Vmac A500246 User manual

www.vmacair.comwww.vmacair.com

Installation Manual for VMAC

Accessory

A500246 Voltage Sense Interlock for

Multifunction Power Systems

®

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

1

Table of Contents

Safety ..............................................................3

Warranty ...........................................................4

General Information.................................................6

Voltage Sense Interlock Installation and Operation ..................8

Getting Started Guide ............................................. 11

Troubleshooting.................................................... 12

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

2

Notice

Copyright © 2022 VMAC Global Technology Inc. All Rights Reserved. These

materials are provided by VMAC for informational purposes only, without

representation or warranty of any kind, and VMAC shall not be liable for errors

or omissions with respect to the materials. The only warranties for VMAC

products and services are those set forth in the express warranty statements

accompanying such products and services, if any, and nothing herein shall be

construed as constituting an additional warranty. Printing or copying of any page

in this document in whole or in part is only permitted for personal use. All other

use, copying or reproduction in both print and electronic form of any part of this

document without the written consent of VMAC is prohibited. The information

contained herein may be changed without prior notice.

Printed in Canada

Additional Application Information

For use with Multifunction Power Systems (MF).

Registered Trademarks

All trademarks mentioned in this manual are the property of their respective

owners. VMAC’s use of manufacturers’ trademarks in this manual is for

identification of the products only and does not imply any affiliation to, or

endorsement of said companies.

Important Information

The information in this manual is intended for certified VMAC installers who

have been trained in installation and service procedures and/or for anyone with

mechanical trade certification who has the tools and equipment to properly and

safely perform the installation or service. Do not attempt installation or service

without the appropriate mechanical training, knowledge and experience.

Follow all safety precautions. Any fabrication for correct fit in modified vehicles

must follow industry standard “best practices”.

Document: 1901201

Changes and Revisions

Revision Revision Details Revised by

Checked by

Implemented

Eng. Tech. Qual.

Mech. Elec.

BECN: 22-157 Add install instructions MSP N/A CAB BDJ N/A 30 Aug. 2022

C ECN 23-017 Update remote gen instr. MSP N/A CAB MSP LPH 1 Aug. 2023

D ECN: 23-224 Update VSI install instructions MSP N/A CAB MSP N/A 6 Dec. 2023

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

3

Safety

Important Safety Notice

The information contained in this manual is based on sound engineering principles,

research, extensive field experience and technical information. Information

is constantly changing with the addition of new models, assemblies, service

techniques and running OEM changes. If a discrepancy is found in this manual,

contact VMAC Technical Support prior to initiating or proceeding with installation,

service or repair. Current information may clarify the issue. Anyone with knowledge

of such discrepancies, who proceeds to perform service and repair, assumes all

risks.

Only proven service procedures are recommended. Anyone who departs from the

specific instructions provided in this manual must first ensure that their safety and

that of others is not being compromised, and that there will be no adverse effects

on the operational safety or performance of the equipment.

VMAC will not be held responsible for any liability, consequential damages, injuries,

loss or damage to individuals or to equipment as a result of the failure of anyone

to properly adhere to the procedures set out in this manual or standard safety

practices.

Safety should be the first consideration when performing any service operations.

If there are any questions concerning the procedures in this manual, or more

information is required, please contact VMAC Technical Support prior to beginning

work.

Safety Messages

This manual contains various warnings, cautions and notices that must be

observed to reduce the risk of personal injury during installation, service or repair

and the possibility that improper installation, service or repair may damage the

equipment or render it unsafe.

This symbol is used to call attention to instructions concerning

personal safety. Watch for this symbol; it points out important

safety precautions, it means, “Attention, become alert! Your

personal safety is involved”. Read the message that follows and

be aware of the possibility of personal injury or death. As it is

impossible to warn of every conceivable hazard, common sense and

industry standard safety practices must be observed.

This symbol is used to call attention to additional instructions or

special emphasis on a specific procedure.

This symbol is used to call attention to instructions on a specific

procedure that if not followed may damage or reduce the useful life

of the compressor or other equipment.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

4

VMAC Standard Warranty (Limited)

For complete warranty information, including both VMAC Standard

Warranty (Limited) and VMAC Lifetime Warranty (Limited)

requirements, please refer to our current published warranty located

at: www.vmacair.com/warranty

If you do not have access to a computer, please contact us and we will

be happy to send you our warranty.

VMAC’s warranty is subject to change without notice.

VMAC Lifetime Warranty (Limited)

A VMAC Lifetime Limited Warranty is offered

on the base air compressor only and only on

UNDERHOOD, Hydraulic Driven, Transmission

Mounted, Gas and Diesel Engine Driven Air

Compressors, Multifunction Power Systems, and

other products as defined by VMAC, provided

that (i) the purchaser fully completes and submits

a warranty registration form within 3 months

of purchase, or 200 hours of operation, whichever occurs first; (ii) services are

completed in accordance with the Owner’s Manual; (iii) proof of purchase of

applicable service kits are made available to VMAC upon request.

The VMAC Lifetime Warranty is applicable to new products shipped on or after 1

October, 2015.

Warranty Registration

Warranty registration for VMAC systems can be completed online or by filling in

the form at the back of each system installation manual. Warranty registration

must be completed and sent to VMAC at the time the system is put into service for

any subsequent warranty claim to be considered valid.

There are 4 ways the warranty can be registered with VMAC:

www.vmacair.com/warranty

warranty@vmacair.com

(877) 740-3202

VMAC - Vehicle Mounted Air Compressors

1333 Kipp Road, Nanaimo, BC, Canada V9X 1R3

LIFETIME

A

I

R

I

N

N

O

V

A

T

E

D

T

R

U

S

T

S

E

R

V

I

C

E

V

A

L

U

E

WARRANTY

Warranty

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

5

VMAC warranty work must be pre-authorized by VMAC. Claims are

processed via our dealer network. If you are not a VMAC dealer,

please select one to work with via our Dealer Locator:

https://www.vmacair.com/dealer-locator/

1) Communicate with VMAC Technical Support at 1-888-241-2289 or

tech@vmacair.com to help diagnose/troubleshoot the problem prior to repair.

VMAC technical support will require the VMAC System ID, and the hours on

the compressor.

2) VMAC will provide direction for repair or replacement of the failed

components.

3) If requested, failed parts must be returned to VMAC for evaluation.

4) Dealers may login to the VMAC website to view the "VMAC Labour Time

Guide" (under “Agreements”) to see the allowable warranty labour times.

5) Warranty invoices must include the Service Ticket number, VMAC System ID#,

hours on the compressor, and a detailed description of the work performed.

6) VMAC Warranty does not cover consequential damages, overtime charges,

mileage, travel time, towing/recovery, cleaning or shop supplies.

7) Dealers submit warranty claims on behalf of the Vehicle Owner/End User

affected by the defective part(s). The dealer ensures that all warranty credits

are refunded back to the Vehicle Owner/End User who made the initial

warranty claim.

VMAC Warranty Claim Process

VMAC Product Warranty Policies & Warranty Registration can be found on the

VMAC website (see previous page for URL).

In order to qualify for Lifetime Warranty (Limited), the completed

warranty registration form must be received by VMAC within 3

months of the buyer receiving the Product(s), or 200 hours of

operation, whichever occurs first.

If the completed warranty registration form has not been received

by VMAC within 3 months of the buyer receiving the Product(s),

or 200 hours of operation, the “Standard” warranty period will be

deemed to commence 30 days from the date of shipment from

VMAC.

Failure to follow the warranty claim process may result in denial of

the warranty claim.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

6

General Information

Optional Equipment Compatibility

While VMAC strives to design systems compatible with optional OEM equipment

(such as running boards), it is impractical to develop systems that accommodate

every OEM and aftermarket option or add-on. Whenever possible, VMAC

endeavors to advise of compatibility issues in the “Additional Application

Information” section of the manual. Even when specific optional equipment is

determined by VMAC to be incompatible, it does not preclude the vehicle upfitter

or end user from modifying the optional equipment to make it compatible with

the installed VMAC system. VMAC does not warrant or accept responsibility or

liability for the fitment, function, or safety of any products modified in any way not

expressly outlined in the installation manual.

Before Starting

Read this manual prior to beginning the installation to ensure familiarity with the

components and how they will fit on the vehicle. Identify any variations from the

application list such as vehicle model, engines, or optional equipment (e.g., dual

alternator, active steering assist, etc.).

Open the package, unpack the components and identify them using the Illustrated

Parts List (IPL) included in the Fastener Pack.

Hose Information

Depending on other installed equipment, it might be necessary to move the air/oil

separation tank from its intended location. The hoses used in VMAC compressor

systems have a specific inner liner that is compatible with VMAC compressor oil.

Use of hoses other than those supplied or recommended by VMAC may cause

compressor damage and may void your warranty. Please contact VMAC for

replacement hoses and further information.

Ordering Parts

To order parts, contact a VMAC dealer. The dealer will ask for the VMAC serial

number, part number, description and quantity. Locate the nearest dealer online at

www.vmacair.com/dealer-locator or call 1-877-912-6605.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

7

Special Tools Required

Table 1 — Torque Table

Standard Grade 8 National Coarse Thread

Size (in) 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4

Foot pounds (ft•lb) 918 35 55 80 110 170 280

Newton meter (N•m) 12 24 47 74 108 149 230 379

Standard Grade 8 National Fine Thread

Size (in) 3/8 7/16 1/2 5/8 3/4

Foot pounds (ft•lb) 40 60 90 180 320

Newton meter (N•m) 54 81 122 244 434

Metric Class 10.9

Size (mm) M6 M8 M10 M12 M14 M16

Foot pounds (ft•lb) 4.5 19 41 69 104 174

Newton meter (N•m) 625 55 93 141 236

• None.

Torque values are with Loctite applied unless otherwise specified.

All fasteners must be torqued to specifications. Use manufacturers’ torque values

for OEM fasteners.

The torque values supplied in Table 1 are intended for VMAC supplied components,

or for use as a guide in the absence of a torque value provided by an OEM.

Apply Loctite 242 (blue) to all fasteners (except nylon lock nuts)

unless otherwise stated.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

8

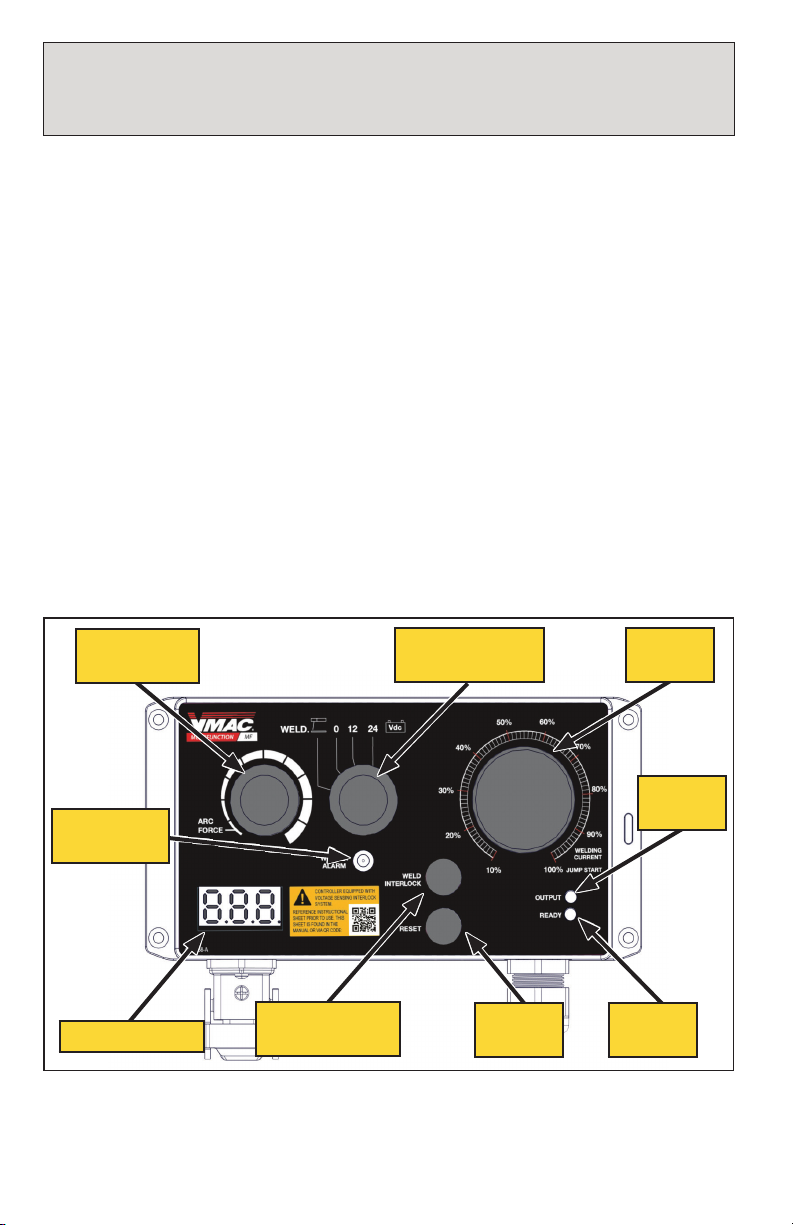

Voltage Sense Interlock

Installation and Operation

Figure 1 — Remote generator control box with Voltage Sense Interlock

Current

knob

Error

LED

On/Off

LED

Reset

button

Weld interlock

button

Voltmeter

ARC FORCE

knob

Weld/Charge

selection knob

Weld alarm

light

Installation

The Welder Control Box includes an 8 ft harness with (×4) plugs.

☐ Mount the Welder Control Box in a convenient location that is protected from

the weather.

☐ Locate harness bundle with the connectors near the main air discharge from

the MF.

☐ Plug one side of the “T” harness with the (×2) flat 5-pin connectors into the

matching connector at the MF unit and the other side into the connector

running to the rocker switches on the Display Panel.

Note: If using the pigtail extension harness, the welder control box should be

installed on the side closest to the rocker switch panel.

☐ Connect the (×2) Welder Control Box connectors into the matching connectors

in the main harness bundle.

Operation

This generator has been equipped with a voltage monitoring circuit to ensure that

charging/welding voltages are operating correctly for the intended process.

The order of operations for connecting batteries or moving the system into weld

mode must be followed exactly or the system disables itself and the generator must

be reset.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

9

If the battery voltage is too low,*.

☐ *Disconnect the battery from all loads. This may allow the battery voltage

to rise high enough to be recognized by the system.

☐ *If the battery does not recover adequate voltage after being disconnected,

battery detection can be temporarily over-ridden by pressing and holding

both the “RESET” and “BATTERY INTERLOCK” button for 5 seconds.

☐ With the battery connected, rotate the “WELD” selection knob to the

appropriate charge mode*.

☐ *The voltage should rise as the system begins charging.

☐ Set the “WELDING CURRENT” knob to 100%.

Charging / Boosting Procedure

Working near lead/acid batteries is dangerous. Batteries contain

sulphuric acid and may generate hydrogen gas during regular

operation. Lead/acid batteries may explode if exposed to a spark.

Never attempt to jump start a frozen battery.

Never overcharge a battery.

Always follow safety precautions when jump starting or charging

a battery, including the use of appropriate Personal Protective

Equipment.

☐ Prior to charging or boosting, ensure the MF is not running, and the booster

cables are disconnected from the battery to be charged.

☐ Set the “WELD” selection knob to 0 V.

☐ Start the MF.

☐ Engage the generator via the toggle switch located at the display box.

☐ The voltmeter should read approximately 0 V.

If “ErX” is displayed*:

☐ *Ensure the booster cables are not shorted together, or connected to the

batteries to be charged, and the “WELD” selection knob is set to “0”.

☐ *Press and hold the “RESET” button for 2 seconds.

☐ Connect the positive clamp to the positive terminal on the battery.

☐ Connect the negative clamp to a good ground (ideally on the engine).

Observe the battery voltage using the Voltmeter*.

☐ *12 V systems should indicate battery voltage above 2.0 V.

☐ *24 V systems should indicate battery voltage above 14.0 V.

If the battery voltage is below the above values, the generator will

not recognize the target and will not unlock the appropriate charge

modes.

Once switched into charge mode, the system will re-enable battery

detection after 60 seconds.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

10

☐ Return the “WELD” selection knob to 0 V.

Weld Procedure

☐ Let the batteries charge for at least 5 minutes.

☐ Try starting the vehicle.

While the MF can provide up to 300 A of start assist, vehicle

starters can draw upwards of 1,200 A while starting.

If the vehicle fails to start, allow it to charge for longer before

attempting to start again.

☐ Prior to starting the Gas MF, set the “WELD” selection knob to 0 V.

☐ Start the Gas MF.

☐ Engage the generator via the toggle switch located at the display box.

☐ The voltmeter should read approximately 0 V.

☐ If “ErX” is displayed*:

☐ *Ensure the weld cables are not shorted together, or connected to the batteries

to be charged, and the “WELD” selection knob is set to “0”.

☐ *Press and hold the “RESET” button for 2 seconds.

☐ Press and hold the “WELD INTERLOCK” button while rotating the “WELD”

selection knob to “WELD”.

☐ If using the optional Current Control Pendant (P/N: A500018), plug it into the

Remote Generator Control Box.

☐ Adjust the “WELDING CURRENT” and “ARC FORCE” as required.

☐ Once welding is complete:*

☐ *If using the Current Control Pendant, disconnect it.

☐ *Set the “WELD” selection knob to 0 V (The “WELD INTERLOCK” button is

not required when returning the “WELD” selection knob to 0 V).

Plugging the optional Current Control Pendant (P/N: A500018) into

the Remote Generator Control Box prior to entering "WELD" mode

will cause an error.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

11

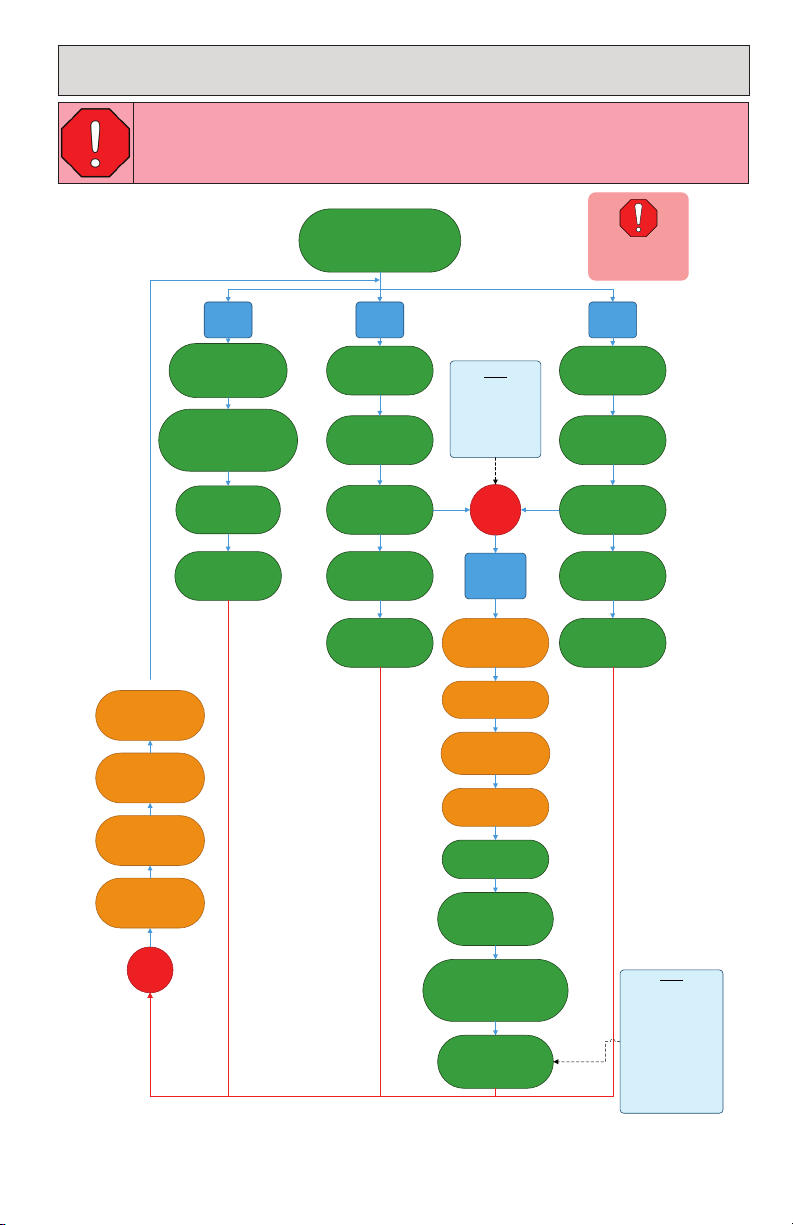

Getting Started Guide

•Ensure boost cables are

disconnected from all loads &

accessories are unplugged

•Start Multifunction

•Genset Switch ON

12V

BOOST

24V

BOOST

WELD

ERROR?

Ensure Weld/Charge

Selection Knob set to

“0V” position

Press & Hold

“RESET” button for 2

seconds

Disconnect boost

cables from all loads

Ensure Weld/Charge

Selection Knob set to

“0V” position

Ensure Weld/Charge

Selection Knob set to

“0V” position

While pressing

“WELD INTERLOCK” button,

move weld/charge selection

knob to “WELD” position

Verify output

voltage on display

Connect boost cables

to 12V battery

Move Weld/Charge

Selection Knob to

“12V” position

Connect boost cables

to 24V battery

Move Weld/Charge

Selection Knob to

“24V” position

Ready to weld Verify output

voltage on display

ERROR 1?

Move Weld/Charge

Selection Knob to

“0V” position

Press & Hold

“RESET” button for 2

seconds

Ready to boost 12V

Press & hold both

“WELD INTERLOCK” &

“RESET” buttons for 5

seconds

Connect boost cables

to 12V or 24V battery

Move Weld/Charge

Selection Knob to

“0V” position

Disconnect boost

cables from all loads

Move Weld/Charge

Selection Knob to

“12V” or “24V” position,

depending on connected

battery

Verify output

voltage on display

Ready to boost 24V

System will boost for

60s and re-measure

battery voltage

TEMPORARY

BATTERY

DETECT

OVERRIDE

INFO

“ERROR 1" occurs

when battery

voltage is less than

2V for 12V battery

or less than 14V for

24V battery

INFO

If battery voltage is

still too low after 60s

of boost, the system

will detect an error

and the override

process must be

repeated until battery

voltage is greater than

2V for 12V battery or

greater than 14V for

24V battery

REV005

Refer to warnings on

pg.8 of installation

manual before use

Refer to warnings on

pg.8 of installation

manual before use

Refer to warnings on

pg.8 of installation

manual before use

Refer to warnings on

pg.8 of installation

manual before use

Disconnect all

accessories from

remote weld box

Disconnect all

accessories from

remote weld box

Read the warnings listed on page 9 prior to proceeding.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

12

Weld Control Box Error Messages

If the voltmeter detects a voltage or state that is not permitted, an error will be

displayed on the screen.

If an error is displayed:

☐ Disconnect the target battery and ensure the booster, or weld cables are not

shorted together.

☐ Return the “WELD” selection knob to 0 V.

☐ Press and hold the “RESET” button for 2 seconds.

☐ If the error persists, contact VMAC for support.

Error Description Corrective Action

Er 0 Voltage detected above bounds

for selected mode.

Gas MF output voltage is greater than 20 V (12 V

boost mode) or 38 V (24 V boost mode).

• Reset system and re-attempt boost procedure.

• Contact Technical Support.

• Remote Current Control Pendant plugged in prior

to setting "WELD" mode (see page 10).

Er 1 Voltage detected under bounds

for selected mode.

Target battery is less than 2 V (12 V boost mode) or

14 V (24 V boost mode).

• Check connection between Gas MF boost cables

and target battery.

• Charge target battery in override mode to

allow battery voltage to rise high enough to be

recognized by system.

• Target battery float voltage is too low to be

charged.

Er 2 Reverse polarity detected.

Reverse polarity of connection from Gas MF boost

cables to target battery.

• Check connection between Gas MF boost cables

and target battery. Verify correct polarity

(+ to + and - to -).

Er 3 Incorrect mode detected.

Incorrect charge mode selected for detected target

battery voltage.

• WELD INTERLOCK button not pressed while

entering WELD mode.

• System not started in 0 V mode, Refer to

page 44.

• Select correct charge mode according to target

battery voltage.

Er 4 Multifunction battery low.

Gas MF battery voltage less than 9.0 V.

• Inspect cables/connections to Gas MF battery.

• Service/replace Gas MF alternator.

Er 5 Multifunction battery high. Gas MF battery voltage greater than 16.0 V.

• Service/replace Gas MF alternator.

Er 6 MCU Reset.

• Inspect wiring harness for damage, short/open

circuit.

• Contact VMAC Technical Support.

888-241-2289 tech@vmacair.com

877-740-3202 warranty@vmacair.com

www.vmacair.com kb.vmacair.com

1333 Kipp Road, Nanaimo, B.C., V9X 1R3 Canada

Manufactured by

®

Table of contents

Other Vmac Automobile Accessories manuals

Vmac

Vmac V910020 Service manual

Vmac

Vmac A500251 User manual

Vmac

Vmac A700308 User manual

Vmac

Vmac VR 7000 9004 User manual

Vmac

Vmac A500237 User manual

Vmac

Vmac A700137 User manual

Vmac

Vmac VR7000 9037 User manual

Vmac

Vmac VR 7000 9018 User manual

Vmac

Vmac A700269 User manual

Vmac

Vmac VR7000 9039 User manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction