VMI Viber X2 User manual

Vibraon Measurement Instruments

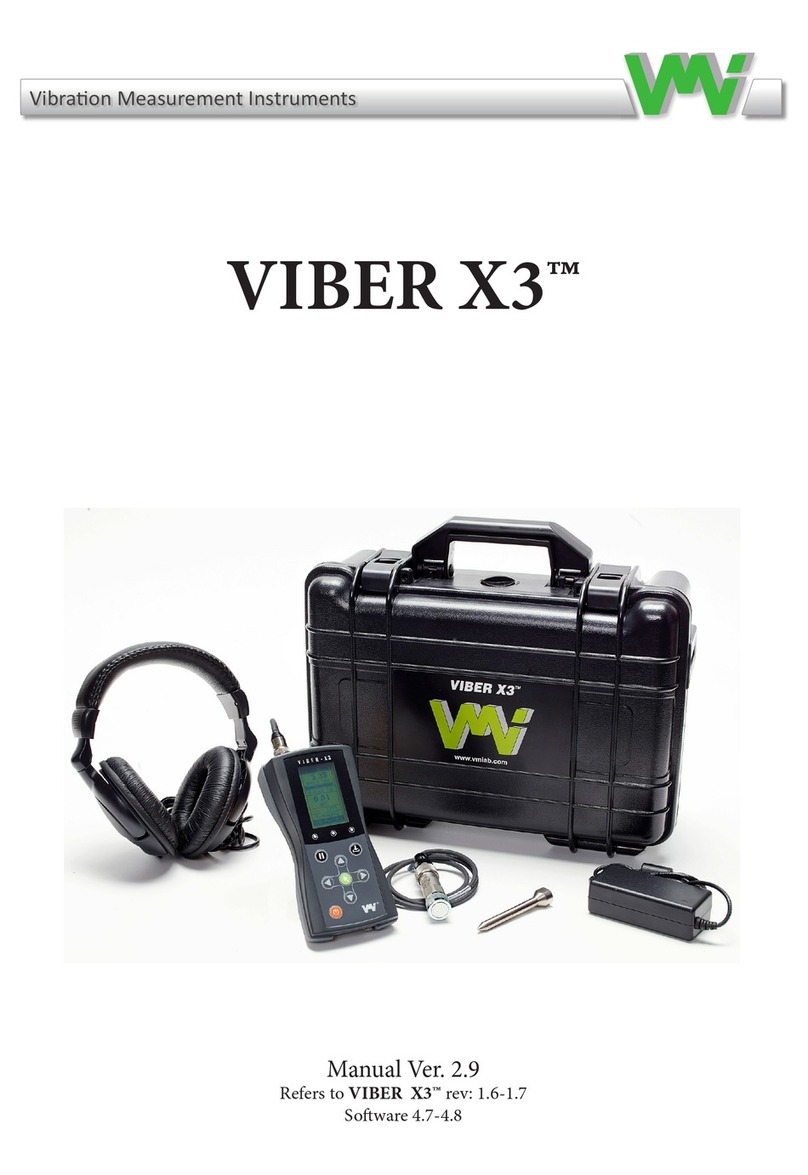

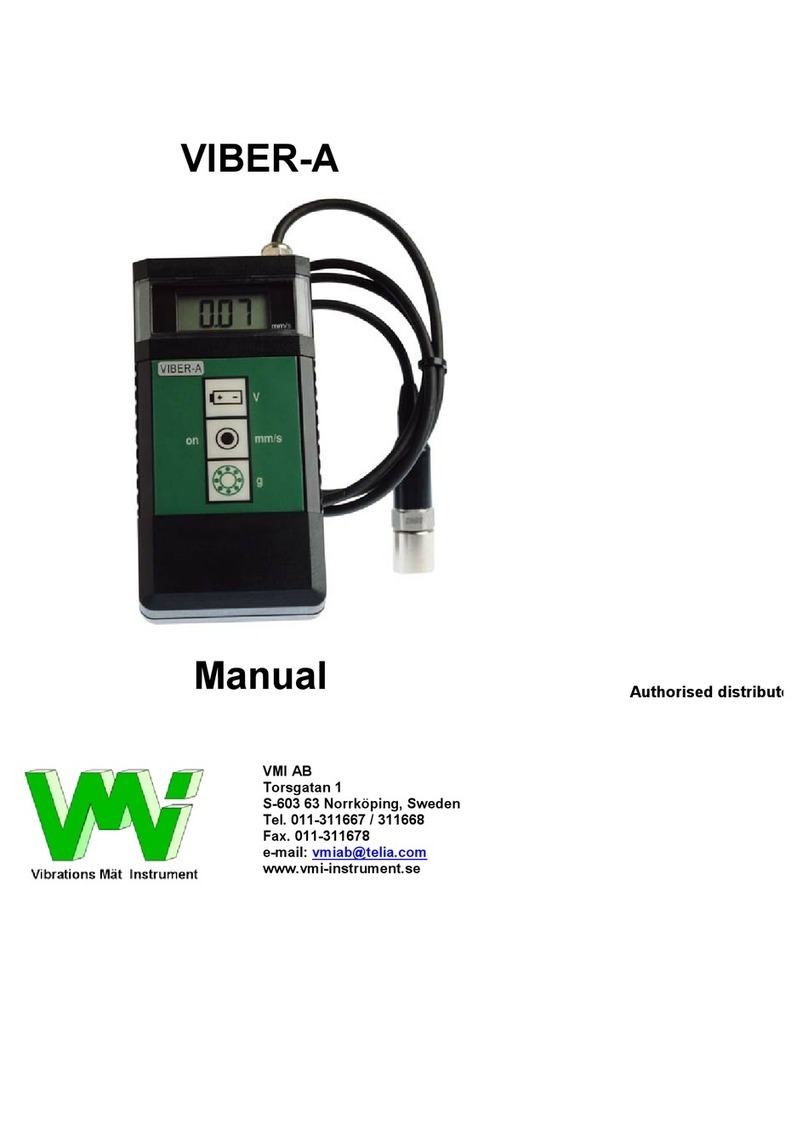

VIBER X1™ Manual

Manual Viber X1_121002.indd 1 10/3/12 9:26 AM

NYA LOGGAN!

VIBER X2™

Manual

VIBER X2™

Manual

Ver. 2.5

Refers to VIBER X2™ rev: 1.7

Software 5.0

1

Vibraon Measurement Instruments

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Manual Viber X1_121002.indd 2 10/3/12 9:26 AM

VIBER X1™VIBER X2™VIBER X3™

VIBER X5™

Our x-series of hand-held instrument

Vibration measurements in progress

Index

1 Important information 4

2 Introduction 5

2.1 Scope of supply 6

2.2 Instrument keypad and LED’s 6

2.2.1 ON/OFF and Menu Key 7

2.2.2 Arrow keys 7

3 Vibration measurement screen 7, 8, 9

4 Warning messages 10, 11

5 Battery status bar 11

5.1 Changing Battery 11

6 How to interpret vibration levels 11, 12

6.1 ISO standard 10816-3 10 12, 13

7 Vibration analysis 14

7.1 Recommended vibration levels in 14, 15

mm/sandcommonndings

7.2 Recommended bearing 16, 17

condition levels

8 Technical data 18, 19

Vibraon Measurement Instruments

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating machines.

Keep a safe distance to rotating parts and secure transducers and transducer cables

from rotating parts. Always follow internal, local and national security

regulations! When working with weights on the rotor always secure the start

switch with a locker and also use the emergency switch for double safety. This is

especially important when the machine is remote controlled.

VMI International AB takes no responsibility for any accidents on people and

machines.

VMI International AB and our authorized dealers will take no

responsibility for damages on machines and plants as the result

of the use of VIBER X1™ measurements.

Even though great efforts are made to make the information in

this manual free from errors and to make the information

complete for the user, there could be items we have missed,

because of the large amount of information. As a result of this,

we might change and correct these items in later issues without

further notice. Also changes in the VIBER X1™ equipment may

take place that affect the accuracy of the information.

Manual Viber X1_121002.indd 3 10/3/12 9:26 AM

4

1 Important information

Safety precautions

Vibration measurement and balancing involves collecting

measurement on rotating machines. Keep a safe distance

away from rotating parts. Secure transducers and transdu-

cer cables from rotating parts. Always follow company,

local and national security regulations! When working

with weights on the rotor, always follow “lock out tag out”

procedures. Secure the start switch with a lock and also use

the emergency switch for double safety. This is especially

important when the machine is remote controlled.

VMI takes no responsibility for any accidents on people

and machines.

VMI and our authorized distributors take no responsibility

for damages on machines or plants as the result of the use

of VIBER X2TM measurements.

Even though great efforts are made to make the information

in this manual free from errors and to make the information

complete for the user, there could be items we have missed,

because of the large amount of information. As a result of

this, we might change and correct these items in later issues

without further notice. Also changes in the VIBER X2TM

equipment may take place that affect the accuracy of this

information.

Vibraon Measurement Instruments

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Manual Viber X1_121002.indd 2 10/3/12 9:26 AM

5

2 Introduction

VIBER X2™ is designed for technicians, mechanics, and

machine operators that need a reliable, fast, and easy to

use tool for basic condition monitoring checks in rough

conditions. The VIBER X2™ instrument has the following

features:

- Accurate measurements in 4 selectable frequency ranges.

- Real-time measurement of the total vibration level and

the Bearing Condition (BC), shown simultaneously.

- Measurement units and display are user selectable from the

following list:

•g-value=(RMS,PeakorPeak-Peak)

•a=m/s(RMS,PeakorPeak-Peak)

•V=mm/sec(RMS,PeakorPeak-Peak)

•V=inch/sec(RMS,PeakorPeak-Peak)

•D=mils(RMS,PeakorPeak-Peak)

•D=μm(RMS,PeakorPeak-Peak)

- Bearing Condition measurements in the frequency range

(0.5 -16 kHz).

- Bar indicator shows measurement stability.

- Fastandeasyfaultanalysisdisplayingthevehighestpeaks

frequecy in RPM or Hz in main screen display.

- Large dynamic range of the vibration signal (up to 50g).

- Low power consumption.

- High performance accelerometer.

- Easy to understand and operate.

- Advanced technology with DSP processor.

- Several languages are available.

- Adjustable Auto-shut off for energy saving.

- Dust and waterproof, for rough use (IP 65).

Vibraon Measurement Instruments

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating machines.

Keep a safe distance to rotating parts and secure transducers and transducer cables

from rotating parts. Always follow internal, local and national security

regulations! When working with weights on the rotor always secure the start

switch with a locker and also use the emergency switch for double safety. This is

especially important when the machine is remote controlled.

VMI International AB takes no responsibility for any accidents on people and

machines.

VMI International AB and our authorized dealers will take no

responsibility for damages on machines and plants as the result

of the use of VIBER X1™ measurements.

Even though great efforts are made to make the information in

this manual free from errors and to make the information

complete for the user, there could be items we have missed,

because of the large amount of information. As a result of this,

we might change and correct these items in later issues without

further notice. Also changes in the VIBER X1™ equipment may

take place that affect the accuracy of the information.

Manual Viber X1_121002.indd 3 10/3/12 9:26 AM

6

2.1 Scope of supply

A complete delivery is:

¥VIBER X2™, machine condition analyzer

¥Embedded Lithium batteries

¥One high performance accelerometer

¥1 m transducer cable

¥Carrying case

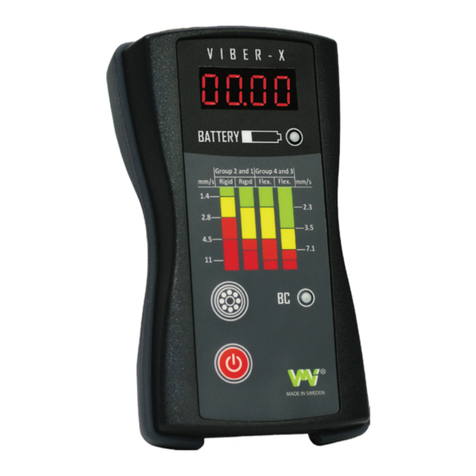

2.2 Instrument keypad and LED’s

The VIBER X2™keypad has:

¥1 ON/OFF key

¥1 Menu key

¥4 arrow keys

¥3 LEDs*

*Green LED lights, when any key is pressed.

*Yellow LED lights, when the measurement is above

the set warning level.

*Red LED lights, when the measurement is above

the set danger level.

2.2.1 ON/OFF and Menu Key

Press the ON/OFF key to start or stop the instrument.

If the setting Auto-shut off is ENABLED, the instrument will automatically shut off after

60 seconds if no key is pressed. Five seconds before the auto-stop, a warning window

will appear on the screen. The user has 5 seconds to press any key, to avoid the shut

off.

The Menu key activates the settings menu from any measurement screen. To return to

measurement press the Menu key once more.

2.2.2 Arrow keys

In the Setting Menu, the LEFT and RIGHT arrows are used to change the value of the

selected item.

The UP and DOWN arrows are used in accordance with the active screen. For details,

see Chapter 3 (Screens description).

2.1 Scope of supply

A complete delivery is:

• VIBERX2™,machineconditionanalyzer

• EmbeddedLithiumBattery

• Accelerometer

• 1mtransducercable

• ACadapter

• Carryingcase

2.2 Instrument keypad and LED’s

The VIBER X2™ keypad has:

• 1ON/OFFkey

• 1Greenmenukey

• 4Arrowkeys

• 3LEDlights*

*Green LED lights, when any key is pressed.

*Yellow LED lights, when the measurement is above

the set warning level.

*Red LED lights, when the measurement is above

the set danger level.

2.1 Scope of supply

A complete delivery is:

¥VIBER X2™, machine condition analyzer

¥Embedded Lithium batteries

¥One high performance accelerometer

¥1 m transducer cable

¥Carrying case

2.2 Instrument keypad and LED’s

The VIBER X2™keypad has:

¥1 ON/OFF key

¥1 Menu key

¥4 arrow keys

¥3 LEDs*

*Green LED lights, when any key is pressed.

*Yellow LED lights, when the measurement is above

the set warning level.

*Red LED lights, when the measurement is above

the set danger level.

2.2.1 ON/OFF and Menu Key

Press the ON/OFF key to start or stop the instrument.

If the setting Auto-shut off is ENABLED, the instrument will automatically shut off after

60 seconds if no key is pressed. Five seconds before the auto-stop, a warning window

will appear on the screen. The user has 5 seconds to press any key, to avoid the shut

off.

The Menu key activates the settings menu from any measurement screen. To return to

measurement press the Menu key once more.

2.2.2 Arrow keys

In the Setting Menu, the LEFT and RIGHT arrows are used to change the value of the

selected item.

The UP and DOWN arrows are used in accordance with the active screen. For details,

see Chapter 3 (Screens description).

Vibraon Measurement Instruments

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Manual Viber X1_121002.indd 2 10/3/12 9:26 AM

7

2.2.1 ON/OFF and Menu Key

Press the ON/OFF key to start or stop the instrument.

If the setting Auto-shut off is ENABLED, the instrument

will automatically shut off after 60 seconds if no key is

pressed. Five seconds before the auto-stop, a warning

window will appear on the screen. The user has 5 seconds

to press any key, to avoid the shut off.

The Menu key activates the settings menu from any

measurement screen. To return to measurement press the

Menu key when the BACK function is selected.

2.2.2 Arrow keys

TheLEFTandRIGHTarrowsareusedtochangethevalue

of the selected item. The UP and DOWN arrows are used

to make choice available on the screen like enable, disable,

units, alarms frequence etc.

3 Vibration measurement screen

Initial screen, shown when starting the instrument.

Vibraon Measurement Instruments

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating machines.

Keep a safe distance to rotating parts and secure transducers and transducer cables

from rotating parts. Always follow internal, local and national security

regulations! When working with weights on the rotor always secure the start

switch with a locker and also use the emergency switch for double safety. This is

especially important when the machine is remote controlled.

VMI International AB takes no responsibility for any accidents on people and

machines.

VMI International AB and our authorized dealers will take no

responsibility for damages on machines and plants as the result

of the use of VIBER X1™ measurements.

Even though great efforts are made to make the information in

this manual free from errors and to make the information

complete for the user, there could be items we have missed,

because of the large amount of information. As a result of this,

we might change and correct these items in later issues without

further notice. Also changes in the VIBER X1™ equipment may

take place that affect the accuracy of the information.

Manual Viber X1_121002.indd 3 10/3/12 9:26 AM

Indicates the battery status

Total Value

Unit

Frequence of the highest peak

Stability bar

Frequency range

Measurements status

Alarm levels

12,6

0,21

2180

6-1600 Hz

RPM

Bearing condition

8

Vibration measurement status can be one of following:

- Measuring (Vibration measuring is ongoing)

- Ranging (The instrument is calculating the best

measurement level range)

- Averaging (Averaging of the measured data)

- Stable (The measurement is stablized)

- Overow (The signal is too high – the measurement is

incorrect/not readable.)

In case of amplitude out of range, the value is shown as 3

stars(***).

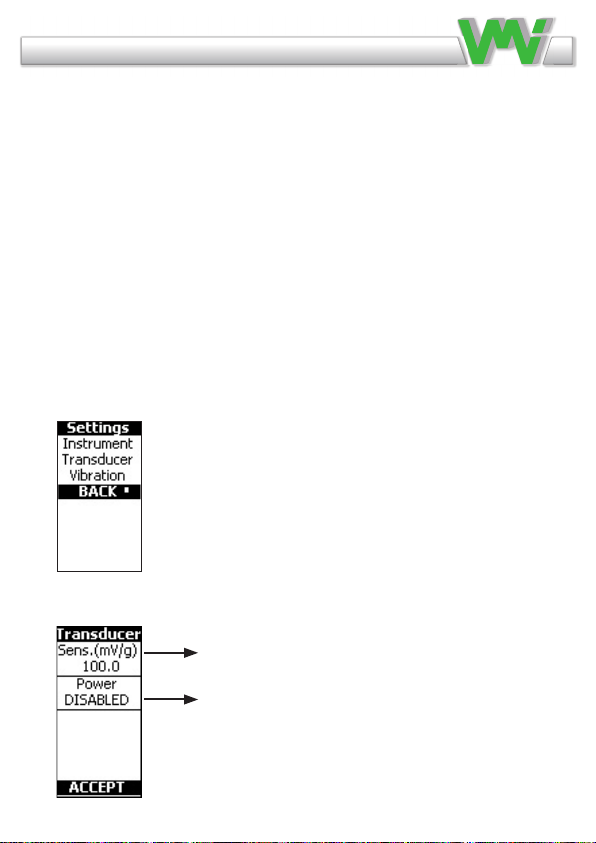

When the Menu key is pressed, the Settings menu is

displayed. Note that all accept/back are made with the green

menu key. The following settings are available:

Vibraon Measurement Instruments

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Manual Viber X1_121002.indd 2 10/3/12 9:26 AM

Select an item in the menu with the UP and

DOWN arrow keys. Open the selected item

with the green menu key.

Set actual sensors sensitivity

Disable power if sensor is external

powered

If transuducer setting is choosen, the following menu is displayed:

9

*Note:CanonlybeusedforvelocityunitRMS

Change the settings of the selected item with the LEFT and

RIGHTarrowkeys.

Vibraon Measurement Instruments

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Manual Viber X1_121002.indd 2 10/3/12 9:26 AM

Enable or disable

Enable or disable

20, 30, 40 sek / 1, 2 or 3 minutes

Choose language by pressing Arrow key

If vibration setting is choosen, the following menu is

displayed.

*Availablelanguagesare:English,Swedish,French,German,Romanian,

Spanish, Portuguese, Czech, and Finnish. For another language please con-

tact VMI’s disributors for availability.

If instrument setting is choosen, the following menu is displayed

g (RMS, Peak or P-P)

mm/s (RMS, Peak or P-P)

m/s2(RMS, Peak or P-P)

µm (RMS, Peak or P-P)

inch/sec (RMS, Peak or P-P)

mils(RMS, Peak or P-P)

Frequency range Hz Frequency range, where the

highest peak is displayed

2 - 400 Hz 2 - 400 Hz

6 - 1600 Hz 6 - 1600 Hz

11 - 3200 Hz 11 - 2000 Hz

10 - 1000 Hz 10 - 1000 Hz

Change of unit (see below)

Choose Hz or RPM

Enable*ordisablealarms

Alarm*settings

Alarm*settings

Change of frequency range (see below)

10

4 Warning messages

The following message may appear in normal operation:

This message may appear if the calibration

data is lost from the permanent FRAM

memory or if the calibration data are

corrupted. In such cases, the instrument must be recalibrated;

otherwise it will measure incorrectly. The message appears

only once, and then default calibration data is used.

When this message appears, the battery

voltage is too low to ensure a correct

running condition. The measurements may be

invalid! The instrument battery must be charged immediately,

using the external charger. To temporarily decrease the power

consumption, the backlight automatically will be switched

OFF. The instrument can still work, but only for a short while.

This message appears only if the Auto shut

off setting is enabled. The user may cancel

the shut off condition, pressing any key

except ON/OFF. If no key is pressed the instrument will shut

off in 5 seconds.

This message appears only if the Transducer

power setting is enabled and indicates that

the transducer is missing or is out of order.

When the Transducer power setting is disabled, the user has

the possibility to use another external source for the vibration

input (a signal generator or a buffered output from another

device).

Calibration

Battery

too low

Shut-off

in 5 sec

Missing

transducer

Vibraon Measurement Instruments

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Manual Viber X1_121002.indd 2 10/3/12 9:26 AM

11

When the instrument starts, the Transducer power setting

is always ENABLED. When this message appears, it will

remain on the screen, even if the transducer is plugged-in. To

continue the normal running mode in such a condition, switch

the screen temporarily to another menu. When you switch

back, the message disappears.

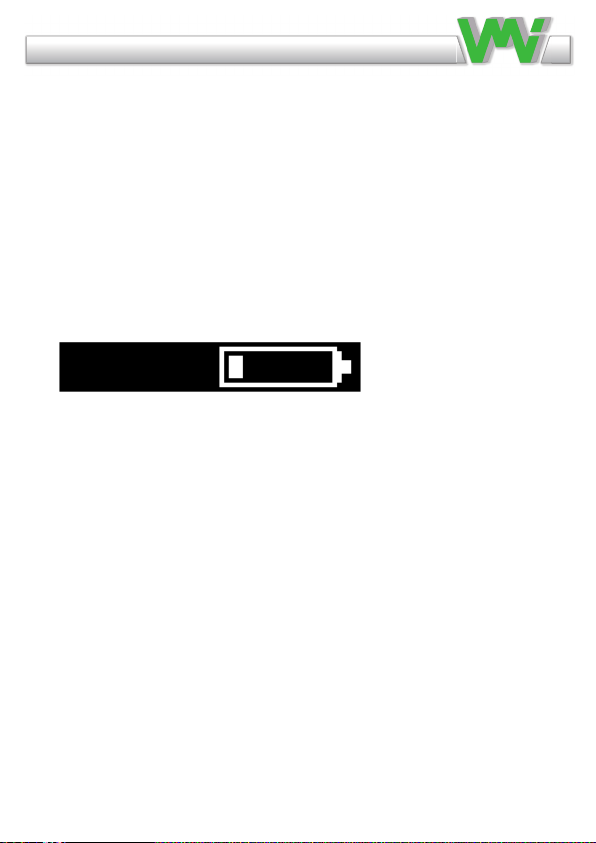

5 Battery status bar

In every measurement screen, at the upper side, a battery

status bar is shown.

The status bar indicates the battery voltage/energy content.

When the battery is charged, a connector symbol is

displayed. If voltage drops to less than 3.3 Volt, the

instrument will shut off.

5.1 Changing Battery

The unit has an embedded Lithium battery and we

recommend that a VMI reseller or service center makes

the replacement.

6 How to interpret vibration levels

User with no previous experience, we recommend to use the

ISO 10816-3 standard.

The standard normally calls for a velocity measurement in

mm/s RMS. To better understand what this measurement

means, think of it as how fast the machine is moving back and

forth. This measure gives a good understanding of the amount

of “break down energy”, causing mainly wear and fatigue in

This message appears only if the Auto-shut off setting is enabled.

The user may cancel the shut-off condition, pressing any key

except ON/OFF. If no key is pressed the instrument will shut off in 5

seconds.

This message appears only if the Transducer power setting is

enabled and

indicates that the transducer is missing or is out of order.

When the Transducer power setting is disabled, the user has the possibility to use

another external source for the vibration input (a signal generator or a buffered output

from another device).

When the instrument starts, the Transducer power setting is always ENABLED.

When this message appears, it will remain on the screen, even if the transducer is

plugged-in. To continue the normal running mode in such a condition, switch the screen

temporarily to another menu. When you switch back, the message disappears.

5 Battery status bar

In every measurement screen, at the upper side, a battery status bar is shown.

The status bar indicatesthe battery voltage/energy content.

When the battery is charged a connector symbol is

displayed. If voltage drops to less than 3.3 Volt, the instrument will shut-off.

3.1 Changing Battery

The unit has an embedded Lithium battery and we recommend that a VMI reseller or

service centre make the change.

4 How to interpret vibration levels

User with no previous experience, should use the ISO 10816-3 standard.

The standard normally calls for a velocity measurement in mm/s RMS. To better

understand what this measurement means, think of it as how fast the machine is

moving back and forth. This measure gives a good understanding of the amount of

“break down energy”, causing mainly wear and fatigue in the machine or the structure.

The instrument measures the total RMS vibration value in the frequency range. This

RMS value is the average sum of all the measured vibrations.

EXAMPLE:

If the simultaneous vibration caused by unbalance is (4mm/s), by misalignment (2

mm/s) and by the gear mesh (5 mm/s), then the total vibration measured on the

VIBER-X2 is 6.7 mm/s.

Shut-off

i n 5 sec

Mi ssi ng

tr ansduce

r

Vibraon Measurement Instruments

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating machines.

Keep a safe distance to rotating parts and secure transducers and transducer cables

from rotating parts. Always follow internal, local and national security

regulations! When working with weights on the rotor always secure the start

switch with a locker and also use the emergency switch for double safety. This is

especially important when the machine is remote controlled.

VMI International AB takes no responsibility for any accidents on people and

machines.

VMI International AB and our authorized dealers will take no

responsibility for damages on machines and plants as the result

of the use of VIBER X1™ measurements.

Even though great efforts are made to make the information in

this manual free from errors and to make the information

complete for the user, there could be items we have missed,

because of the large amount of information. As a result of this,

we might change and correct these items in later issues without

further notice. Also changes in the VIBER X1™ equipment may

take place that affect the accuracy of the information.

Manual Viber X1_121002.indd 3 10/3/12 9:26 AM

12

the machine or the structure.

The instrument measures the total RMS vibration value in the

frequency range. This RMS value is the average sum of all

the measured vibrations. In the actual frequence range.

CALCULATION:

If the simultaneous vibration caused by unbalance is (4mm/s),

by misalignment (2 mm/s) and by the gear mesh (5 mm/s),

then the total vibration measured on the VIBER X2 is 6.7

mm/s.

6.1 ISO standard 10816-3

TheISOstandardclassiesthemachinesdifferentlyifthe

machinesareexibleorrigid.Thisreectsthelocationofthe

machine’s stiff-body resonance related to the basic

running speed of the machine.

For example, a machine supported by rubber or springs has a

resonance at low running speeds. The machine starts vibrate

at low RPM. When the speed is

increased above the resonance

frequency, the vibration is redu-

ced. This machine is considered

exible.

Resonance is easily found when

aexiblemachineisrunningup

or down in speed. The reso-

nances are located at the RPM

where the vibration has a local

maximum level. Modern machi-

nes that have high RPM’s and

Total vibration (RMS) =

4.1 ISO standard 10816-3

The ISO standard classifies the machines differently if the machines are flexible or

rigid. This reflects the location of the machine's stiff-body resonance related to the

basic running speed of the machine.

For example, a machine supported by rubber or springs have a resonance at low

running speeds. The machine starts vibrate at a low rpm. When the speed is increased

above these resonance frequencies, the vibration is reduced. This machine is

considered flexible.

Resonance is easily found when a

flexible machine is running up or

down in speed. The resonances are

located at the rpm where the

vibration has a local maximum

level.

Modern machines that have high

rpmʼs and flexible bearing supports

and foundations, can be treated as

flexible, even when they arenʼt

mounted on rubber or springs.

Group 1:

Large machines with rated power above

300kW.

Electrical machines with shaft height H

> 315mm.

Operating speed ranges from 120 to

15000 rpm.

Group 2:

Medium-sized machines with a rated power above 15kW up to and including 300kW.

Electrical machines with shaft height between

160 < H < 315 mm.

Operating speed normally above 600 rpm.

Group 3:

Pumps with multi vane impeller and with separate driver with rated power above 15kW.

Group 4:

Pumps with multi vane impeller and with integrated driver with rated power above 15kW.

The ISO 10816-3 standard allows for slightly higher limits when a foundation is

considered more flexible than rigid.

A conclusion from this is a resonance condition should not be allowed or at least must

be avoided at operating speeds. In practice, this also includes the double speed as well

as any other natural excitation frequency such as blade passage.

Vibraon Measurement Instruments

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Manual Viber X1_121002.indd 2 10/3/12 9:26 AM

Total vibration (RMS) = √4*4+2*2+5*5 = 6,7 mm/s

13

exiblebearing

supportsandfoundations,canbetreatedasexible,even

when they aren’t mounted on rubber or springs.

Group 1:

Large machines with rated power above 300kW.

Electrical machines with shaft height H > 315mm.

Operating speed ranges from 120 to 15000 RPM.

Group 2:

Medium-sized machines with a rated power above 15kW up

to and including 300kW.

Electrical machines with shaft height between

160 < H < 315 mm.

Operating speed normally above 600 RPM.

Group 3:

Pumps with multi vane impeller and with separate driver with

rated power above 15kW.

Group 4:

Pumps with multi vane impeller and with integrated driver

with rated power above 15kW.

The ISO 10816-3 standard allows for slightly higher limits

whenafoundationisconsideredmoreexiblethanrigid.

A conclusion from this is a resonance condition should not

be allowed or at least must be avoided at operating speeds.

In practice, this also includes the double speed as well as any

other natural excitation frequency such as blade passage.

Vibraon Measurement Instruments

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating machines.

Keep a safe distance to rotating parts and secure transducers and transducer cables

from rotating parts. Always follow internal, local and national security

regulations! When working with weights on the rotor always secure the start

switch with a locker and also use the emergency switch for double safety. This is

especially important when the machine is remote controlled.

VMI International AB takes no responsibility for any accidents on people and

machines.

VMI International AB and our authorized dealers will take no

responsibility for damages on machines and plants as the result

of the use of VIBER X1™ measurements.

Even though great efforts are made to make the information in

this manual free from errors and to make the information

complete for the user, there could be items we have missed,

because of the large amount of information. As a result of this,

we might change and correct these items in later issues without

further notice. Also changes in the VIBER X1™ equipment may

take place that affect the accuracy of the information.

Manual Viber X1_121002.indd 3 10/3/12 9:26 AM

14

The next logical step is to use more advanced analyzers like

VIBER X3™ or VIBER X5™ to learn the frequency behind

the vibration and thus the exact mechanical fault.

The practice of this is beyond the scope of this manual.

7 Vibration analysis

7.1 Recommended vibration levels

The following is an extraction of part of the old standard ISO

2372class4,largemachinesonexiblefoundations,with

somecommonndingsadded.

Usethissimpliedlistasarstindication,whenapproaching

a newly commissioned machine or after some time in opera-

tion. Investigate the reason for any machine that vibrates

above 3 mm/s RMS.

• 0–3mm/s0–0,12in/s

Small vibrations - None or very small bearing wear. Rather

low noise level.

• 3–7mm/s0,12–0,28in/s

Noticeable vibration levels are often concentrated to some

specicpartaswellasdirectionofthemachine.Noticeable

bearing wear. Seal problems occur in pumps etc. Increased

noise level; try to investigate the reason. Plan an action during

next regular stop. Keep the machine under

observation and measure at shorter time intervals than

before to detect a deterioration trend if any. Compare

vibrations to other operating variables.

Vibraon Measurement Instruments

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Manual Viber X1_121002.indd 2 10/3/12 9:26 AM

15

• 7–11mm/s0,28–0,43in/s

Large vibrations. Bearings running hot. Bearing wear-out cau-

ses frequent replacements. Seals wear out, leakage of all kinds

evident. Cracks in welding and concrete foundations. Screws

and bolts are loosening. High noise level. Plan

action soonest. Do your best to discover the cause. You are

wearing down investments quickly.

• 11–mm/s0,43−in/s

Very large vibrations and high noise levels. This is

detrimental to the safe operation of the machine. Stop

operation if technically or economically possible. Few machi-

nes can withstand this level without internal or

external damage. Reduce any further running time to an abso-

lute minimum.

Vibraon Measurement Instruments

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating machines.

Keep a safe distance to rotating parts and secure transducers and transducer cables

from rotating parts. Always follow internal, local and national security

regulations! When working with weights on the rotor always secure the start

switch with a locker and also use the emergency switch for double safety. This is

especially important when the machine is remote controlled.

VMI International AB takes no responsibility for any accidents on people and

machines.

VMI International AB and our authorized dealers will take no

responsibility for damages on machines and plants as the result

of the use of VIBER X1™ measurements.

Even though great efforts are made to make the information in

this manual free from errors and to make the information

complete for the user, there could be items we have missed,

because of the large amount of information. As a result of this,

we might change and correct these items in later issues without

further notice. Also changes in the VIBER X1™ equipment may

take place that affect the accuracy of the information.

Manual Viber X1_121002.indd 3 10/3/12 9:26 AM

16

Vibraon Measurement Instruments

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating machines.

Keep a safe distance to rotating parts and secure transducers and transducer cables

from rotating parts. Always follow internal, local and national security

regulations! When working with weights on the rotor always secure the start

switch with a locker and also use the emergency switch for double safety. This is

especially important when the machine is remote controlled.

VMI International AB takes no responsibility for any accidents on people and

machines.

VMI International AB and our authorized dealers will take no

responsibility for damages on machines and plants as the result

of the use of VIBER X1™ measurements.

Even though great efforts are made to make the information in

this manual free from errors and to make the information

complete for the user, there could be items we have missed,

because of the large amount of information. As a result of this,

we might change and correct these items in later issues without

further notice. Also changes in the VIBER X1™ equipment may

take place that affect the accuracy of the information.

Manual Viber X1_121002.indd 3 10/3/12 9:26 AM

7.2 Recommended bearing condition levels

The bearing condition value is the total RMS value of the

acceleration of all high frequency vibrations within the

range from 500 Hz up to 16000 Hz with the unit “g”. Find

the machine speed. Follow this line up to the judgment lines

and read the value on the left axis.

The diagram on the next page is a guide to interpret the

bearing condition value. If vibrations of other causes (e.g.

owsurge,gearmesh)arewithinintheselectedfrequency

range, this can give a high bearing condition value without

any bearing faults. A high bearing condition value can also

be acquired if the bearing is poorly lubricated or is overloa-

ded (e.g. by misalignment, or large belt forces).

17

Vibraon Measurement Instruments

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating machines.

Keep a safe distance to rotating parts and secure transducers and transducer cables

from rotating parts. Always follow internal, local and national security

regulations! When working with weights on the rotor always secure the start

switch with a locker and also use the emergency switch for double safety. This is

especially important when the machine is remote controlled.

VMI International AB takes no responsibility for any accidents on people and

machines.

VMI International AB and our authorized dealers will take no

responsibility for damages on machines and plants as the result

of the use of VIBER X1™ measurements.

Even though great efforts are made to make the information in

this manual free from errors and to make the information

complete for the user, there could be items we have missed,

because of the large amount of information. As a result of this,

we might change and correct these items in later issues without

further notice. Also changes in the VIBER X1™ equipment may

take place that affect the accuracy of the information.

Manual Viber X1_121002.indd 3 10/3/12 9:26 AM

17

18

Vibraon Measurement Instruments

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Manual Viber X1_121002.indd 2 10/3/12 9:26 AM

Technical data VIBER X2

Vibraon transducer Accelerometer Standard nom 100

mV/g

(Selectable sensivity in

the instrument)

0,1 - 99999 mV/g

Input amplitude range

Vibraon Max 50g RMS With other sensor up

to 500 g

Bearing condion Max 30 gBC

Dynamic range 80 dB (at 159 Hz with auto ranging)

Frequency range

Vibraon

2 - 400 Hz

10 - 1000 Hz

6 - 1600 Hz

11 - 3200 Hz

Note 1

Bearing condion 0.5 to 16 kHz

Vibraon units g-value, mm/s, mm/s2, in/s, µm, mils Note 2

Amplitude presenta-

on RMS, Peak, Peak-Peak Note 2

Analysis Five highest peaks can be displayed

Frequency range of

peak detecon

Frequency range

Note 3

2 - 400 Hz

6 - 1600 Hz

11 - 2000 Hz

10 - 1000 Hz

Accuracy

Vibraon ±3 % Note 4

Bearing condion ±5 % Note 4a

Frequency/RPM ±0.2 %

Baery Rechargable Lithium 2300 mA/h max 60°C Note 5

Operang me 1 week normal use

External charger 5,0 V regulated @ 2000 mA

LCD display B&W 64 x 120 pixels with background light Note 6

Enclosure protecon IP65

Operang temp. range 0 to 50°C Note 7

Weight 340 gram Note 8

Size (L x W x H) 145mm x 77mm x 47mm

Table of contents

Other VMI Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

ATI Technologies

ATI Technologies Q45S/87 O & M Manual

ATAGO

ATAGO MASTER Series instruction manual

Wagner Meters

Wagner Meters ORION 950 instruction manual

Veratron

Veratron VMH Series user manual

Alpha Moisture Systems

Alpha Moisture Systems SADPminiEx instruction manual

ALDON

ALDON 4022-26 instruction manual