VMI VVS OL82 User manual

VMI Vision System

VVS (OL82)

Technical Manual

Version VVSX 13.0.12.0, VVSU 3.0.6

Revision no. 4

Issue date 2016-07-11

This page has been left blank intentionally.

World-wide support

Headquarters

P.O. Box 161

8160 AD Epe

The Netherlands

+31 651 533 912 (24 HOURS AT CALL, 7 DAYS A WEEK AVAILABLE)

+31 578 679 111

Internet

www.vmi-group.com

Copyright on product

VMI products shall not be copied, reproduced or transmitted by buyer and/or (end-) user,

nor disclosed or surrendered in any form and/or in any way to third parties, nor shall it

be used for the reproduction or copying of such product(s) without explicit written

permission of VMI.

Copyright on design, technical documents, drawings, video tapes, CDs, DVDs

All information and data (design, technical documents, drawings, etc.) provided by VMI

are protected by the law of copyright and shall remain the exclusive property of VMI.

The information enclosed in the product and/or manufacturing methods shall remain

the exclusive property of VMI.

Information as mentioned above and data shall not be copied, reproduced or transmitted by

buyer and/or (end-) user, nor disclosed or surrendered in any form and/or in any way to

third parties, nor shall it be used for the re‑production or copying of such product(s) without

explicit written permission of VMI.

Copyright on software

The buyer and/or (end-) user acquires the non‑exclusive right to use the software to which

VMI holds the intellectual property rights, only for the use of the product(s).

Buyer and/or (end-) user may not copy such software, except for making a backup

for its own use.

VMI retains the intellectual property rights of the software, as mentioned above.

VMI shall not be obliged to provide the source code for the software, as mentioned above.

VMI shall not be obliged to provide the buyer with updated versions of software,

as mentioned above, or software updates as released by any of

the third‑party suppliers of VMI.

It is the owner’s responsibility to make regular back‑ups of all control components such as

PCs and PLCs.

Chapter

Preface

Preface

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 i

Guarantee

VMI Holland BV will evaluate machine performance and correct information during

the contract period, provided that such concerns are reproducible, have been reported to

VMI in writing and are acknowledged by VMI. The end user will render all reasonable

assistance to correct the concerns.

Problems which result from misuse or non-adherence to VMI instructions are not covered

by this guarantee.

VMI assumes no responsibility for injuries, production loss or other consequential damage

due to any errors in or incompleteness of this manual.

Intellectual property

The copyright on this manual and any other information supplied remains the property of

VMI Holland BV.

The information may only be used for installation, training and servicing according to

the function it was originally intended for.

Re-use, re-engineering, reproduction or transmission, other than mentioned here,

in any form, in whole or in part, by electronic or mechanical means,

without the prior written approval of VMI, is prohibited.

It is not allowed to remove Copyright © or trademark ™ notices.

Third-party trademarks and/or copyright material are property of their owners.

VMI registered trademarks

Apexer®, AZ Retrax®, CORTEXX®, Edgiq®, EXXIUM®, FLEXX®, FLEXX Technology®,

INDIVION®, MAXX®, MAXX Technology®, MILEXX™, PHARYS™, Revolute®, Strainext®,

UNIXX®, VMI®, VMI Group®, VMI PIXXEL®, VMI Synchrodrum®.

Manual revisions

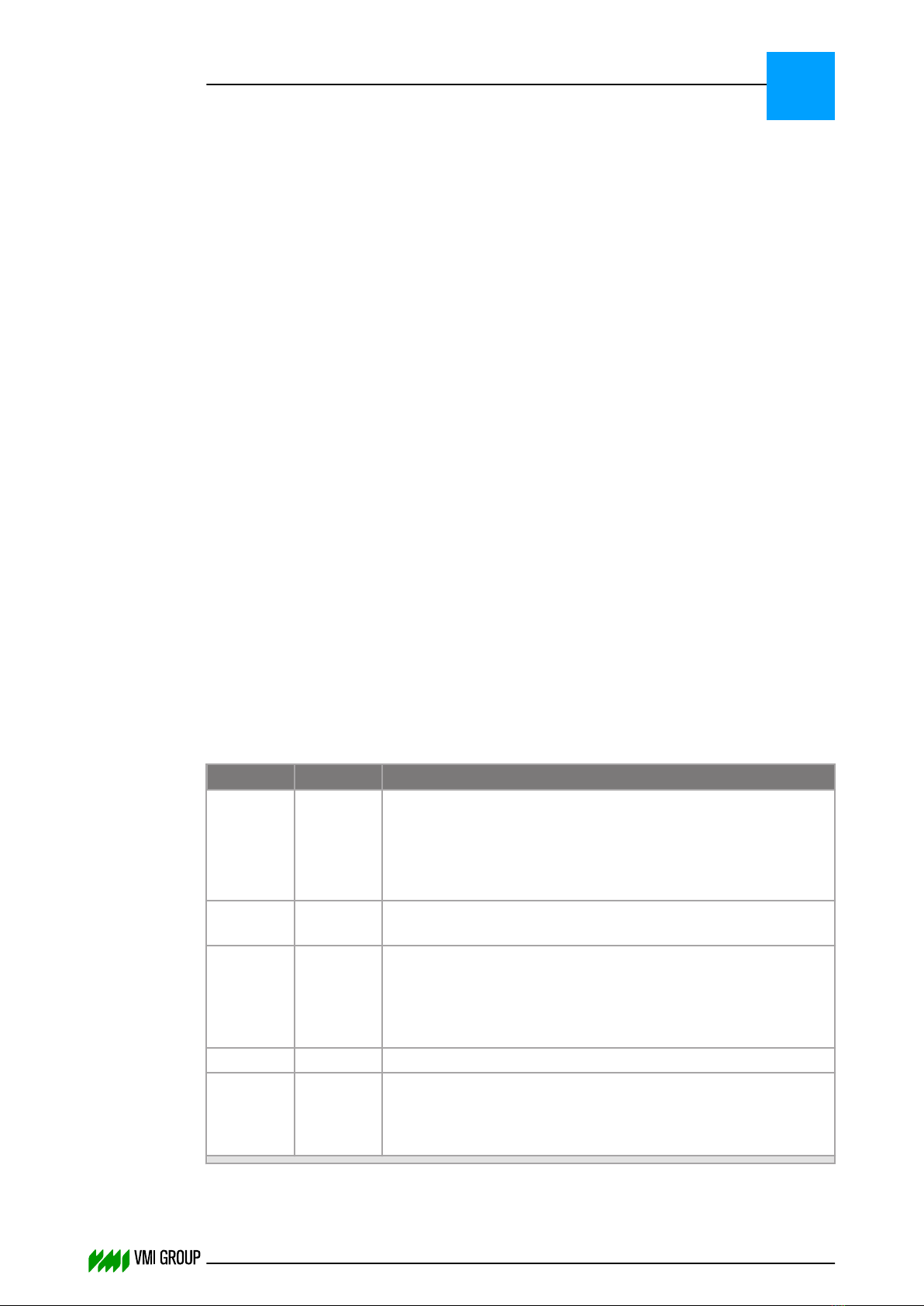

Date Revision Remarks

2016-07 4 New camera types OL8221 and OL8251 with display.

Minor editorial changes in the following sections:

●System architecture on page 4

‑

4

●Camera types on page 4

‑

8

2016-06 3 Fixed the description for the 'Encoder inhibit time' in VVS Config

file definitions on page 3

‑

11.

2016-02 2 ● Added Windows Embedded Standard 7 VVS IPC

functionality.

● Minor editorial changes

● VVSX 13.0.12.0

2015-11 1 Alignment, adjustment, and calibration moved to chapter 5.

2015-06 0 Initial version for the VMI IPC platform.

● VVSX 13.0.0.10

● VVSU 3.0.6

PREFACE

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 ii

Contents

1 About this manual ............................................................................... 1-1

1.1 General ................................................................................... 1-3

1.2 Audience ................................................................................ 1-4

1.3 Abbreviations .......................................................................... 1-5

2 Safety .................................................................................................... 2-1

2.1 General ................................................................................... 2-3

3 Installation and configuration ............................................................ 3-1

3.1 Installation .............................................................................. 3-3

3.1.1 General ................................................................... 3-3

3.1.2 Install VVSU on a maintenance PC ........................ 3-3

3.2 Configuration .......................................................................... 3-5

3.2.1 General ................................................................... 3-5

3.2.2 Configure the Kepware OPC Server ....................... 3-5

3.2.3 Configure the OPC wrapper file .............................. 3-6

3.2.3.1 OPC wrapper file definitions .............................. 3-6

3.2.3.2 OPC wrapper address definition ........................ 3-8

3.2.3.3 Breaker measurement options ........................... 3-8

3.2.3.4 Carcass measurement options .......................... 3-10

3.2.3.5 Tread measurement options .............................. 3-10

3.2.4 Configure the VVSConfig.ini file .............................. 3-10

3.2.5 VVS Config file definitions ....................................... 3-11

3.2.6 Configure the CAN network .................................... 3-15

3.2.6.1 Addresses of all devices in the CAN network .... 3-15

3.2.6.2 How to set the address of actuator RK4004 ...... 3-16

3.2.6.3 How to set the address of Beckhoff BK5120 ..... 3-18

3.2.6.4 How to set the address of the camera ............... 3-18

3.2.6.5 How to set the virtual address of the camera ..... 3-19

3.2.6.6 Configure the number of cameras on the CAN

bus .....................................................................

3-19

4 Functional description ........................................................................ 4-1

4.1 General ................................................................................... 4-3

4.2 System architecture ................................................................ 4-4

4.2.1 General ................................................................... 4-4

4.2.2 Modular system ....................................................... 4-4

4.2.3 MAXX / EXXIUM ..................................................... 4-5

4.2.4 VAST / MILEXX ....................................................... 4-6

4.3 VVS Software ......................................................................... 4-7

4.4 Camera types ......................................................................... 4-8

5 Alignments, adjustments and calibrations ....................................... 5-1

5.1 Tooling .................................................................................... 5-3

5.2 Connect to VVS ...................................................................... 5-4

5.3 VVS Breaker ........................................................................... 5-5

5.3.1 Align the camera and light source ........................... 5-5

5.3.2 Adjust and focus the camera ................................... 5-7

5.3.3 Calibrate the camera ............................................... 5-14

5.3.4 Calibrate the actuator .............................................. 5-17

5.3.5 Calibrate the encoder .............................................. 5-23

5.4 VVS Tread .............................................................................. 5-25

CONTENTS

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 iii

5.4.1 Align the camera ..................................................... 5-25

5.4.2 Adjust and focus the camera ................................... 5-26

5.4.3 Calibrate the camera ............................................... 5-30

5.5 VVS Carcass .......................................................................... 5-33

6 Parameters ........................................................................................... 6-1

6.1 General ................................................................................... 6-3

6.2 Parameter buffer .................................................................... 6-4

6.2.1 Material parameters for Breaker ............................. 6-4

6.2.1.1 Offsets ................................................................ 6-5

6.2.1.2 Tip correction ..................................................... 6-5

6.2.1.3 Breaker dimensions ........................................... 6-6

6.2.1.4 Split breaker ....................................................... 6-6

6.2.1.5 90° Breaker ........................................................ 6-6

6.2.1.6 Algorithm and splice correction .......................... 6-7

6.2.1.7 Material scan example ....................................... 6-8

6.2.1.8 Splice correction ................................................ 6-9

6.2.2 Material parameters for Carcass ............................. 6-10

6.2.2.1 Offset ................................................................. 6-11

6.2.2.2 Width and width tolerances ................................ 6-11

6.2.2.3 Tilt tolerances ..................................................... 6-12

6.2.2.4 Material angle .................................................... 6-12

6.2.3 Material parameters for Tread ................................. 6-12

6.2.3.1 Offset ................................................................. 6-13

6.2.3.2 Width and width tolerances ................................ 6-13

6.2.3.3 Calibration length ............................................... 6-13

6.3 Command buffer ..................................................................... 6-14

6.3.1 Command parameters ............................................ 6-14

6.4 Status buffer ........................................................................... 6-16

6.4.1 Feedback signals (word 0) ...................................... 6-16

6.4.2 Sensor errors (word 1) ............................................ 6-18

6.4.3 Functional description (word 2) ............................... 6-19

6.4.4 Actual position measurements (word 3-9) ............... 6-20

6.4.5 Extended status bits (word 10-11) .......................... 6-21

6.4.6 Extended status words (word 12-31) ...................... 6-21

6.5 System parameters ................................................................ 6-22

6.5.1 Default breaker system parameters. ....................... 6-22

6.5.2 Default carcass system parameters ........................ 6-23

6.5.3 Default tread system parameters ............................ 6-24

6.5.3.1 How to measure the mechanical gain for a

tread server ........................................................

6-24

6.5.3.2 How to measure the camera to end conveyor

distance ..............................................................

6-25

6.6 Actuator parameters ............................................................... 6-26

6.7 Sensor parameters ................................................................. 6-27

6.8 Communication scenarios ...................................................... 6-29

6.8.1 POWER UP sequence ............................................ 6-29

6.8.2 HOME command sequence .................................... 6-29

6.8.3 CENTERING command sequence .......................... 6-30

6.8.4 TREAD CENTERING command sequence ............ 6-31

6.8.4.1 Tread read profile command sequence ............. 6-31

6.8.4.2 Tread centering command sequence ................ 6-32

6.8.5 EMERGENCY STOP recovery sequence ............... 6-32

6.8.6 HEARTBEAT sequence .......................................... 6-33

CONTENTS

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 iv

7 VVSU Operation ................................................................................... 7-1

7.1 General ................................................................................... 7-3

7.2 Start VVSU ............................................................................. 7-4

7.3 Screen layout (generic) .......................................................... 7-5

7.3.1 Main screen layout .................................................. 7-5

7.3.2 Menu bar ................................................................. 7-5

7.3.3 Interface Status ....................................................... 7-9

7.3.4 Screen Selection ..................................................... 7-10

7.3.4.1 Status screen ..................................................... 7-11

7.3.4.2 Calibration screen (for advanced users only) .... 7-13

7.3.4.3 System screen (for advanced users only) .......... 7-15

7.3.4.4 Material screen (for advanced users only) ......... 7-16

7.3.4.5 Actuator screen (only for advanced users) ........ 7-17

7.3.4.6 Display sensor screen ........................................ 7-18

7.3.4.7 Material scan screen .......................................... 7-19

7.3.4.8 Sensor screen (for advanced users only) .......... 7-22

7.3.4.9 History scan data screen ................................... 7-23

8 Troubleshooting .................................................................................. 8-1

8.1 Communication ...................................................................... 8-3

8.1.1 VVSU is not able to detect the VVSX server .......... 8-3

8.1.1.1 Setting the priority of the network card .............. 8-4

8.1.2 VVSU shows an error while attempting to connect

to the VVSX server ..................................................

8-4

8.2 Device detection at startup ..................................................... 8-11

8.2.1 Actuator version retrieval error ................................ 8-11

8.2.2 Camera Version retrieval error ................................ 8-12

8.2.3 Encoder detection error ........................................... 8-12

8.3 CAN-bus problems ................................................................. 8-14

8.3.1 Too many CAN timeout messages shown in the

VVSX window ..........................................................

8-14

8.4 Breaker centering problems ................................................... 8-16

8.4.1 Breaker centering switches too late to TE center

mode .......................................................................

8-16

8.4.2 Breaker centering switches too early to body

center mode ............................................................

8-17

8.4.3 Only half of the breaker is seen in the material

scan .........................................................................

8-18

8.4.4 Sometimes side guiding is applied when splice

guiding is selected ...................................................

8-19

8.4.5 Interfering ambient light ........................................... 8-19

8.5 Guiding problems ................................................................... 8-20

8.5.1 VVS is not guiding the Breaker material ................. 8-20

8.5.2 Splice guiding is not working ................................... 8-22

8.5.3 Homing problem (RK4004) ..................................... 8-23

8.5.4 Actuator RK4004 is not guiding breaker material ... 8-23

8.5.5 Correction overshoot ............................................... 8-24

8.5.6 Camera samples are delayed due to overexposure

of the camera ..........................................................

8-24

8.6 Calculation problems .............................................................. 8-26

8.6.1 VVS LE set point is calculated on the wrong side of

the material .............................................................

8-26

8.6.2 Holes in the body-ply are detected by the camera .. 8-27

8.6.3 Deviation between measured and actual bodyply

width (only for 24x) ..................................................

8-28

CONTENTS

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 v

8.7 Mechanical problems ............................................................. 8-30

8.7.1 Sudden conveyor movement in one direction ......... 8-30

8.8 Calibration problems .............................................................. 8-31

8.8.1 The camera does not have the right set of

parameters ..............................................................

8-31

8.8.2 Region Of Interest (ROI) problems ......................... 8-31

8.8.3 Tread width measurement problem ........................ 8-31

8.8.4 Actuator errors ........................................................ 8-31

8.9 Upgrade camera firmware ...................................................... 8-33

8.9.1 Check the current camera firmware version ........... 8-33

8.9.2 Upgrade the camera firmware ................................. 8-34

Index ..................................................................................................... 1

CONTENTS

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 vi

1

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 1-2

This page has been left blank intentionally.

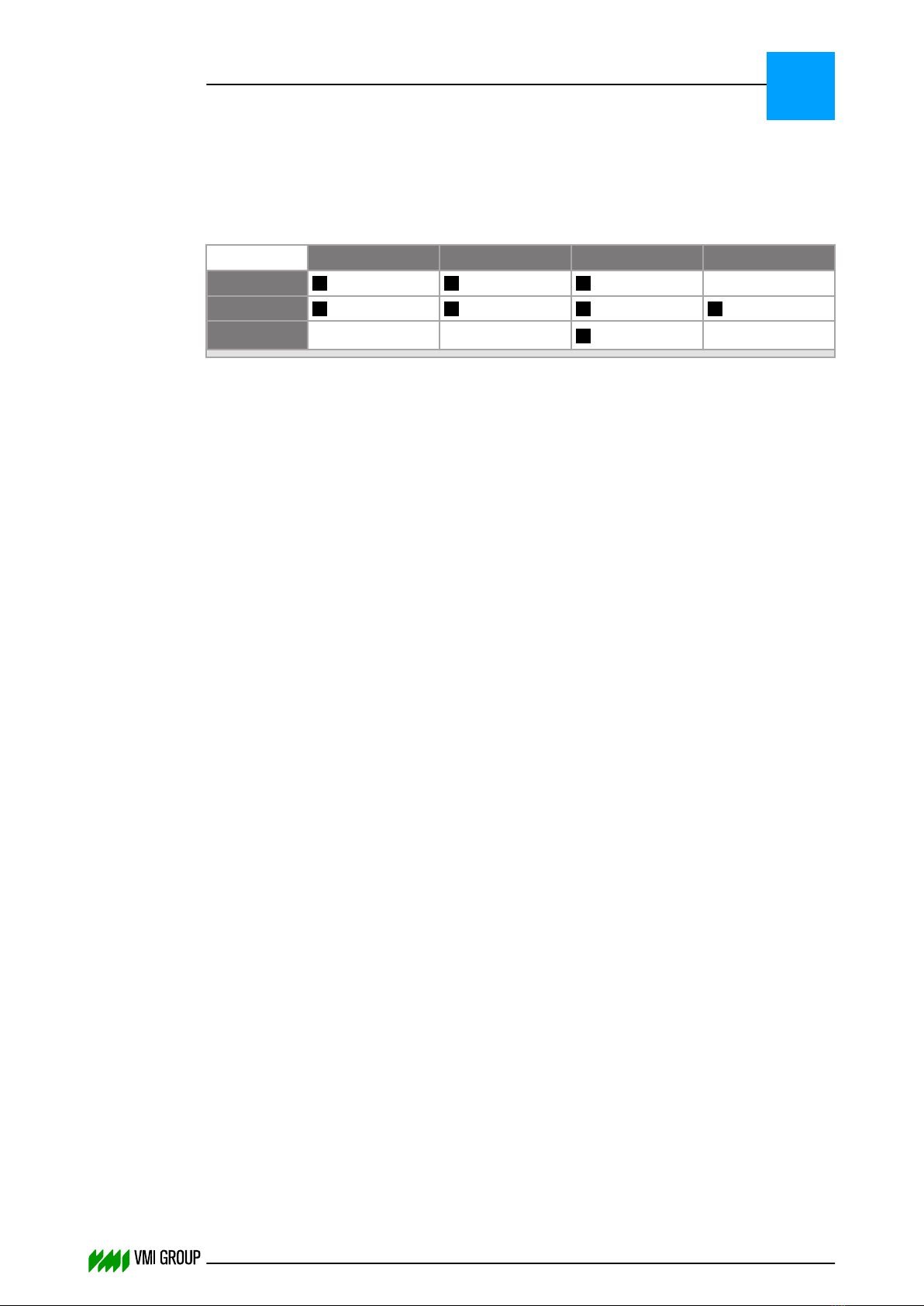

1.1 General

This is a specialist manual for the VMI Vision System (VVS) and it applies to VVS installed

on the standard VMI IPC plaform.

VVS is installed on the following VMI machines:

MAXX EXXIUM 24X VAST / MILEXX

Tread –

Breaker

Carcass –1– –

Notes:

1. MAXX tire building machines use a VMI3D application with Matrix Vision BlueLYNX

cameras (VVSC).

ABOUT THIS MANUAL

General 1

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 1-3

1.2 Audience

This manual is made to help VMI Vision System (VVS) specialist personnel that are

responsible for the following:

● Configuration

● Maintenance

● Alignments, adjustments and calibrations

Operator information for VVS is described in the technical manual of the installation.

ABOUT THIS MANUAL

Audience 1

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 1-4

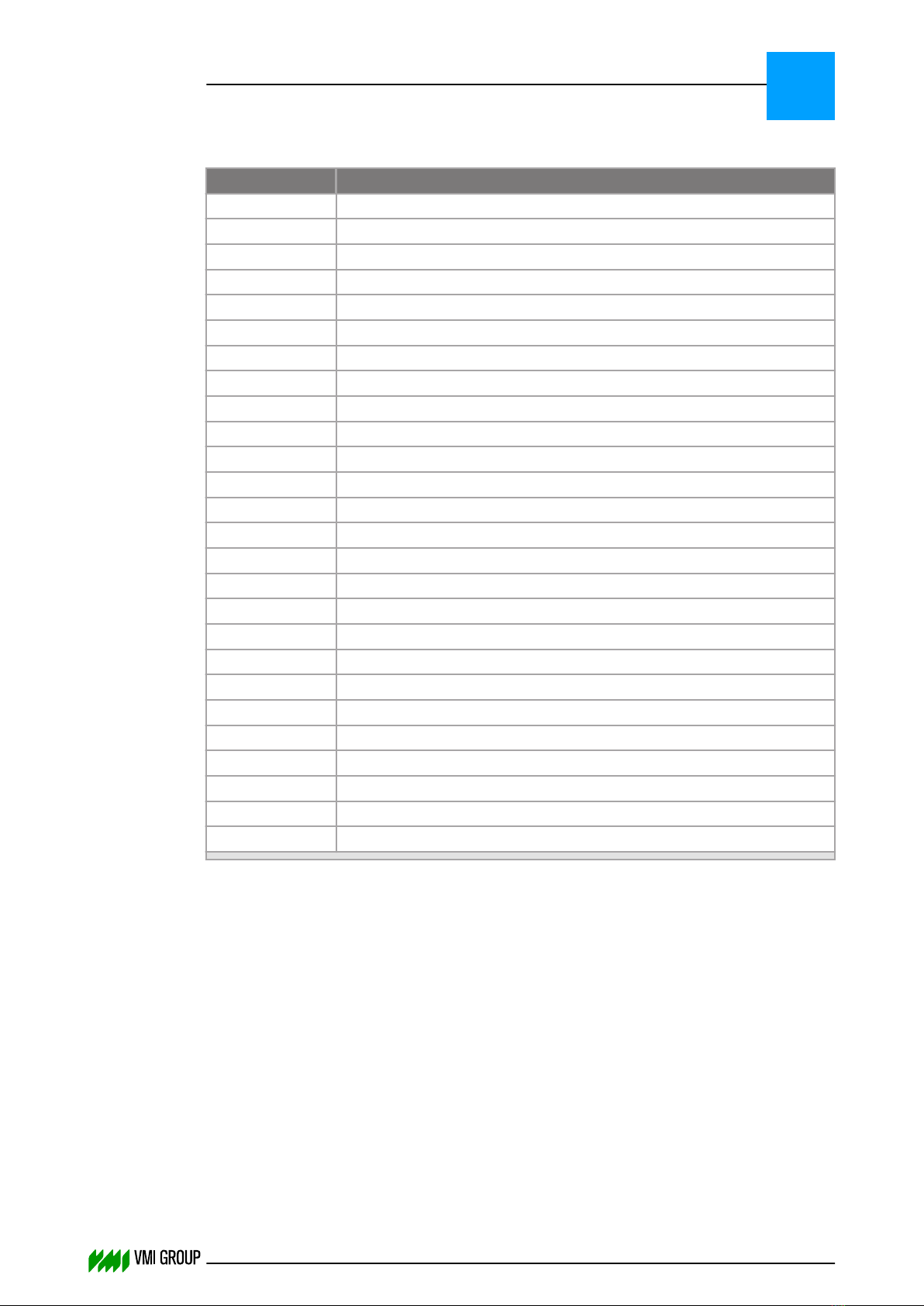

1.3 Abbreviations

Abbreviation Description

BP Body-ply

BR Breaker

CC Carcass

CAN Controller Area Network

CLX ControlLogix

HMI Human Machine Interface

IL Innerliner

IPC Industrial PC

LE Leading End

LED Light‑Emitting Diode

OPC OLE (Object Linking and Embedding) for Process Control

PA Pre-assembly

PLC Programmable Logic Controller

SPC Statistical Process Control

TBM Tire building machine

TCL Tip Correction Length

TC-LE Tip Correction - Leading End

TC-TE Tip Correction - Trailing End

TD Tread

TE Trailing End

VAST VMI All Steel Truck tire building machine

VMI Veluwse Machine Industrie

VVS VMI Vision System

VVSC VMI Vision System Carcass

VVSU VVS User interface software

VVSX VVS Controller software

ABOUT THIS MANUAL

Abbreviations 1

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 1-5

ABOUT THIS MANUAL

Abbreviations 1

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 1-6

This page has been left blank intentionally.

2

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 2-2

This page has been left blank intentionally.

2.1 General

Refer to the machine manual for machine specific safety instructions.

SAFETY

General 2

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 2-3

SAFETY

General 2

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 2-4

This page has been left blank intentionally.

3

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592 3-2

This page has been left blank intentionally.

Table of contents