soluon in warm clean

water. Apply with a clean sponge, so

cloth or so- fibre brush then rinse in

clean water and dry.

Sasfactory on most

surfaces

Fingerprints Detergent and warm water,

alternavely, hydrocarbon solvent

Proprietary spray-applied

polishes available to

clean and minimise

remarking

Stubborn spots,

stains and light

discolouraon

Mild, non-scratching creams and

polishes. Apply with so cloth or so

sponge andrinse off residues with

clean water and dry

Avoid cleaning pastes with

abrasive addions. Do not

use chloride soluons

Water marking. Light

rust staining

rinse off residues with clean water and

dry

Heang or heavy

discolouraon

Nylon-type pad, e.g. ‘Scotchbrite’ Use on brushed and

polished finishes along

the grain.

May brighten dull finishes

To avoid a patchy

appearance, the whole

surface may need to be

treated

Paint, graffi Proprietary alkaline or solvent paint

strippers, depending upon paint type.

Use so nylon or bristle brush on

paerned surfaces

Apply as directed by

manufacturer

Badly neglected

surfaces with

accumulated grime

deposits

A fine, abrasive paste as used for car

body refinishing, e.g. ‘T-cut’ rinsed

clean to remove all paste material &

dried

FACTORS AFFECTING MAINTENANCE

Surface contaminaon and the formaon of deposits must be prevented. These

deposits may be minute parcles of iron or rust from other sources used in the

building of new premises and not removed unl aer the stainless steel items

have been fixed. Industrial and even naturally occurring atmospheric condions

can cause deposits that can be equally corrosive, e.g. salt deposits from marine

condions. A working environment which offers more aggressive condions, e.g.

hot & humid, such as in a swimming pool, increases the speed of discolouraon

and therefore requires maintenance on a more frequent basis. Modern

processes use many cleaners, sterilisers and bleaches for hygienic purposes. All

these proprietary soluons, when used in accordance with makers' instrucons,

are safe, but if used incorrectly (e.g. warm or concentrated), can cause

discolouraon and corrosion on the surface of any quality of stainless steel.

Strong acid soluons are somemes used to clean masonry and ling of

buildings but they should never be permied to come into contact with metals,

including stainless steel. If this should happen, the acid soluon must be

removed immediately by copious applicaons of water.

BRUSHED STAINLESS STEEL

When the steel has become extremely dirty, perhaps following periods of

neglect or aer being subjected to a parcularly aggressive environment, mild

abrasion only (such as scrubbing with a nylon or other non- scratching scourer)

may be necessary. Ordinary steel wool soap pads should never be used as they

may leave parcles of mild steel on the surface of the stainless steel, which may

cause localised areas of rusng. Stainless steel soap pads, are quite suitable.

POLISHED STAINLESS STEEL

A highly polished surface will be permanently marked by the use of abrasives

which, therefore, should be avoided at all costs. Discolouraon, heavy dirty or

rust which may resist normal cleaning methods can be removed using a

proprietary stainless steel cleaner followed by a clear water rinse. Some

deposits and stains encountered in catering and medical applicaons can be

difficult to remove. It should be noted that nearly all abrasive cleaners will

scratch a bright annealed or 2B finish of stainless steel. On other finishes the

cleaner should be used in the direcon of the polish. A clean dust and grit-free

cloth should be used to avoid scratching. In all cases the mildest cleaning

procedure that will do the job efficiently should be used.

P3

P2

POWDER COATED STEEL

Carefully remove any loose deposits with a wet cloth.

Use a so cloth and a mild household detergent soluon to remove dust, salt

and other deposits.

Rinse off with clean fresh water.