VMI VIBER-A User manual

VMI AB

Torsgatan 1

S-603 63 Norrköping, Sweden

Tel. 011-311667 / 311668

Fax. 011-311678

e-mail: [email protected]

www.vmi-instrument.se

A

uthorised distribut

o

VIBER-A

Manual

Page 2

Page 3

Warranty disclaimer

VMI AB warrants the products to be free from defects in material and

workmanship under normal use and service within two years from

the date of purchase and which from our examination shall disclose

to our reasonable satisfaction to be defective.

Warranty claimed products shall be returned prepaid to VMI AB for

service. We reserve the right to repair or to replace defective

products.

Always try to explain the nature of any service problem. At best by

fax, e-mail or letter. Check first all natural problems, like empty

batteries, broken cables, etc. When returning the product, be sure to

indicate that the purpose is to make repairs and indicate the original

date of shipment to you if possible.

General

The VIBER-A is a fully portable broadband vibrometer used in

preventive as well as active maintenance work on rotating

machinery. A complete set comprises an instrument, a vibration

transducer with magnet support and an extension tip.

VIBER-A is measuring the effective velocity (mm/s RMS)

(displacement (µm Peak) or in/s is option) in the frequency range

between 10 and 3200 Hz. This range covers most of the frequencies

that will occur for the majority of mechanical malfunctions and

imperfections. Examples are unbalance, misalignment of shafts and

gears, cavitation and other fluid generated vibrations.

The judgement of the measured levels is greatly supported by

several vibration standards. The close comparison between vibration

levels and actual wear being performed on the machinery will quickly

build up a local knowledge. The experience should be used to

optimise the type of action required when higher vibrations are

found.

A common standard for judgement of vibrations is ISO 10816-3 and

may be available from your domestic standardisation authority. This

standard is an upgrade of older standards that has been in use for

several decades and has a world wide acceptance as a good

judgement for continuos and long lasting operation of machinery. It is

rare that this standard is found to be too restrictive so any reason to

judge vibration with a less exacting judgement should be well backed

by practical experience.

Page 4

Functions

Start of the instrument

Press this symbol key and the instrument starts to

measure.

The instrument will be shut off automatically after

approximately 2,5 minutes.

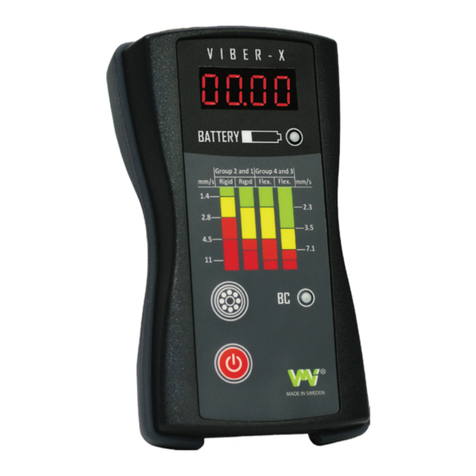

Battery check

Press this symbol key and keep it pressed and the

instrument shows the battery voltage.

Change the battery when the voltage is below 7 volts.

The battery capacity of an ordinary type is enough for

approximately 20 hours of constant operation or 350

measurement.

The battery capacity of an alkaline type is enough for

approximately 40 hours of constant operation or 1000

measurement.

Bearing condition

Press this symbol key and keep it pressed. The

instrument measures instantaneously a bearing condition

value in the range between 3.200Hz to 20.000Hz.

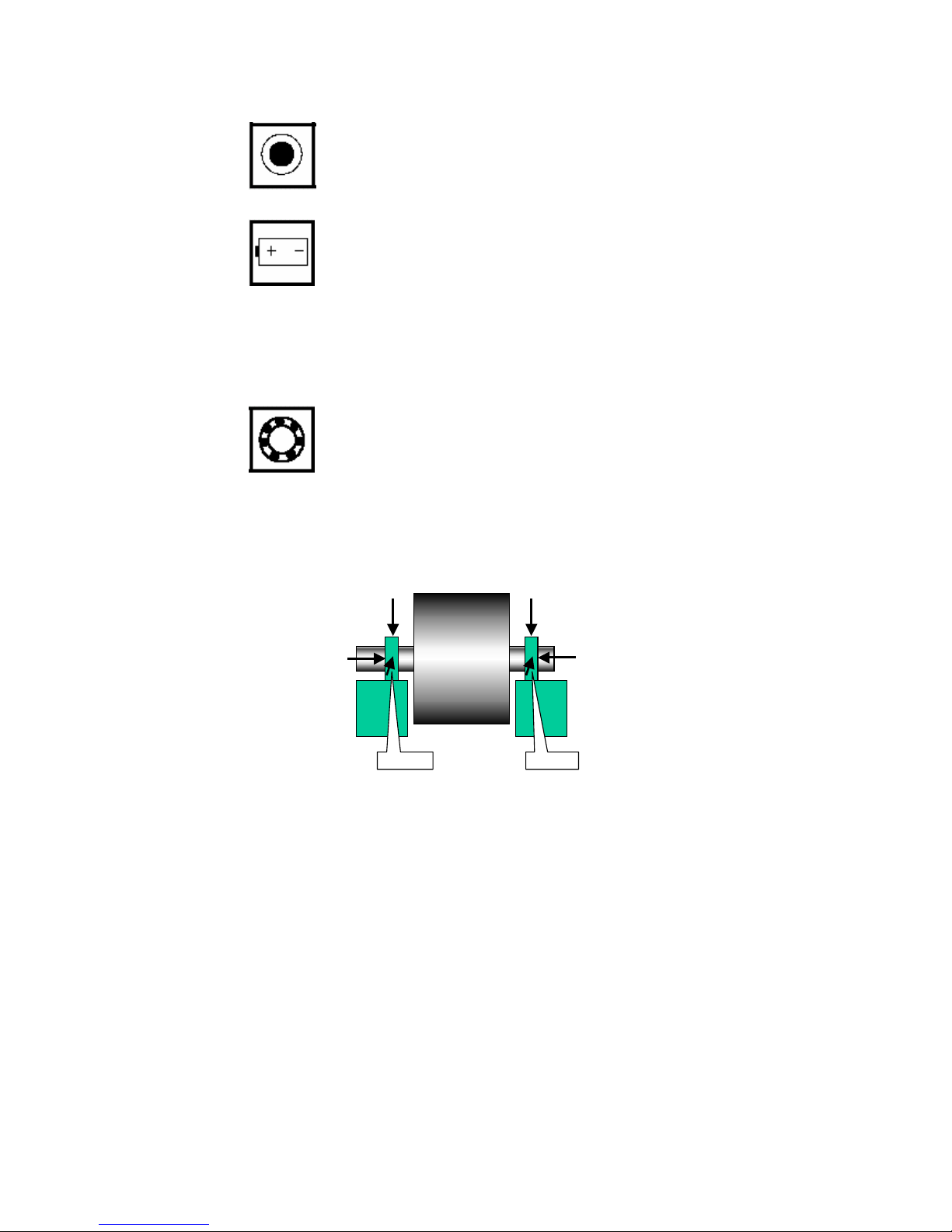

Placing of the measuring point.

The measurements should be taken on or as close to the bearing as

possible and only in horizontal, vertical and axial directions.

Bearing

Bearing

V

H H

V

A A

Page 5

How to make good measurements.

The sensitivity direction of the transducer coincides with the centre

axis of the transducer. The transducer end (with the M6 stud) is

pushed firmly against the measurement point. The main purpose is

to make the complete transducer to fully participate in the motion of

the measurement point. Try to hold the transducer in a vertical,

horizontal or axial direction as possible, even if the machine surface

does not have these directions. Read the instrument held with the

free hand. Note a stable reading as well as a fluctuating one, since

the fluctuation itself is a valuable information regarding the reason for

the vibration.

When the transducer is mounted with the magnet the frequency

range of the measurement is reduced to about 2.000 to 3.000Hz

depending on the flatness of the measuring surface.

When the measuring tip is used the frequency range is reduced to

about 800 to 1500Hz.

Note

When using the magnet or the measuring tip the bearing condition

value can be substantially changed. Use the M6 stud on the

transducer for high frequency measurements.

Vibrations at high frequencies can sometimes cause measurement

problems. Pressing the transducer more firmly should not change the

reading. If in doubt, always try to adjust the contact point first.

Secondly, if shown to be necessary, mount the transducer with the

M6 stud.

All normal measurements on vertical or horizontal machinery should

follow the three perpendicular axis of true vertical, horizontal and

axial directions. The reason is that you should keep to the main

stiffness directions caused by normal non symmetrical properties of

the foundation, piping, supports etc. It will result in better

understanding if the basic measurements are made in this way.

Page 6

The VIBER-A is mainly intended for measurements against the

housing and bearings of machinery according to the intentions

of the standards. You can also use it to measure other parts

such as piping, valves, etc. Note that in some cases the mass of

the transducer may influence the reading. A good rule is to

consider readings on surfaces that are lower in mass than 10

times the mass of the transducer doubtful.

How to interpret vibration measurements.

A user with no previous experience to interpret the results is

recommended to use the ISO 10816-3 standard together with a good

portion of common sense.

Be prepared to find exemptions making the judgements harder than

the standards, rather than finding exemptions allowing for higher

vibrations.

The standard normally calls for a measure in velocity based on mm/s

RMS. To better understand what this measure means it can be

helpful to consider the reading as a mean value of the back and

forward motion. This measure gives a good understanding of the

amount of "break down energy", causing mainly wear and fatigue

work, in the machine or the structure being measured.

The instrument is measuring the total RMS-value of the vibration

within the instrument frequency range. This RMS-value is a special

sum or average of all the different causes of vibration.

EXAMPLE:

If the simultaneous vibration caused by unbalance is (4mm/s), by

misalignment (2 mm/s) and by the gearmesh (5 mm/s) then the total

vibration measured on the VIBER-A is 6.7 mm/s.

Total vibration =

Page 7

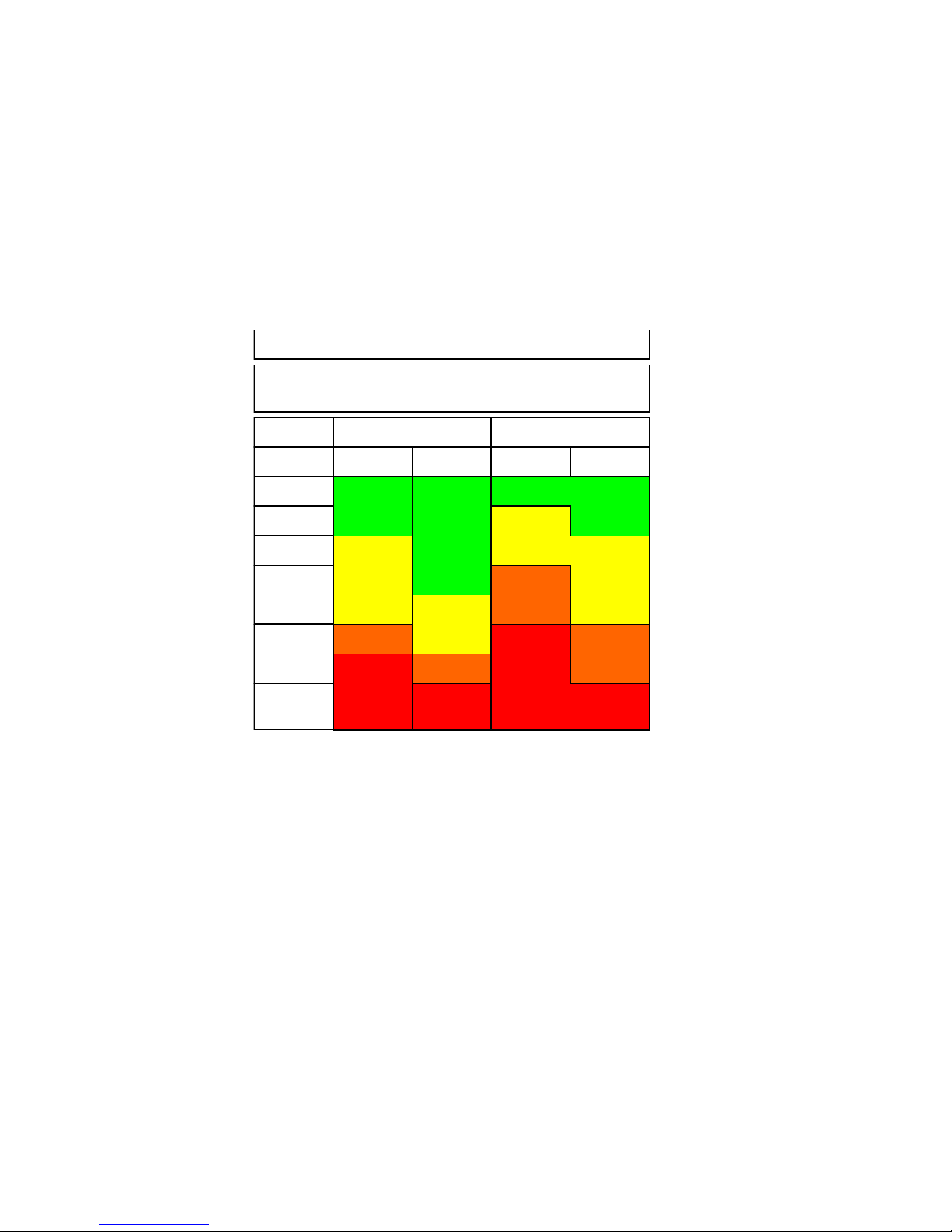

The ISO standard is classifying the machines differently if the

machines are considered as flexible or rigid mounted. This reflects

the location of the machines stiff-body resonance’s related to the

basic running speed of the machine.

For instance, a machine supported by rubber or springs often have

resonance’s at low running speeds. The machine starts vibrate at

certain low rpm. When the speed is increased above these

resonance frequencies the vibration is reduced. This machine is

considered flexible.

A resonance can easily be found when a flexible machine is running

up or down in speed. The resonance’s are located at the rpm´s

where the vibration have a local maximum level.

Rigid Flexible Rigid Flexible

Group 1 and 3 Group 2 and 4

Industrial machines with power above 15kW and

nominal speeds between120 -15000 r/min

mm/s

Unit

0-1.4

1.4-2.3

2.3-2.8

2.8-3.5

3.5-4.5

4.5-7.1

7.1-11

11--

Extraction's from ISO 10816-3

Page 8

Modern machines have high rpm´s and flexible bearing-supports and

foundations and can be treated as flexible even when it is not

mounted on rubber or springs.

The ISO 10816-3 standard allows for slightly higher limits when a

foundation is considered flexible than when if it is rigid. A conclusion

from this is also that a resonant condition in principle is not allowed

or at least should be avoided at operating speeds. In practice this

also includes the double speed as well as any other natural

excitation frequency such as blade passage etc.

A great advantage with proper vibration measurements and the use

of vibration standards is that you can judge the future maintenance

cost very reliably already at first start-up. If you find levels above 3

mm/s RMS, you can be rather sure that the machine will cause

increased activities in maintenance. The specific cost and action is of

course individual to the machine design.

As always when using schematic judgement like this, be very careful

to use common sense in the application of the recommendations.

A certain machine is producing its specific vibration frequency

pattern depending on the transducer location and the machine

properties.

The next logical step is therefore to apply filtering of the transducer

signal to learn the frequency behind the vibration and thus the exact

mechanical fault. The practice of this is beyond the scope of this

manual.

Looseness

By measuring the vibration on both sides of a bolt joint it is possible

to find loosness in the connection. Two machine parts joined

together should have the same vibration level on both sides of the

joint.

Bolts fixed in concrete foundations should have the same vibration

level as the concrete if they are not loose.

Page 9

Recommended vibration levels in mm/s an common findings.

The following is in part an extraction of the old standard ISO 2372

class 4, large machines on flexible foundations, with some common

findings added.

This simplified list can be used, as a first consideration, when you

approach a machine newly commissioned or after some time in

operation.

Take as a good housekeeping rule to investigate the reason for any

machine that vibrates above 3 mm/s RMS. Do not leave them above

7mm/s without being assured that they will sustain long term

operation without increased wear since the machines capable of that

are very few.

•0 – 3 mm/s

Small vibrations. None or very small bearing wear. Rather low noise

level.

•3 – 7 mm/s

Noticeable vibration levels often concentrated to some specific part

as well as direction of the machine. Noticeable bearing wear. Seal

problems occur in pumps etc. Increased noise level. Try to

investigate the reason. Plan action during next regular stop. Keep

the machine under observation and measure at smaller time

intervals than before to detect a deterioration trend if any. Compare

vibrations to other operating variables.

•7 – 18 mm/s

Large vibrations. Bearings running hot. Bearing wear-out cause

frequent replacements. Seals wear out, leakage of all kinds evident.

Cracks in weldings and concrete foundations. Screws and bolts are

loosening. High noise level. Plan action soonest. Do your best to

reveal the reason. You are wearing down investments quickly.

•18 – mm/s

Very large vibrations and high noise levels. This is detrimental to the

safe operation of the machine. Stop operation if technically or

economically possible considering the plant stop cost. No known

machine will withstand this level without internal or external damage.

Reduce any further running time to an absolute minimum.

Page 10

Resonance

When working with vibrations in machine maintenance, you will soon

find that resonance is a common but rather unknown problem in

modern machinery.

To understand a resonance you can compare with the string of a

guitar. The string has its natural basic tune that will ring as soon as

the string is struck. The actual frequency of the tune depends on the

stiffness and the distributed mass of the string.

All machines have similar built in "tunes" with corresponding

properties consisting of stiffness and mass in the form of mechanical

strings such as shafts, beams, floors and in all mechanical parts.

If any natural excitation (= alternating force) in the machine has the

same or nearly the same frequency as a resonance frequency the

vibration will be amplified in this machine part, a much higher level

will occur than would be the case if the resonance would be shifted

away from the excitation frequency..

One common resonance frequency is the critical speed of a shaft

which depends on the stiffness and mass of the shaft, but

resonance’s exist in all machine parts as well as in supporting beams

and concrete floors.

A natural excitation force is for example unbalance at the running

speed, misalignment on mainly twice the speed etc.

THE BASIC RULE IS THAT THE RESONANCE’S OF ANY PART

IN THE MACHINE SHOULD NOT COINCIDE WITH ANY NATURAL

IMPULSE IN THE MACHINE.

A broad band vibrometer can not recognise the frequencies of

the vibration but as a rule most high vibrations are caused by

only one mechanical problem.

Page 11

To identify the presence of a resonance, measure the vibration levels

in three perpendicular directions at the bearings. If you find a

measurement with at least three times higher level than in the other

directions you should consider a resonance a likely possibility. The

resonance is amplifying the mechanical force and thus gives a high

vibration in that direction. The resonance makes the machine

unnecessarily sensitive to mechanical forces.

It is possible to locate the resonance peak while the speed of the

machine is changing. The resonance frequency is located at that rpm

where the vibration has a local maximum.

The proper action against a resonance is very different depending on

its location, operating conditions etc. It will normally require good

experience to alter the situation. One reason is that the modification

affects the basic mechanical design of the machine and where you

normally require the competence of the machine designer.

We recommend you however not to hesitate to consider such

modifications since the change of the resonance frequency normally

is cheap compared to the high maintenance cost that will follow any

attempt to run a machine in long term operation under the influence

of a resonance.

A TEMPORARY AND SOMETIMES PERMANENT SOLUTION TO

A RESONANCE PROBLEM IS TO CHANGE THE SHAFT SPEED

OF THE MACHINE, IF POSSIBLE.

Page 12

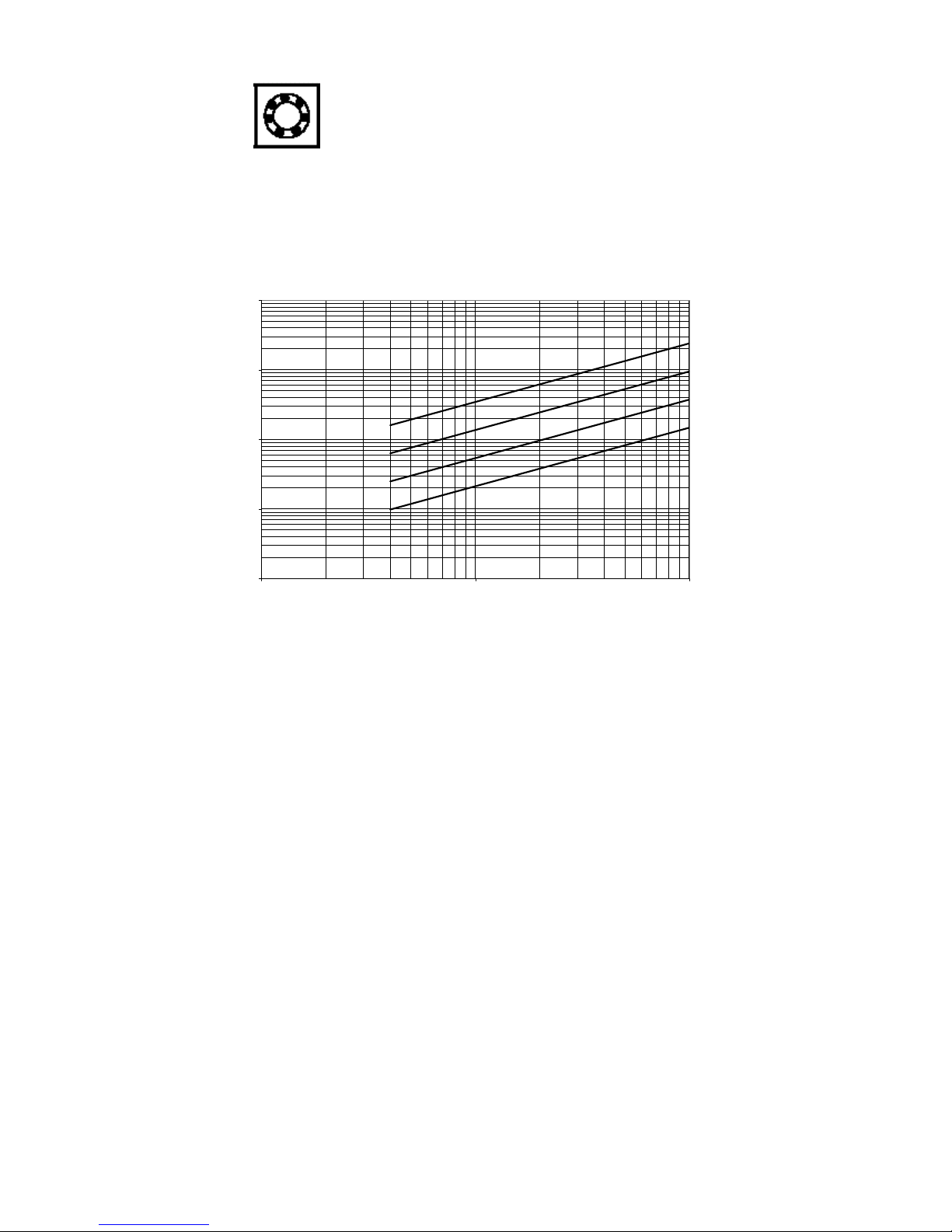

Press the green bearing symbol, keep it pressed and the instrument

measures the bearing condition value .

The bearing condition value is RMS value of all high frequency

vibrations in the range of 3.200 Hz to 20.000 Hz.

This average has the unit g(= acceleration due to gravity)

Bearing condition value with unit “g” RMS

The diagram above is only a guide to interpret the bearing condition

value. If vibrations of other causes (e.g. flow surge, gearmesh) are

within in the frequency range 3200 - 20000 Hz this can give a high

bearing condition value without the bearing being damaged.

A high bearing condition value can also be acquired if the bearing is

poorly lubricated or is overloaded (e.g. by misalignment, or belt

forces).

0,01

0,1

1

10

100

100 1000 10000

RPM

2000 3000400 60004000

500

Good

Acceptable

Fair

Failing

Replace

Page 13

What is a bearing condition value?

The bearing condition value in Viber-A is the sum average value,

RMS value, of all high frequency vibrations between 3200 Hz to

20000 Hz.

This value is an acceleration average with the unit "g" because high

frequencies give a large signal if it is measured in acceleration.

When the balls or rollers rotate inside the bearing a wide-band noise

and vibration arises. This noise and vibration are increased if the

bearing is poorly lubricated, overloaded due to misalignment or has a

damaged surface.

Because this is a wide-band noise and vibration it is possible to

select any frequency or frequency band as a measurement of

bearing condition.

If the selected frequency band includes low frequencies the bearing

condition value would also include vibrations from unbalances,

misalignment, etc., and not purely from bearing vibrations and would

therefor be difficult to interpret.

If the selected frequency band only includes very high frequency

noise and vibrations we would need special vibration transducers

that are very rigidly and closely mounted to the bearing because the

machine structure works as a mechanical filter for high frequencies.

VIBER-A is measuring the bearing condition value between 3200 Hz

to 20000 Hz, similar to many other instruments. Within this frequency

range there exist a common experience in the evaluation of the

bearing condition level.

Normal machinery vibrations such as unbalance, misalignment, etc.,

rarely has vibrations above 3200 Hz. The upper frequency limit of

20.000 Hz is selected because most vibration transducers have an

upper frequency limit of about 7000 Hz, without special mounting

arrangements, and the transducer signal is very low above 20000Hz.

NOTE!

A high bearing condition value should always be used as a request

to make frequency analysis.

High bearing condition values can appear at gear boxes, converting

machines with cutters and similar machines without any bearing

faults because they "naturally" produce frequencies above 3200 Hz.

Page 14

Balancing with VIBER-A

It is only possible to balance machines where the unbalance is the

major cause of vibration.

Do not change the position of the vibration transducer after the start

of the balancing procedure.

Balancing using this method requires only three consecutive trial

runs and changing the balance status of the rotor.

Only measurement of the vibration level is needed.

Balancing will of course only reduce the vibration caused by

unbalance.

A balancing round will often be a good approach and a first attempt

to find the reason for increased vibration. If the balancing attempt is

not successful, the cause can be loose rotor parts etc.

If the machine speed is variable, be sure to choose the same speed

during every trial run. Do not search the speed that gives the highest

vibration. Such speeds mostly show non-linear results.

Start the procedure by measuring on the bearings looking for high

levels in major directions. Choose a point that should have a good

connection to a balancing plane where you can put in a weight in the

machine. You must use the same radius for the trial weights and the

balancing weights.

Page 15

This is the procedure for the

TWO-POINT BALANCING METHOD:

TRIAL RUN 1:

Select the running speed and choose the measuring point. Measure

and note the vibration level and stop the machine. Note this vibration

as reading A.

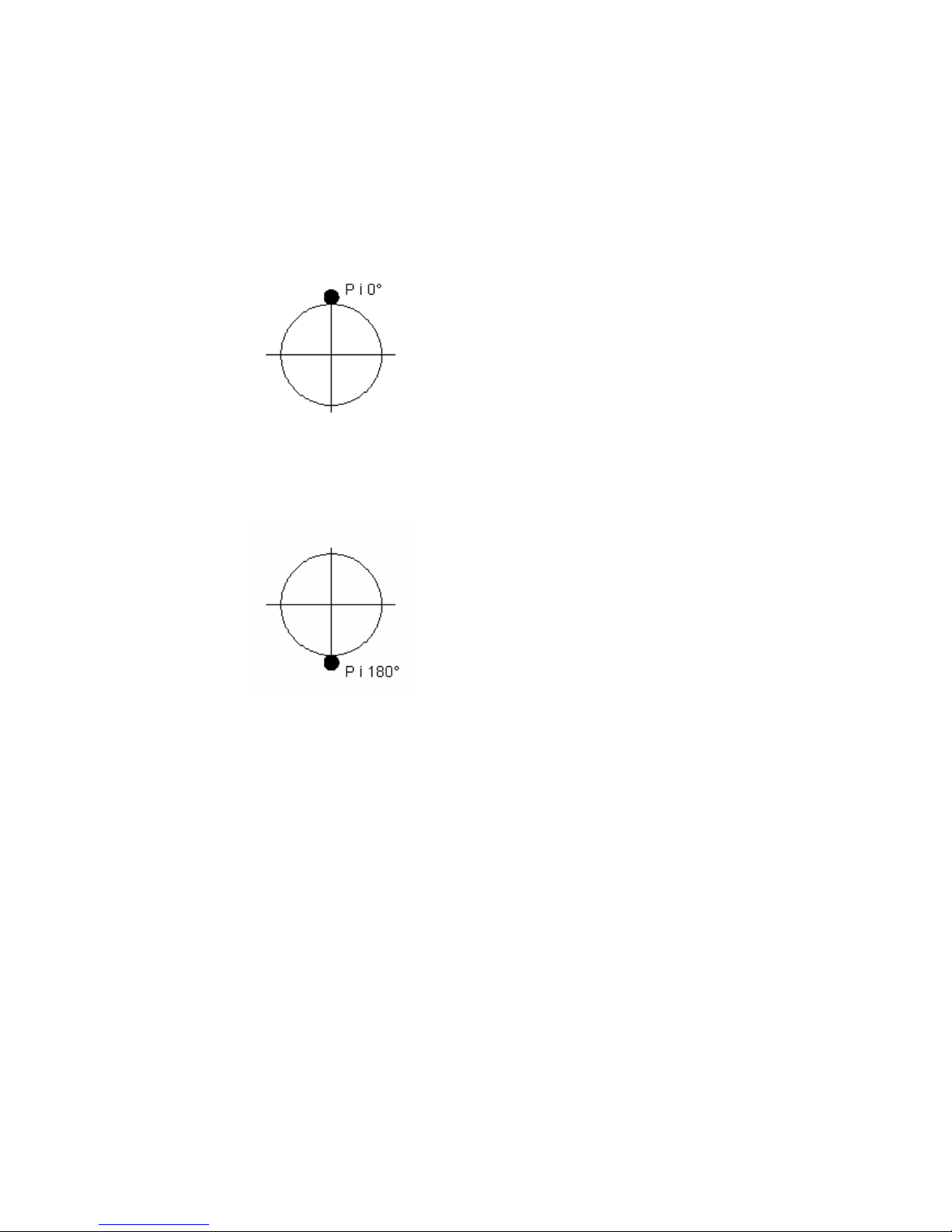

TRIAL RUN 2:

Put in a trial weight in the balancing

plane. Note the location and size of the

balancing weight. Use its weight, volume

or length (if you have a band material) as

a measure of the size of the trial weight.

Call the trial weight P in any measure

proportional to the weight.

Measure and note the vibration level and

stop the machine.

Note this vibration as reading 2.

TRIAL RUN 3:

Move the trial weight 180 degrees to a

position opposite its first

location.

Measure and note the vibration level and

stop the machine.

Note this vibration as reading 3.

Page 16

CALCULATION

We now have all the necessary machine information to start the

calculations.

Compare the vibration levels reading 2 and reading 3.

Call the highest of reading 2 and reading 3 for Band the smallest

for C.

Draw a figure where you use a length measure proportional to the

actual vibration level measured on each reading A, Band C

respectively. Use a scale that gives you as large a figure as possible.

The accuracy depends largely on the size of the figure.

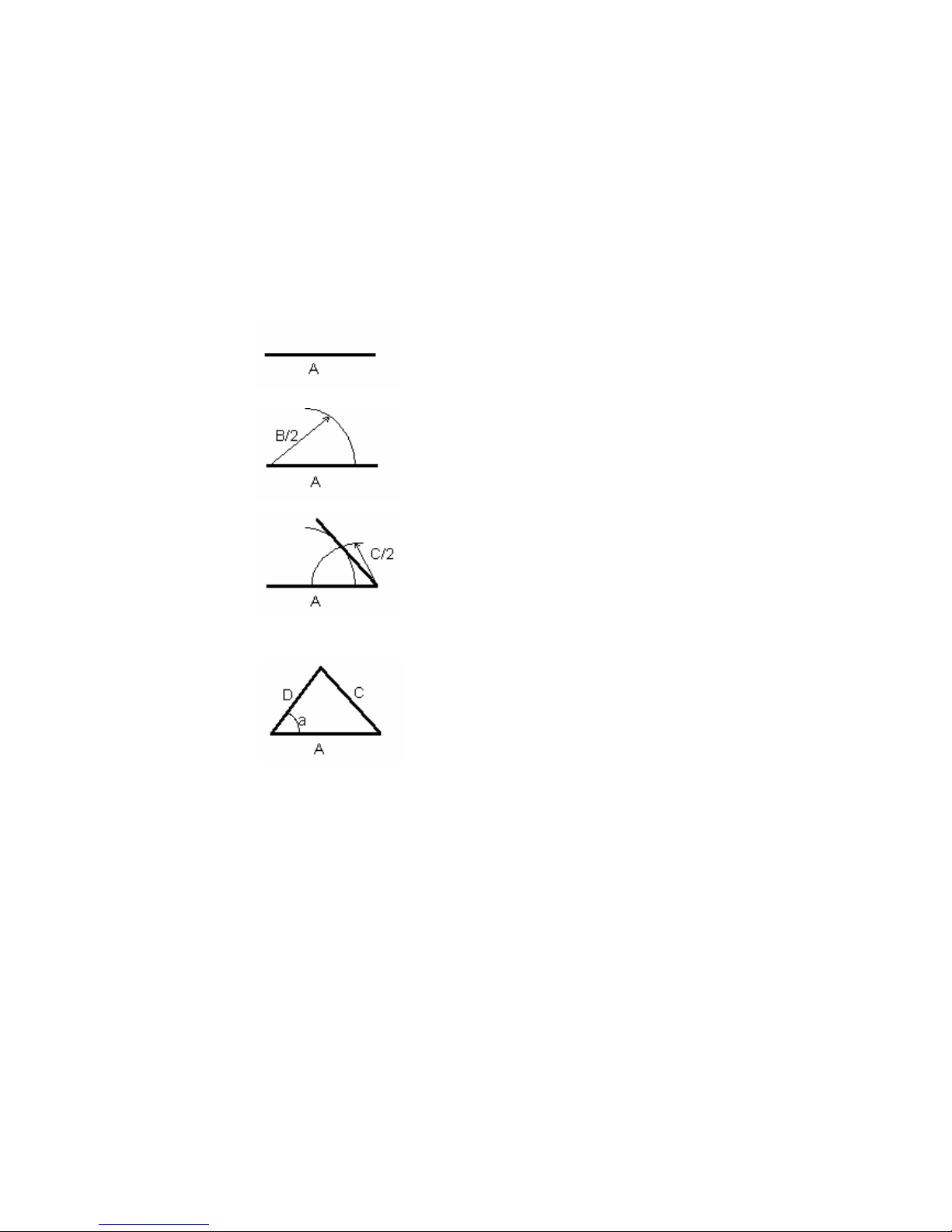

STEP 1: Draw Aas a horizontal line. Use a

scale so you achieve good use of the actual

paper.

STEP 2: Draw an arc centred at left end of

Ahaving the radius equal to 1/2 (HALF) the

length of B.

STEP 3: Draw an arc centred at right end

of Ahaving the radius equal to 1/2 (HALF)

the length of C. Mark the crossing of the

two arcs. Draw a line starting from the right

end of Athrough the crossing of the to arcs

and with the length proportional to C.

STEP 4: Join the upper tip of Cwith the left

end of Athat a triangle shaped figure is

made. Mark this new line as D. The angle

position of the balancing weight is the

angle (a) in the left corner of the figure

between line Dand base line A.

Page 17

THE SIZE OF THE BALANCING WEIGHT

The SIZE of the balancing weight that you should put on the

balancing plane is proportional to the size of the trial weight with the

same relation as the line Ato Din the figure. In other words:

trial weight P* the length of A

Balancing weight BW = ------------------------------------------

the length of D

You can measure Aand Din the figure. You may soon realise that

best results are obtained when the triangle has approximately equal

sides.

THE ANGLE POSITION OF THE BALANCING WEIGHT

When we had the trial weight in position C

we had a lower vibration than in position

B. The trial weight in position C must

therefore be on the proper half of the

rotor.

The balancing weight should be

positioned (a) degrees from the position

of the trial weight C.

The angle (a) can be measured on your rotor in either the direction

against or with rotation. You must make a qualified guess and try

one alternative. If the vibration is not reduced the other location may

be the better.

The balancing may be stopped when the highest radial direction is

below 3 mm/s rms.

Page 18

MISCELLANEOUS

If you prefer to calculate the balancing weight, this is the formula:

TROUBLE HINTS

The most difficult task in balancing is to guess a suitable size of the

trial weight because we do not know the unbalance sensitivity of the

machine. The whole balancing procedure depends on the changes in

vibration level that occur when we add a trial weight. If the trial

weight is too small compared to the unbalance we cannot measure

any changes in the vibration levels and the measurements A, Band

Cbecome almost equal. The triangle in our figure becomes flat.

If the trial weight is too large compared to the unbalance the

measurements Band Cbecome very large compared to the

measurement Aand the triangle in our figure becomes very high and

narrow.

This produces an uncertainty in our calculations.

If the triangle cannot be formed well, use the results to guess a

better trial weight size or try a location of the trial weight a quarter

turn away from the first position.

If the triangle cannot be formed at all there are often two major

reasons:

1. Something is loose. Check the fit between the rotor and

shaft. Check bolt joints. Is dirt gradually falling off during

each run?

2. The vibration does not depend on unbalance. You are trying

to balance a machine where the unbalance is very small and

where the vibration comes from other faults. E.g.

misalignment, gearbox, cavitation in pumps etc.

Page 19

BALANCING USING THE THREE-POINT METHOD.

The three point method gives you the size and the location angle (a)

without guessing the position of the balancing weight. Be sure to

choose the same speed during all trial runs and the same radius for

all trial weights and the balancing weight.

Step 1.

With the rotor operating at normal

speed, measure and note the original

vibration level as R1.

In our example: R1 = 8mm/s

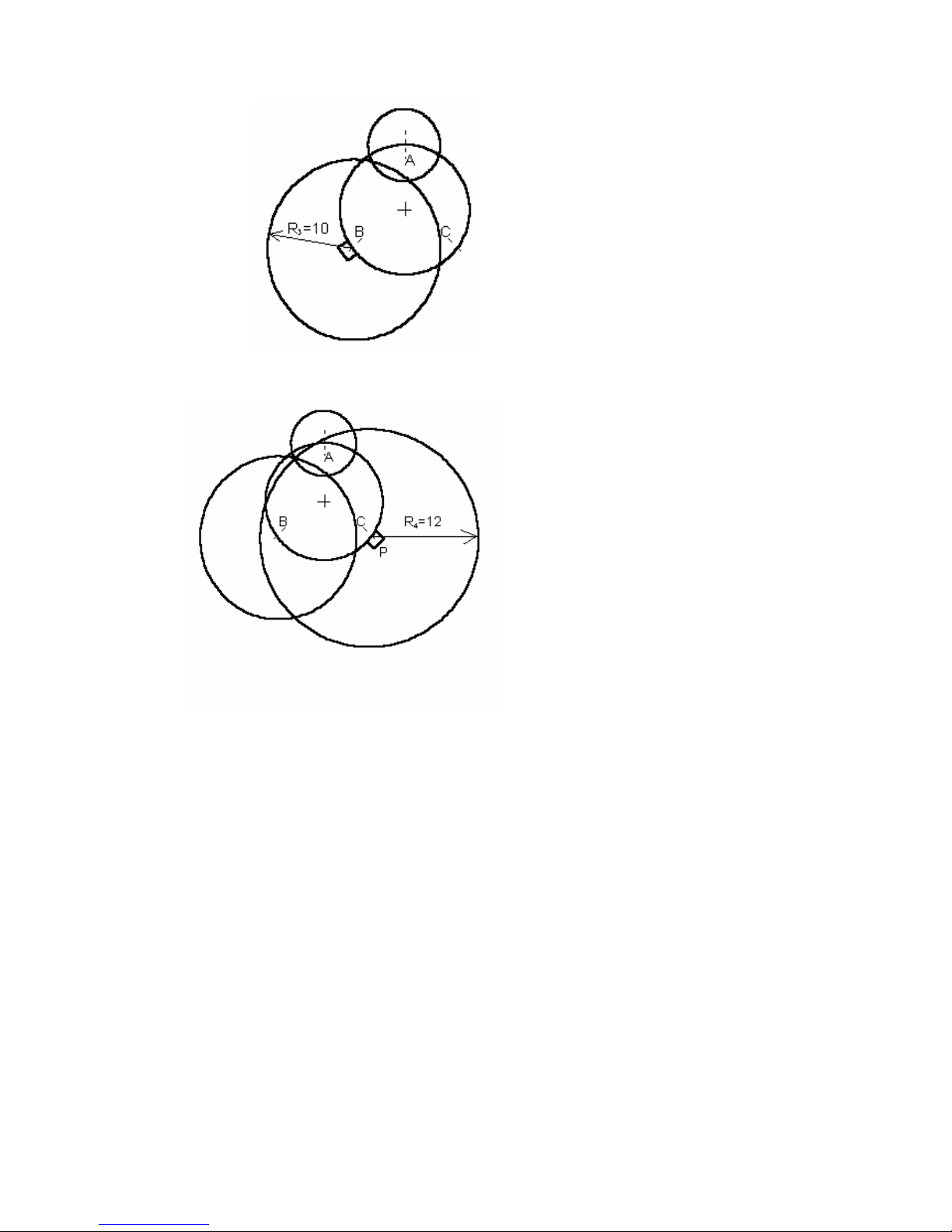

Draw a circle with a radius proportional

to R1 and then use the same scale for

the rest of the procedure.

Step 2.

Stop the rotor. Mark three points on the

rotor, approximately 120 degrees apart

where we later will add trial weights.

Call these points A, Band C. These

three points do not need to be exactly

120 degrees apart but the accuracy

decreases the more you leave equal

spacing. You have to measure your

chosen angle position as accurate as

possible.

Step 3.

Put in a trial weight in position A. Start

the rotor and measure the vibration

level R2.

In our example R2 = 5mm/s. Draw a

circle proportional to R2 with the centre

in position A.

Page 20

Step 4.

Move the trial weight to position

B. Start the rotor and measure

the vibration level R3.

In our example R3 = 10mm/s.

Draw a circle proportional to R3

with the centre in position B.

Step 5.

Move the trial weight to

position C. Start the rotor

and measure the vibration

level R4.

In our example R4 =

12mm/s.

Draw a circle proportional to

R4 with the centre in

position C.

Table of contents

Other VMI Measuring Instrument manuals